Steel Structure Factory Building

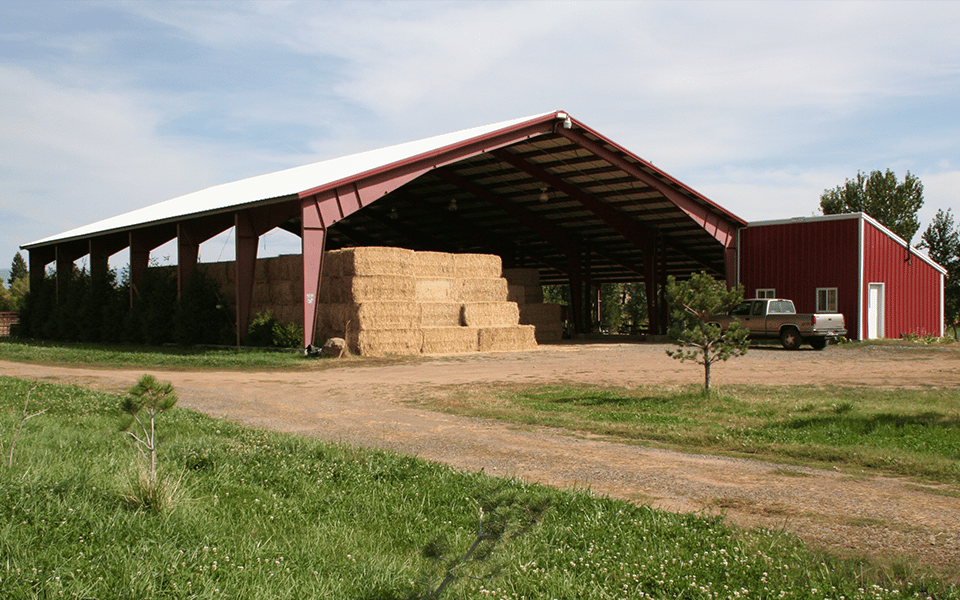

Steel Factory Building

Normally, the span of the factory is relatively large. More and more people choose the PEB steel structure factory now, because of low cost and short construction period. A light steel frame factory means that the mainframe is made of steel. It includes steel columns, steel beams, steel roof truss, and etc. The steel structure factory walls can be made of color steel tiles, sandwich panels, or brick walls.

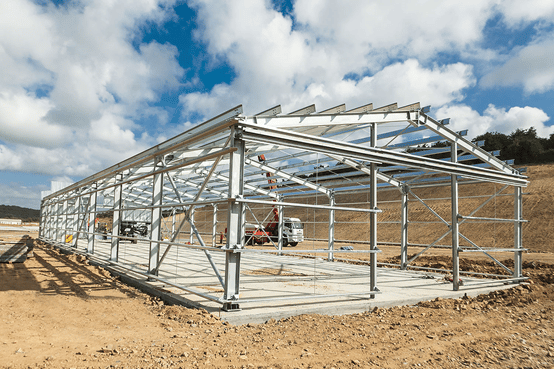

The PEB factory is a new concept of environmentally friendly and economical light steel building with light steel as the framework, sandwich panel as the maintain material, and standard modular series for spatial integration. The components are connected by bolts.

It can be assembled and disassembled conveniently and quickly, realizes the general standardization of temporary buildings, and establishes an environmentally friendly, energy-saving, fast, and efficient construction concept, and makes the temporary steel structure building enter a series of developing, integrated production, supporting supply, inventory, and availability. A stereotyped product can be used for many times turnover.

Related Industrial Metal Steel Buildings

WHY CHOOSE KHOME AS YOUR SUPPLIER?

K-HOME is one of the trusted factory manufacturers in China. From structural design to installation, our team can handle various complex projects. You will receive a prefabricated structure solution that best suits your needs.

You can send me a WhatsApp message (+86-18338952063), or send an email to leave your contact information. We will contact you as soon as possible.

Basic Structure (can be customized)

Embedded parts are components that are pre-buried in a concealed project.

The components placed during the pouring of the structure are used for lap joints when building the superstructure.

It facilitates the installation and fixation of the foundation of external engineering equipment. Most of the embedded parts are made of metal

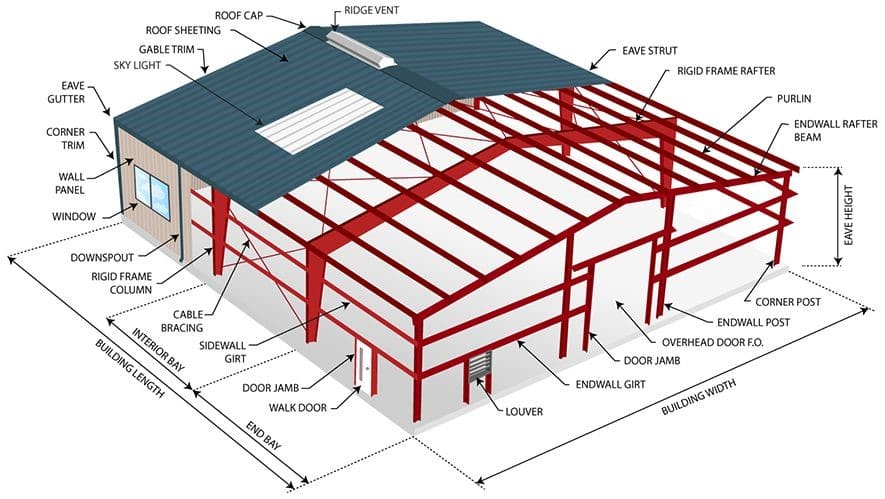

It is connected to the frame column and as a fulcrum for other beams.

The steel frame type is H-section Steel. Material: Q235B, Q355B, Q298.

The steel frame uses shot blasting to remove the rust, reaching the Sa2.0 standard, Improving the roughness of the work piece and the adhesion of the subsequent paint film.

It also includes Crane Beam, Floor Secondary Beam.

The steel frame type is Hot roll H-section Steel. Material: Q235B, Q355B.

We did 3 layers paint: Primer + Intermediate Paint + Top Paint We’ll paint 2 times per layer, the total paint thickness is around 125μm~150μm based on the local environment.

There are floor purlins, wall purlins, and roof purlins.

Roof purlin sits between the roofing sheets and the roof beam.

It acts as support for the sheet to ensure it is firmly attached and safely in place, and transmits the roof load to the steel frame.

Floor purlins sit between the second floors. It acts as a support for the floor board to ensure the second floor is more durable.

The steel purlins are processed by hot-coiled sheet and cold-bent, with thin wall, light weight, excellent cross-section performance, and high strength.

The material is Q195 or Q345.Common Type: Z-shaped steel purlins and C-shaped steel purlins.

There are two options for the wall. One is sandwich panel; the other is wall steel sheet.

Rock Wool Sandwich Panel surface is 0.2-0.4mm steel sheet.

The core material: EPS/ Rock wool/PU/Glass wool. The thickness is 50mm/75mm/100mm.

It is good at heat insulation, fireproof, soundproof, high loading bearing strength.

The wall steel sheet surface is galvanized and color coated. It is good at high corrosion resistance and powerful cohesion.

Steel Structure Factory Building Advantages

As steel structures are used more and more widely in the market, people are paying more and more attention to steel structure factory buildings, and steel structure factory buildings have many advantages, such as:

More Metal Building Kits

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.