Ukuqonda indima yoQhagamshelwano lweZakhiwo zeNsimbi

Ukudityaniswa kwesakhiwo sentsimbi yindlela ebalulekileyo yobugcisa bokuqinisekisa ukuthembeka kwesakhiwo kunye nokhuseleko. Ngokudibanisa ngokuqinileyo amacandelo ahlukeneyo ezakhiwo zetsimbi, ziququzelela ukuhanjiswa kwemithwalo egudileyo kwaye ngaloo ndlela kugcinwe ukuzinza okupheleleyo kwesakhiwo sensimbi.

Ezi nkcukacha zoqhagamshelwano zidibanisa amacandelo ezakhiwo zensimbi ezizimeleyo - ezifana neentsimbi, iikholomu, kunye neetrasi - zibe yinto edibeneyo, ezinzileyo. Uyilo lwabo kunye nomgangatho wokwakha kuchaphazela ngokuthe ngqo ukhuseleko, ukuqina, kunye nokusebenza kwesakhiwo, okubenza babe likhonkco elibalulekileyo elibalulekileyo kulwakhiwo lwentsimbi. Nokuba zezezakhiwo zorhwebo eziphakamileyo, iindawo zokugcina zoshishino, okanye iiprojekthi zebhulorho, iindlela ezifanelekileyo zokudibanisa zenza ukuba isakhelo sensimbi sixhathise ngokufanelekileyo amandla ahlukeneyo angaphandle afana nomxhuzulane, umoya, kunye nomsebenzi we-seismic, ukuqinisekisa ukuthembeka kwesakhiwo ngexesha lokusetyenziswa kwexesha elide.

Izinto eziBalulekileyo zoNxibelelwano lweSteel Structure Types

Iindlela zokudibanisa eziqhelekileyo zezakhiwo zetsimbi ziquka iintlobo ezintathu eziphambili: ukudibanisa okudibeneyo, ukudibaniswa kwe-bolted, kunye ne-riveted connections.

I-Welded Connections: Amandla kunye noYilo lweMfezeko

Ukudityaniswa kwe-welded yindlela yokudibanisa esetyenziswa ngokubanzi kwizakhiwo zesakhiwo sentsimbi. Ngokunyibilikisa isinyithi kumaqondo obushushu aphezulu ukudibanisa amacandelo ensimbi yesakhiwo, bafezekisa amajoyina asisigxina abumba ama-nodes aqhubekayo e-monolithic, abonisa amandla abalaseleyo kunye nokuqina.

Iindlela zokudibanisa eziqhelekileyo ziquka i-butt welds kunye ne-fillet welds: i-butt welds isetyenziselwa ukudibaniswa kokuphela kwamacandelo, ngelixa i-fillet welds ifanelekile ukudibanisa ikona. Uxhumo oludibeneyo lusetyenziswa ngokubanzi kumacandelo ensimbi eyenziwe ngefektri, ngokukodwa kwiimeko ezineemfuno eziqinileyo zokuchaneka kunye nomthamo wokuthwala umthwalo. Nangona kunjalo, inkqubo ye-welding idinga ukulawulwa okungqongqo kweeparameters ukuphepha imiba enjengoxinzelelo oluseleyo, ukuguqulwa kwecandelo, okanye ukunciphisa amandla kwindawo echaphazelekayo ukushisa-ezi ngxaki ezinokuthi zichaphazele ubomi benkonzo yexesha elide yesakhiwo.

Uqhagamshelwano oluBolted: Ukuguquguquka kunye nokuLula kweNdibano

Ukudibanisa okufakwe kwi-bolted yenye indlela yokudibanisa isakhiwo sentsimbi esetyenziswa ngokuqhelekileyo, ukuphumeza ukudibanisa phakathi kwamacandelo esakhiwo ngokusebenzisa iibholiti eziqiniweyo.

Ngokukhusela izakhi zentsimbi kunye neebholiti kunye namantongomane, ukudibaniswa kwebholiti kunika iingenelo ezihlukeneyo ngokubhekiselele kwindibano elula kunye nokuguqulwa. Le ndlela yokudibanisa ifaneleke ngokukodwa ukwakhiwa kwendawo, njengoko isusa imfuno yezixhobo ezikhethekileyo ze-welding, ivumela ukulungiswa ngokukhawuleza kumacandelo kunye nokugcinwa okulandelayo.

Imidibaniso ebolithiweyo ihlelwa ikakhulu ngokweendidi ezimbini: uqhagamshelo oluqhelekileyo lwebholiti kunye noqhagamshelo oluphezulu lwamandla. Uqhagamshelwano oluqhelekileyo oluboshiweyo ludlulisa imithwalo ngokusebenzisa ukukhuhla kunye nomthamo wokuthwala, ngelixa uxhulumaniso oluphezulu lwamandla aphezulu lubonelela ngomthamo ophezulu wokuthwala umthwalo-wenza amajoyina anganyangekiyo kwi-friction ngokulayishwa kwangaphambili kwaye anokumelana nemithwalo eguquguqukayo. Kwizakhiwo ezibalulekileyo ezineemfuno eziphezulu zokuthembeka, ezifana neebhulorho kunye nezixhobo zokuxhasa izixhobo, ukudityaniswa kwe-bolted bolted kuyamkelwa ngokubanzi ngenxa yokumelana nokukhathala okukhulu.

Uqhagamshelwano oluBolted: Ukuguquguquka kunye nokuLula kweNdibano

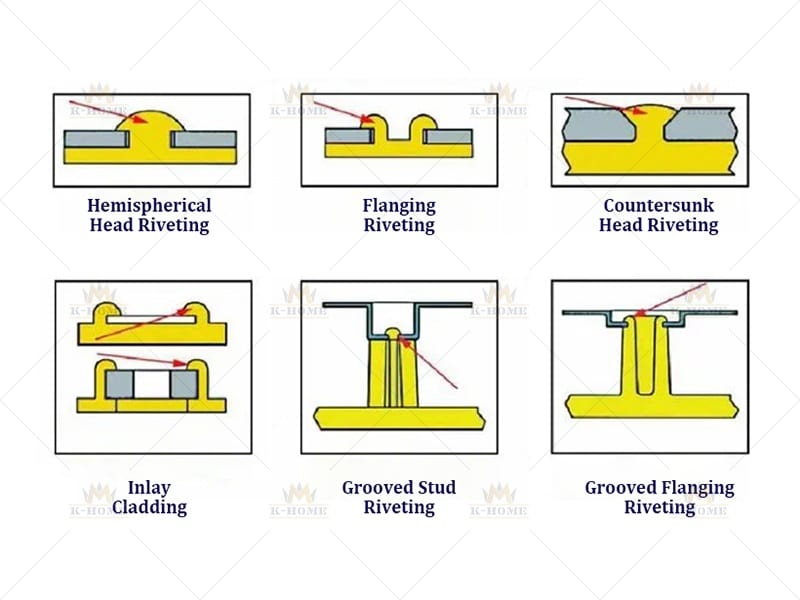

Uqhagamshelo oluluqilima lunembali ende yesicelo kubunjineli bolwakhiwo lwentsimbi kwaye lwakha lwasebenza njengendlela ephambili yodibaniso lwesakhiwo sentsimbi yemveli. Nangona itekhnoloji ye-welding kunye ne-bolts-high-power bolts ziye zaxhaphaka, ukusetyenziswa koqhagamshelo oludibeneyo kwizakhiwo zanamhlanje kuye kwancipha ngokuthe ngcembe ngenxa yobukhulu bokusebenza kunye nokusebenza okuphantsi.

Le ndlela yokudibanisa ibandakanya ukuqhuba i-rivets eshushu okanye ebandayo ngokusebenzisa imingxuma esele igrunjwe ngaphambili kumacandelo esakhiwo sentsimbi, ukwenza amajoyina asisigxina ngokusebenzisa i-mechanical interlock. Inokuqina okugqwesileyo kunye nokumelana nokudinwa, kwaye yayikhe yasetyenziswa ngokubanzi kwizakhiwo ezinobunzima obufana neebhulorho ezindala kunye neendibano zocweyo zamashishini. Nangona kunjalo, inkqubo yolwakhiwo loqhagamshelo oluluqilima lufuna umsebenzi ophezulu kunye nolungelelwaniso lwemingxuma oluchane kakhulu, olukhokelele ekutshintshweni kwabo ngokuthe ngcembe ngeendlela zoqhagamshelo olusebenzayo kulwakhiwo lwangoku olusekwe ngokufanelekileyo.

Ukufunda okuNxulumene nangakumbi: Intshayelelo yoLwakhiwo lweNsimbi kunye noYilo kunye noFakelo

Izicelo kunye neeNgcebiso eziSebenzayo zoQhagamshelwano lweZakhiwo zeNsimbi

Umphumo wesicelo sokudityaniswa kwesakhiwo sensimbi kuxhomekeke ekukhetheni uhlobo olufanelekileyo lokudibanisa kwinqanaba lokuqala, kunye nokusebenza okusemgangathweni ngexesha lokwakhiwa nokulawulwa kokugcinwa kokusetyenziswa kwexesha elide. Ezi ziqhagamshelo zenza indlela yokuphunyezwa esebenzayo yokudibanisa isakhiwo sensimbi, echaphazela ngokuthe ngqo ukhuseleko lwesakhiwo, ukuzinza, kunye nobomi bokwenene benkonzo yesakhiwo.

Ingaba kukudityaniswa kwamacandelo awenziwe ngefektri okanye udibaniso lwendawo yokudibanisa okudityanisiweyo, imisebenzi kufuneka yenziwe ngokuhambelana neemfuno zesayensi ezisekelwe kwimiba ethile. Ngexesha elifanayo, ulawulo olululo oluvakalayo kunye nendlela yokulondoloza kufuneka isungulwe ukuze kuqinisekiswe ukuba iindawo zokudibanisa zihlala zigcina imeko ethembekileyo.

Ulukhetha njani uhlobo loQhagamshelwano lweSistimi esiLungileyo kwiZakhiwo zentsimbi?

Ukukhethwa kweendlela zokudityaniswa kwesakhiwo sensimbi kufuna ukwenza izigqibo emva kokwenza uhlalutyo lwenjongo kunye nengqiqo, ngokusekelwe kwiimeko zangempela zeprojekthi kunye nokuqwalasela ngokubanzi izinto eziphambili ezichaphazelayo ezifana neemfuno zesakhiwo, iimeko zomthwalo, iimeko zokusingqongileyo kunye neemeko zokwakha.

- Iimfuno zesakhiwo: Izakhiwo eziphakamileyo eziphakamileyo kufuneka zixhathise umoya okanye i-seismic deformation, kunye ne-ductility yoxhumo oluphezulu lwe-bolted bolt inokuthintela ukuphuka kwe-brittle; kwizakhiwo ezineemeko zoxinzelelo oluzinzileyo, ezifana neendawo ezincinci zokugcina iimpahla kunye nezakhiwo zeofisi, udibaniso oludityanisiweyo lunokulinganisa ukubumbana kunye nomthamo wokuthwala umthwalo.

- Imiqathango yomthwalo: Izakhiwo zokuhlala, izakhiwo zeofisi eziqhelekileyo, kunye nezakhiwo ezifanayo zixhomekeke ikakhulu kwimithwalo engatshintshiyo efana nesakhiwo sobunzima obufileyo kunye nobunzima besixhobo esisisigxina, apho ukuqina, ukuzinza, kunye nokusebenza kweendleko zokudityaniswa kwe-welded kunokuhlangabezana neemfuno; izityalo zoshishino, iindawo zokugcina iimpahla, kunye nezinye izibonelelo kufuneka zithwale imithwalo eguquguqukayo enjengokushukuma kwezixhobo zoomatshini kunye nefuthe, kunye noqhagamshelwano oluphezulu lwe-bolted bolted lunikeza ukuxhathisa ukukhathala okuphezulu, ukugcina ukuthembeka koqhagamshelwano phantsi kokulayisha ngokuphindaphindiweyo.

- Imiba yokusingqongileyo: Kwiindawo ezinobungozi ezifana neendawo eziselunxwemeni kunye nemimandla yemizi-mveliso, imidibaniso ebolithiweyo ibonakalisa ukuguquguquka ngakumbi konyango lokuchasa umhlwa kunye nokutshintshwa okufanelekileyo okulandelayo, okukhokelela ekuguquguqukeni okuphezulu; kwimimandla ebandayo, utshintsho lwamaqondo obushushu luthambekele ekubangeleni ukucutshungulwa kwecandelo kunye nokwandiswa, kwaye ukuguquguquka koqhagamshelo oludityanisiweyo kunokulungelelanisa ngcono ukuguqulwa okunjalo, ukunciphisa uxinzelelo oludibeneyo.

- Iimeko zokwakha: Kwiindawo ezikude, iindawo ezingenazo izixhobo ze-welding, okanye iiprojekthi ezineeshedyuli zokwakha eziqinileyo, ukudibaniswa kwe-bolted kunenkqubo yokuhlanganisana elula kwaye ayifuni izixhobo ezinzima, ezinokuphucula ukusebenza kakuhle kokwakhiwa; nangona kunjalo, kumacandelo enziwa kwangaphambili kwifektri, udibaniso oludityanisiweyo lunokuphunyezwa kwindawo esemgangathweni, okwenza kube lula ukulawula ukuchaneka kunye nomgangatho. Emva kokwenziwa kwangaphambili, amacandelo ahanjiswa kwindawo yokufakelwa, ukulinganisa zombini umgangatho kunye neshedyuli.

KUTHENI UKHETHA U-KHOME NJENGOMNIKI WAKHO?

K-HOME ngomnye wabavelisi befektri abathembekileyo eTshayina. Ukusuka kuyilo lwesakhiwo ukuya kufakelo, iqela lethu linokusingatha iiprojekthi ezahlukeneyo ezinzima. Uya kufumana isisombululo sokwakheka kwangaphambili esilungele iimfuno zakho.

Ungandithumelela a Umyalezo we-WhatsApp (+ 86-18338952063), okanye thumela i-imeyile ukushiya iinkcukacha zakho zoqhagamshelwano. Siza kuqhagamshelana nawe ngokukhawuleza.

Ulawulo loMgangatho kunye nokuHlolwa koQhagamshelwano lweZakhiwo zeNtsimbi esele zenziwe

Nokuba yeyiphi indlela yoqhagamshelo eyamkelweyo, ulawulo olungqongqo lwekhwalithi lubalulekile ekuqinisekiseni ukhuseleko lwesakhiwo. Ngexesha le-fectoral prefabrication stage, i-welders kufuneka ibambe iziqinisekiso ezifanelekileyo, izinto ze-welding kufuneka zomiswe, kwaye iiparitha ze-welding kufuneka zibekwe esweni ngexesha langempela ukuphepha iziphene; kumacandelo okudityaniswa kwebholiti, ukuchaneka kokulungiswa kwemingxuma yebholithi kufuneka kuqinisekiswe ukuqinisekisa ukufakwa ngokufanelekileyo. Ngexesha lokwakhiwa kwendawo, iindawo zokudityaniswa kufuneka zicocwe phambi kwe-welding; iibholiti kufuneka ziqiniswe ngokulandelelana, kwaye iibholiti zokuqina okuphezulu kufuneka zisetyenziswe ngezitshixo ezikhethekileyo zetorque ngokweemfuno ezichaziweyo zokulayisha kwangaphambili.

Iindlela zokuhlola kunye nokwamkelwa kufuneka zikhethwe ngokusekelwe kwiimfuno ezithile: Uvavanyo lwe-ultrasonic lusetyenziselwa ukudibanisa i-welded ukubona iziphene zangaphakathi, kunye nokuhlolwa kwe-radiographic yongezwa kwiindawo eziphambili, kunye nokuhlolwa kwakhona kuyadingeka emva kokulungiswa kwesiphako. Kuqhagamshelo lwebhoti, ukuhlolwa kwesampulu yokulayishwa kwangaphambili kuyenziwa, kunye nokutshekishwa kwinani leentambo eziveziweyo kunye nokuqina koqhagamshelwano; kwiindawo ezinobungozi, ukuqinisekiswa rhoqo kweengubo ezichasene ne-corrosion kuyimfuneko. Ngethuba lokusetyenziswa kwexesha elide, ukuhlolwa okuqhelekileyo kwee-nodes zokudibanisa kufuneka kuqhutywe, kugxininise kwiingqungquthela ze-weld, ukukhulula i-bolt kunye nokugqwala, kunye nomonakalo wokugubungela. Imiba enokubakho efana ne-corrosion kunye ne-fatigue cracks kufuneka ichongwe kwaye iqwalaselwe ngokukhawuleza ukuthintela ukunyuka kweengozi zokhuseleko.

- Uvavanyo lwe-Ultrasonic yeeWelds zeSakhiwo seNsimbi

- Uvavanyo lweRadiographic yeZakhiwo zeNsimbi

- Ukuhlolwa okubonakalayo kweeWelds kuLawulo loMgangatho

Dinga uncedo?

Nceda undazise iimfuno zakho, njengendawo yeprojekthi, ukusetyenziswa, L * W * H, kunye nokhetho olongezelelweyo. Okanye sinokwenza isicatshulwa ngokusekelwe kwimizobo yakho.

Malunga noMbhali: K-HOME

K-home Steel Structure Co., Ltd ithatha indawo ye-120,000 square metres. Sibandakanyeka kuyilo, uhlahlo lwabiwo-mali lweprojekthi, ulwakhiwo, kunye ukufakwa kwezakhiwo zentsimbi ye-PEB kunye neepaneli zesandwich ezineziqinisekiso zekontraka zebakala lesibini jikelele. Iimveliso zethu zigubungela izakhiwo zentsimbi ezikhanyayo, Izakhiwo zePEB, izindlu ze-prefab zamaxabiso aphantsi, izindlu zeekhonteyina, intsimbi ye-C / Z, iimodeli ezahlukeneyo zepleyiti yensimbi yombala, i-PU sandwich panels, iipaneli ze-eps sandwich, iipaneli ze-sandwich zoboya, iipaneli zegumbi elibandayo, iipleyiti zokucoca, kunye nezinye izinto zokwakha.