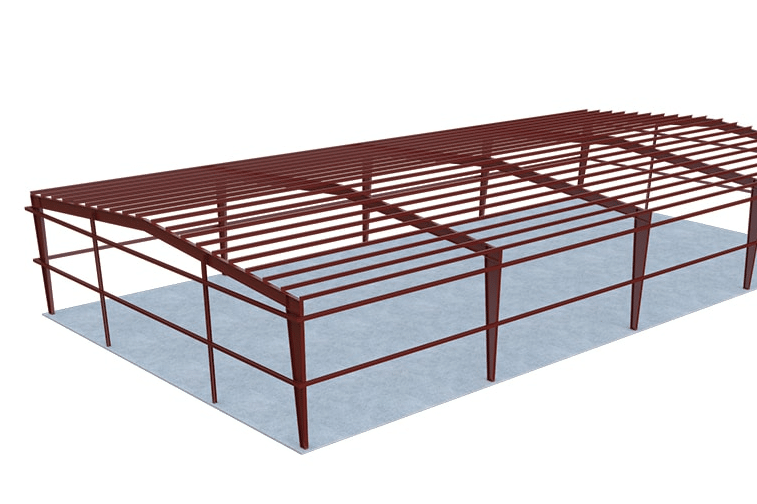

Steel Structure Gym Building Kit Design(80✖230)

Prefab steel structure gym building is usually made of hot-dipped galvanized H-section steel, and all components are connected together by high strength bolts.

Its fast installation, flexible design, and competitive price make it getting more and more popular in large-span warehouses or workshops, gymnasiums, shopping malls, and other public buildings. Choosing this pre-engineered 80 x 230 steel structure gym building type will save you both time and money.

Specification

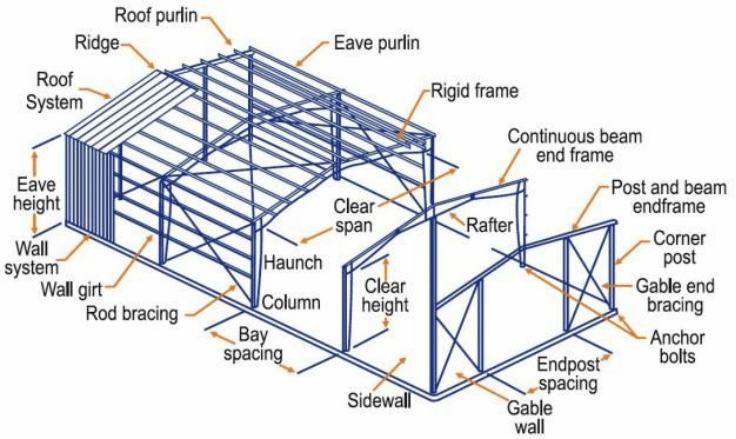

| Main Frame | H-Beam | Secondary Frame | C-Purlin/Z-Purlin |

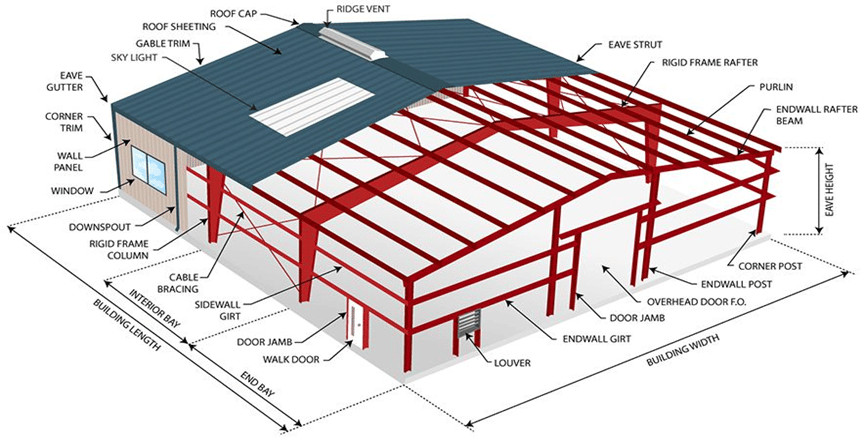

| Wall Material | EPS, Rock wool, Polyurethane sandwich panels, and others. | Roof Material | EPS, Rock wool, Polyurethane sandwich panels and others. |

| Roof Pitch | 1:10 or customized | Stair & Floor Deck | Customized |

| Ventilation | Customized | Door & Window | Customized |

| Fastener | Included | Sealant & Flashing | Included |

Advantages

Compared with other construction, steel structure gym building has advantages in use, design, construction, and comprehensive economy. The construction speed is fast, the construction pollution is small, the weight is light, the cost is low, and it can be moved at any time. These advantages of steel frame building make it a future development trend. Metal structure buildings are widely used in large-span industrial plants, warehouses, cold storages, high-rise buildings, office buildings, multi-story parking lots and residential buildings, and other construction industries.

1. Earthquake Resistance

Most of the roofs of the pre-engineered buildings are sloping roofs, so the roof structure basically adopts a triangular roof truss system made of cold-formed steel members. This steel structural system has a stronger ability to resist earthquakes and horizontal loads and is suitable for areas with a seismic intensity of more than 8 degrees.

2. Wind Resistance

The steel frame structure has lightweight, has high strength, has good overall rigidity, and has strong deformation ability. The weight of the building is only one-fifth of that of the brick-concrete structure, and it can resist a hurricane of 70 meters per second, so that life and property can be effectively protected.

3. Durability

The steel frame structure building is all composed of galvanized steel component system, which is anti-corrosion and anti-oxidation. Effectively avoid the impact of corrosion of steel plates during construction and use, and increase the service life of steel components, making it up to 50 years or more.

4. Thermal Insulation

The thermal insulation material used is mainly a sandwich panel, which has a good thermal insulation effect. The thermal resistance value of thermal insulation cotton with a thickness of about 100mm can be equivalent to a brick wall with a thickness of 1m.

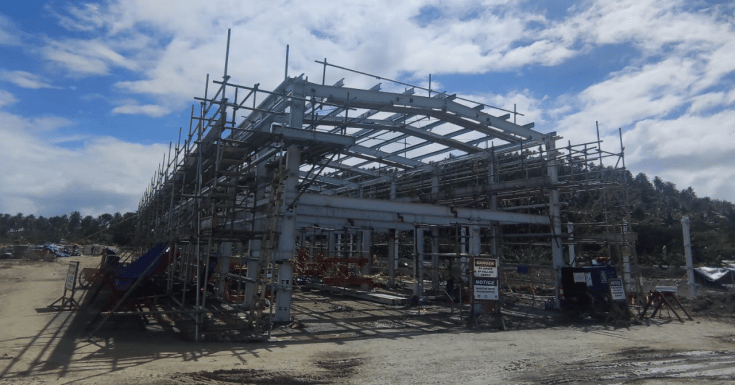

5. Fast Installation

All the components of the steel structure gym building are prefabricated in the factory in advance, and only need to be connected with bolts according to the drawings after being transported to the customer’s site. There are few reprocessing links, the overall installation speed is fast, and it is less affected by the weather, environment, and seasons. For a building of about 1,000 square meters, only 8 workers and 10 working days can complete the whole process from foundation to decoration.

6. Environmental Protection & Energy Saving

Prefabricated steel structure buildings require less reprocessing of construction materials on-site, reducing environmental pollution caused by waste. Steel structure housing materials can be 100% recycled, truly green, and pollution-free. At the same time, all-steel structure buildings use high-efficiency energy-saving walls, which have good thermal insulation, heat insulation, and sound insulation effects, and can reach 50% energy saving standards.

FAQs

Other Steel Building Kits Design

Articles Selected for You

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.