Pali njira zambiri zowotcherera muzitsulo, koma arc kuwotcherera kumagwiritsidwa ntchito makamaka. Chifukwa zida zowotcherera arc ndizosavuta, zosavuta kugwiritsa ntchito, komanso mtundu wa weld ndi wodalirika, pali zabwino zambiri.

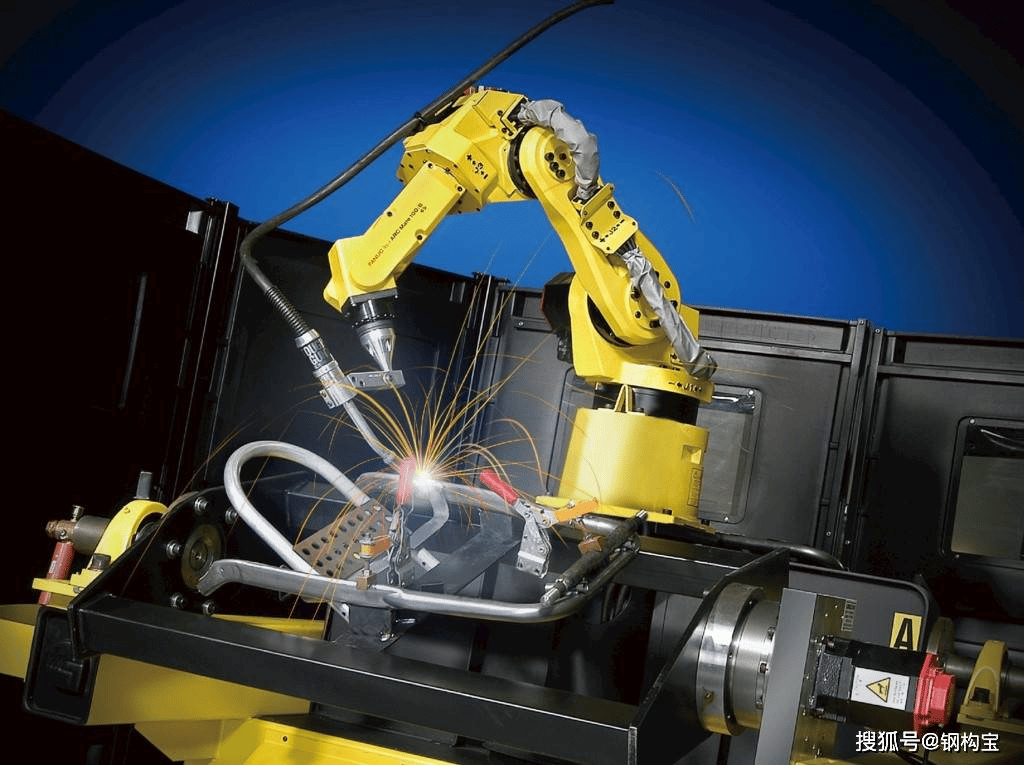

Arc kuwotcherera kungagawidwe kukhala kuwotcherera arc manual, kuwotcherera arc otomatiki kapena odziyimira pawokha ndi kuwotcherera gasi-zotetezedwa malinga ndi kuchuluka kwa magwiridwe antchito komanso mtundu wazinthu zomwe zimagwiritsidwa ntchito poteteza chitsulo chosungunuka pakuwotcherera.

Ndiye zotsatirazi ndi njira kuwotcherera nyumba zitsulo izi.

Kuwerenga Kwambiri: Wophatikizana Wophatikizana Wophatikiza mu Chitsulo chachitsulo

3 Mitundu ya Kuwotcherera kwa Arc

1. Kuwotcherera kwa Arc Manual

Njira yodalira kutentha kwa arc imatchedwa kuwotcherera kwa arc. Kuwotcherera kwa arc pamanja ndi mtundu wa kuwotcherera kwa arc ndi ndodo yowotcherera yamanja, yomwe imagwiritsidwa ntchito kwambiri pakuwotcherera zitsulo.

The weldment ndi electrode ndi maelekitirodi awiri omwe amapanga arc, arc imapanga kutentha kwambiri, weldment ndi electrode yosungunuka, mapeto a electrode amasungunuka kuti apange droplet, kusintha kwa kuphatikizika kwazitsulo zoyambira zachitsulo chosungunuka. , mapangidwe a dziwe ndi mndandanda wa zovuta zakuthupi-zitsulo. Pamene arc imayenda, dziwe losungunuka lamadzimadzi limazizira pang'onopang'ono ndi kunyezimira ndi kupanga weld.

Pansi pa kutentha kwapamwamba, kuzizira mu electrode ❖ kuyanika pazitsulo zopangira zitsulo zosungunuka, kuphimba pamwamba pa dziwe losungunuka lachitsulo, silingathe kuteteza kutentha kwa dziwe losungunuka lachitsulo ndi zotsatira zovulaza za okosijeni ndi mpweya. nayitrogeni mu mlengalenga, ndipo nawonso mu chosungunuka dziwe mankhwala anachita ndi seeping aloyi, etc., mu kuzirala ndi solidification wa zitsulo pamwamba, kupanga zoteteza slag chipolopolo.

2. Kuwotcherera kwa arc kumadzimadzi kapena kodziwikiratu

Kuwotcherera kwa arc kumadzimadzi kumaposa kuwotcherera pamanja chifukwa cha kutentha kwa arc, kotero kumakhala ndi kuzama kwakukulu kolowera, mtundu wa weld wofananira, zofooka zochepa zamkati, pulasitiki wabwino komanso kulimba kwamphamvu. Ubwino wa kuwotcherera kwa semi-automatic submerging arc uli pakati pa kuwotcherera kwa arc komwe kumalowetsedwa pansi ndi kuwotcherera pamanja.

Kuphatikiza apo, kuwotcherera kwa arc otomatiki kapena odziwikiratu kumakhala ndi liwiro lalitali, kuwongolera kwakukulu, kutsika mtengo komanso malo abwino ogwirira ntchito. Komabe, kugwiritsa ntchito kwawo kumachepetsedwa ndi zikhalidwe zake, chifukwa chowotcherera chiyenera kusuntha motsatira njanji yowotcherera, kotero payenera kukhala zinthu zina zogwirira ntchito.

3. Kuwotcherera kotetezedwa ndi gasi

Zomwe zimadziwikanso kuti fusion gas arc welding, CO2 kapena mpweya wa inert umagwiritsidwa ntchito popanga malo otetezera am'deralo kuzungulira arc kuti ateteze kuukira kwa mpweya woyipa ndikuwonetsetsa kukhazikika kwa njira yowotcherera.

Kuwotcherera kwa malo onse, khalidwe labwino, kufulumira kusungunuka, kuthamanga kwambiri, kupulumutsa mphamvu, palibe chifukwa chochotsa slag yowotcherera pambuyo pa kuwotcherera, koma ndiyenera kudziwa kuti tcheru chiyenera kulipidwa kuti tipewe mphepo pamene kuwotcherera.

Zida Zowotcherera

Zida zowotcherera zimaphatikizapo maelekitirodi, waya, ufa wachitsulo, flux, gasi, etc.

ndodo yowotcherera

Mzere wachitsulo womwe umadzaza cholumikizira chowotcherera pamoto kapena kuwotcherera kwamagetsi. Elekitirodi nthawi zambiri amapangidwa ndi zinthu zomwezo monga workpiece. Elekitirodi ndi electrode yosungunuka ya electrode arc kuwotcherera ndi zokutira, zomwe zimapangidwa ndi zokutira ndi kuwotcherera pachimake.

waya zokutira

Waya ndi waya wowotcherera waya womwe umagwiritsidwa ntchito ngati zitsulo zodzaza kapena ngati kondakitala wamagetsi. Mu kuwotcherera gasi ndi kuwotcherera kwa mpweya wa tungsten wotetezedwa ndi arc, waya wowotcherera amagwiritsidwa ntchito ngati zitsulo zodzaza; Mu kuwotcherera kwa arc pansi pamadzi, kuwotcherera kwa esG ndi kuwotcherera kwina kwa GAS-shield arc, waya wowotcherera ndi zitsulo zodzaza ndi electrode conductive. Pamwamba pa waya wowotchererayo samakutidwa ndi anti-oxidation flux.

Metal ufa

Ufa wachitsulo umatanthawuza gulu lachitsulo lomwe kukula kwake kuli kosakwana 1mm. Single zitsulo ufa, aloyi ufa ndi ena refractory pawiri ufa ndi zitsulo katundu ndi yaikulu ya zipangizo za ufa zitsulo.

ikuyenda

Flux, yomwe imatchedwanso brazing agent, ili ndi tanthauzo lalikulu, kuphatikiza mchere wosungunuka, zinthu zachilengedwe, gasi yogwira ntchito, nthunzi yachitsulo, etc. kuchepetsa kusagwirizana kwa mawonekedwe pakati pazitsulo zoyambira ndi solder.

gasi

Gasi ndi chimodzi mwa zigawo zinayi zofunika za zinthu (zina zitatu ndi zolimba, zamadzimadzi ndi plasma). Mpweya ukhoza kupangidwa ndi atomu imodzi (mwachitsanzo, mpweya wabwino), mamolekyu oyambira a chinthu chimodzi (mwachitsanzo, mpweya), mamolekyu apawiri azinthu zambiri (mwachitsanzo, mpweya woipa), ndi zina zotero.

Mkhalidwe ndi Zofunikira

Owotcherera adzakhala oyenerera pophunzitsidwa ndikupeza ziphaso zoyenerera asanayambe ntchito yowotcherera.

Kwa ma weld ofunikira a magawo ofunikira, malekezero onse a welds kapena mphambano ya ma welds ayenera kusindikizidwa ndi code yowotcherera.

Pamaso kuwotcherera mbali kuwotcherera ayenera kutsukidwa dothi pafupi pamwamba pa kuwotcherera, monga oxide sikelo, mafuta, anticorrosive utoto, etc.

Mukawotchera pansi pa zero digiri Celsius, izi ziyenera kuwonedwa:

- Onetsetsani kuti chowotcherera chikhoza kuchepa momasuka panthawi yowotcherera;

- musagwiritse ntchito nyundo yolemera kuti mumenye zigawo zomangika;

- Pamaso kuwotcherera, kuchotsa ayezi ndi matalala pa welded structural mbali;

- Pamaso kuwotcherera, preheat malinga ndi makonzedwe, kutentha enieni anatsimikiza malinga ndi ndondomeko mayeso.

Pamaso kuwotcherera ayenera preheated malinga ndi makonzedwe, ayenera losindikizidwa kuwotcherera mavabodi (ukonde), nthiti mbale, kugawa mapeto (makundi malangizo) ndi cholumikizira poyera mapeto a kusiyana;

Mbali zobisika zamapangidwe azitsulo ziyenera kutenthedwa, zokutira ndi kusindikizidwa pambuyo poyendera.

Awiri kumbali matako kuwotcherera ayenera kusankha kuwotcherera muzu, kutola kuwotcherera muzu angagwiritse ntchito fosholo pneumatic, mpweya arc gouging, gouging ndi makina processing njira.

Mipikisano wosanjikiza kuwotcherera adzakhala welded mosalekeza, ndipo aliyense wosanjikiza chiphaso chowotcherera adzatsukidwa ndi kufufuzidwa mu nthawi pambuyo kuwotcherera, ndi zolakwika adzachotsedwa pamaso kuwotcherera.

Pakuwotcherera, gwiritsani ntchito malo owotcherera athyathyathya momwe mungathere.

Pa kuwotcherera, musagwiritse ntchito elekitirodi ndi peeling kapena dzimbiri kuwotcherera pachimake ndi flux ndi yonyowa pokonza agglomeration ndi slag chipolopolo kuti wasungunuka; Waya wowotcherera ndi msomali wowotcherera uyenera kutsukidwa ndi mafuta ndi dzimbiri musanagwiritse ntchito.

Kuwerenga kwina: Kuyika ndi Kapangidwe kazitsulo zachitsulo

Ntchito yomanga yogwiritsidwa ntchito koyamba ndi chitsulo, zida zowotcherera, njira zowotcherera, chithandizo cha kutentha kwapambuyo pa kuwotcherera, ndi zina zotere, zimayenera kuwunika njira yowotcherera, kulemba lipoti lowunika, ndikuwunika njira yowotcherera malinga ndi lipoti lowunika.

Nthawi yowotcherera yowotcherera yopitilira miyezi isanu ndi umodzi iyenera kuwunikiridwanso.

Kuwotcherera, ma welders ayenera kutsatira njira yowotcherera, osati kuwotcherera kwaulere ndi arc pazitsulo zapansi kunja kwa mkanda wowotcherera.

Olowa m'matako, T-woboola pakati olowa, olowa ngodya, mtanda olowa matako kuwotcherera ndi matako ndi ngodya olowa kuphatikiza kuwotcherera, ayenera kukhala pa malekezero onse a kuwotcherera arc ndi mbale kutsogolo, zakuthupi ndi poyambira mawonekedwe ayenera kukhala chimodzimodzi monga kuwotcherera.

Kutalika kwa arc ndi kuwotcherera kwa lead: kuwotcherera pansi pamadzi kuyenera kukhala kwakukulu kuposa 50mm, kuwotcherera kwapamanja ndi kuwotcherera kotetezedwa ndi gasi kuyenera kupitilira 20mm. Pambuyo kuwotcherera, kudula gasi kuyenera kugwiritsidwa ntchito kudula arc ndi mbale yotsogolera, ndikupukutidwa bwino, sikuyenera kuponyedwa pansi ndi nyundo.

Weld ming'alu, kuwotcherera sadzagwira popanda chilolezo, ayenera kudziwa chifukwa, anapereka ndondomeko kukonza akhoza kukonzedwa. Chiwerengero cha kukonzanso kwa gawo lomwelo la weld sayenera kupitirira kawiri. Zikachitika kangapo kawiri, kukonzanso kumayenera kuchitidwa molingana ndi kukonza.

Pambuyo kuwotcherera, wowotchererayo ayenera kuyeretsa slag pamwamba pa weld ndi spatter mbali zonse, ndikuyang'ana maonekedwe a weld. Pambuyo poyang'anitsitsa, chizindikiro chachitsulo chowotcherera chidzapangidwa pa gawo lazitsulo lazitsulo lomwe likufotokozedwa mu ndondomekoyi.

Chitsulo cha carbon structural chiyenera kuziziritsidwa ku kutentha kozungulira mu weld, ndipo chitsulo chochepa cha aloyi chiyenera kumangiriridwa kwa maola 24 isanayambe kuyang'ana.

PEB Steel Building

Zowonjezera Zina

Kupanga FAQs

- Momwe Mungapangire Zida Zomangira Zitsulo & Zigawo

- Kodi Ntchito Yomanga Zitsulo Imawononga Ndalama Zingati?

- Ntchito Zomanga Zomangamanga

- Kodi Ntchito Yomanga Yomangamanga ya Steel Portal ndi chiyani

- Momwe Mungawerengere Zojambula Zachitsulo Zomangamanga

Mabulogu Osankhidwira Inu

- Mfundo Zazikulu Zomwe Zikukhudza Mtengo wa Malo Osungiramo Zitsulo

- Momwe Zomanga Zitsulo Zimathandizira Kuchepetsa Kuwonongeka Kwachilengedwe

- Momwe Mungawerengere Zojambula Zachitsulo Zomangamanga

- Kodi Nyumba Zazitsulo Ndi Zotsika mtengo Kuposa Nyumba Zamatabwa?

- Ubwino Wa Nyumba Zazitsulo Zogwiritsa Ntchito Paulimi

- Kusankha Malo Oyenera Pamamangidwe Anu Azitsulo

- Kupanga Tchalitchi cha Prefab Steel

- Passive Housing & Metal -Zopangidwira Wina ndi Mnzake

- Zogwiritsa Ntchito Zomanga Zachitsulo Zomwe Mwina Simukuzidziwa

- N'chifukwa Chiyani Mukufunikira Nyumba Yokhazikika

- Kodi Muyenera Kudziwa Chiyani Musanapange Malo Opangira Zitsulo?

- Chifukwa Chake Muyenera Kusankha Nyumba Yachitsulo Yachitsulo Panyumba Yamatabwa Yamatabwa

Lumikizanani nafe >>

Muli ndi mafunso kapena mukufuna thandizo? Tisanayambe, muyenera kudziwa kuti pafupifupi nyumba zonse zachitsulo za prefab zimasinthidwa makonda.

Gulu lathu la engineering lizipanga molingana ndi liwiro la mphepo yam'deralo, kuchuluka kwa mvula, length*width*kutalika, ndi zina zowonjezera. Kapena, tikhoza kutsatira zojambula zanu. Chonde ndiuzeni zomwe mukufuna, ndipo tidzachita zina!

Gwiritsani ntchito fomuyi kuti mufike ndipo tidzalumikizana nanu mwachangu momwe tingathere.

Za Wolemba: K-HOME

K-home Malingaliro a kampani Steel Structure Co., Ltd chimakwirira kudera la 120,000 masikweya mita. Timagwira ntchito pakupanga, bajeti ya polojekiti, kupanga, ndi kupanga kukhazikitsa PEB zitsulo nyumba ndi mapanelo a masangweji okhala ndi ziyeneretso zapagulu lachiwiri. Zogulitsa zathu zimaphimba zitsulo zopepuka, Nyumba za PEB, nyumba zotsika mtengo za prefab, nyumba zotengera, C/Z chitsulo, mitundu yosiyanasiyana ya mbale zitsulo zamitundu, mapanelo a masangweji a PU, mapanelo a masangweji a eps, mapanelo a masangweji a ubweya wa miyala, mapanelo azipinda zozizira, mbale zoyeretsera, ndi zida zina zomangira.