steel structure workshop

metal workshop / prefab workshop / steel workshop buildings / prefabricated workshop / modular workshop buildings / prefab workshop buildings

Steel Structure Workshop is an industrial building usually used for manufacturing, processing, assembly, and maintenance products. This building mainly uses steel as a supporting structure, so it has strong wind resistance, seismic, and durability.

WHY CHOOSE KHOME AS YOUR SUPPLIER?

K-HOME is one of the trusted factory manufacturers in China. From structural design to installation, our team can handle various complex projects. You will receive a prefabricated structure solution that best suits your needs.

You can send me a WhatsApp message (+86-18338952063), or send an email to leave your contact information. We will contact you as soon as possible.

steel structure workshop

At K-HOME, we understand that steel structure workshop buildings come in various shapes and sizes, and the possibilities for customization are endless. As such, we offer customized solutions that can meet the unique needs of businesses and individuals. Our steel workshop buildings are designed to accommodate large-scale machinery and equipment, and we provide insulation and ventilation systems to ensure the comfort of workers.

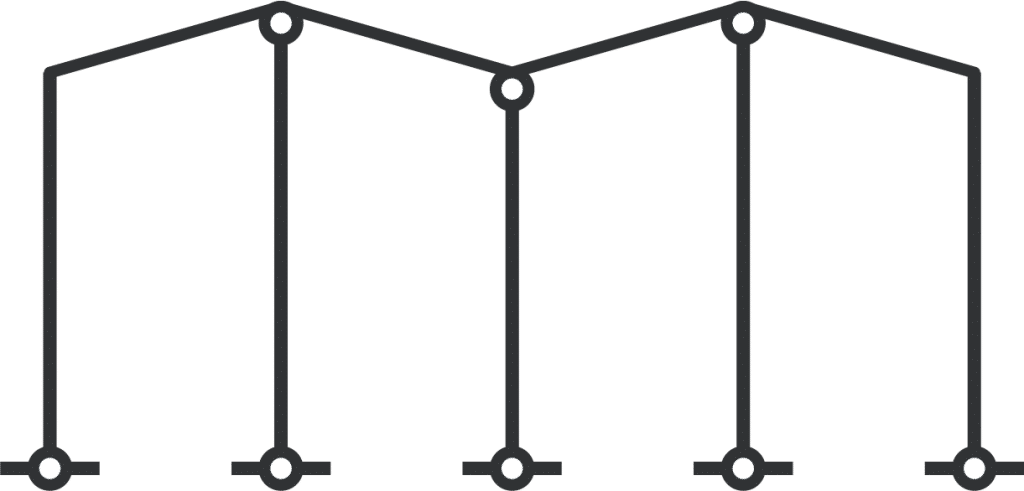

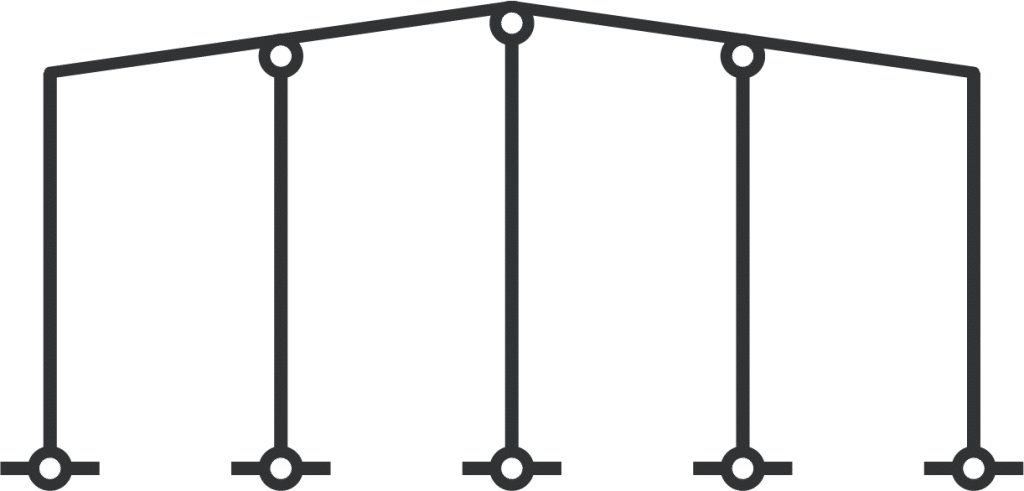

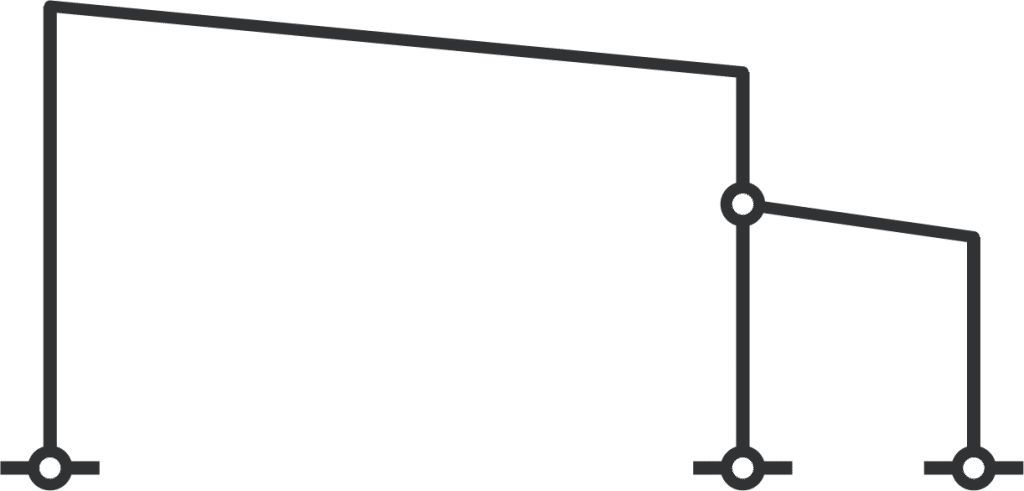

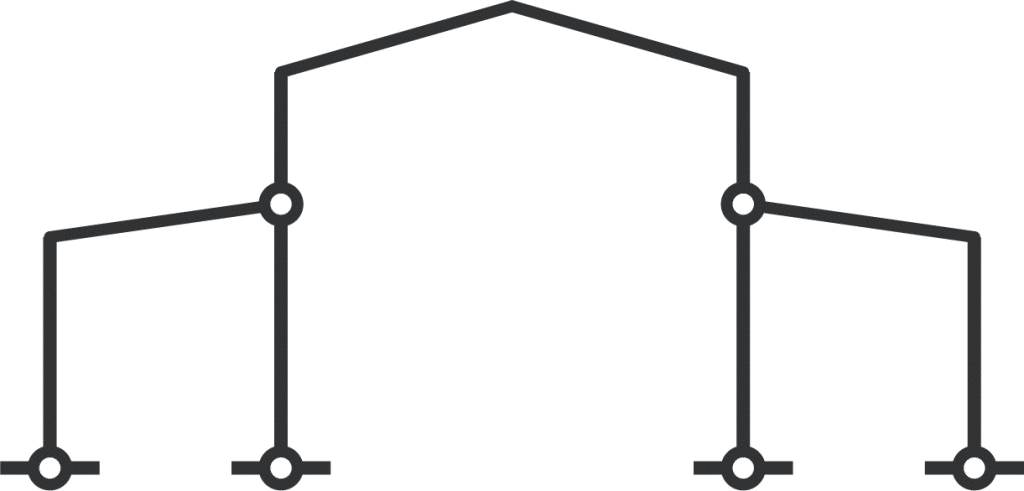

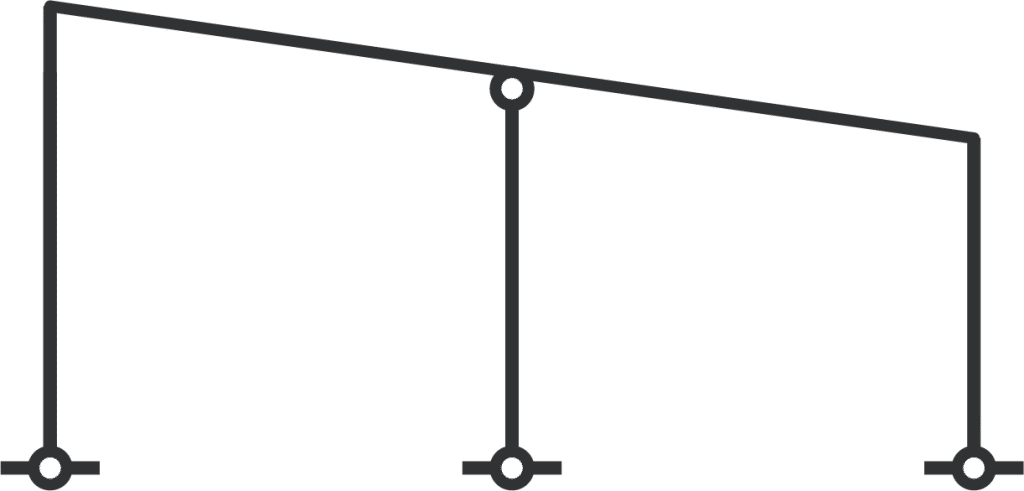

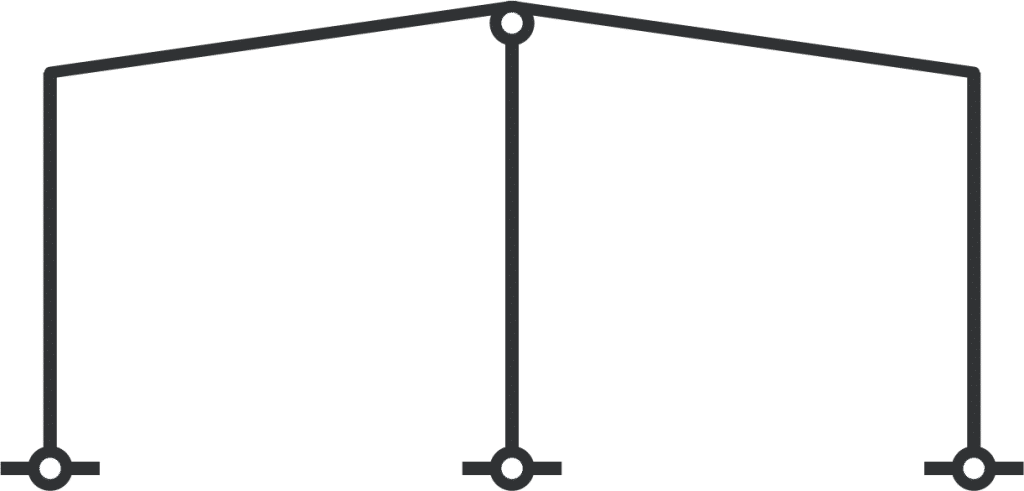

Single-span Overhanging Eaves Single-span Double-sloped Roofs Multi-span Multi Double-sloped Roofs Multi-span Double-sloped Roofs High-low Span Single-sloped Roofs High-low Span Double-sloped Roofs Double-span Single-sloped Roofs Double-span Double-sloped Roofs

K-HOME is the most efficient, reliable, and high-quality steel building supplier in the market. We offer a wide range of products that include workshop buildings, which are meticulously designed to meet a variety of needs. Our prefabricated metal buildings have large spans that maximize space utilization, and our on-site seminar buildings reduce building timetables and costs.

Moreover, we ensure that our workshop structures are adapted to the local architectural specifications and geographical location. All of our steel workshops are designed to withstand wind and snow loads specific to your location. With a focus on function and space utilization, we use a multi-functional design approach to maximize available space while providing necessary functions such as electrical installation, pipeline systems, elevated heavy-duty machines, and high-quality jewelry that meet different standards.

At K-HOME, we provide practical, sustainable, and affordable solutions for businesses and individuals who require multi-functional and durable structures. Our professional and experienced employees work diligently to update your information and provide the best possible solution to meet your needs and requirements. Contact us today to discuss your specific requirements, and our team will provide you with the best solution that meets your needs.

More Steel Building Kits

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.