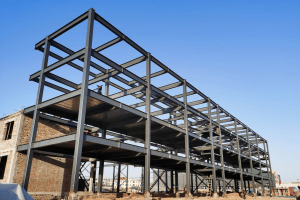

Multi-Story Steel Building

Used in Industrial, Commercial, and Residential Buildings.

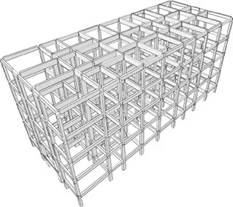

With the rapid development of the economy, Multi-Story Steel Building can be seen everywhere in cities, and the appearance is particularly pleasing to the eye. The multi-story steel structure generally adopts a frame-type structural system, also known as a multi-story steel frame structure.

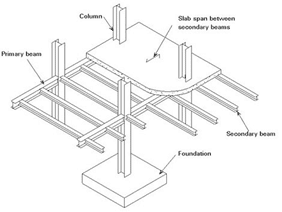

Multi-story steel structures are generally composed of columns, steel beams, floor structures, support structures, wall panels, or wall frames. The number of layers is ≤10, and the height is ≤60m. The existence of multistory steel structures has brought great changes to our daily life. The following is a brief introduction to the multi-story steel structure buildings.

Multi-Story Steel Building Gallery>>

1. Design

K-Home is a comprehensive company that can provide one professional design. From Architectural drawings, steel structure layout, the installation guide layout, etc.

Every designer in our team has at least 10 years of experience. You don’t have to worry about the unprofessional design affecting the safety of the building.

A professional design can help you save costs because we clearly know how to adjust and give you the most cost-effective solution, few companies will do this.

2. Manufacturing

Our factory has 2 production workshops with large production capacity and short delivery time. Generally, the lead time is around 15 days. All production is an assembly line, and each link is responsible and controlled by professional personnel. The important things are rust removal, welding, and painting.

Rust Remove: The steel frame uses shot blasting to remove the rust, reaching the Sa2.0 standard, Improve the roughness of the workpiece and the adhesion of the paint.

Welding: welding rod we choose is a J427welding rod or J507welding rod, they can make welding seam without defects.

Painting: The standard color of the paint is white and gray(customizable). There are 3 layers in total, the first layer, the middle layer, the face layer, the total paint thickness is around 125μm~150μm based on the local environment.

3. Mark and Transportation

K-Home attaches great importance to mark, transportation, and packaging. Although there are many parts, in order to make you clear and reduce the site work, we mark each part with labels and take photos.

In addition, K-Home has rich experience in packing. the packing location of the parts will be planned in advance and the maximum usable space, as far as possible to reduce the number of packings for you and reduce the cost of shipping.

4. Detailed Installation Service

Before you received the cargo, a full set of installation files will be sent to you. You can download our sample installation file below for your reference. There are detailed house parts sizes, marks.

Also, If this is the first time for you to install the steel building, our engineer will customize a 3d installation guide for you. You don’t need to worry about the installation.

WHY CHOOSE KHOME AS YOUR SUPPLIER?

K-HOME is one of the trusted factory manufacturers in China. From structural design to installation, our team can handle various complex projects. You will receive a prefabricated structure solution that best suits your needs.

You can send me a WhatsApp message (+86-18338952063), or send an email to leave your contact information. We will contact you as soon as possible.

Details Of Multi-Story Steel Building

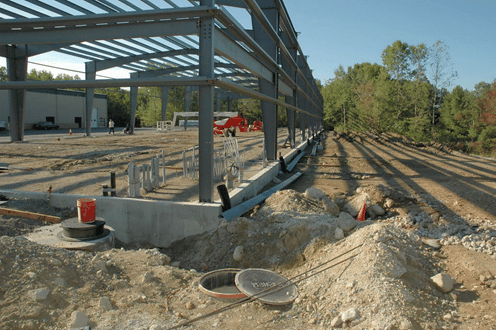

Floor Structure

General requirements for the foundation of multi-story steel structure buildings, the foundation of the same structural unit should not be partly natural foundation, partly artificial foundation, nor should two or more types of soil layers with different properties be used as the bearing layer of the ground.

When the foundation floor or pile ends of high-rise buildings of structural buildings are close to or partially enter the inclined surface of the underlying soil layer, it is advisable to deepen the foundation or increase the length of the pile, so that the bottom of the foundation of the pile ends are all in the same lower bedroom, so as to avoid the possibility of producing inconsistencies. Settled evenly.

The steel structure building site cannot avoid the edged sections of rivers, lakes, and rivers that may slip or crack during earthquakes. Targeted foundation stabilization measures should be taken, and the foundation’s stability should be strengthened. If there is a liquefiable soil layer within the range of the foundation bearing layer under the foundation of the high-rise building in the earthquake area, measures should be taken to eliminate the adverse effect of the liquefaction of the soil layer on the superstructure.

To completely eliminate the adverse effects of the liquefaction and subsidence of the foundation soil layer on the steel structure building, one of the following measures can be selected according to local conditions:

1: When adopting densification methods, such as vibrating method, sand pile compaction method, dynamic compaction method, etc., when reinforcing the foundation, it should be treated to the lower interface of the liquefaction depth of the soil layer, and the standard penetration hammer number of the soil layer after treatment should be less than The measured value should be greater than the critical value of soil liquefaction.

2: When a deep foundation is used, the depth of the bottom surface of the foundation buried in the stable soil layer below the liquid depth should not be less than 500mm.

3: When the steel structure building adopts the pile foundation, the length of the pile end extending into the stable soil layer below the liquefaction depth shall be calculated and determined according to the bearing capacity of the pile, and shall not be less than the following values. Liquefiable soil.

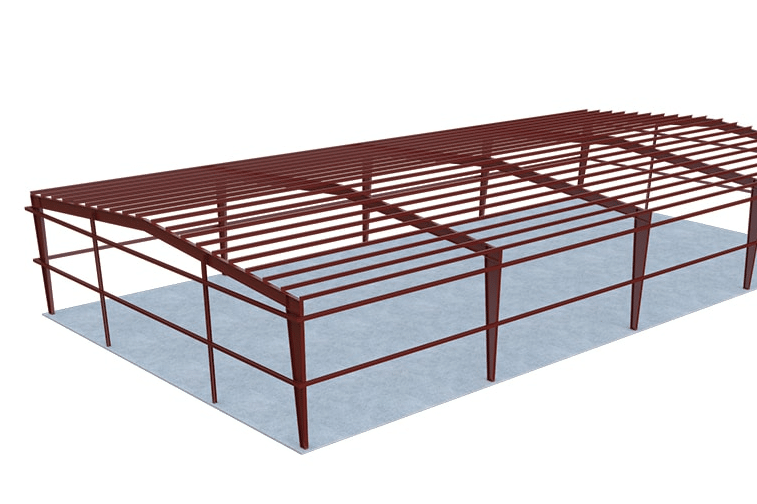

Steel Frame Structure System

Due to the excellent comprehensive benefit index of steel structures, in recent years, multi-story steel structure buildings have also been widely used. Its structural forms mainly include multi-layer frame, frame-support structure, frame tube, suspension, giant frame, etc.

Frame structure features — flexible plane layout, uniform stiffness distribution, small lateral stiffness, large ductility, long natural vibration period, and insensitivity to earthquake action.

Cylinder structure features — the cylinder structure formed by the frame, the inner cylinder and other vertical members mainly bear the vertical load, the outer frame mainly bears the lateral load, and the rigid floor structure acts as the transverse partition of the frame cylinder.

Steel Frame Shear Wall System

Steel Frame Shear Wall System is composed of the embedded steel plate and beam-column frame. The embedded steel plate only bears the horizontal shear force transmitted along the frame beam and column and does not bear the vertical load of the structure. If the steel plate wall is continuously arranged along the height direction of the building, under the action of horizontal load, its stress situation is similar to that of the web of a cantilever beam fixed vertically to the ground. In the frame-steel plate shear wall structure, the frame is equivalent to the flange of the cantilever beam, the shear wall is equivalent to the web of the cantilever beam, and the frame beam is equivalent to the transverse stiffener of the cantilever beam web. The commonly used folded plate shear wall rib is perpendicular to the beam and parallel to the column.

Advantages and disadvantages of steel frame shear wall structure

The steel frame shear wall structure has the advantages of being lightweight, which can reduce the earthquake effect and reduce the cost of the foundation; it can provide more space for use; when the horizontal stiffness of the structure is the same, the amount of steel used is less than that of the pure frame structure.

At the same time, because the steel frame shear wall itself only bears the horizontal load, the vertical load is completely borne by the surrounding frame columns. The steel frame shear wall structure fully meets the seismic design requirements of the first anti-seismic defense line with a low axial compression ratio; the setting of the steel frame shear wall can alleviate the ductility of the beam-column joint area.

The steel frame shear wall can continue to bear the load after buckling (thin plate) or post-yielding buckling (thick plate), the structure not only makes the frame have good ductility but also provides damping energy dissipation capacity by the plastic development of the steel itself. The ductility of concrete structures is greatly increased. The steel frame shear wall structure can ideally meet the three-level seismic and two-stage design

Although it has the above characteristics and advantages, the research of steel frame walls is limited to the theoretical aspect, and no design criteria are proposed.

Advantages of Steel Structure Multi-story Building:

1. Beautiful and practical: The lines of the multi-story steel structure building are simple and smooth, with a modern sense. Colored wall panels are available in a variety of colors, while other materials can be used for the walls, allowing for greater flexibility.

2. Simple construction and short construction period: all the components needed to build a multi-story steel structure building are prefabricated in the factory, and only need to be simply assembled on the construction site, thus greatly shortening the construction period, a building of 6000 square meters, The basic installation can be completed in just 40 days.

3. Reasonable cost: The multi-story steel building is light in weight, so the basic cost can be reduced, the construction speed is fast, and it can be completed and put into production as soon as possible. The comprehensive economic benefit is much better than that of concrete structure buildings.

4. Durable and easy to maintain: multi-story steel structure buildings can resist harsh weather, and only need to do simple maintenance.

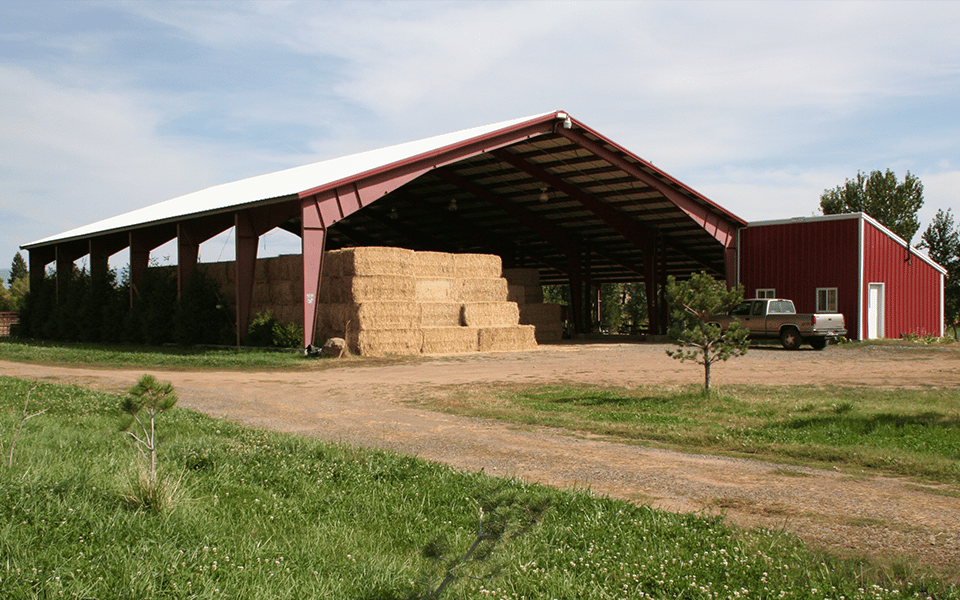

5. Wide range of uses: steel structure buildings can be applied to factories, warehouses, office buildings, gymnasiums, hangars, etc. It is not only suitable for single-story long-span buildings, but also for the construction of multi-story steel structure buildings or high-rise steel structure buildings.

Steel Building Solutions

K-home serves prefabricated industrial, agricultural, and commercial buildings. We can provide you with the most efficient design and construction solutions for the fast and smooth construction of your steel building project.

Blogs Selected for You

No matter where you are in the build process, we have the resources, tools, and guidance to ensure your project is a true success.

View All Blogs >

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.