Steel Structure Farm Shed

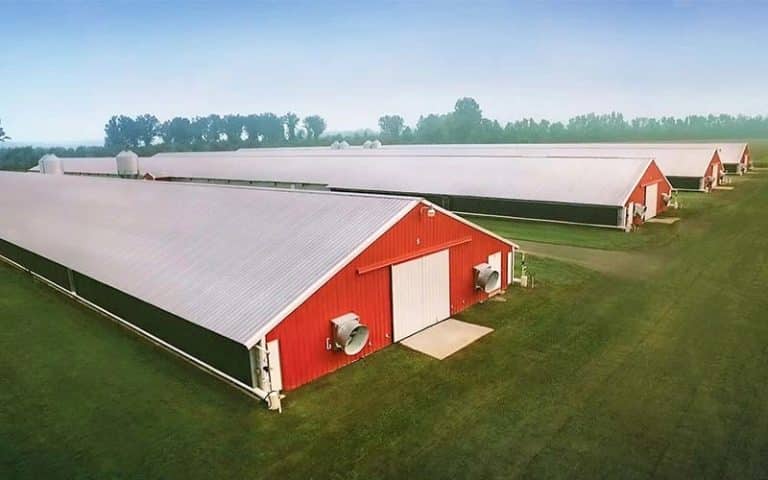

Steel Structure poultry / livestock farm shed

Poultry Steel Structure Farm Shed Basic Structure

Steel structure poultry farm shed can be divided into different types of livestock animals: poultry steel structure farm shed and livestock steel structure farm sheds.

Poultry steel structure breeding shed includes: steel structure chicken coops, steel structure duck houses and steel structure goose houses; livestock steel structure breeding shed include: steel structure pig houses, steel structure sheep houses and steel structure cowhouses, etc.

Compared with the traditional concrete poultry farm shed, all the components of the steel structure poultry farm shed are prefabricated in the factory, and only need to be assembled on site.

structural performance is good, the construction period is short, and the wind and earthquake resistance are strong. In the event of earthquakes, typhoons and other disasters, the steel structure can avoid the collapse of the shed.

The steel structure is relatively light in weight, which can reduce injuries and deaths such as collapse and smashing.

The on-site construction period is short, there is basically no wet work, and there will be no environmental pollution of dust and sewage.

The steel structure can be disassembled to facilitate the relocation of the plant, and the steel can be recycled, which is more energy-saving and environmentally friendly and reduces environmental pollution.

the steel structure poultry farm shed has a smaller structural component section and a relatively larger building area.(learn more about Benefits)

Related Agricultural Steel Buildings

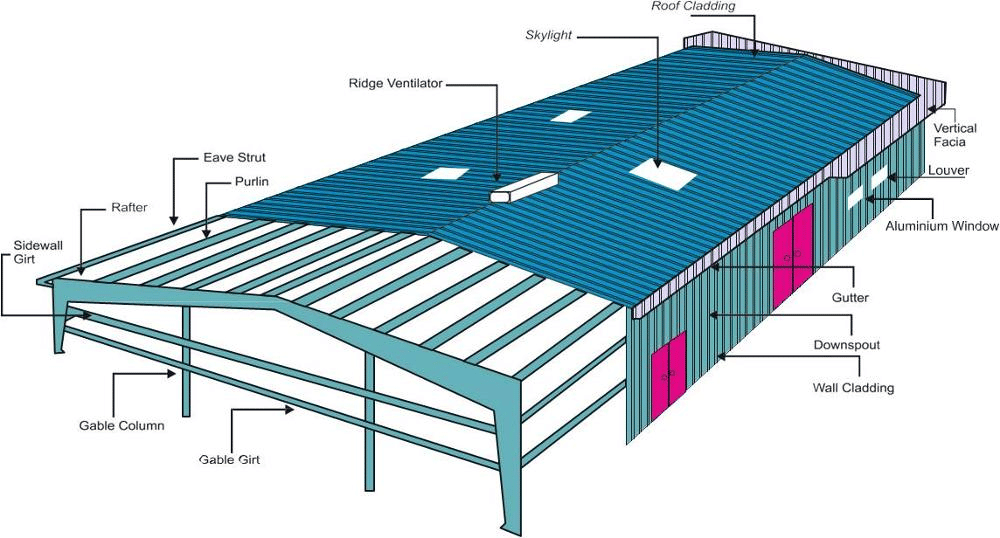

The PEB Steel Building

The Other Additional Attachments

WHY CHOOSE KHOME AS YOUR SUPPLIER?

K-HOME is one of the trusted factory manufacturers in China. From structural design to installation, our team can handle various complex projects. You will receive a prefabricated structure solution that best suits your needs.

You can send me a WhatsApp message (+86-18338952063), or send an email to leave your contact information. We will contact you as soon as possible.

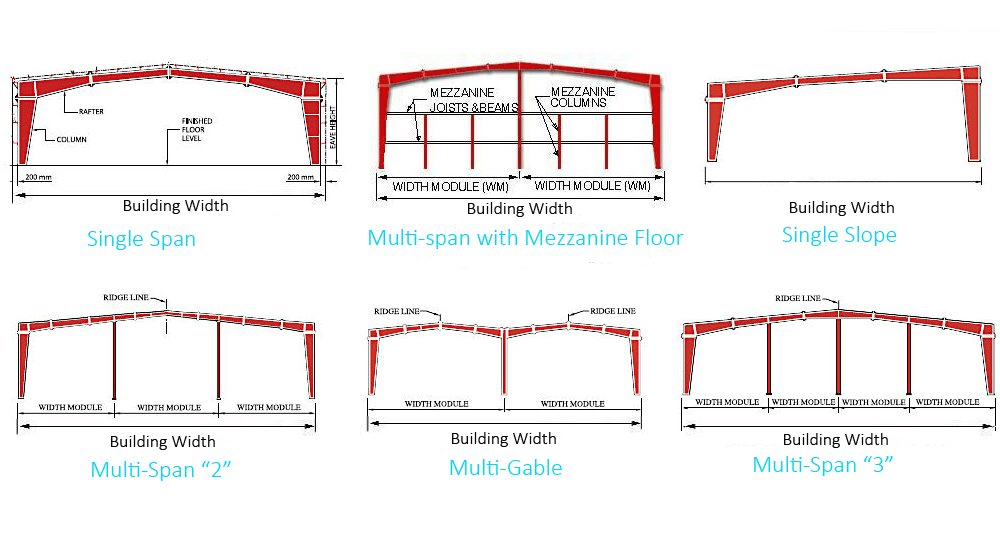

Six types of steel structure farms shed

Portal Steel Structure

Portal steel structure sheds are directly called portal frame systems. The main axis of the shed is perpendicular to the horizontal plane, and a herringbone structure platform with a large diameter at one time is used for clamping workpieces. This type of project is mainly used to process heavy and simple complete machines with large radial dimensions and absolute axial dimensions.

Single-span Steel Structure

Steel structure sheds are normally equipped with various single-span frames, such as a four-station horizontal indexing tool post or a multi-station turret type active indexing beam frame.

Double-span Steel Structure

The double tool holders of the double-span steel structure shed are distributed in parallel or perpendicular to each other.

Horizontal Steel Structure

Horizontal steel structure shed is divided into steel structure level rail horizontal shed and steel structure skewed rail horizontal sheds. Its skewed track structure can make the shed more rigid and easy to clean.

Top Steel Structure

The top type steel structure shed is equipped with a general tailstock or a steel structure tailstock, which is suitable for turning longer machines and disc machines with a small diameter.

Chuck Type Steel Structure

The chuck-type steel structure shed has no tailstock, which is suitable for turning pan (including short shaft) complete machines. The clamping mode is mostly automatic or hydraulic control, and the chuck structure mostly has adjustable jaws or no quenched jaws.

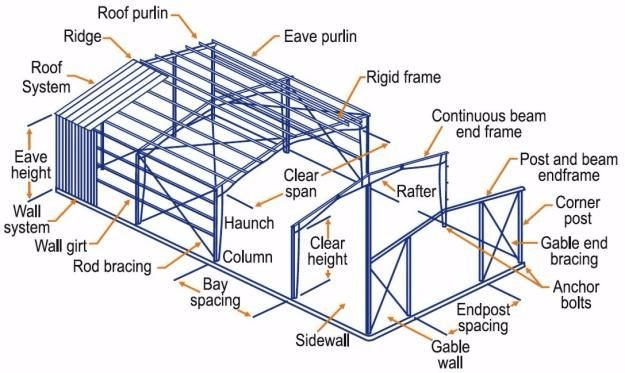

The components of the steel structure poultry farm shed

Single-story steel structure poultry farm sheds are generally a spatial rigid frame composed of purlins, skylight frames, roof trusses, brackets, columns, crane beams, brake beams (or trusses), various supports, and wall frames.

In addition, there are some minor components such as working platforms, ladders, doors and windows, etc.

Insulation measures for poultry farm shed

Poultry such as chickens and ducks have high temperature requirements during the breeding period. The traditional brick house thermal insulation is relatively poor, while the thermal insulation effect of the steel structure factory building is obvious.

Steel structure walls and roofs use special thermal insulation materials. In terms of thermal insulation materials:

These materials have the characteristics of high temperature resistance, low linearity, etc., avoid air flow and heat dissipation, and ensure long-lasting insulation Performance, and the life of the material is basically in line with the life of the building, during this period of time there is no need for maintenance, which greatly reduces the investment cost, and saves expenses and resources to the greatest extent.

More Metal Building Kits

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.