Kev Tswjhwm Zoo Ntawm Steel Structure Production

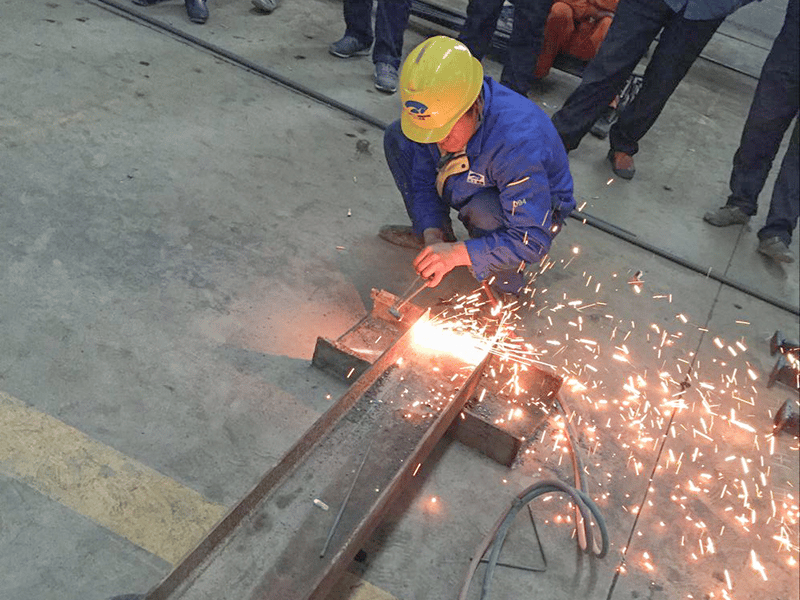

Gas txiav (cushion txiav los yog nplaim taws) yuav tsum zoo dua yog CNC txiav, precision txiav, thiab semi-automatic txiav. Thaum txiav cov saum toj no yog siv unconditionally, phau ntawv txiav yuav siv tau, thiab cov cuab yeej pab xws li pwm-ua yuav tsum tau siv. Nyob rau tib lub sijhawm, 3-Lub machining pub ntawm 4 hli yog machined los yog smoothed nrog ib tug sib tsoo log.

Rau strip-shaped steel phaj qhov chaw, qhov ntev slits ntawm ob sab yuav tsum tau roj-txiav tib lub sij hawm los tiv thaiv saber los ntawm deformed. Thaum tsis muaj kev hloov pauv roj welding ua tiav tib lub sijhawm, ntu ntu roj-txiav yuav tsum tau siv, thiab 30-50mm sab laug ib ntus ntawm ob qhov kawg ntawm qhov txiav thiab nruab nrab ntawm ntu. Tom qab lub khob txias txias, txiav tawm 30-50mm txhua qhov chaw.

Kev txiav roj yuav tsum tau nqa tawm ntawm lub platform tshwj xeeb, thiab yuav tsum muaj cov kab lossis taw tes sib cuag ntawm lub platform thiab cov phaj hlau yuav tsum tau txiav. Tag nrho cov khoom tseem ceeb, tshwj tsis yog tias tau teev tseg hauv cov duab kos duab, yuav tsum tsis txhob muab cov ntaub ntawv luv luv.

Tag nrho cov hlau yuav tsum tau rov kuaj xyuas raws li cov kev cai ntawm cov lus qhia ua ntej siv. Yog hais tias muaj deformation, thiab lwm yam., txoj kev yuav tsum ncaj thiab kho yam tsis muaj kev puas tsuaj rau cov hlau. Kev sib txuas cov txheej txheem steel yuav tsum tau ua ua ntej.

Rau qhov tso cai sib txawv ntawm vuam, qhov ua thiab sib dhos ntawm cov khoom siv hlau, thov xa mus rau "High Steel Regulations" thiab "Inspection Regulations". Qhov chaw ntawm splicing nodes ntawm cov khoom loj yuav tsum tau pom zoo los ntawm lub tsev tsim.

Kawm paub ntau ntxiv txog kev cuam tshuam tus nqi / Tus nqi ntawm Lub Tsev Hlau

Steel Structure Vuam Siv Kev Tswj Xyuas Zoo

Pre-weld preheating thiab post-weld cua sov kev kho mob: Rau cov welds uas yuav tsum tau pre-welded thiab tom qab vuam thaum tshav kub kub kev kho mob, lub preheating kub los yog tom qab cua sov kub yuav tsum tau raws li cov tam sim no lub teb chaws cov qauv los yog txiav txim los ntawm lub cov txheej txheem kuaj.

Lub cheeb tsam yog nyob rau ntawm ob sab ntawm lub weld hlaws, thiab qhov dav ntawm txhua sab yuav tsum yog ntau tshaj 1.5 npaug ntawm lub thickness ntawm weldment, thiab yuav tsum tsis txhob tsawg tshaj li 100 hli; tom qab kev kho cua sov yuav tsum tau nqa tawm tam sim tom qab vuam, thiab lub sijhawm tuav yuav tsum tau txiav txim siab raws li lub thickness ntawm lub phaj, 1h ib 25 hli phaj thickness.

Nws yog nruj me ntsis txwv tsis pub pib lub arc ntawm lub hauv paus hlau sab nraum lub weld cheeb tsam. Lub cheeb tsam ntawm arc pib nyob rau hauv qhov zawj yuav tsum tau welded ib zaug, thiab tsis muaj arc crater yuav tsum tau tso tseg.

Multi-layer welds yuav tsum tsis tu ncua welded, thiab txhua txheej ntawm welds yuav tsum tau ntxuav nyob rau hauv lub sij hawm tom qab vuam.

4 Cov pa roj carbon monoxide steel yuav tsum tau txias rau qhov kub thiab txias hauv qhov vuam, thiab cov hlau tsis tshua muaj hlau yuav tsum raug kuaj xyuas tsis muaj kev puas tsuaj ntawm qhov vuam 24 teev tom qab ua tiav ntawm vuam.

Nyob rau hauv kev sib txuas ntawm cov phaj tuab thiab cov pob qij txha nrog lub thickness ntawm ntau tshaj 20 hli, chav tsev tsim kho (nrog rau kev tsim khoom thiab kev teeb tsa yuav tsum ua txhua yam tsim nyog ntsuas los tiv thaiv laminar tearing nyob rau hauv cov thickness kev taw qhia.

Ntxiv mus, thaum lub phaj thickness ≥ Thaum lub thickness yog 30 hli, nyob rau hauv thiaj li yuav tiv thaiv txheej txheem tearing nyob rau hauv lub thickness kev taw qhia, ua ntej welding, ultrasonic flaw detection yuav tsum tau nqa tawm nyob rau hauv lub cheeb tsam ntawm 2 lub sij hawm lub phaj thickness ntxiv rau 30 hli ntawm ob sab. ntawm lub centerline ntawm lub hauv paus hlau weld. Yuav tsum tsis muaj kab nrib pleb, interlayers thiab Defects xws li delamination muaj.

Thaum lub zos thaub qab phaj siv rau vuam, ntxiv rau qhov sib txawv me me ntawm lub hauv paus ntawm lub vuam zawj, uas yuav tsum ua kom tau raws li cov qauv tsim, cov phaj rov qab thiab cov vuam yuav tsum tau txuas nrog zoo, kom cov vuam ntws tuaj yeem yaj mus rau hauv lub phaj thaub qab, thiab ua tau raws li cov cai hauv qab no:

- Cov kev xav tau ntawm cov phaj rov qab yuav tsum yog tib yam li cov khoom siv vuam.

- Txoj kev pretreatment ntawm lub nraub qaum phaj yuav tsum zoo ib yam li cov khoom siv welded.

- Tom qab vuam tiav lawm, lub phaj rov qab raug tshem tawm los ntawm kev txiav. Thawj feem ntawm kev sib txuas ntawm cov khoom siv thiab cov phaj rov qab yuav tsum tau smoothed thiab xyuas seb puas muaj cov kab nrib pleb.

Thaum welding rau ntawm qhov chaw embedded, ntsuas xws li nyias electrodes, tsis tshua muaj tam sim no, txheej txheej, thiab ntu vuam yuav tsum tau siv los tswj qhov kub ntawm tag nrho cov embedded ib feem kom tsis txhob kub hnyiab thiab coagulation.

Thaum vuam nyob ib ncig ntawm peb sab thiab ib ncig ntawm lub fillet, cov ces kaum yuav tsum tau welded tsis tu ncua. Cov tswv cuab ntawm cov qauv hlau yuav tsum tsis txhob welded nyob rau hauv kev ntxhov siab. Welds yuav tsum tsis txhob sib tshooj ntau li ntau tau.

Steel Structure Installation Engineering Siv Kev Tswj Xyuas Zoo

- Thaum hoisting seem steel kem, siv ob-point hoisting txoj kev. Tom qab lub hoisting nyob rau hauv qhov chaw thiab ruaj, kev txhawb nqa ib ntus yog muab los tiv thaiv nws los ntawm kev qaij los ntawm cua lossis lwm yam sab nraud.

- Cov qauv hlau yuav tsum muaj daim ntawv pov thawj khoom zoo thaum nws nkag mus rau hauv qhov chaw, thiab nws cov haujlwm me me xws li vuam kev sib txuas, txuas txuas, thiab cov khoom siv hlau yuav tsum tsim nyog.

- Tshawb xyuas qhov ruaj khov ntawm cov khoom siv hoisting, xaiv cov tshuab hoisting kom tsim nyog, thiab txiav txim siab txog kev lag luam thiab kev ua haujlwm hoisting.

- Cov qauv steel yuav tsum ua tau raws li cov qauv tsim thiab specifications. Lub deformation ntawm cov qauv hlau thiab cov tev ntawm cov txheej los ntawm kev thauj mus los, stacking, hoisting, thiab lwm yam yuav tsum tau kho thiab kho.

- Rau kev teeb tsa ntawm ntau txheej los yog cov neeg ua haujlwm siab, tom qab lub hoisting ntawm txhua txheej ua tiav, nws yuav tsum raug kho raws li cov ntaub ntawv lees paub nruab nrab thiab ntsuas cov ntaub ntawv, thiab cov chaw tsim khoom yuav tsum tau ceeb toom kom kho qhov ntev ntawm cov tswv cuab. yog tias tsim nyog.

- Rau cov nodes uas yuav tsum tau nruj nyob rau hauv tus tsim, ob lub dav hlau nyob rau hauv kev sib cuag yuav tsum yog 70% nyob ze rau ib leeg thiab xyuas nrog ib tug 0.3mm feeler gauge. Qhov siab tshaj plaws ntawm cov npoo yuav tsum tsis txhob ntau tshaj 0.8mm.

- Txoj hauj lwm ntawm lub horn yuav tsum xyuas kom meej lub rigidity ntawm lub hauv qab ntawm kem, thiab cov kev npaj ntawm lub horn yuav tsum tau tso cai rau lub kem los yog lub hauv paus yuav tsum tau dais ntxiv loads.

- Qhov chaw axis ntawm txhua kab yuav tsum tau coj ncaj qha los ntawm cov kab tswj hauv av, tsis yog los ntawm axis ntawm sab qis; pem teb qhov siab ntawm cov qauv yuav tsum tau tswj raws li tus txheeb ze elevation los yog tsim elevation.

- Tom qab qhov chaw khov kho tau tsim, qhov sib txawv ntawm cov kab hauv qab phaj thiab lub hauv paus nto yuav tsum tau hloov los ntawm cov pob zeb zoo thiab cov khoom siv hauv lub sijhawm.

- Thaum lub steel qauv thauj, stacked thiab ntsia, lub stability ntawm cov qauv yuav tsum tau guaranteed, thiab cov qauv yuav tsum tsis txhob deformed mus tas li.

- Nyob nruab nrab ntawm cov khoom siv hlau txuas nrog lub zog muaj zog bolts, reaming tsis raug tso cai, thiab cov roj-txiav reaming yog nruj me ntsis txwv. 12. Rau qhov tseeb installation thiab tso cai yuam kev ntawm cov khoom, thov mus rau "High Steel Regulations", "Steel Regulations" thiab "Inspection Regulations".

- Pre-embedded bolts: Thaum lub sij hawm pouring txheej txheem, nws yog tsim nyog los xyuas kom meej tias lub hauv paus bolts nyob rau hauv qhov chaw. Nyob rau txhua theem ntawm kev tsim kho, kev ntsuas yuav tsum tau ua los tiv thaiv bolts, threads thiab txiv ntseej los ntawm kev puas tsuaj, corrosion thiab paug. Cov ntsia liaj qhov rooj uas faus rau hauv lub hauv paus yuav tsum huv si thiab tsis muaj khib nyiab.

- Grouting: Lub grouting ntawm lub phaj hauv qab ntawm kab ke yuav tsum tau ua tom qab cov qauv tau dhau qhov kev sib tw, theem thiab verticality test, muaj kev txhawb nqa txaus, thiab yog qhov tseeb thiab ruaj khov nrog cov tswv cuab txuas mus tas li. Qhov chaw nyob hauv qab phaj yuav tsum tau muab tshem tawm thiab ntxuav ua ntej grouting. Kev lag luam grout yuav tsum tau npaj, sib tov thiab grouted raws li cov neeg tsim khoom cov lus qhia. Kev ntsuam xyuas yuav tsum tau ua yog tias tsim nyog.

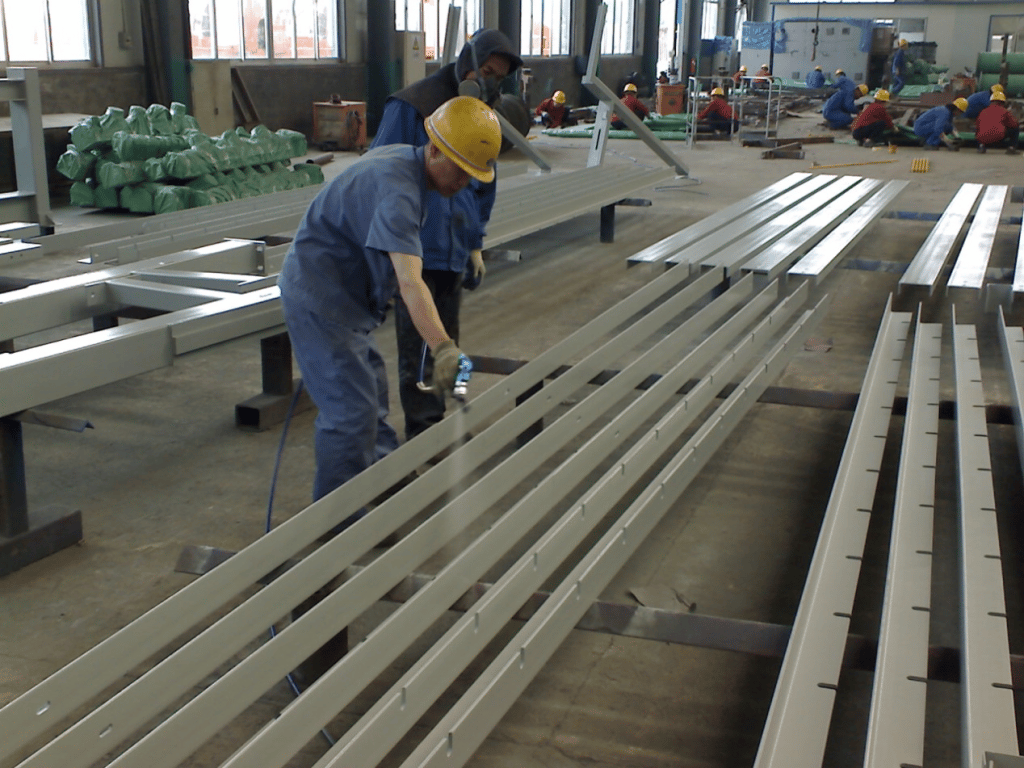

- Thaum txhim kho lub profiled steel kem, tswj lub flatness thiab compactness ntawm kem ko taw, zawm lub stud bolts, thiab master lub verticality ntawm profiled steel kem.

Nyeem ntxiv: Steel Structure Installation & Design

Steel Structure Anti-Corrosion Siv Kev Tswj Xyuas Zoo:

Ua ntej cov qauv hlau yog pleev xim rau, cov burrs, xeb, oxide nplai, roj stains thiab txuas rau ntawm qhov chaw ntawm cov khoom yuav tsum raug tshem tawm tag nrho, thiab cov xeb yuav tsum tau muab tshem tawm kom huv si los ntawm sandblasting, tua blasting, thiab lwm yam. Kev tshem tawm xeb tuaj yeem ua tau los ntawm cov tshuab hluav taws xob. , Pneumatic xeb tshem tawm cov cuab yeej kom huv si tshem tawm xeb, tom qab steel nto xeb tshem tawm tsim nyog, nws yuav tsum tau pleev xim rau hauv lub sijhawm txwv.

Rau cov khoom uas tau los tiv thaiv xeb primer, tab sis muaj kev puas tsuaj, xeb, tev, thiab lwm yam, thiab qhov chaw uas tsis tau anti-xeb primer, lawv yuav tsum tau kho nrog cov xim kov-up. Cov kev cai tshwj xeeb yog: siv epoxy zinc-nplua nuj primer los kho cov tshuaj tiv thaiv xeb, thiab tom qab ntawd raws li qhov chaw, ua lub sealer, midway xim, thiab topcoat nyob rau hauv kev txiav txim.

Tom qab cov bolts txuas rau ntawm qhov chaw yog screwed, cov xim tiv thaiv xeb yuav tsum tau siv raws li cov qauv tsim. Rau cov bolts siv nyob rau hauv cov huab cua qhib los yog nyob rau hauv lub nruab nrab corrosive ib puag ncig, ntxiv rau kev siv cov tshuaj tiv thaiv xeb, cov pob qij txha ntawm cov hlau txuas yuav tsum tau muab ntim nrog tshuaj pleev los yog putty nyob rau hauv lub sij hawm.

Kev Tswjhwm Zoo Ntawm Steel-Concrete Structure:

Txhawm rau daws qhov sib txawv ntawm qhov sib txawv ntawm cov hlau profiled thiab cov hlau tuav ntawm cov nqaj thiab cov pob qij txha hauv cov profiled steel-pob zeb thav duab, kom paub qhov txuas ntxiv thiab nkag mus ntawm cov kab tseem ceeb hauv kab hauv qab mus rau sab saum toj thiab xyuas kom meej. nws txoj kev ncaj ncees, nws yog ib qho tsim nyog yuav tau ua cov kab hlau profiled thiab kab ua ntej ua.

Ua raws li cov lus qhia ntxaws ntxaws ntawm txoj haujlwm perforation ntawm steel bar: Tsis tas li ntawd, txhawm rau siv lub rub ntsia liaj qhov rooj thaum lub formwork tau txais kev txhawb nqa, cov ncauj lus kom ntxaws tsim ntawm txoj hauj lwm ntawm rub lub qhov muag ntawm lub steel kem yuav tsum tau nqa tawm.

Ua ntej kev teeb tsa ntawm cov qauv hlau, qhov chaw axis ntawm lub tsev, lub axis ntawm lub hauv paus thiab txoj hauj lwm thiab qhov siab ntawm lub thauj tog rau nkoj bolts yuav tsum tau kuaj xyuas, thiab lub hauv paus yuav tsum tau kuaj thiab cov txheej txheem xa thiab txais yuav tsum tau ua.

Lub zog ntawm lub hauv paus pob zeb yuav tsum ua tau raws li cov qauv tsim ua ntej kev teeb tsa; cov ntsiab lus siv ntawm lub hauv paus axis cim thiab qhov siab yuav tsum yog thiab ua tiav; lub installation ntawm profiled steel kem: tswj qhov nce, tswj qhov ntsug, tswj txoj hauj lwm, txoj hauj lwm ntawm lub thauj tog rau nkoj ntsia liaj qhov rooj thiab cov chaw txhawb nqa yuav tsum yog qhov tseeb.

Cov hlau phaj rov qab phaj siv nyob rau hauv kev teeb tsa ntawm cov kab hlau profiled yuav tsum tau teem rau hauv qab phaj ntawm kem ko taw ze rau lub thauj tog rau nkoj ntsia liaj qhov rooj, thiab ob pawg ntawm cov phaj rov qab yuav tsum tau teem rau ntawm ib sab ntawm txhua qhov ntsia liaj qhov rooj. Kev sib cuag ntawm lub phaj nraub qaum thiab lub hauv paus nto thiab hauv qab ntawm kab yuav tsum tiaj tus thiab nruj. Ua ntej grouting lub phaj hauv qab ntawm lub hauv paus, lub phaj rov qab yuav tsum tau welded thiab tsau.

Lub ntsiab qhov cuab lub zog ntawm lub reinforced steel kem yuav tsum tau muab tso rau hauv nruj raws li cov ncauj lus kom ntxaws tsim cov ntsiab lus ntawm txoj hauj lwm ntawm lub ntsiab reinforcement. Nws yuav tsum tau muab sau tseg tias txoj hauj lwm ntawm lub ntsiab reinforcement dhau los ntawm flange phaj ntawm profiled steel beam yog qhov tseeb, thiab qhov verticality ntawm qhov no ntawm qhov kev txhawb zog yog yuav tsum tau thaum lub sij hawm tag nrho cov txheej txheem ntawm kev tsim kho.

Thaum txhim kho lub ntsiab qhov cuab lub zog los ntawm lub profiled steel beam los yog steel txhawb corbel flange phaj, ua ntej dhau lub reinforcement yuav tsum tau kev cob cog rua los ntawm lub reinforcement qhov los ntawm hauv qab mus rau sab saum toj, thiab ces siv ib tug tshwj xeeb lub tes tsho los mus txuas nrog lub hauv qab reinforcement.

Lub stirrups ntawm cov pob qij txha ntawm cov profiled steel-pob zeb thav duab tuaj yeem ua tiav rau hauv lub tes tsho qhib vim muaj kev cuam tshuam ntawm cov kab hlau profiled thiab cov hlau txhawb nqa corbel webs. Factory pre-soldered) vuam.

Thaum lub sij hawm ua cov hlau phaj nyob rau sab saum toj ntawm kem, nws yog ib qho tsim nyog yuav tsum tau tshwj tseg qhov cuab lub zog raws li cov txiaj ntsig ntawm kev sib sib zog nqus tsim ntawm lub ntsiab qhov cuab lub zog. Lub weld yuav tsum tau ntim nrog qhov sib txawv ntawm lub qhov tshwj xeeb thiab qhov cuab lub zog, thiab sab saum toj ntawm lub vuam yuav tsum tau yaug nrog rau saum npoo ntawm lub phaj thauj tog rau nkoj;

Ua tib zoo xav txog qhov ntev ntawm cov khoom siv raw, ua cov khoom xyaw tsim nyog, thiab tswj tus naj npawb ntawm steel bar pob qij txha nyob rau hauv tib seem kom tau raws li qhov yuav tsum tau ntawm cov specification.

Txoj hauj lwm ntawm steel bar pob qij txha, qhov sib nrug ntawm stirrups, thiab lub kaum sab xis ntawm stirrup hooks yuav tsum tau ua raws li cov kev cai ntawm kev tsim kho specifications thiab tsim, thiab concealed txais yuav tsum tau ua.

Ua ntej lub kem txhawb nqa, cov hlau yuav tsum tau popped rau hauv qab, thiab txoj hauj lwm ntawm kem yuav tsum nyob rau hauv nruab nrab, thiab txoj hauj lwm ntawm lub reinforcement ntawm kem yuav tsum tau kho.

Pob zeb ua kom rov qab los vim muaj kev cuam tshuam ntom ntom nti ib ncig ntawm ntu steel thiab cawv ntawm ntu steel nqaj nyob rau saum toj ntawm kem, nws nyuaj rau ncuav nrog cov pob zeb ua kom zoo tib yam. Kev xaiv ntawm tus kheej-compacting pob zeb nrog nws tus kheej-leveling thiab nws tus kheej-compacting zog tuaj yeem ua kom muaj kev tsim kho zoo.

Kev sib xyaw ua ke tsis tuaj yeem ua tau yog tias nws nrawm dhau, qhov siab ntawm tshauv yuav tsum tau tswj ntawm li 0.5m txhua lub sijhawm, thiab lub sijhawm ncua ntawm ob zaug ntawm tshauv yuav tsum tau tswj ntawm li 15 feeb.

Thaum nchuav cov pob zeb, siv cov roj hmab rau txhawm rau tawm tsam sab nraud ntawm lub formwork, tshwj xeeb tshaj yog cov plaub fab ntawm kem, txhawm rau xyuas seb cov pob zeb puas tau nchuav nruj, thiab nws yuav pab tau kom tshem tawm cov pores hauv cov pob zeb.

Tiv Tauj Peb >>

Muaj lus nug lossis xav tau kev pab? Ua ntej peb pib, koj yuav tsum paub tias yuav luag txhua lub tsev prefab steel yog customized.

Peb pab neeg ua haujlwm engineering yuav tsim nws raws li lub zos cua ceev, nag load, length * dav * qhov siab, thiab lwm yam kev xaiv ntxiv. Los yog, peb tuaj yeem ua raws li koj cov duab kos. Thov qhia kuv qhov koj xav tau, thiab peb yuav ua lwm yam!

Siv daim ntawv thov kom ncav cuag thiab peb yuav tiv tauj koj sai li sai tau.

Txog Tus Sau: K-HOME

K-home Steel Structure Co., Ltd npog thaj tsam ntawm 120,000 square meters. Peb koom nrog hauv kev tsim, qhov project pob nyiaj siv, fabrication, thiab installation of PEB steel structures thiab sandwich panels nrog rau qib ob-qib kev cog lus kev tsim nyog. Peb cov khoom npog lub teeb steel qauv, PEB buildings, pheej yig prefab tsev, thawv tsev, C / Z steel, ntau yam qauv ntawm cov xim hlau phaj, PU sandwich panels, eps sandwich panels, pob zeb wool sandwich panels, chav txias panels, purification daim hlau, thiab lwm yam khoom siv.