Kwiminyaka yakutshanje, inkqubo yokufudukela ezidolophini ikhula ngokukhawuleza nangokukhawuleza, kwaye isakhiwo sentsimbi esakhiwe ngaphambili ishishini lizuze uphuhliso olungazange lubonwe ngaphambili. Abantu baneemfuno eziphezulu neziphezulu zokusebenziseka kunye nokhuseleko lwezakhiwo. Kubunjineli bokwakha banamhlanje, uyilo lwesakhiwo sentsimbi ineengenelo ezithile, yaye ukusetyenziswa kwayo kulwakhiwo kuya kusiba banzi. Idityaniswe neminyaka yamava omsebenzi, K-home Isishwankathelo esisi-8 solwazi olusisiseko malunga nesakhiwo sentsimbi, umxholo mde, nceda uwufunde ngomonde:

1. Iimpawu zoLwakhiwo lwentsimbi:

- Isakhiwo sentsimbi sinobunzima

- Ukuthembeka okuphezulu komsebenzi wesakhiwo sensimbi

- Intsimbi inokumelana nokungcangcazela kakuhle (umothuko) kunye nokumelana nempembelelo

- Isakhiwo sensimbi sinokuhlanganiswa ngokuchanekileyo kwaye ngokukhawuleza

- Kulula ukwenza isakhiwo esitywiniweyo

- Ulwakhiwo lwentsimbi kulula ukurhwaphiliza

- Ukunganyangeki komlilo wesakhiwo sensimbi

2. Amabanga kunye neePropati zeSteel Structures ezidla ngokusetyenziswa

- Intsimbi yesakhiwo seCarbon: Q195, Q215, Q235, Q255, Q275, njl.

- I-alloy ephantsi yamandla aphezulu ensimbi yesakhiwo

- Umgangatho ophezulu we-carbon structural steel kunye ne-alloy structural steel

- Injongo ekhethekileyo yentsimbi

3. Imigaqo yoKhetho lweMathiriyeli yeZakhiwo zentsimbi

Umgaqo wokukhethwa kwezinto eziphathekayo wesakhiwo sensimbi kukuqinisekisa ukuthwala umthamo wesakhiwo somthwalo kunye nokuthintela ukungaphumeleli kwe-brittle phantsi kweemeko ezithile. Kuqwalaselwa ngokubanzi ngokokubaluleka kwesakhiwo, iimpawu zomthwalo, ifom yesakhiwo, imeko yoxinzelelo, indlela yokudibanisa, ubukhulu bentsimbi kunye nendawo yokusebenza. ye.

Iindidi ezine zetsimbi ezicetywayo "kwiKhowudi yoYilo lweZakhiwo zeNsimbi" i-GB50017-2003 luhlobo "lufanelekileyo" kwaye lukhetho lokuqala xa iimeko zivuma. Ukusetyenziswa kwezinye iindidi akunqatshelwe, nje ukuba intsimbi esetyenzisiweyo ihlangabezana neemfuno zenkcazo.

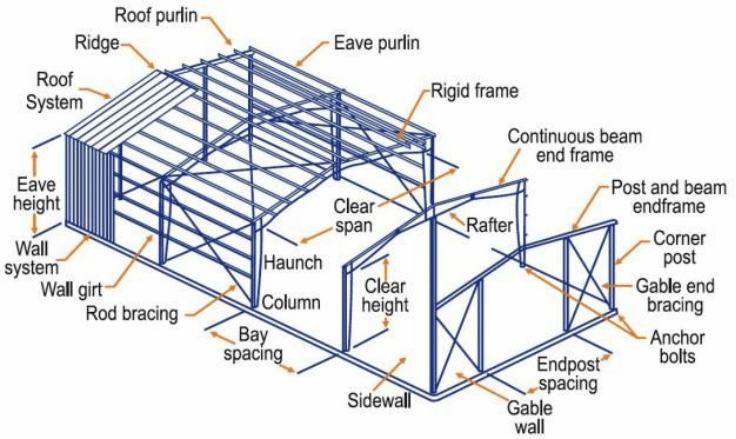

Okwesine, umxholo ophambili wezobugcisa wesakhiwo sensimbi:

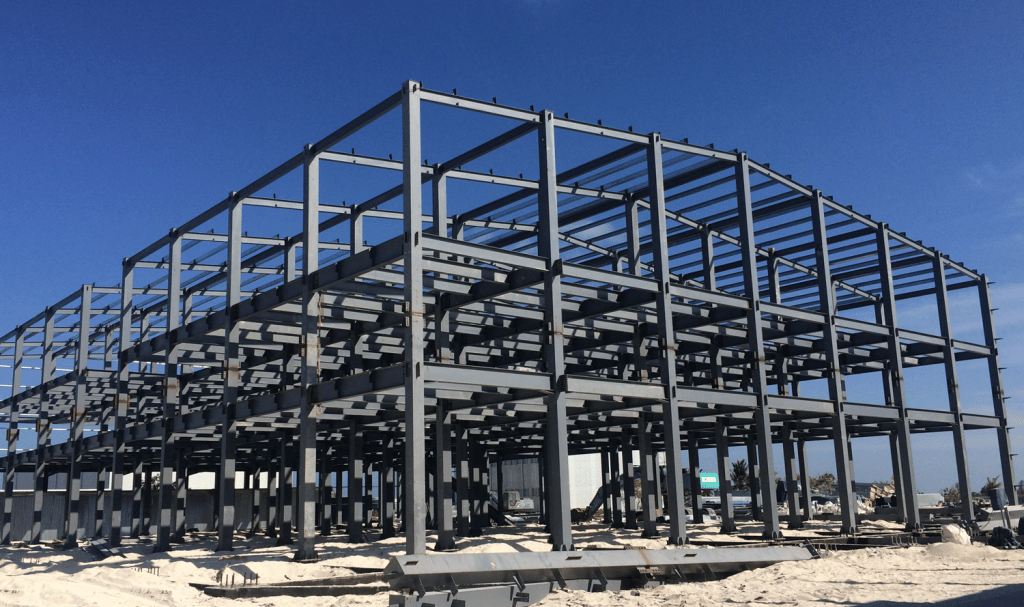

(a) Iteknoloji yesakhiwo sentsimbi ephezulu. Ngokobude besakhiwo kunye neemfuno zokuyila, isakhelo, inkxaso yesakhelo, isilinda kunye nesakhiwo sesakhelo esikhulu sisetyenziswe ngokulandelanayo, kwaye amacandelo anokuba yintsimbi, i-concrete eqinisiweyo eqinisiweyo okanye ikhonkrithi ye-tube yensimbi. Amalungu ensimbi alula kunye ne-ductile, kwaye anokuthi adityaniswe okanye agqitywe, afanelekele izakhiwo eziphezulu eziphezulu; amalungu ekhonkrithi aqinisiweyo aqinile anokuqina okuphezulu kunye nokumelana nomlilo okulungileyo, kwaye afanelekile kwizakhiwo eziphakamileyo kunye nezakhiwo eziphakamileyo okanye izakhiwo ezisezantsi; umbhobho wentsimbi ikhonkrithi kulula ukwakha, Kuba izakhiwo ikholamu kuphela.

(b) Itekhnoloji yolwakhiwo lwentsimbi emajukujukwini. Isakhiwo sensimbi yesithuba sineenzuzo zokulula, ukuqina okuphezulu, ukubonakala okuhle kunye nesantya sokwakha ngokukhawuleza. Igridi yebhola edityanisiweyo ecaba, igridi enamacandelo amaninzi aguquguqukayo kunye neqokobhe eliqhagamshelweyo elinombhobho wentsimbi njengoko intonga zezona ntlobo zezakhiwo ezinesona sixa sikhulu sesakhiwo sentsimbi kwilizwe lam. Ineenzuzo zokuqina kwendawo enkulu kunye nokusetyenziswa kwentsimbi ephantsi kwaye inokubonelela ngeCAD epheleleyo kwindlela yokuyila, yokwakha kunye nokuhlola. Ukongeza kwisakhiwo segridi, kukwakho nezakhiwo zekhebula zokumisa i-span ezinkulu kunye nezakhiwo ze-cable-membrane kwizakhiwo zesithuba.

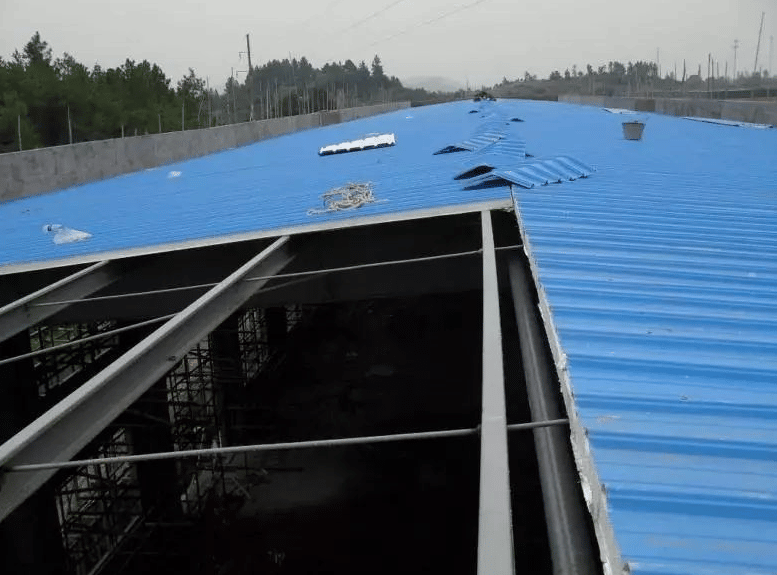

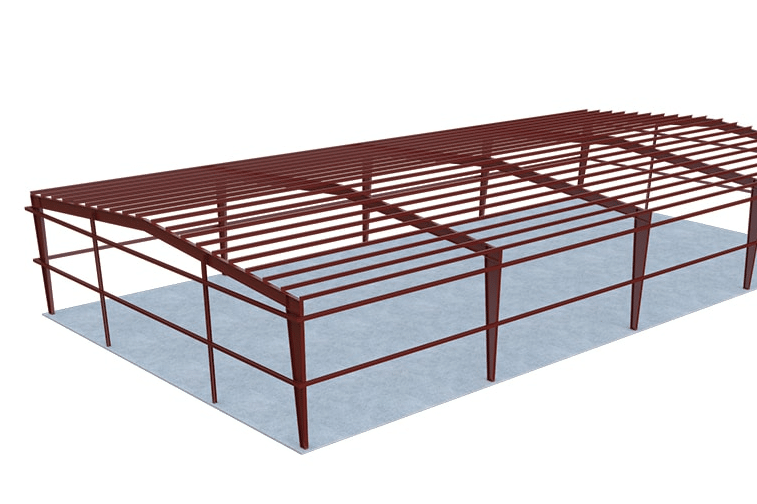

(c) Itekhnoloji yesakhiwo sentsimbi ekhanyayo. Ifom entsha yesakhiwo esineendonga kunye neemvulophu zephahla zenziwe ngeeplati zetsimbi ezinombala okhanyayo. Inkqubo yesakhiwo sentsimbi ekhaphukhaphu eyenziwe ngamacandelo amakhulu amancinci anodonga lwentsimbi emise okwe-H kunye nophahla lwe-purlins oludityanisiweyo okanye olujikelezwe ngamacwecwe ensimbi ngaphezu kwe-5mm, intsimbi ejikelezayo eyenziwe ngeenkqubo zokuxhasa eziguquguqukayo kunye nokudibanisa ibholithi ephezulu. I-30m okanye ngaphezulu, ubude bunokufikelela ngaphezu kweemitha ezilishumi, kwaye iikhreyini ezikhanyayo zingasetwa. Ubungakanani bensimbi esetyenzisiweyo yi-20-30kg / m2. Ngoku kukho iinkqubo zoyilo ezisemgangathweni kunye namashishini akhethekileyo emveliso, enomgangatho olungileyo wemveliso, isantya sofakelo olukhawulezayo, ukhaphukhaphu, utyalo-mali oluphantsi, kwaye ulwakhiwo alukhawulelwanga ngamaxesha onyaka, alungele zonke iintlobo zezityalo ezikhanyayo.

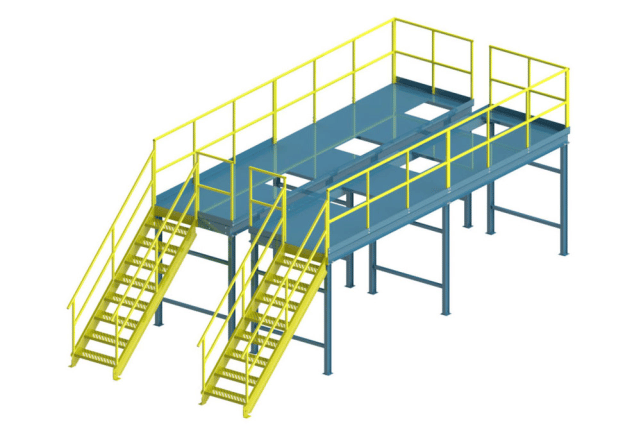

(d) Itekhnoloji yolwakhiwo oluhlanganisiweyo lwentsimbi. I-beam kunye ne-column-load-bearing structure eyenziwe ngentsimbi yecandelo okanye i-steel management and concrete components is a steel-concrete structure composite, kunye noluhlu lwesicelo lwayo luye lwanda kwiminyaka yamuva. Isakhiwo esihlanganisiweyo sineenzuzo zombini zentsimbi kunye nekhonkrithi, ngamandla onke aphezulu, ukuqina okulungileyo, kunye nokusebenza kakuhle kwe-seismic. Xa isakhiwo sekhonkrithi sangaphandle sisetyenzisiweyo, sinokumelana nomlilo ongcono kunye nokuxhathisa ukubola. Amalungu adibeneyo esakhiwo anokunciphisa ngokubanzi inani lentsimbi nge-15 ukuya kwi-20%. Umgangatho odibeneyo kunye neekhonkrithi zentsimbi ezifakwe kwi-tubular zinezinto eziluncedo ezingaphantsi okanye ezingekho phantsi, ukwakhiwa okufanelekileyo kunye nokukhawuleza, kunye namandla amakhulu okunyusa. Ifanelekile kwiiplanga zesakhelo, iikholomu kunye nemigangatho yezakhiwo ezininzi okanye izakhiwo eziphakamileyo ezinomthwalo omkhulu, isakhiwo semizi-mveliso iikholamu kunye nemigangatho, njl.

(e) Uqhagamshelo lwebholiti ephezulu kunye neteknoloji yewelding. Iibholiti zamandla aphezulu zigqithisa uxinzelelo ngokungqubuzana kwaye zenziwe ngamacandelo amathathu: iibholiti, amantongomane kunye neewasha. Uxhumo oluphezulu lwebholithi lunenzuzo yokwakhiwa okulula, ukuchithwa okuguquguqukayo, umthamo ophezulu wokuthwala, ukunyamezela ukukhathala okulungileyo kunye nokuzivalela, kunye nokhuseleko oluphezulu. Ithathe indawo ye-riveting kunye ne-welding inxalenye kwiprojekthi kwaye ibe yindlela yokudibanisa ephambili kwimveliso kunye nokufakwa kwezakhiwo zetsimbi. Kwizixhobo zentsimbi kunye neepleyiti ezishinyeneyo ezenziwe kwindawo yokusebenzela, ukuwelda okuzenzekelayo kwe-arc okuzenzekelayo kufuneka kusetyenziswe, kunye nebhokisi ye-clapboard yebhokisi kufuneka isebenzise ukunyibilika kwe-slag ye-electro slag kunye nezinye iiteknoloji. Kwintsimi yofakelo kunye nolwakhiwo, itekhnoloji ye-welding ye-semi-automatic, i-gas-shielded flux-cored welding wire kunye ne-self-shielded flux-cored welding wire technology kufuneka isetyenziswe.

(f) Iteknoloji yokukhusela isakhiwo sentsimbi. Ukukhuselwa kwezakhiwo zetsimbi kubandakanya ukukhuselwa komlilo, ukuchasana nokubola kunye nokukhusela i-rust. Ngokuqhelekileyo, akukho mfuneko yokwenza unyango oluchasene nomhlwa emva konyango lwe-corosion-retardant coating treatment, kodwa kusafuneka ukuba ibe unyango oluchasayo kwizakhiwo ezinegesi edlayo. Kukho iintlobo ezininzi zeengubo zasekhaya ze-retardant, ezifana nochungechunge lwe-TN, i-MC-10, njl. Phakathi kwazo, i-MC-10 i-fire retardant i-coatings iquka ipeyinti ye-alkyd ye-enamel, ipeyinti yerabha eneklorini, ipeyinti ye-fluororubber kunye nepeyinti ye-chlorosulfonated. Ekwakhiweni, ukugqoka okufanelekileyo kunye nobukhulu bokutya kufuneka kukhethwe ngokohlobo lwesakhiwo sensimbi, iimfuno zebanga lokumelana nomlilo kunye neemfuno zokusingqongileyo.

5. IiNjongo kunye neMilinganiselo yoLwakhiwo lweNsimbi:

Ubunjineli besakhiwo sentsimbi bubandakanya ubunzima obuninzi bobugcisa kwaye kufuneka bulandele imigangatho yelizwe kunye neshishini ekukhuthazeni nasekusetyenzisweni kwayo. Amasebe olawulo okwakhiwa kwendawo kufuneka anikele ingqalelo kulwakhiwo lwenqanaba lobuchwephesha lobunjineli besakhiwo sensimbi, aququzelele ukuqeqeshwa kwamaqela okuhlola umgangatho, kwaye ashwankathele iindlela zokusebenza kunye nezicelo zobuchwepheshe obutsha ngexesha elifanelekileyo. Iikholeji kunye neeyunivesithi, amasebe oyilo kunye namashishini okwakha kufuneka akhawulezise ukuqeqeshwa kobuchwephesha bobunjineli bentsimbi kunye nokukhuthaza iteknoloji evuthiweyo yesakhiwo sentsimbi yeCAD. Iqela lezemfundo ephakamileyo kufuneka basebenzisane nophuhliso lweteknoloji yesakhiwo sentsimbi, lenze utshintshiselwano olubanzi lwezemfundo kunye nemisebenzi yoqeqesho ekhaya nakwamanye amazwe, kwaye iphucule ngenkuthalo inqanaba lilonke loyilo lwesakhiwo sentsimbi, imveliso, ukwakhiwa kunye nokufakwa kweteknoloji, kwaye inokuvuzwa kwikamva elikufutshane.

6. Indlela yoQhagamshelwano lweZakhiwo zeNsimbi

Kukho iintlobo ezintathu zeendlela zokudibanisa kwizakhiwo zetsimbi: uxhulumaniso lwe-weld, uxhumano lwe-bolt kunye ne-rivet uxhumano.

(a), uQhagamshelwano lwe-Welding Seam

Ukudityaniswa komthungo we-welding kukunyibilika ngokuyinxenye i-electrode kunye ne-weldment ngubushushu obuveliswa yi-arc, kwaye emva koko udibanise kwi-weld emva kokupholisa, ukuze udibanise i-weldment iyonke.

Izinto eziluncedo: akukho buthathaka becandelo lecandelo, ukugcinwa kwentsimbi, isakhiwo esilula, ukuveliswa okulula, ukuqina koxhulumaniso oluphezulu, ukusebenza kakuhle kokutywinwa, kulula ukuyisebenzisa ngokuzenzekelayo phantsi kweemeko ezithile, kunye nokusebenza kakuhle kwemveliso.

Ukungalungi: Indawo echaphazelekayo yokushisa yentsimbi kufuphi ne-weld ngenxa yokushisa okuphezulu kwe-welding ingaba brittle kwezinye iindawo; ngexesha lenkqubo ye-welding, intsimbi ixhomekeke kubushushu obuphezulu obusasazwa ngokungafaniyo kunye nokupholisa, okukhokelela kwi-welding yoxinzelelo olushiyekileyo kunye ne-deformation eyintsalela yesakhiwo. Ukuthwala umthamo, ukuqina kunye nokusebenza kunempembelelo ethile; ngenxa yobunzima obuphezulu besakhiwo esidibeneyo, iintanda zendawo zilula ukwandisa kuyo yonke into emva kokuba zenzeke, ngakumbi kumaqondo aphantsi. Iziphene zinokuthi zenzeke ezinciphisa amandla okudinwa.

(b), uQhagamshelwano lweBolt

Uqhagamshelo oluboshiweyo kukudibanisa iziqhagamshelo zibe ngumzimba omnye ngeebholiti, ezifana nezibophelelo. Kukho iindidi ezimbini zokudityaniswa kwebholiti: udibaniso oluqhelekileyo lwebhoti kunye noqhagamshelwano oluphezulu lwamandla.

Izinto eziluncedo: inkqubo yokwakha elula kunye nofakelo olufanelekileyo, ngokukodwa ukulungelelaniswa kwendawo kunye nokudibanisa, kunye nokulula ukuchithwa, ezifanelekileyo kwizakhiwo ezifuna ukudibanisa kunye nokuchithwa kunye nokudibanisa kwexeshana.

Ukungalungi: Kuyimfuneko ukuvula imingxuma kwi-plate kwaye ulungelelanise imingxuma xa kuhlanganiswa, okwandisa umsebenzi wokuvelisa kwaye kufuna ukuchaneka okuphezulu kokuvelisa; imingxunya ye-bolt nayo iyancipha i-cross-section yamacandelo, kwaye iindawo ezidibeneyo zihlala zifuna ukugqithelana okanye zongeza ukudibanisa okuncedisayo. I-Plate (okanye i-angle yentsimbi), ngoko ke isakhiwo sinzima kwaye sibiza intsimbi.

(c), uQhagamshelwano lweRivet

Uqhagamshelo lwe-rivet yi-rivet ene-semi-circular prefabricated head at one end, kwaye intonga yesikhonkwane ifakwe ngokukhawuleza emngxunyeni wesikhonkwane sokudibanisa isiqwenga emva kokutshisa okubomvu, emva koko esinye isiphelo sifakwe kwintloko yesikhonkwane nge-rivet. umpu ukwenza uqhagamshelwano luqine. eqinileyo.

Izinto eziluncedo: ukuhanjiswa kwamandla e-riveted kuthembekile, iplastikhi kunye nokuqina kulungile, umgangatho kulula ukuwujonga kunye nokuqinisekisa, kwaye unokusetyenziselwa ubunzima kunye nokuthwala ngokuthe ngqo izakhiwo zomthwalo oguqukayo.

Ukungalungi: Inkqubo ye-riveting iyinkimbinkimbi, indleko yokuvelisa ngumsebenzi kunye nezinto eziphathekayo, kwaye ukuqina kwabasebenzi kuphezulu, ngoko ke ithathelwe indawo yi-welding kunye ne-high-power-bolt bolt uxhumano.

Iindidi zoQhagamshelwano kwiZakhiwo zentsimbi

7. uQhagamshelwano lwe-Welding

(a) Indlela yokuWelding

Indlela ye-welding esetyenziswa ngokuqhelekileyo kwizakhiwo zetsimbi i-arc welding, kubandakanywa i-arc welding manual, i-automatic okanye i-semi-automatic arc welding, kunye ne-gas shielded welding.

I-arc welding ye-manual yeyona ndlela isetyenziswa ngokuqhelekileyo kwizakhiwo zetsimbi, kunye nezixhobo ezilula kunye nokusebenza okuguquguqukayo kunye nokufanelekileyo. Nangona kunjalo, iimeko zabasebenzi zihlwempuzekile, ukusebenza kakuhle kwemveliso kungaphantsi kwe-welding ngokuzenzekelayo okanye i-semi-automatic, kwaye ukuhluka komgangatho we-weld kukhulu, okuxhomekeke kwinqanaba elithile kumgangatho wezobugcisa we-welder.

Umgangatho we-weld we-welding ngokuzenzekelayo uzinzile, iziphene zangaphakathi ze-weld zincinci, iplastiki ilungile, kunye nokuqina kwempembelelo kulungile, okufanelekile ukuwelda i-welds emide ngqo. I-Semi-automatic welding ifanelekile kwi-welding curves okanye i-welds nayiphi na imilo ngenxa yokusebenza ngesandla. I-welding ye-automatic kunye ne-semi-automatic kufuneka isebenzise i-welding wire kunye ne-flux efanelekileyo kwintsimbi engundoqo, i-welding wire kufuneka ihlangabezane neemfuno zemigangatho yelizwe, kwaye i-flux kufuneka inqunywe ngokweemfuno zenkqubo ye-welding.

I-gas shielded welding isebenzisa igesi ye-inert (okanye i-CO2) igesi njengendlela yokukhusela ye-arc ukwahlula isinyithi esityhidiweyo emoyeni ukugcina inkqubo ye-welding izinzile. Ukufudumeza kwe-arc ye-gas shielded welding kugxininiswe, isantya se-welding sikhawuleza, kwaye ubunzulu bokungena bukhulu, ngoko ke amandla e-weld aphezulu kune-welding manual. Kwaye iplastiki elungileyo kunye nokumelana nomhlwa, kufanelekile ukuwelda kweepleyiti zentsimbi ezishinyeneyo.

(b), Imo yeWeld

Ifom yokudibanisa i-welding seam inokwahlulwa ibe ziifom ezine: i-butt joint, i-lap joint, i-T-shaped joint kunye ne-fillet joint ngokwendawo edibeneyo yamacandelo adibeneyo. Iintsimbi ezisetyenziselwa olu dibaniso zikwiindlela ezimbini ezisisiseko, i-butt welds kunye ne-fillet welds. Kwisicelo esithile, kufuneka kukhethwe ngokwamandla okudibanisa, kudibaniswa nokuvelisa, ukufakwa kunye neemeko ze-welding.

(c) Ulwakhiwo lweWeld

1. Buttweld

Iiwelds ze-Butt zihambisa amandla ngokuthe ngqo, ngokutyibilikayo, kwaye azinaxinzelelo lubalulekileyo, ngoko zisebenza kakuhle ngoomatshini kwaye zilungele udibaniso lwamalungu athwele imithwalo emileyo kunye neguqukayo. Nangona kunjalo, ngenxa yeemfuno ezikumgangatho ophezulu we-butt welds, i-gap ye-welding phakathi kwe-weldments ingqongqo, kwaye isetyenziswa ngokubanzi kuqhagamshelo olwenziwe kwifektri.

2. Fillet weld

Uhlobo lwe-welds ye-fillet: i-welds ye-fillet inokwahlulwa ibe yi-welds ye-fillet yecala ngokuhambelana ne-force acting direction kunye ne-front fillet welds perpendicular ku-force acting direction kunye ne-obliquely intersecting force acting direction ngokwe-direct direction yabo ubude kunye ne-direction of force force yangaphandle. . i-welds ye-slate fillet kunye ne-welds ezingqongileyo.

Ifom ye-cross-sectional ye-fillet weld ihlukaniswe ngohlobo oluqhelekileyo, uhlobo lwe-slope flat kunye nohlobo lokungena olunzulu. I-hf emfanekisweni ibizwa ngokuba yisayizi yefayili ye-weld ye-fillet. Umlinganiselo wecala lomlenze wecandelo eliqhelekileyo ngu-1: 1, efana nonxantathu ochanekileyo we-isosceles, kwaye umgca wokuhambisa amandla ugobe ngokugqithiseleyo, ngoko uxinzelelo lwexinzelelo lunzulu. Kwisakhiwo esithwele ngokuthe ngqo umthwalo oguqukayo, ukwenzela ukuba ukuhanjiswa kwamandla kube lula, i-fillet weld yangaphambili kufuneka yamkele uhlobo lwe-slope oluthe tye kunye nomlinganiselo wecala lemiphetho ye-fillet 1: 1.5 (icala elide kufuneka lilandele indlela amandla angaphakathi), kunye ne-fillet ye-weld yecala kufuneka ithathe umlinganiselo we-1. : 1 ukungena okunzulu.

8. UQhagamshelwano lweBolt

(ukuya). Ubume boQhagamshelwano lweBolt oluQhelekileyo

Ifomu kunye nokucaciswa kweebholiti eziqhelekileyo

Ifom eqhelekileyo esetyenziswe yisakhiwo sensimbi luhlobo lwentloko enkulu ye-hexagonal, kwaye ikhowudi yayo imelwe yileta uM kunye negama kunye nobubanzi (mm). I-M18, M20, M22, M24 isetyenziswa ngokuqhelekileyo kubunjineli. Ngokwemigangatho yamazwe ngamazwe, iibholithi zimelwe ngokufanayo ngamabakala abo okusebenza, afana “nebakala 4.6”, “ibakala 8.8” njalo njalo. Inani elingaphambi kwedesimali libonisa ubuncinci bokuqina bezinto zebholt, ezifana ne "4" ye400N/mm2 kunye ne "8" ye800N/mm2. Amanani emva kwedesimali (0.6, 0.8) abonisa umlinganiselo wesivuno sempahla ye-bolt, oko kukuthi, umlinganiselo wenqaku lesivuno ukuya kumandla amancinci amancinci.

Ngokomatshini wokuchaneka kweebholithi, iibholithi eziqhelekileyo zohlulwe zibe ngamanqanaba amathathu: A, B, kunye noC.

Iibholiti ze-A kunye ne-B-grade (iibholiti ezisulungekisiweyo) zenziwe ngentsimbi yomgangatho we-8.8, ezijikwa ngezixhobo zoomatshini, ezinemigangatho egudileyo kunye nemilinganiselo echanekileyo, kwaye zixhotyiswe ngemingxunya yeklasi I (oko kukuthi, imingxuma yebholithi igrunjwa okanye yandiswa amacandelo adibeneyo , udonga lomngxuma lugudile, kwaye umngxuma uchanekile). Ngenxa yokuchaneka kwayo okuphezulu komatshini, ukunxibelelana ngokusondeleyo nodonga lomngxuma, ukudityaniswa konxibelelwano oluncinci, kunye nokusebenza kakuhle koomatshini, ingasetyenziselwa ukudityaniswa nokucheba okukhulu kunye nemikhosi eqinile. Nangona kunjalo, kuninzi-umsebenzi onzima kwaye kubiza ukuvelisa kunye nokufaka, ngoko ke kusetyenziswa kancinci kwizakhiwo zentsimbi.

Iibholiti zeBakala C (iibholiti ezirhabaxa) zenziwe ngentsimbi ye-4.6 okanye ye-4.8, i-rough processing, kwaye ubungakanani abuchanekanga ngokwaneleyo. Kuphela uhlobo lwemingxuma ye-II efunekayo (oko kukuthi, imingxuma yebholithi ibethelwa kwindawo enye ngexesha elinye okanye ibhorwe ngaphandle kwe-drill. Ngokuqhelekileyo, ububanzi bomngxuma bukhulu kunobo bolt. I-diameter yentonga yi-1 ~ 2mm enkulu). Xa i-shear force ihanjiswa, i-deformation yoxhulumaniso inkulu, kodwa ukusebenza kokuhambisa amandla e-tensile kusalungile, umsebenzi awufuni izixhobo ezikhethekileyo, kwaye iindleko ziphantsi. Ngokuqhelekileyo isetyenziselwa udibaniso oluboshiweyo kuxinzelelo kunye noqhagamshelo lwesibini lokucheba kwizakhiwo ezilayishwe ngokwestatically okanye ngokungathanga ngqo.

ULungiselelo loQhagamshelwano oluQhelekileyo oluBolted

Ukulungelelaniswa kweebholiti kufuneka kube lula, okufanayo kunye nokudibanisa, ukuhlangabezana neemfuno zamandla, kwaye isakhiwo kufuneka sibe nengqiqo kwaye kulula ukuyifaka. Kukho iindidi ezimbini zolungiselelo: ecaleni-nge-cala kunye ne-staggered (njengoko kubonisiwe kumfanekiso). I-parallel ilula, kwaye i-staggered ihlangene ngakumbi.

(B). Iimpawu zoxinzelelo loQhagamshelwano oluQhelekileyo oluBoltiweyo

- Uqhagamshelo lwebholithi yokucheba

- Uqhagamshelwano lwebholithi yoxinzelelo

- Tsala-shear uqhagamshelwano lwebholithi

(C). Iimpawu zoxinzelelo lweeBolts zokuqina okuphezulu

Ukudityaniswa kwe-bolted bolted ephezulu kunokwahlulwa ibe luhlobo lwe-friction kunye nodidi loxinzelelo ngokoyilo kunye neemfuno zamandla. Xa uxhulumaniso lwe-friction luphantsi kokucheba, ukuchasana okuphezulu kwefriction kunokwenzeka phakathi kwamacwecwe xa i-shear force yangaphandle ifikelela kumda womda; xa i-slip isihlobo senzeke phakathi kwamacwecwe, kuthathwa ukuba uxhulumaniso aluphumelelanga kwaye lonakaliswe. Xa uqhagamshelo olunoxinzelelo luchetyiwe, amandla okukhuhlana avunyelwe ukuba woyiswe kwaye ukutyibilika okuzalana phakathi kwamacwecwe kwenzeka, kwaye ke amandla angaphandle angaqhubeka nokwanda, kunye nokusilela kokugqibela kokucheba isikrufu okanye umngxuma othwele uxinzelelo. yimeko yomda.

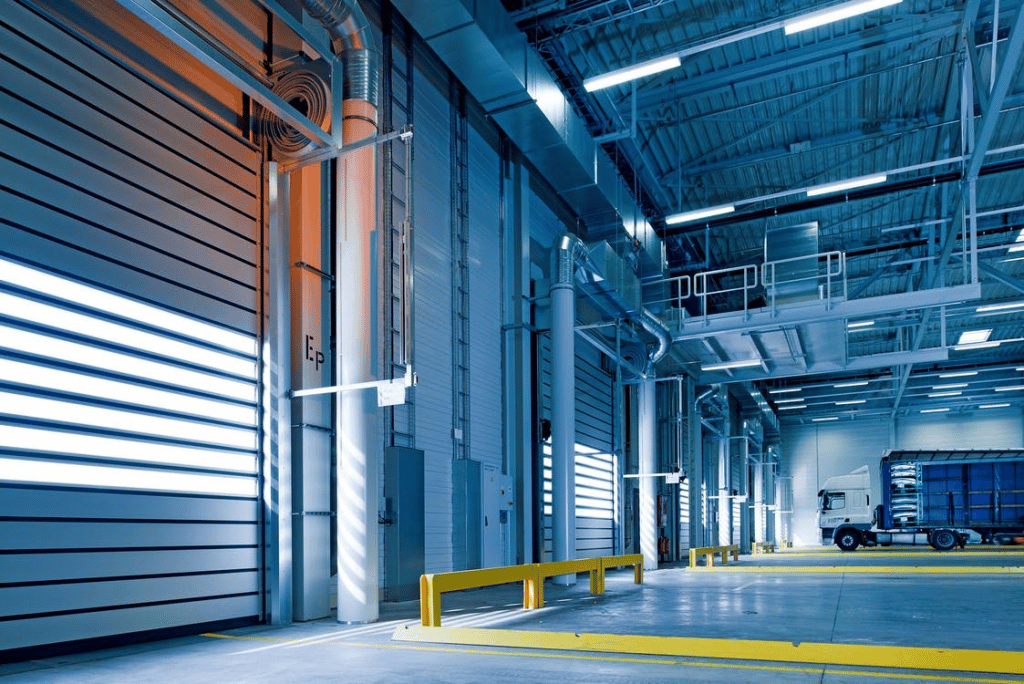

I-Henan Steel Structure Engineering Technology Co., Ltd. igxile ekwakhiweni kweeworkshops zesakhiwo sentsimbi, iindawo zokugcina iimpahla, iiworkshops kunye nezinye iiprojekthi, kwaye inokubonelela ngeekowuteshini, unikezelo, imizobo yokufakela kunye nezinye iinkonzo ngokwebhajethi. Ngemibuzo emininzi, nceda uqhagamshelane neqela lethu leengcali.

Ukufundwa okucetywayo

Qhagamshelana nathi >>

Unemibuzo okanye ufuna uncedo? Ngaphambi kokuba siqale, kufuneka wazi ukuba phantse zonke izakhiwo zentsimbi ze-prefab zenziwe ngokwezifiso.

Iqela lethu lobunjineli liya kuyilwa ngokwesantya somoya wasekhaya, umthwalo wemvula, length*width*ubude, kunye nezinye iinketho ezongezelelweyo. Okanye, sinokulandela imizobo yakho. Nceda undixelele imfuno yakho, kwaye siya kwenza okuseleyo!

Sebenzisa ifom ukufikelela kwaye siya kuqhagamshelana nawe ngokukhawuleza.

Malunga noMbhali: K-HOME

K-home Steel Structure Co., Ltd ithatha indawo ye-120,000 square metres. Sibandakanyeka kuyilo, uhlahlo lwabiwo-mali lweprojekthi, ulwakhiwo, kunye ukufakwa kwezakhiwo zentsimbi ye-PEB kunye neepaneli zesandwich ezineziqinisekiso zekontraka zebakala lesibini jikelele. Iimveliso zethu zigubungela izakhiwo zentsimbi ezikhanyayo, Izakhiwo zePEB, izindlu ze-prefab zamaxabiso aphantsi, izindlu zeekhonteyina, intsimbi ye-C / Z, iimodeli ezahlukeneyo zepleyiti yensimbi yombala, i-PU sandwich panels, iipaneli ze-eps sandwich, iipaneli ze-sandwich zoboya, iipaneli zegumbi elibandayo, iipleyiti zokucoca, kunye nezinye izinto zokwakha.