Ungakweqi Ulwazi Oludumile Mayelana Nezakhiwo Zezimboni Ze-Portal Steel Frame

Ngokuvamile, i-portal steel frame industrial building iyinhlangano isakhiwo sezimboni ngesakhiwo sensimbi njengohlelo lwayo oluyinhloko lokuthwala umthwalo. Idizayini yayo eyinhloko isekusebenziseni uhlaka lwensimbi yephothali njengesisekelo esithwala umthwalo oyinhloko—emise okweminyango yansuku zonke, ilula kodwa izinzile ngokwanele ukuthwala isisindo sesakhiwo esiyinhloko. Futhi kuwuhlobo oluvamile lwe-lightweight, olunezingxenye eziyinhloko ezithwala umthwalo ohlanganisa imishayo yensimbi namakholomu ensimbi, ethula isakhiwo esiphelele esimise “somnyango” esifanekisela izakhiwo zezimboni zohlaka lwensimbi yephothali.

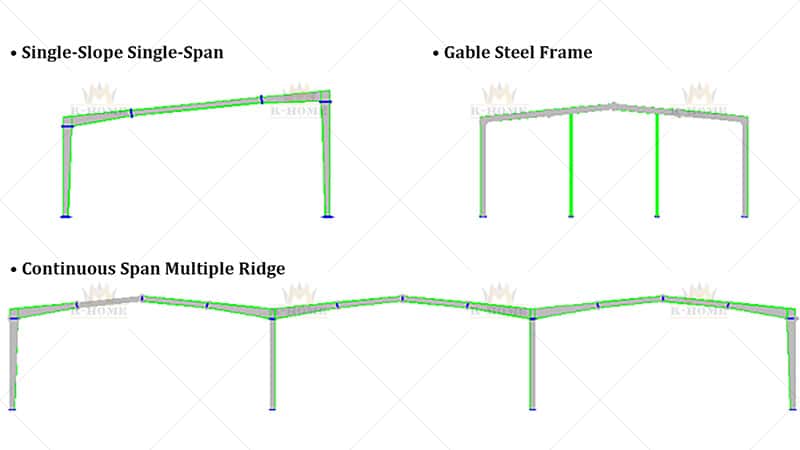

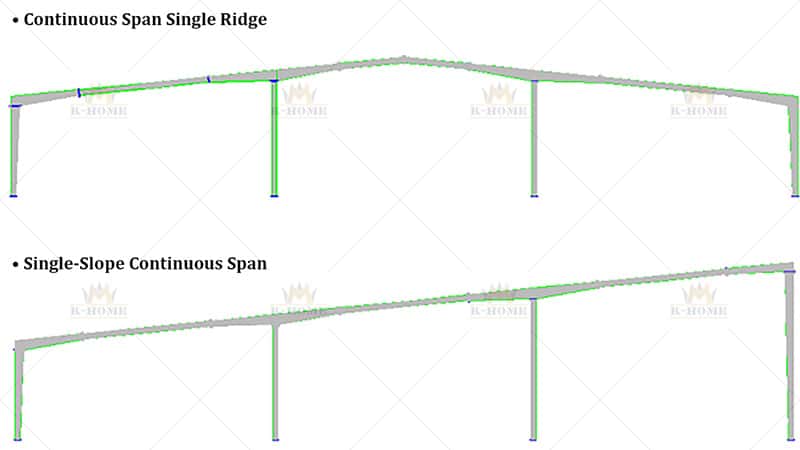

Ifomu lesakhiwo sezakhiwo zezimboni zohlaka lwensimbi ye-portal lingalungiswa ngokuguquguqukayo ukuze libe nezidingo zangempela. Ngokuqondile, izakhiwo zezimboni ze-portal steel lightweight zilungele izakhiwo zeshabhu lensimbingaphandle kwama-cranes okukhiqiza, kuyilapho ezisindayo ziyimfuneko kulabo abadinga ama-cranes ukuthutha izinto ezisindayo/impahla. Ngokuya ngesakhiwo, banikela nge-single-span, i-double-span, kanye nezinketho ze-multi-span, futhi zingahlonyiswa ngama-eaves overhangs, izijobelelo, noma zithuthukiselweizakhiwo zensimbi ezinezitezi eziningingokwezidingo zephrojekthi. Ukulungiswa komuntu siqu (isb., ama-eaves angavumeli imvula, izithasiselo ezincane ezisizayo) nazo zingalungiselelwa zona.

Lezi zinzuzo zenza uhlaka lwensimbi ye-portal izakhiwo zezimboni zifaneleke kahle izidingo zemboni yezokwakha. Ngaphandle kwamakholomu asekelayo amaningi, agwema ukuphazamiseka lapho ebeka okokusebenza kwasembonini, egcina izimpahla, noma ehambisa imisebenzi yabasebenzi. Ngaphezu kwalokho, izingxenye zabo ezibalulekile zingenziwa ngaphambili ezimbonini futhi zihlanganiswe esizeni—lokhu akufinyezi nje kuphela umjikelezo wokwakhiwa kwezakhiwo zezimboni zohlaka lwensimbi yephothali kodwa futhi kuqinisekisa ikhwalithi engaguquki. Futhi banomoya onamandla, iqhwa, nokumelana nokuzamazama komhlaba, okuqinisekisa ukuzinza kwesikhathi eside.

Namuhla, izakhiwo zezimboni zohlaka lwensimbi ye-portal akuzona nje kuphela ukukhetha kokuqala kwezindawo zokusebenzela zasefekthri nezindawo ezinkulu zokugcina kodwa futhi zithembekile ezindaweni zokuhweba kanye nezindawo zamasiko nezokuzijabulisa. Eqinisweni, wonke amaphrojekthi adinga indawo yangaphakathi evulekile abeka kuqala izakhiwo zezimboni zohlaka lwensimbi yengosi, njengoba zilinganisela ukusebenza, ukusebenza kahle, nokuqina—izizathu ezibalulekile zokuduma kwazo ekwakhiweni kwesimanjemanje.

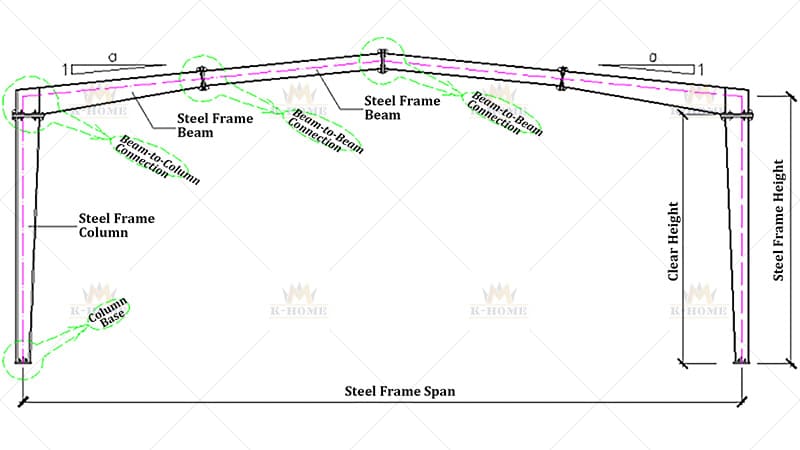

Qonda Kalula Izingxenye Nemininingwane Yesakhiwo Yezakhiwo Zezimboni Zohlaka Lwensimbi Yephothali

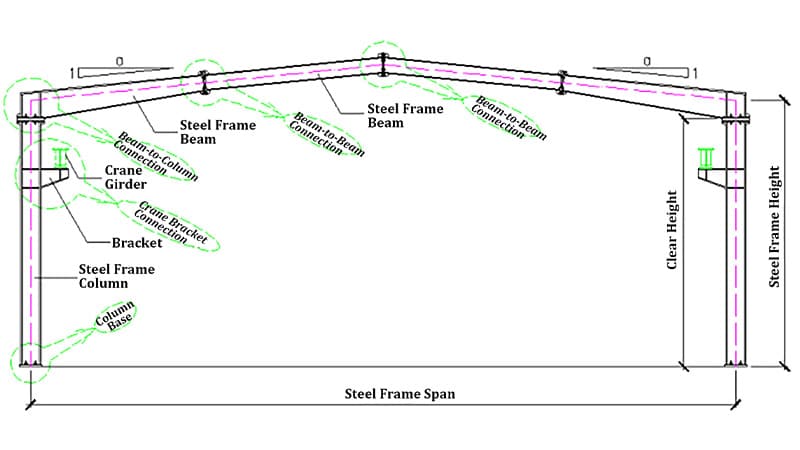

Ezingxenyeni eziyinhloko zesakhiwo sezakhiwo zezimboni zohlaka lwensimbi yephothali, amakholomu nemishayo yophahla ingaklanywa njengamalungu ewebhu eqinile amise okuka-H noma ama-lattice. Ukuze kuncishiswe ukusetshenziswa kwensimbi, lawa malungu angase futhi asebenzise isigaba esiguquguqukayo esisekelwe ekusabalaleni komdwebo wesikhathi sokugoba. Nakuba amalungu e-solid-web esebenzisa insimbi ethe xaxa, kulula ukuwenza futhi asetshenziswe kabanzi kumaphrojekthi asebenzayo wezakhiwo zemboni yohlaka lwensimbi yephothali.

Ngokwesakhiwo sesibili sezakhiwo zezimboni zohlaka lwensimbi ye-portal, insimbi enezindonga ezincane ezakhiwe ngokubanda ikhethwa kuma-purlins ophahleni kanye namagithi odonga; uma isikhala sekholomu yesitshalo sidlula u-12m, ama-purlins ohlobo lwe-truss ayonga kakhulu. Njengamalungu aguquguqukayo, isakhiwo sesibili sixhuma kuhlaka oluqinile oluyinhloko ngamabholithi—sithwala imithwalo esuka ohlelweni oluvalekile, siyidlulisele esakhiweni esiyinhloko, futhi sinikeze ukusekelwa okuseceleni ukuze kuthuthukiswe ukuzinza okuphelele kwesakhiwo esikhulu kumabhilidi emboni wohlaka lwensimbi.

Umnyombo wesistimu yokuvalelwa yezakhiwo zezimboni zohlaka lwensimbi ye-portal amaphaneli ahlanganisiwe, ngokuvamile enziwe ngamashidi ensimbi amancane akhiwe ngama-roll noma ezinye izinto eziyinhlanganisela engasindi. Lawa maphaneli axhunywe esakhiweni sesibili ngokusebenzisa izindlela ezithile zokuthwala imithwalo yangaphandle efana nomoya, iqhwa, nemithwalo yokwakha. Kuyaphawuleka ukuthi amaphaneli okuvala awasekelwa nje kuphela isakhiwo sesibili kodwa futhi anganikeza ukusekelwa kwe-lateral kwesakhiwo sesibili, okuthuthukisa ukuzinza kwesakhiwo sesibili ngezinga elithile.

Ngaphezu kwalokho, ngemva kokuba amaphaneli okuvala exhunywe esakhiweni sesibili, akha ukuqina okuqinile kwe-shear endizeni yawo—into eyaziwa ngokuvamile ngokuthi “umphumela we-diaphragm.” Lo mphumela uvumela izakhiwo zemboni yozimele wensimbi yephothali elayishwe indiza ukuthi zibe nokusebenza kwesakhiwo esithile.

Ukwengeza, izisekelo zophahla kanye nezinsimbi ze-inter-ikholomu zezakhiwo zezimboni zohlaka lwensimbi yephothali ngokuvamile ziklanywa njengamalungu e-tension, okuqinile okuhlanganisa insimbi eyindilinga okuyiyona ndlela ekhethwayo. Uma isakhiwo sihlanganisa ama-cranes anamandla angaphezu kwamathani angu-5, i-inter-colum bracings kufanele ishintshwe ngensimbi ye-engeli noma ezinye izinsimbi zensimbi zesigaba. Okwamakholomu aphakathi kwekholomu esakhiweni se-mezzanine ingxenye yezakhiwo zezimboni zozimele wensimbi yephothali, insimbi ye-engeli noma ezinye izinsimbi zensimbi zesigaba nazo kufanele zikhethwe.

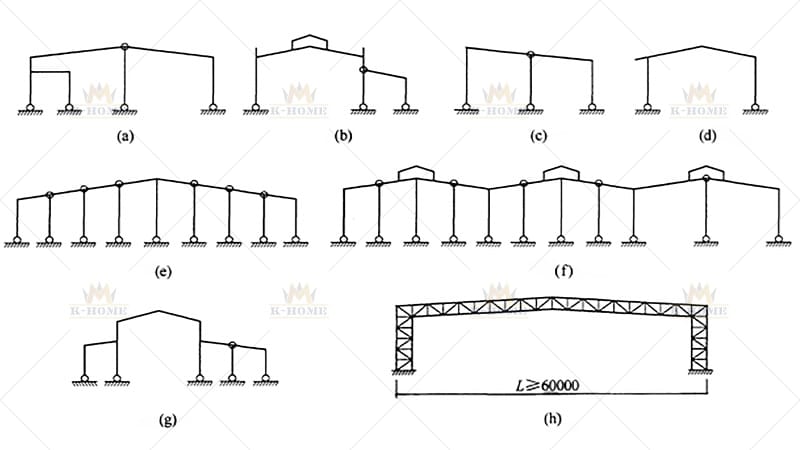

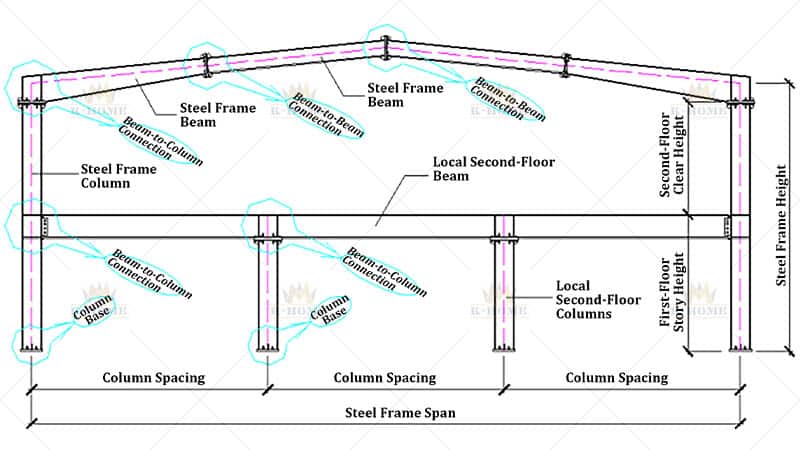

Ngokuvumelana nezidingo zangempela zezakhiwo, izakhi zohlaka lwensimbi yephothali ezinosayizi abahlukahlukene zingahlelwa futhi zihlanganiswe ukuze zakhe izinhlobo ezihlukahlukene zesakhiwo, ezihlangabezana nezidingo zokusetshenziswa kwezakhiwo ezihlukahlukene ezinesitezi esisodwa. Amafomu avamile ahlanganisa lawo anama-mezzanine ingxenye, anama-ventilators noma amapharaphethi, anama-lean-tos, kanye nama-eaves overhangs. Angase futhi aklanywe njenge-single-slope, i-multi-span ene-ridge eyodwa nemithambeka ephindwe kabili, i-multi-span enama-ridge amaningi kanye nemithambeka eminingi, kanye nezikhala eziphakeme neziphansi ezihlangene. Ngaphezu kwalokho, amafreyimu ensimbi yohlobo lohlaka lwensimbi nawo asetshenziswa kwezinye izimo.

▪ Amafomu Ayisisekelo we Izakhiwo ze-Portal Steel FrameA

▪ Amajoyinti Endaba Yesibili Yasendaweni Abheke Kuzinhlelo Zozimele Zezindaba Eziningi

Ezinhlotsheni eziphuma kokunye zesakhiwo samafreyimu ensimbi ye-portal, okokusebenza kwe-crane kungabuye kuhlelwe ngendlela eguquguqukayo ngokuya ngezidingo zangempela, futhi izikhala eziyingxenye yesitezi sesibili zingangezwa ngesikhathi esifanayo.

Empeleni, ozimele bephothali ye-gable nabo bayingxenye yesigaba samafreyimu ephothali ane-span eminingi; umehluko omkhulu ulele kumakholomu awo amaphakathi, umumo wesigaba wawo uzungeziswa ngama-degree angu-90 uma kuqhathaniswa namakholomu ozimele wephothali avamile.

Ukukhethwa Kwensimbi Kwezakhiwo Zezimboni Zohlaka Lwensimbi Yephothali Ngokusekelwe Kumazinga Namabanga Avamile

Ukukhethwa kwensimbi yezakhiwo zezimboni zohlaka lwephothali kuzosuselwa kumazinga kazwelonke aseShayina Ikhodi Yokuklanywa Kwezakhiwo Zensimbi (GB 50017) kanye Ukucaciswa Kobuchwepheshe Kwezakhiwo Zensimbi Yezakhiwo Zozimele Zephothali Yesisindo Sokukhanya (GB 51022). Amamaki ensimbi asetshenziswa kakhulu kanye nezimo zokusetshenziswa kwawo ami kanje:

Insimbi ye-Q235, njengenketho evame ukusetshenziswa kakhulu neyongayo, inamandla okukhiqiza angu-235N/mm² futhi inamandla amahle, i-ductility, nokushisela. Ihlangabezana nezidingo zezakhiwo eziningi ze-portal frame ngaphandle kwama-cranes noma ama-cranes amancane-tonnage; akuyona nje into ekhethwayo yamafreyimu amakhulu (imishayo, amakholomu) kodwa futhi insimbi evame ukusetshenziselwa izakhiwo zesibili (ama-purlins, amabhande odonga);

Insimbi ye-Q355 (eyake yaqokwa njenge-Q345) ifanele izingxenye ezibaluleke kakhulu, ezinamandla okukhiqiza angu-355N/mm². Amandla ayo acishe abe ngama-36% aphezulu kunalawo ensimbi ye-Q235. Uma isakhiwo sine-span enkulu, umthwalo osindayo (njengama-cranes amakhulu-tonnage), noma isikhala esikhulu sekholomu, ukusetshenziswa kwensimbi ye-Q355 kunganciphisa ngokuphumelelayo usayizi wezingxenye eziphambanayo futhi kulondoloze ukusetshenziswa kwensimbi. Nakuba iyunithi yentengo yayo iphakeme kancane, inikeza umnotho ongcono kakhulu, futhi ivamise ukusetshenziselwa amafreyimu amakhulu (imishayo, amakholomu) angaphansi kwemithwalo emikhulu.

Izinsimbi ezinamandla aphakeme njenge-Q390, i-Q420, ne-Q460 azivamile ukusetshenziswa kumafreyimu ephothali futhi zibhekwa kuphela kumaphrojekthi amakhulu kakhulu anamakhreni ayisipesheli esindayo noma izimo zomthwalo owedlulele. Sekukonke, i-Q235B noma i-Q355B ivame ukusetshenziselwa amafreyimu ayinhloko (imishayo, amakholomu), kuyilapho i-Q235 insimbi ivame ukwamukelwa ezakhiweni zesibili (ama-purlins, amabhande odonga).

Izimiso Zesakhiwo Esisebenzayo Sezakhiwo Zezimboni Zohlaka Lwensimbi Yephothali

Isakhiwo se-Portal Steel Frame Industrial Buildings silandela i-logical yokuhlela ehlelekile, egxile kumafreyimu aqinile asemaceleni, ama-longitudinal bracing, amasistimu e-enclosure, nezakhiwo zesibili. Imininingwane imi kanje:

- I-Lateral Rigid Frame Isakhiwo (Isistimu Eyinhloko Yokumelana Ne-Lateral Force): "Njengohlaka" lwezakhiwo zemboni yozimele wensimbi yephothali, amafreyimu aqinile asemaceleni athwala yonke imithwalo eqondile kanye nemithwalo esemaceleni. Ezibayeni, kufanele zinqunywe ngokusekelwe ezidingweni zenqubo ezifana nobubanzi bomugqa wokukhiqiza, ukwakheka kwezinto zokusebenza, namaphaseji okusebenza. Isikhathi esivamile somnotho sisukela ku-18m kuya ku-36m; ama-span amakhulu (isb., ngaphezu kwama-45m) ayenzeka ngokobuchwepheshe kodwa adinga ukuqhathanisa ngokomnotho—ngezinye izikhathi ukusebenzisa ama-trusses noma abakaki konga kakhulu. Amafreyimu aqinile angemuva angahlelwa njenge-span eyodwa, i-span kabili, noma i-multi-span. Ezakhiweni ezinama-span amaningi, amakholomu amaphakathi ngokuvamile athatha uhlobo lwamakholomu anamaphinikhodi, ahlanganiswe nemishayo ukuze enze ukwakhiwa kube lula nokulondoloza izinto zokwakha. Isikhala sekholomu (okungukuthi, ibanga eliphakathi kwamafreyimu aqinile) kuyisici esibalulekile esithinta ukusetshenziswa kwensimbi nomnotho; isikhala esivamile sekholomu yezomnotho singu-6m kuya ku-9m, futhi 7.5m noma 8m sisetshenziswa kakhulu ezimweni ezingenawo ama-cranes noma ama-cranes amathoni amancane. Ukwenyuka kwezikhala zamakholomu (isb., kuye ku-12m) kuzokwandisa kakhulu ukusetshenziswa kwensimbi emishayweni yohlaka oluqinile kanye nemishayo ye-crane, kodwa kunciphisa inani lamafreyimu aqinile nezisekelo—kudingeka uhwebo oluphelele, futhi ukusetshenziswa kwensimbi kuma-purlins namahithi odongeni nakho kuzokhuphuka ngokufanele. Ukuphakama kwe-Eave kunqunywa ngokuvunyelwa kwesevisi, ukuphakama kwesitimela se-crane, nokuphakama kwesakhiwo sophahla; i-roof slope ngokuvamile i-5% kuya ku-10% (cishe i-1/20 kuya ku-1/10) -i-slope encane kakhulu ayihambisani nokukhipha amanzi, kuyilapho i-slope enkulu kakhulu yandisa umthamo wokwakha kanye nokusetshenziswa kwensimbi.

- Isakhiwo Sohlelo Lokubhula Longitudinal (Ukuqinisekisa Ukuzinza Kukonke): Isistimu ye-longitudinal bracing isebenza “njengemigqa” yezakhiwo zezimboni zohlaka lwensimbi yephothali, exhumanisa amafreyimu aqinile asemaceleni endaweni yonke ezinzile ukuze amelane nemithwalo yobude bobude (njengemithwalo yomoya emide, amandla okuzamazama komhlaba, namandla amabhuleki e-longitudinal crane) nokuqinisekisa ukuzinza ngesikhathi sokufakwa. Ngokuphathelene nezikhundla zesakhiwo, ukubopha okuvundlile ophahleni kuvame ukuhlelwa ezindaweni zokugcina (zokuqala noma zesibili) kanye namatheku aphakathi kwezigaba zokushisa ngezikhathi ezithile (isb, ≤60m); kuma-workshops amade, amajoyinti okwandisa izinga lokushisa kufanele asethwe, kufakwe i-bracing ezinhlangothini zombili zamalunga. I-inter-colum bracing kufanele ihlelwe ezindaweni ezifanayo njenge-roof horizontal bracing ukuze kwakheke uhlelo oluqinile lwe-lateral force-resisting truss, ukudlulisa imithwalo esisekelweni. Kumafomu esakhiwo, insimbi eyindilinga eyindilinga (eqiniswe ngama-turnbuckles) noma amafomu ensimbi e-engeli avame ukusetshenziswa—insimbi eyisiyingi eyindilinga ilula futhi iyonga, ithwala ukungezwani kuphela (eklanywe njengamalungu e-tension), okwenza kube indlela evamile kakhulu. Lapho i-cross bracing ingakwazi ukufakwa ezindaweni ezinezicabha ezinkulu ezivulekayo noma amaphaseji, i-portal bracing ingasetshenziswa esikhundleni salokho. Imisebenzi yayo eyinhloko ihlanganisa ukuhlinzeka ngamaphuzu okusekela angaphandle kwendiza amakholomu ozimele aqinile ukuze kuncishiswe ubude bawo obusebenzayo, ukudlulisa nokumelana namandla avundlile amade, nokuqinisekisa ukuzinza okuphelele kwesakhiwo ngesikhathi sokufakwa.

- Isistimu Yokuvala kanye Nesakhiwo Sesibili Sesakhiwo: Ukuhlukaniswa kwesakhiwo se-purlins nezinsimbi zodonga ezakhiweni zohlaka lwensimbi yephothali kunqunywa ngokuyinhloko amandla nokuqina kwamaphaneli ophahla namaphaneli odonga, nesikhala esivamile esingu-1.5m. Ukuze kuncishiswe ubude obusebenzayo obungaphandle kwendiza be-purlins namagithi odongeni futhi kuthuthukiswe umthamo wokuthwala umthwalo, i-tie rod kanye nesistimu ye-strut (ngokuvamile eyenziwe ngensimbi eyindilinga) kufanele ifakwe ukuze yakhe uhlelo oluqinile lokuthwala amandla. Amakholomu omoya ahlelwe kuma-gables ukuze athwale imithwalo yomoya edluliswa ngamapaneli odonga lwe-gable; amaphethelo awo aphezulu ancike emishayweni yozimele eqinile ngamapuleti okugcina, okuvumela ukudluliswa kwakho kokubili amandla avundlile naqondile.

- Inqubo Yesakhiwo Esifingqiwe: Inqubo yesakhiwo esiyinhloko sezakhiwo zohlaka lwensimbi yephothali ilandela umqondo wokuthi “okugxile kokufunwayo → ukuhlela kokuqala → isakhiwo esihlelekile → ukubala nokwenza kahle”. Okokuqala, thola ubude be-span, ubude, i-crane tonnage, kanye nezindawo zomnyango ngokusekelwe ezidingweni zenqubo; bese uqale uqinisekise isikhala sekholomu esinengqondo ngokwezomnotho (isb., 7.5m) kanye nomthambeka wophahla (isb, 1/10); ngokulandelayo, hlela amafreyimu aqinile asemaceleni ukuze akhe isistimu yokuthwala umthwalo oyinhloko; bese ufaka i-longitudinal bracing, ukusetha i-roof bracing kanye ne-inter-colum bracing ezindaweni zokugcina kanye nendawo ephakathi kwezigaba zokushisa ukuze kwakhiwe isakhiwo sendawo esizinzile; ngokulandelayo, ukuhlela ngokunengqondo izakhiwo zesibili ezifana nama-purlins, amabhande odonga, kanye nezinhlelo zawo zothayi; ekugcineni, setha uhlelo lwe-gable futhi uhlele amakholomu omoya. Ekugcineni, zonke izakhiwo kufanele zimodelwe, zibalwe, futhi zithuthukiswe kusetshenziswa isofthiwe yokubala yesakhiwo (njenge-PKPM, YJK) ukuze kuqinisekiswe ukuthi zonke izimiso zesakhiwo ziyahlangatshezwa.

Amaphuzu Okudizayina Ezakhiwo Zezimboni Zohlaka Lwensimbi Yephothali: Ukumelana Nesimo Somhlaba kanye Nokuvikela Umlilo

Lapho uklama izakhiwo zezimboni ze-portal steel frame ukumelana nokuzamazama komhlaba, into yokuqala okufanele ugxile kuyo ukucabangela kokuhleleka okuphelele: ubukhulu nokuqina kwesakhiwo se-workshop kumele kusatshalaliswe ngokulinganayo. Lokhu kuqinisekisa ukuthi indawo yokusebenzela isebenza ngendlela efanayo futhi ishintsha ngendlela ehlelekile ngaphansi kwesenzo sokuzamazama komhlaba, kuncishiswe ubungozi bokugcwala ngokweqile kwendawo kanye nokulimala kwesakhiwo okulandelayo okubangelwa ukuqina okungalingani. Ngomklamo wesakhiwo esiphambene, amafreyimu aqinile afaneleka kakhulu, noma amafreyimu lapho i-truss yophahla namakholomu akha izinga elithile lokuqiniswa—lo mklamo uvumela ngokugcwele ukusebenza okuthwala umthwalo wesakhiwo sensimbi, wehlisa ukuwohloka kwesakhiwo esiphambanayo, futhi uthuthukise nakakhulu umthamo wokuzamazama komhlaba.

Kubaluleke kakhulu ukuqaphela ukuthi umonakalo omkhulu kuma-workshops embonini ye-portal steel frame ubangelwa ukungazinzi kwamalungu kunokuba amandla amalungu anganele. Ngakho-ke, ukuhlelwa okunengqondo kwesistimu yokuhlanganisa ibalulekile: ukubekwa kwesayensi kwezingxenye ezifana nokubrashi phakathi kwamakholomu kanye nokuhlanganisa i-roof truss evundlile kungaqinisekisa ngempumelelo ukusimama okuphelele kwesakhiwo seshabhu futhi kuvimbele ukungazinzi kwelungu ngaphansi kwesenzo sokuzamazama komhlaba. Ukwengeza, ukuklanywa kwama-node okuxhuma kwesakhiwo kufanele kulawulwe ngokuqinile-kubalulekile ukuqinisekisa ukuthi ama-node awahluleki ngaphambi kwesigaba esigcwele samalungu esakhiwo, okuvumela amalungu ukuthi angene esimweni sokusebenza sepulasitiki futhi amunce ngokugcwele amandla okuzamazama komhlaba, ngaleyo ndlela akhulise ukumelana nokuzamazama kwesakhiwo.

Izinzuzo Eziyinhloko Zezakhiwo Zezimboni Ze-Portal Steel Frame: Ukusebenza kahle, Isisindo Sokuzimela kanye Nokuzivumelanisa Nesikhala

Ukuduma kwezakhiwo zezimboni zohlaka lwensimbi yephothali emkhakheni wezimboni kusuka ezinhlelweni zazo ezingokoqobo ezicini eziningi. Ukuqala ngokusebenza kahle kokwakhiwa, izingxenye zesakhiwo sensimbi zalezi zakhiwo zingakhiqizwa ngobuningi emafektri, kuqedwe isidingo somsebenzi oyinkimbinkimbi wokuthulula esizeni; uma sesithuthelwe endaweni yokwakha, isakhiwo singaqedwa ngokuhlanganisa izingxenye. Yonke le nqubo ilula futhi iyasebenza, ifinyeza kakhulu umjikelezo wokwakha wephrojekthi futhi isize amabhizinisi aqale ukukhiqiza ngokushesha.

Mayelana nokwakha isisindo somzimba, inzuzo yezakhiwo zezimboni zensimbi ye-portal iphawuleka nakakhulu: inganciphisa isisindo sesakhiwo sesakhiwo cishe ngama-30%. Lesi sici sibaluleke kakhulu ezimweni ezimbili—eyodwa yizindawo ezinomthamo ophansi wokuthwala isisekelo, lapho isisindo somuntu esilula sinciphisa ukucindezela esisekelweni futhi sehlise izindleko zokuqiniswa kwesisekelo; enye indawo enezinga eliphezulu lokuqina kokuzamazama komhlaba, lapho isakhiwo esilula sinciphisa amandla angenakunyakaziswa ngaphansi kwesenzo sokuzamazama komhlaba, okuholela emnothweni obanzi ongcono kakhulu uma kuqhathaniswa nezinhlelo zesakhiwo zikakhonkolo eziqinisiwe zendabuko.

Uma kukhulunywa ngokusetshenziswa kwendawo kanye nokuvumelana nezimo, izakhiwo zezimboni zohlaka lwensimbi ye-portal nazo zisebenza kahle. Ubude bawo bomnotho ngokuvamile busukela kumamitha angama-24 kuye kwangama-30, buhlinzeka ngendawo eyanele yokusebenza futhi kuhlangatshezwane nezidingo zendawo enkulu yemisebenzi yezimboni ehlukahlukene njengokucubungula imishini nokugcinwa kwezinto; ngesikhathi esifanayo, umklamo wesakhiwo unikeza ukuguquguquka okuphezulu. Amabhizinisi angalungisa isakhiwo sibe yizitezi eziningi noma izilungiselelo ze-span eziningi ngokusekelwe ezidingweni zabo zangempela zokukhiqiza, futhi afake ngisho nezinto zokusebenza ezikhethekile zezimboni ezifana nama-cranes, azivumelanisa ngokugcwele nezimo zokukhiqiza zezimboni ezahlukene.

Idizayini Yokuvikela Umlilo: Bhekana Nokushoda Kokumelana Nokushisa Kwensimbi futhi Ugweme Ingozi Yokugoqa

Izakhiwo zezimboni zohlaka lwensimbi ye-portal zinobuthakathaka obuphawulekayo: ukumelana nomlilo ompofu wezakhiwo zabo zensimbi. Uma izinga lokushisa lensimbi selingaphezu kuka-100 ℃, ukusebenza kwayo kuyashintsha kancane kancane njengoba izinga lokushisa likhuphuka: amandla aqinile ehla ngokuqhubekayo, kuyilapho ipulasitiki ikhula; lapho izinga lokushisa lifinyelela ku-500℃, amandla ensimbi ehla aze afike ezingeni eliphansi kakhulu, angakwazi ukusekela isisindo sesakhiwo, okungase ekugcineni kuholele ekuweni kwesakhiwo sensimbi.

Ngakho-ke, amakhodi okuklama asho ngokucacile ukuthi uma izinga lokushisa elingaphezulu lesakhiwo sensimbi lingase libe endaweni engaphezu kuka-150 ℃, kufanele kuthathwe izinyathelo zokuvikela ukushisa nokuvikela umlilo. Njengamanje, isixazululo esivame ukusetshenziswa kakhulu embonini siwukusebenzisa izigqoko ezingashisi ebusweni besakhiwo sensimbi-lezi zimbozo zakha ungqimba olushisayo olushisayo ezindaweni ezishisa kakhulu, zinciphisa izinga lokushisa kwensimbi, ukuthenga isikhathi sokuhlenga umlilo, nokuvikela ukusebenza kwensimbi ekuwohlokeni okusheshayo, ukugwema ngokuphumelelayo ingozi yokuwa kwesakhiwo.

Mayelana Nombhali: K-HOME

K-home Inkampani Steel Structure Co., Ltd ihlanganisa indawo 120,000 square metres. Sisebenza ekwakhiweni, isabelomali sephrojekthi, ukwenziwa, kanye ukufakwa kwezakhiwo zensimbi ze-PEB kanye namaphaneli amasemishi aneziqu zenkontileka ezijwayelekile zebanga lesibili. Imikhiqizo yethu imboza izakhiwo zensimbi ezilula, Izakhiwo ze-PEB, izindlu ze-prefab ezibiza kancane, izindlu zezitsha, insimbi ye-C/Z, amamodeli ahlukahlukene epuleti lensimbi enombala, amaphaneli esemishi le-PU, amaphaneli esisemishi se-eps, amaphaneli amasemishi e-rock wool, amaphaneli egumbi elibandayo, amapuleti okuhlanza, nezinye izinto zokwakha.