Prefabricated Warehouse

prefabricated warehouse building / steel warehouse / warehousing solutions / modern warehouse / prefab warehouse / commercial warehouse storage

What is the Prefabricated warehouse?

A prefabricated warehouse, also known as a prefab warehouse or pre-engineered warehouse, is a type of industrial or commercial building that is built using pre-engineered components that are manufactured off-site and then assembled at the final location. This construction method is also known as modular construction or prefab construction. Prefabricated warehouses offer several advantages over traditional construction methods, including cost savings, speed of construction, and flexibility in design. These warehouses are designed to be quickly and efficiently assembled, providing a cost-effective and time-saving solution.

WHY CHOOSE KHOME AS YOUR SUPPLIER?

K-HOME is one of the trusted factory manufacturers in China. From structural design to installation, our team can handle various complex projects. You will receive a prefabricated structure solution that best suits your needs.

You can send me a WhatsApp message (+86-18338952063), or send an email to leave your contact information. We will contact you as soon as possible.

How to get a cheap prefabricated warehouse building?

If you are looking for cost-effective choices for prefabricated warehouses, there are several ways to minimize expenditure. Keep in mind that the total cost will depend on various factors, including the size of the warehouse, the selected materials, the design complexity and location. There are some prompts here:

Standardized design: Choose a standardized design that can be obtained from prefabricated building manufacturers. These designs are usually more cost-effective because their production is large, which reduces production costs.

Simple design: The design of the warehouse is simple and clear. Complex design with complex functions may increase costs. Direct and simple functional design may be more affordable.

Basic materials: Choose basic but durable materials. Choose materials that meet the necessary standards and durability, without unnecessary decorations to help reduce costs. K-HOME will provide you with the most cost-effective material choice, and we will provide you with high-quality prefabricated warehouses that afford it.

Note for size: Larger warehouses are usually relatively small in warehouses. If possible, optimize the size of the warehouse to meet your needs without more space. The same area but different sizes may bring different prices. If there are no special requirements, you can give your land area and expected size to K-HOME, and we will optimize it according to your requirements.

When planning cheap prefabricated warehouses, it is important to achieve a balance between saving costs and the quality and function of the final structure. Cooperation with experienced professionals and thoroughly studying your choice will help ensure that you get the best value for your budget. Please contact K-HOME immediately to get your exclusive solution.

Prefabricated warehouse steel structure

At K-HOME, we understand that prefabricated warehouse buildings come in various shapes and sizes, and the possibilities for customization are endless. As such, we offer customized solutions that can meet the unique needs of businesses and individuals.

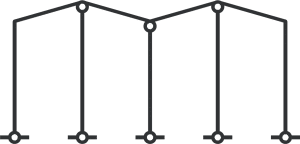

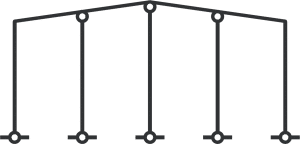

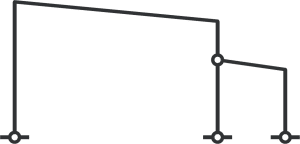

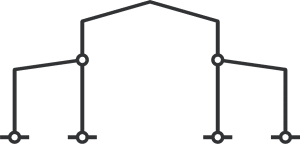

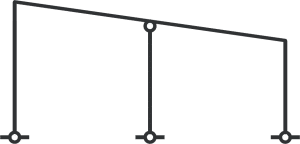

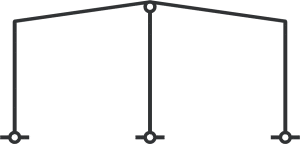

Single-span Overhanging Eaves Single-span Double-sloped Roofs Multi-span Multi Double-sloped Roofs Multi-span Double-sloped Roofs High-low Span Single-sloped Roofs High-low Span Double-sloped Roofs Double-span Single-sloped Roofs Double-span Double-sloped Roofs

Prefabricated warehouse manufacturer

Before selecting a prefabricated warehouse building manufacturer, it’s important to thoroughly research and consider factors such as the company’s reputation, experience, the quality of materials used, customization options, and customer reviews. Additionally, obtaining quotes and consulting with representatives from these companies can help you make an informed decision based on your specific project requirements.

K-HOME offers prefabricated steel buildings for various applications. We provide design flexibility and customization.

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.