I-PEB Izakhiwo zentsimbi zisebenza njengenkxaso esisiseko yale mihla iindawo zokugcina zoshishino kunye nezakhiwo zokusebenzela. Amandla abo aphezulu aqinisekisa ixesha elide, ukusebenza okuzinzileyo kwezityalo kunye nezibonelelo. Nangona kunjalo, iimeko zemozulu zohluka kakhulu kumazwe nakwimimandla. Ezinye iifektri zikwindawo efumileyo, kufutshane nolwandle, okanye kwiindawo ezinemvula unyaka wonke. Abanye bangqongwe ngumsi ophuma kwimizi-mveliso yonke imihla. Le miba yokusingqongileyo ngokuthe ngcembe ikhokelela kwi-corrosion kwizakhiwo zentsimbi.

Ekuhambeni kwexesha, umhlwa awushiyi nje amabala amabi izakhiwo ezenziwe ngentsimbi-kwanciphisa amandla entsimbi ngokwayo, inciphisa ubomi benkonzo yezi asethi zoshishino.

Unga kanjani izixhobo zokwakha intsimbi ukunqanda ukunxitywa kwendalo kunye nokukrazula ukugcina uzinzo lwexesha elide?

Insimbi yolwakhiwo iyona nxalenye yomthwalo ongundoqo weebhulorho, iiworkshops, kunye neendawo zokugcina, kwaye ubomi bayo benkonzo yoshishino akufanele "bufinyezwe" ngokulula ngokubola. Kodwa eneneni, iindleko zonyaka zokulondoloza, ukuhla kwexabiso lempahla, kwaneengozi zokhuseleko ezibangelwa kukudleka ehlabathini lonke ziye zaba “ngumthwalo ofihlakeleyo” kumaqela obunjineli nakubanini-mpahla.

Ngapha koko, xa ujongana nezi zoyikiso zomhlwa, kunzima ukungayihoyi loo ngcali umzobo wesakhiwo sentsimbi—ubuchule bokulungisa—lelona nyathelo libalulekileyo lokukhusela. Asingomsebenzi wepeyinti olula owenzelwa iinjongo zobuhle; endaweni yoko, sisisombululo ekujoliswe kuso sokuthintela umhlwa. Le nkqubo ilula kodwa isebenzayo yokutshiza ayigcini nje kuphela ukugcina izakhiwo zentsimbi zizinzile ngamaxesha onke kwaye inqande iindleko eziphezulu zokugcina kamva kodwa ngokunyanisekileyo yandisa ubomi benkonzo yee-asethi zoshishino.

Nceda uqonde ngokucacileyo ukuba yintoni kanye kanye iNkqubo yokuPeyintwa kweSteel Structure?

Ngamafutshane, umzobo wesakhiwo sentsimbi yinkqubo esebenzisa izixhobo zokutshiza zobuchwephesha ukwenza ipeyinti okanye umgubo wesinyithi unamathele ngokulinganayo kumphezulu wentsimbi kwaye ekugqibeleni wenze ifilimu ekhuselayo.

Le filimu ekhuselayo iyakwazi ukuhlukanisa ngokuthe ngqo intsimbi ekukhukulisekeni kwendawo yangaphandle, ngaloo ndlela ikhusela ngokufanelekileyo insimbi ekugwemeni. Ngexesha elifanayo, kunokunciphisa ukuguga kunye nokukrazula kwintsimbi ebangelwa ukungqubuzana ngexesha lokusetyenziswa, ngokusisiseko kunceda ukwandisa ubomi bokwenene benkonzo yentsimbi.

Kwiinkalo ezininzi, ezinje ngolwakhiwo lwentsimbi, ukwenziwa koomatshini, kunye nobunjineli bokwakha, umzobo wesakhiwo sentsimbi ayisiyiyo kuphela itekhnoloji ephambili ephambili yonyango lomphezulu, kodwa kunye nendlela ebalulekileyo yokujongana nokunxitywa kwendalo kunye nokukrazula kwentsimbi, njengemiba eqhelekileyo efana ne-rust kunye ne-corrosion ekusebenziseni imihla ngemihla. Kwaye le nkqubo idlala indima engenakulinganiswa ekugcineni ukusebenza kwentsimbi kunye nokunciphisa iindleko zokugcina.

Iindidi ezahlukeneyo zeNdlela yokuBamba ngeNtsimbi yePayinti yeSteel Structure kunye neSikhokelo sokuSebenza

Ukutshiza okumanzi: Uhlobo lwesiNtu lokuPyinta ukupeyinta iSithili soKwakha

Ukutshiza okumanzi luhlobo lwePainting yeSteel Structure, kwaye ikwayindlela esetyenziswa kakhulu yokutshiza iPainting Structural Steel ngoku. Ngokukodwa, ibhekisa kwinkqubo apho abasebenzi batshiza ipeyinti ngqo kumphezulu wentsimbi xa umphezulu usekwimeko emanzi. Le ndlela inokwenza i-coating eqhubekayo, evala i-steel surface ukuze ihlukanise umswakama kunye ne-oksijeni, ngaloo ndlela idlala indima ekukhuseleni i-rust kunye nezinye iintlobo ze-corrosion.

Nangona kunjalo, kufuneka kuqatshelwe ukuba ekubeni ipeyinti isetyenziswe xa umphezulu umanzi, ukutshiza ngokuphindaphindiweyo kudla ngokufuneka ukuba kwenziwe i-coating egudileyo, iyunifomu, kunye ne-aesthetically pleasing. Isizathu esona sizathu sokwenza oku kukuqinisekisa ukuba ubukhulu bokutya budibana nomgangatho ofunekayo, ongenakukwazi ukubonelela ngokhuseleko oluthembekileyo kuphela kodwa ugweme izithuba okanye ubukhulu obungalinganiyo befilimu yepeyinti. Ukutshiza okumanzi ngokuqhelekileyo kuyinkqubo ekhethiweyo yeeprojekthi ezifana nezixhobo zesakhiwo sensimbi yokuhlobisa, njengoko inokuqwalasela zombini imbonakalo kunye nokuthintela ukubola, kwaye ihambelana kakuhle neemfuno zangempela ze-Steel Structure Painting.

Ukutshiza ngePowder: Isisombululo esiZinzileyo sePainting yeStructure Structure

Ukutshiza ngomgubo yenye indlela ebalulekileyo kwi-Steel Structure Painting kwaye iphinda iwele ngaphakathi kwendawo yokutshiza iPainting Structural Steel. Inkqubo yayo ibandakanya amanyathelo amabini abalulekileyo: okokuqala, ukutshaja i-powder coating kunye nombane we-static, kwaye okwesibini, usebenzisa umoya oxinyiweyo ukutshiza umgubo ohlawulisiweyo phezu kwentsimbi. Umbane osisigxina ubangela ukuba ipowder ibambelele ngokuqinileyo kwindawo yesinyithi; emva koko, ngokuqhelekileyo kusetyenzwa ngenkqubo yokufudumeza kunye nokunyanga, ngexesha apho umgubo unyibilika kwaye wenze umaleko oqinileyo, ongagugiyo wokubopha ngentsimbi.

Olu hlobo lokwaleka lunokuqina okubalaseleyo kunye neempawu. Iyakwazi ukumelana nokungqubana rhoqo kwaye iqhelane nemekobume yemizi-mveliso erhabaxa, ke isoloko isetyenziswa kwiimeko ezinje ngemizimveliso njengokwenziwa koomatshini kunye nezakhiwo zentsimbi enzima. Xa kuthelekiswa nepeyinti engamanzi, ukugquma komgubo kuvelisa inkunkuma encinci; ke ngoko, kwizicelo zeSteel Structure Painting and Spray Painting Structural Steel, ikwalukhetho olulungele ukusingqongileyo.

Ukufakwa kweGalvanizing: Indlela edumileyo yokuNqanda ukuRhakala kwePainting yeSteel Structure

I-galvanization yenye yeendlela ezisetyenziswa kakhulu kwi-steel structure yokudweba, kwaye ifaneleke ngokukodwa kwiiprojekthi apho ukuthintela ukugqwala kwexesha elide kuyimfuno ephezulu. Ngaphezu koko, ngokumalunga nomsebenzi wokukhusela, unokuphinda uncedise i-Spray Painting Structural Steel. Inkqubo ye-galvanization ibandakanya ukusebenzisa ngokuthe ngqo umaleko we-zinc okanye i-aluminiyam kumphezulu wensimbi ngokusebenzisa i-electrochemical reaction. Ezi zinyithi zenza umaleko okhethekileyo wokukhusela kwindawo yentsimbi; olu luhlu lwentsimbi luhlambalaza phambi kwentsimbi engaphantsi, kwaye ngale ndlela, intsimbi ngokwayo inokukhuselwa ngokufanelekileyo kwi-corrosion kunye nomonakalo.

Inkqubo yokufakwa kwegalari yamkelwa ngokubanzi luluntu ngenxa yokusebenza kwayo ngokulula, ukonga kweendleko eziphezulu, kunye nobomi benkonzo ende. Nakwiimeko ezingqongileyo ezirhabaxa njengeendawo eziselunxwemeni apho umhlwa uthande ukukhawulezisa, usenokukhusela izakhiwo zentsimbi ubuncinci amashumi eminyaka. Njengenkqubo yonyango yeklasi kwipeyinti yesakhiwo sensimbi, isetyenziswa rhoqo kwiiprojekthi zeziseko ezinjengamabhuloho, iinqaba zokuhambisa, kunye nezakhelo zetsimbi zeendawo zokugcina zoshishino; ngamanye amaxesha, ikwasetyenziswa ngokudityaniswa ne-Spray Painting Structural Steel ukuqhubela phambili ukuphucula umphumo wokukhusela.

Ukupeyintwa koLwakhiwo lweNsimbi kwiindibano zocweyo: IiMfuno eziNgqongileyo zokuLwa nokuRhakala ezimisela isiphumo soKhuseleko

Emva kokugqiba ukupeyinta okuchasene ne-corrosion kumacandelo ensimbi (inxalenye ephambili yomdwebo wesakhiwo sensimbi), kuyimfuneko ukuba uqale ukuseta indawo evaliweyo yesikhashana kunye nokwahlula ukuthintela ukunyathela ngengozi ngabasebenzi okanye umonakalo kwi-coating ebangelwa ukungqubana nezinto zangaphandle.

Ukongezelela, kwiiyure ze-4 emva kokupenda, ukuba kukho umoya onamandla okanye imvula, kubalulekile ukugubungela ngexesha elifanelekileyo izakhiwo zetsimbi ezipeyintiweyo zokukhusela, ukukhusela uthuli ukuba unamathele kwi-coating okanye umswakama ovela kwi-seep in, oya kuchaphazela umphumo wokubambelela phakathi kwengubo kunye nentsimbi. Ukuba amacandelo ensimbi epeyintiweyo kufuneka ahanjiswe, abasebenzi kufuneka banikele ingqalelo ekuziphatheni ngokucokisekileyo ngexesha lokulayisha kunye nokukhupha, ukuphepha umonakalo wokugubungela obangelwa ukungqubana okanye ukudonsa.

Ngaphandle koko, amacandelo entsimbi epeyintiweyo akufuneki adibane nolwelo oluneasidi ukuthintela ukubola kwesibini kotyatyazo-le yinkcukacha ebalulekileyo kwisakhiwo sentsimbi sokupeyinta ukunqanda ukubola. Ngexesha lokupeyinta okuchasene ne-corrosion (inkqubo engundoqo yokupeyinta isakhiwo sentsimbi), ubushushu be-ambient kufuneka balawulwe phakathi kwe-15 ℃ kunye ne-38 ℃; xa iqondo lobushushu lingaphezulu kwe-40℃, umsebenzi kufuneka unqunyanyiswe ngoko nangoko. Oku kungenxa yokuba xa upeyinta ubuso bentsimbi kwiqondo lokushisa eliphezulu, amaqamu anokuthi enze, okuya kunciphisa ukunamathela kwefilimu yepeyinti. Ngokufanayo, ukupeyinta kwe-anti-corrosion akukwazi ukuqhutyelwa ukuba umswakama womoya udlula i-85% okanye kukho ukudibanisa kwindawo yecandelo.

Ngaphezu koko, ngexesha lokuqulunqwa kwamacandelo ensimbi yokwakhiwa kwe-workshop yesakhiwo sensimbi, kwiinkcukacha ezifana neendawo ezifihliweyo kunye ne-interlayers yesakhiwo ekunzima ukuyichitha emva koko, ukuchithwa kunye ne-anti-corrosion umzobo kufuneka kugqitywe kwangaphambili ukuphepha ukushiya iingozi ezifihliweyo ze-rust-oku kubaluleke kakhulu kwangaphambili kwimisebenzi ehlobene ne-Steel Structure Painting.

Amanqaku anxulumeneyo

Dinga uncedo?

Nceda undazise iimfuno zakho, njengendawo yeprojekthi, ukusetyenziswa, L * W * H, kunye nokhetho olongezelelweyo. Okanye sinokwenza isicatshulwa ngokusekelwe kwimizobo yakho.

Malunga noMbhali: K-HOME

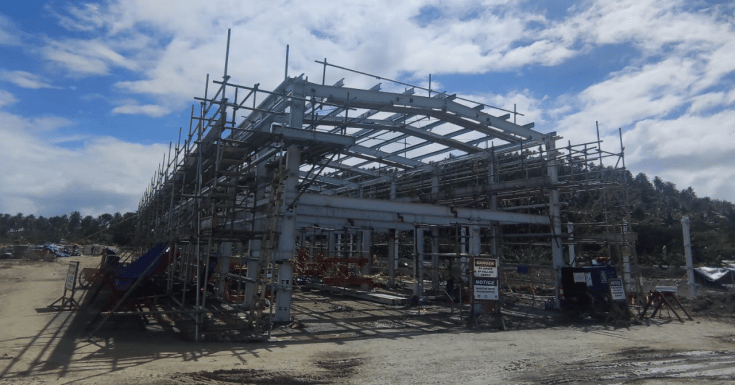

K-home Steel Structure Co., Ltd ithatha indawo ye-120,000 square metres. Sibandakanyeka kuyilo, uhlahlo lwabiwo-mali lweprojekthi, ulwakhiwo, kunye ukufakwa kwezakhiwo zentsimbi ye-PEB kunye neepaneli zesandwich ezineziqinisekiso zekontraka zebakala lesibini jikelele. Iimveliso zethu zigubungela izakhiwo zentsimbi ezikhanyayo, Izakhiwo zePEB, izindlu ze-prefab zamaxabiso aphantsi, izindlu zeekhonteyina, intsimbi ye-C / Z, iimodeli ezahlukeneyo zepleyiti yensimbi yombala, i-PU sandwich panels, iipaneli ze-eps sandwich, iipaneli ze-sandwich zoboya, iipaneli zegumbi elibandayo, iipleyiti zokucoca, kunye nezinye izinto zokwakha.