Steel Distribution Centers

Distribution center / metal distribution center / steel distribution center / prefab distribution center / regional distribution center

What is the distribution center?

The distribution center is a series of operations specializing in distribution operations in the logistics distribution operation. The distribution center is the combination of the function of the goods center, the division center, and the processing center, and has a higher level of allocation and delivery. A distribution center, often abbreviated as DC, is a critical component of logistics and warehouses’ support chain management process. Action where Products are received from suppliers, stored temporarily, and then realistically to various retail Locations, Wholesalers, or directly to customers. Distribution centers are pivotal in ensuring that products reach their intended destinations edible and on time, Storage, processing, division of goods, distribution, and delivery. The distribution center should Basically meet the following requirements: ① Mainly serving specific user services. ② Powerful delivery function. ③ Perfect information network. ④ The radiation range is small. ⑤ Multi-variety and small batches. ⑥ Mainly distribution and supplemented by storage.

WHY CHOOSE KHOME AS YOUR SUPPLIER?

K-HOME is one of the trusted factory manufacturers in China. From structural design to installation, our team can handle various complex projects. You will receive a prefabricated distribution center solution that best suits your needs.

You can send me a WhatsApp message (+86-18338952063), or send an email to leave your contact information. We will contact you as soon as possible.

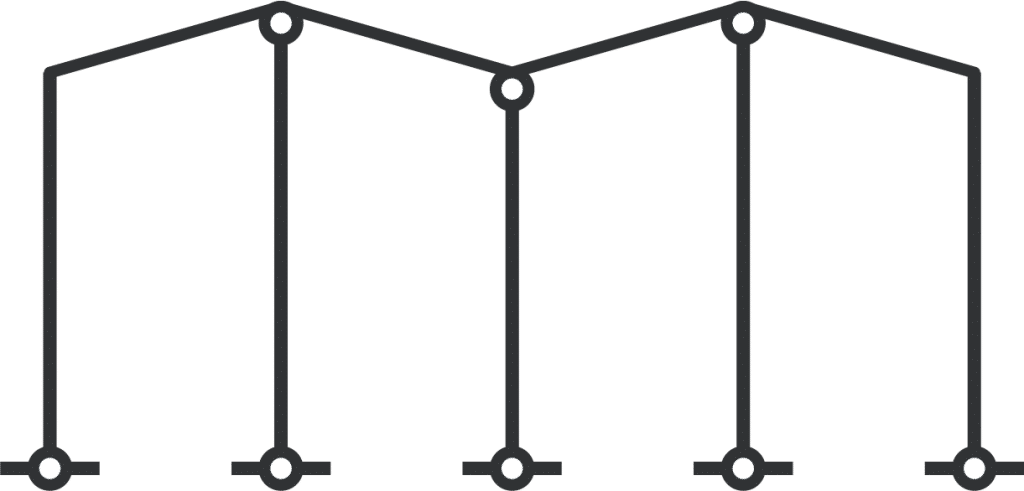

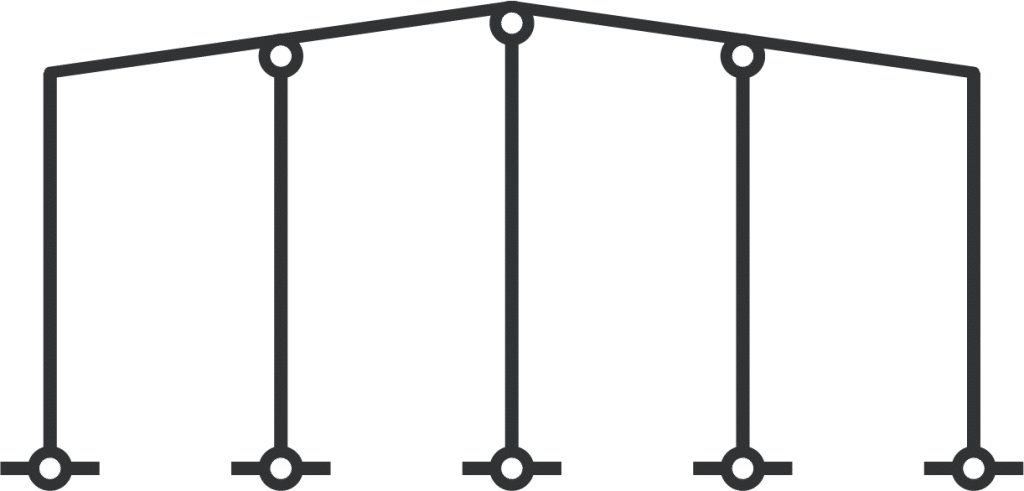

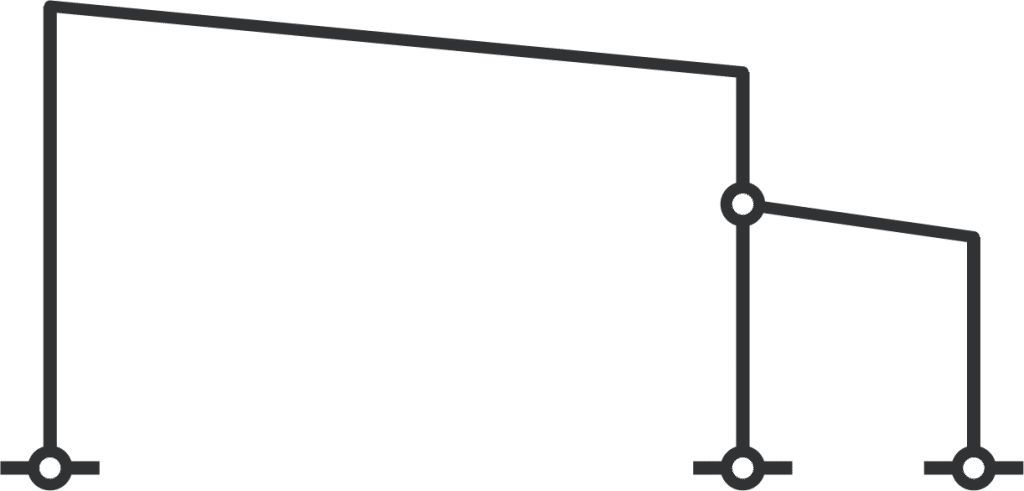

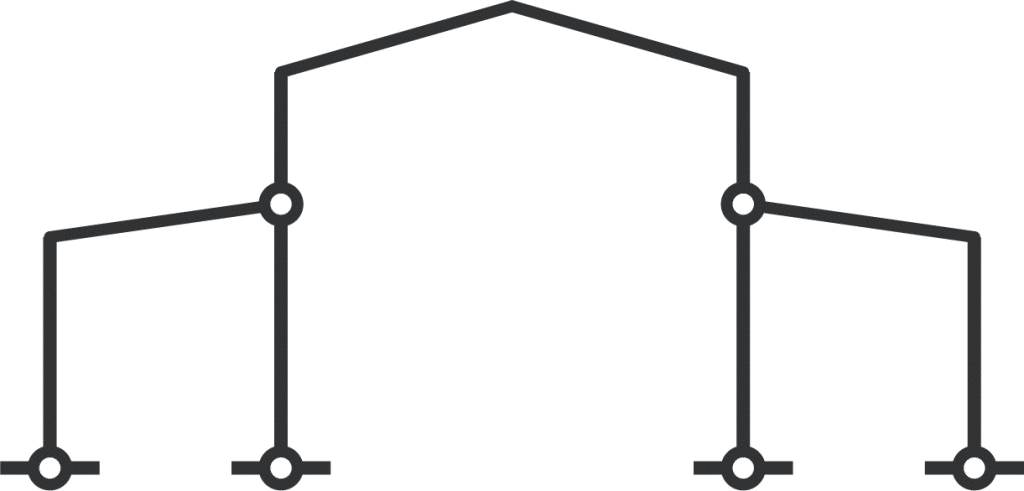

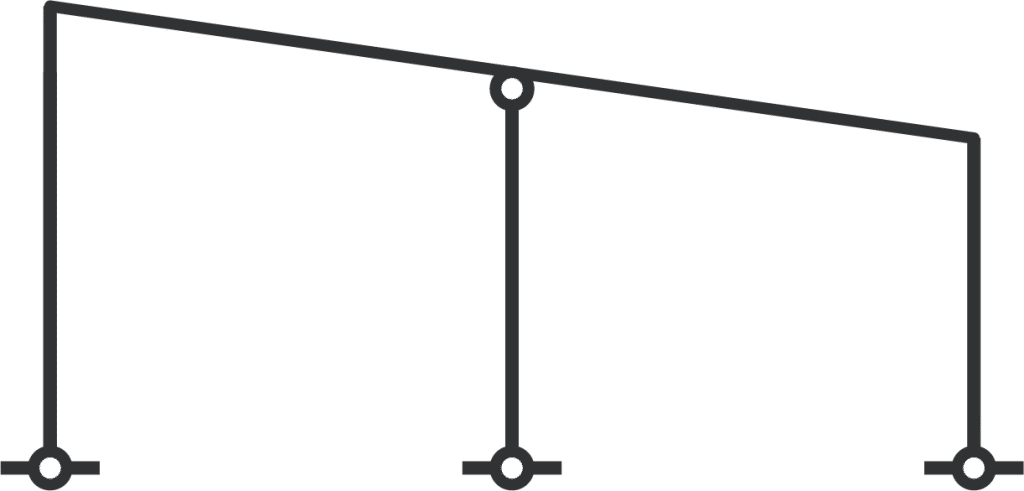

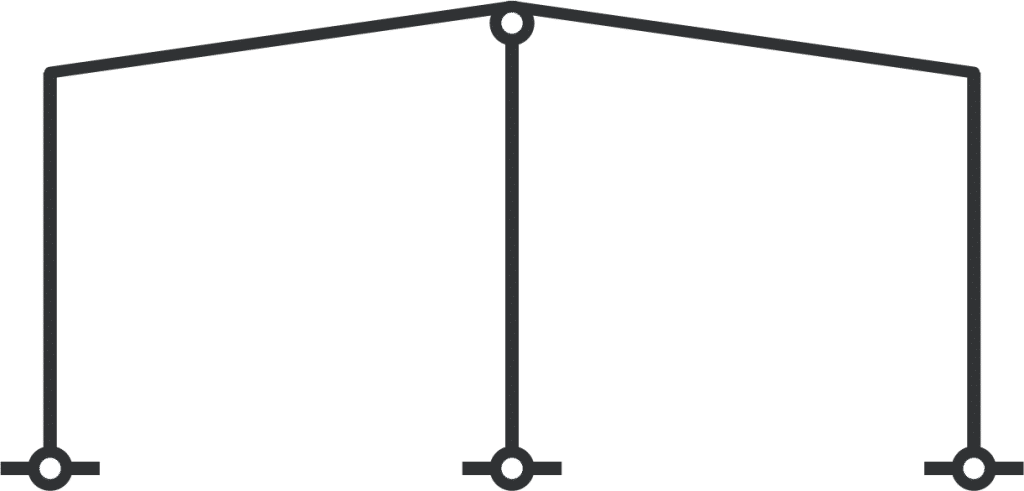

Steel Distribution Center types

Single-span Overhanging Eaves Single-span Double-sloped Roofs Multi-span Multi Double-sloped Roofs Multi-span Double-sloped Roofs High-low Span Single-sloped Roofs High-low Span Double-sloped Roofs Double-span Single-sloped Roofs Double-span Double-sloped Roofs

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.