Welding ndiye njira yofunika kwambiri yolumikizirana zitsulo pakadali pano. Zili ndi ubwino wosafowoketsa zigawo zamagulu, kukhazikika bwino, kapangidwe kosavuta, kumanga kosavuta ndi ntchito yokha.

Ntchito yolumikizirana ndikuphatikiza mbale zachitsulo kapena zitsulo zowoneka bwino kukhala mamembala mwanjira inayake kapena kuphatikiza zigawo zingapo kukhala gawo lonse, kuti zitsimikizire kuti zimagwira ntchito limodzi.

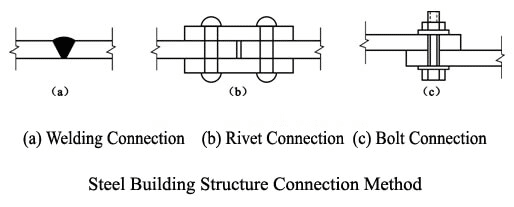

Njira zolumikizirana ndi zitsulo: Kutulutsa, rivet ndi kugwirizana kwa bolting.

Chitsulo Building Structure kulumikizana-Kuwotcherera

kugwirizana welded ndi kutentha kwaiye ndi arc kupanga elekitirodi ndi kuwotcherera mbali m`deralo kusungunuka, pambuyo condensation kuwotcherera, kuti kulumikiza mbali kuwotcherera mu umodzi.

Ubwino ndi kuipa kwa kugwirizana welded

ubwino:

- Sichifooketsa gawo chigawo, kupulumutsa chitsulo;

- Akhoza welded mu mawonekedwe aliwonse a zigawo zikuluzikulu, kuwotcherera akhoza mwachindunji welded, ambiri safuna zolumikizira ena, zigawo zosavuta, kupanga ntchito yopulumutsa;

- Kulimba kwa kugwirizana kuli bwino ndipo kuuma ndi kwakukulu;

- Zosavuta kugwiritsa ntchito zokha, zopanga zambiri.

kuipa:

- Zomwe zili m'dera lokhudzidwa ndi kutentha pafupi ndi weld zimakhala zowonongeka;

- Kuwotcherera kupsinjika kotsalira ndi kusinthika kumapangidwa m'zigawo zowotcherera, zomwe zimakhala ndi zotsatira zoyipa pamapangidwewo.

- Zomangamanga zimakhudzidwa kwambiri ndi ming'alu. Pamene mng'alu wa m'deralo uchitika, ukhoza kufalikira mofulumira ku gawo lonse, makamaka pa kutentha kochepa, kuphulika kwa brittle kumakhala kosavuta kuchitika.

Kuwerenga Kwambiri: Structural Steel Welding & Wophatikizana Wophatikizana Wophatikiza mu Chitsulo chachitsulo

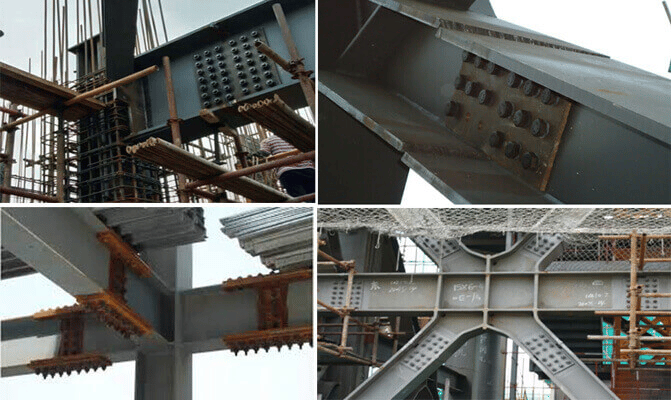

Kulumikizana kwa Steel Building Structure-Bolting

Kulumikizana kwa bolting kuli ndi mwayi woyika bwino, makamaka yoyenera kuyika ndi kulumikiza malo, komanso yosavuta kusokoneza, yoyenera kufunikira kusonkhanitsa ndi kusokoneza dongosolo ndi kugwirizana kwakanthawi. Kuipa kwake ndikofunika kukoka pa dzenje ndikuunjikira dzenje lopusa, ndikuwonjezera ntchito yopangira; Bowo la bawuti limafooketsanso gawo la membala, ndipo mbale yolumikizira iyenera kulumikizidwa wina ndi mnzake kapena kuwonjezera mbale yolumikizira kapena chitsulo cha Angle ndi zolumikizira zina, chifukwa chake zimawononga chitsulo chochulukirapo kuposa kugwirizana kwa kuwotcherera.

Gwirizanani ndi mabawuti wamba

Malingana ndi zofunikira za khalidwe la khoma la dzenje, mabowo amagawidwa m'magulu awiri: mabowo a kalasi I (A, B) ndi mabowo a kalasi II (C).

Kulumikizana kokhala ndi bawuti kwa bowo la mtundu wa I kumakhala ndi kukameta ubweya wambiri komanso mphamvu yoberekera kuposa ya mtundu wa Type II, koma kupanga bowo la Type I ndizovuta komanso zodula.

Mabowo a Class A ndi B ali ndi zofunika kwambiri popanga mabowo, koma ndizovuta kukhazikitsa komanso kutsika mtengo, kotero sagwiritsidwa ntchito kawirikawiri. Mabowo a Class C ndi ovuta komanso osalondola, koma osavuta kukhazikitsa. Amagwiritsidwa ntchito kwambiri muzitsulo zazitsulo.

Maboti amphamvu kwambiri

Kachitidwe ka kukameta ubweya wa bawuti pogwiritsa ntchito bawuti yamphamvu kwambiri ndi yosiyana ndi yolumikizira bawuti wamba. Bawuti wamba imasamutsa mphamvu yakumeta ubweya ndi kukana kukameta ubweya wa bawuti komanso kukakamizidwa, pomwe kulumikizana kwamphamvu kwamphamvu kwambiri kumasuntha kukameta ubweya ndi kukana kwamphamvu pakati pa mbale zolumikizidwa.

Kuyika kudzera pa wrench yapadera, sungani natiyo ndi torque yayikulu kuti wonongayo ikhale ndi vuto lalikulu. Kuthamanga kwapamwamba kwa bawuti yamphamvu kwambiri kumamatira mbali zolumikizidwa kotero kuti kukhudzana kwa zigawozo kumatulutsa mphamvu yolimbana kwambiri, ndipo mphamvu yakunja imafalikira ndi kukangana. Kulumikizana uku kumatchedwa kulumikizidwa kwamphamvu kwambiri kwa bawuti.

Kuchita kwa bawuti kumawonetsedwa ndi momwe bolt imagwirira ntchito, monga 4.6, 8.8, 10.9.

Nambala isanakwane decimal imawonetsa kulimba kwa bawuti, ndipo nambala pambuyo pa decimal ikuwonetsa chiŵerengero champhamvu cha flexural.

Mphamvu ya kalasi 4.6, 8.8 ndi 10.9 mabawuti wa 400N/mm2, 800N/mm2 ndi 1000N/mm2 motero.

Maboti a Class C ndi 4.6 kapena 4.8 ndipo amapangidwa ndi chitsulo cha Q235.

Maboti a Giredi A ndi B ndi a giredi 5.6 kapena 8.8 ndipo amapangidwa ndi chitsulo chochepa cha alloy kapena pambuyo pochiza kutentha.

Maboti amphamvu kwambiri ndi giredi 8.8 kapena 10.9, opangidwa ndi zitsulo 45, zitsulo 40B ndi chitsulo cha 20MnTiB.

Pali mitundu iwiri yowerengera pamalumikizidwe amphamvu kwambiri:

1. Kugwirizana kwa mikangano kumangodalira kukana kwamphamvu kwamphamvu pakati pa mbale zomwe zimagwirizanitsidwa kuti zipereke mphamvu, ndipo kukana kwachitsulo kwangogonjetsedwa monga malire a malire a kugwirizana. Choncho, kukameta ubweya wa kugwirizana ndi kochepa ndipo kukhulupirika ndikwabwino.

2. Kulumikizana kwamtundu wa kupanikizika ndi kukangana pakati pa mbale yolumikizira ndi mphamvu yolumikizira bolt, kumeta ubweya wa bolt kapena kukakamiza (kupanikizika) koyipa kwa malire a mphamvu yolumikizira yolumikizira.

Maboti amphamvu kwambiri amabowoleredwa m’mabowo. Kulumikizana kwamtundu wa friction, pobowo kuposa bawuti m'mimba mwake mwadzina 1.5-2.0mm, 1.0-1.5mm kuthamanga kwamtundu. Pofuna kupititsa patsogolo kukangana, malo okhudzana ndi mgwirizano ayeneranso kuthandizidwa.

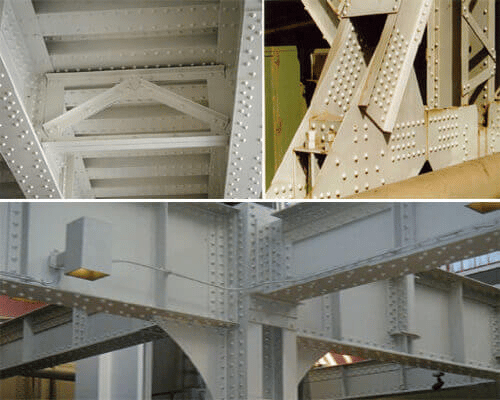

Chitsulo Chomangira Cholumikizira-Rivet

Kulumikizana kwa Rivet ndikopanga ma rivets okhala ndi mutu wa msomali wopangidwa ndi semicircular kumapeto kwina, ndikuyika mwachangu ndodo ya msomali mu dzenje la msomali wa cholumikizira ikatenthedwa, ndiyeno gwiritsani ntchito mfuti yothamangitsa kuti muthamangitse mbali inayo kumutu kwa msomali. pangitsa kulumikizana kukhala kotetezeka.

ubwino: odalirika riveting mphamvu kufala, plasticity wabwino, kulimba, khalidwe n'zosavuta fufuzani ndi chitsimikizo, angagwiritsidwe ntchito katundu wolemetsa ndi mwachindunji kubala zosintha katundu dongosolo.

kuipa: ndondomeko ya riveting ndi yovuta, mtengo wopangira ntchito ndi zipangizo, ndi kuwonjezereka kwa ntchito, kotero zasinthidwa ndi kuwotcherera ndi kugwirizana kwakukulu kwa bawuti.

The kugwirizana akafuna ndi khalidwe lake mwachindunji zimakhudza ntchito ntchito ya zitsulo kapangidwe. Kugwirizana kwa zitsulo kuyenera kugwirizana ndi mfundo za chitetezo ndi kudalirika, kufalitsa mphamvu zomveka bwino, kapangidwe kosavuta, kupanga kosavuta ndi kupulumutsa zitsulo. Cholowacho chiyenera kukhala champhamvu chokwanira komanso kukhala ndi malo okwanira oti agwirizane.

PEB Steel Building

Zowonjezera Zina

Kupanga FAQs

- Momwe Mungapangire Zida Zomangira Zitsulo & Zigawo

- Kodi Ntchito Yomanga Zitsulo Imawononga Ndalama Zingati?

- Ntchito Zomanga Zomangamanga

- Kodi Ntchito Yomanga Yomangamanga ya Steel Portal ndi chiyani

- Momwe Mungawerengere Zojambula Zachitsulo Zomangamanga

Mabulogu Osankhidwira Inu

- Mfundo Zazikulu Zomwe Zikukhudza Mtengo wa Malo Osungiramo Zitsulo

- Momwe Zomanga Zitsulo Zimathandizira Kuchepetsa Kuwonongeka Kwachilengedwe

- Momwe Mungawerengere Zojambula Zachitsulo Zomangamanga

- Kodi Nyumba Zazitsulo Ndi Zotsika mtengo Kuposa Nyumba Zamatabwa?

- Ubwino Wa Nyumba Zazitsulo Zogwiritsa Ntchito Paulimi

- Kusankha Malo Oyenera Pamamangidwe Anu Azitsulo

- Kupanga Tchalitchi cha Prefab Steel

- Passive Housing & Metal -Zopangidwira Wina ndi Mnzake

- Zogwiritsa Ntchito Zomanga Zachitsulo Zomwe Mwina Simukuzidziwa

- N'chifukwa Chiyani Mukufunikira Nyumba Yokhazikika

- Kodi Muyenera Kudziwa Chiyani Musanapange Malo Opangira Zitsulo?

- Chifukwa Chake Muyenera Kusankha Nyumba Yachitsulo Yachitsulo Panyumba Yamatabwa Yamatabwa

Lumikizanani nafe >>

Muli ndi mafunso kapena mukufuna thandizo? Tisanayambe, muyenera kudziwa kuti pafupifupi nyumba zonse zachitsulo za prefab zimasinthidwa makonda.

Gulu lathu la engineering lizipanga molingana ndi liwiro la mphepo yam'deralo, kuchuluka kwa mvula, length*width*kutalika, ndi zina zowonjezera. Kapena, tikhoza kutsatira zojambula zanu. Chonde ndiuzeni zomwe mukufuna, ndipo tidzachita zina!

Gwiritsani ntchito fomuyi kuti mufike ndipo tidzalumikizana nanu mwachangu momwe tingathere.

Za Wolemba: K-HOME

K-home Malingaliro a kampani Steel Structure Co., Ltd chimakwirira kudera la 120,000 masikweya mita. Timagwira ntchito pakupanga, bajeti ya polojekiti, kupanga, ndi kupanga kukhazikitsa PEB zitsulo nyumba ndi mapanelo a masangweji okhala ndi ziyeneretso zapagulu lachiwiri. Zogulitsa zathu zimaphimba zitsulo zopepuka, Nyumba za PEB, nyumba zotsika mtengo za prefab, nyumba zotengera, C/Z chitsulo, mitundu yosiyanasiyana ya mbale zitsulo zamitundu, mapanelo a masangweji a PU, mapanelo a masangweji a eps, mapanelo a masangweji a ubweya wa miyala, mapanelo azipinda zozizira, mbale zoyeretsera, ndi zida zina zomangira.