Pre Engineered Building Construction

Pre Engineered Metal Building / Pre Engineered Steel Buildings / Pre Engineered Building Structure / Pre-Engineered Heavy Steel Building / Pre Engineered Structures

What is the Pre Engineered Building Construction?

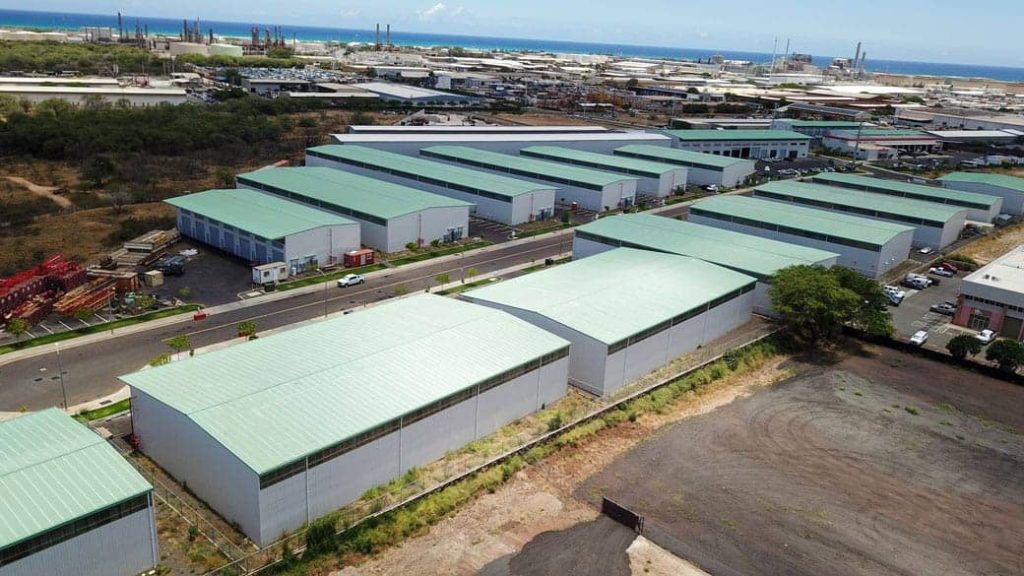

In the rapidly evolving construction world, efficiency and cost-effectiveness are more critical than ever. If you are a factory owner, warehouse manager, or involved in the building industry, it’s time to consider the revolutionary advantages of pre engineered building construction. Pre engineered building construction is a new form of building construction, made from an organized combination of custom-designed structural steel members to meet users’ architecture and engineering requirements. PEB steel structure involves sub-structure or members in a building made from structural steel, linked and fixed by bolts, and rivets. Pre engineered steel structures are fabricated in the factory and assembled on-site. They are steel structures built over a structural concept of primary structure, secondary structure, roof, wall sheeting connected, and various other building components.

WHY CHOOSE KHOME AS YOUR SUPPLIER?

K-HOME is one of the trusted pre engineered building suppliers in China. From structural design to installation, our team can handle various complex projects. You will receive a pre engineered building solution that best suits your needs.

You can send me a WhatsApp message (+86-18338952063), or send an email to leave your contact information. We will contact you as soon as possible.

Pre Engineered Building Construction Advantages

Pre engineered building construction has multiple advantages, making it a widely used building solution in both industrial and commercial fields. The following are the main advantages of pre engineered building construction:

1. Cost Saving: Factory production and standardized design effectively control the cost of PEB. By mass production and reducing on-site operations, material and labor costs can be significantly reduced. The PEB steel structure price per square meter can be 25%-30% lower than conventional steel buildings. Site erection cost is low because of faster erection times and easier erection process. In addition, the pre engineered building construction process has also reduced on-site waste and unnecessary expenses.

2. Quick Erection: All steel components are fabricated at the factory and linked by bolts at the site. So the erection process is fast, step by step, easy to install, and requires simple equipment. 60% less construction time is required compared with the traditional R.C.C(reinforced concrete) building. Pre engineered building construction can be put into use faster, meeting the rapid expansion of enterprises or urgent project needs.

3. Flexibility: Pre Engineered Buildings are flexible in any requirement of design, including building dimensions, structural forms, exterior styles, etc. What’s more, pre engineered building construction is easy to expand in the future and also economically with low transportation costs.

4. Quality Control: Since the components of PEBs are produced in a controlled factory environment, the quality of materials and construction is consistently high. This results in buildings that are not only durable but also meet strict quality standards. The on-site assembly process of pre engineered building construction will be simpler, but strict construction standards must still be followed to ensure the overall quality, reliability, and stability of the building.

5. Reduced Maintenance: Pre Engineered Buildings are designed with durability in mind. The materials used are often resistant to common issues such as rust and corrosion, which means your building will require less maintenance over its lifespan. Meanwhile, the structure of PEB is simple and clear, making it easy for daily maintenance and repair. This translates to long-term savings and fewer disruptions to your operations.

6. Energy Efficiency: Nowadays, pre engineered building construction are the green solution for the environment with CO2 reduction, energy efficiency, and recyclability. PEB is made of high-strength steel and high-quality materials, with excellent durability and corrosion resistance. This enables PEB to maintain stable performance over the long term and reduce maintenance costs. Meanwhile, the PEB steel structure is simple and clear, making it easy for daily maintenance and repair.

PEB steel structure Manufacturer

K-HOME is a leading PEB steel structure manufacturer, dedicated to providing top PEB solutions worldwide. K-HOME is not limited to providing pre engineered buildings themselves, but also provides related building materials, lifting equipment, overall planning services, etc. Committed to meeting customers’ diverse needs in the field of construction. From initial design consultation to after-sales service, K-HOME’s team of engineers and project managers ensure seamless communication and timely and effective resolution of customer issues.

Pre Engineered Building Components

pre engineered buildings consist of the following components:

Primary Structure / Main Frames: Primary members are the main load-carrying and support members of a pre-engineered building. The main frame members include columns, rafters, and other supporting members. The shape and size of these members vary based on the application and requirements. Usually made from hot-rolled steel sections (such as H-beams, I-beams, etc.). They are precisely processed and prefabricated in the factory and then transported to the site for assembly.

Secondary Structure / Cold Formed Members: Secondary structural framing refers to purlins, girts, eave struts, wind bracing, flange bracing, base angles, clips, and other miscellaneous structural parts. Purlins, girts, and eave struts are cold-formed steel members that have a minimum yield strength of 345 MPa (50,000 psi) and will conform to the physical specifications of GB/ISO/CE or equivalent.

Roof & Wall Panels: Common roof and wall panel materials in pre engineered building construction include color steel plates, profiled steel plates, etc., which have good waterproof and thermal insulation properties. Standard steel panels are 0.3,0.4 0.5 mm or 0.6 mm thick and have a minimum yield strength of 345 MPa. Steel panels are hot-dipped and galvanized with zinc or zinc-aluminium coating. The base material is pretreated, before applying a corrosion-resistant primer and top coat. The combined thickness of the painted film is 25 microns on the front side and 12 microns on the reverse side.

Other Building Accessories: Other building accessories include anchor bolts, and fasteners(bolts, nuts, turnbuckle, expansion bolts). These pre engineered steel buildings can be provided with different structural and non-structural additions such as skylights, wall lights, turbo vents, ridge ventilators, louvers, roof monitors, doors & windows, trusses, mezzanine floors, fascias, canopies, crane systems, insulation etc., based on the customer’s requirements.

Applications of Pre Engineered Buildings

Pre engineered building construction are the most flexible solutions for contractors and owners. With the advantages of low cost, high durability, perfect quality control and fast erection. The application of PEBs:

Industrial: Factory, Workshop, Warehouse, Cold Storage, Steel Mill, Assembly Plant;

Commercial: Showrooms, Supermarket, Offices, Shopping Center, Exhibition Halls, Logistic Centers, Multi-pupose Buildings;

Public: Schools, Hospitals, Conference Halls, Laboratories, Museums, Stadiums;

Others: Farms, Utility Shelters, Pump Stations, Hangars;

Pre Engineered Buildings Services

After over 20 years engineering experience on abroad, our company have completed several steel structure project cases in African countries, like Tanzania, Rwanda, Burundi, Botswana etc. Our business are expanding to more countries worldwide this year, such as Southeast Asia, the South American countries etc.

Our factory has 2 production workshops with large production capacity and short delivery time. generally, the lead time is around 15 days. All production is assembly line, and each link is responsible and controlled by professional personnel. The important thing is rust remove, welding and painting. Rust Remove:The steel frame uses shot blasting to remove the rust, reaching the Sa2.5 standard, Improve the roughness of the workpiece and the adhesion of the paint. Welding: welding rod we chooses is J427 welding rod or J507 welding rod, they can make welding seam without welding defects.such as Cracked, Bulge. Painting: The standard color of the paint is white and gray. There are total 3 layers, fist layer, middle layer, the face layer, the total pain thickness is around 125μm~150μm based on local environment.

Mark and Transportation: There are many parts, in order to make you clear and reduce the site work, we’ll mark each part with labels and take photos. In addition, we also have rich experience in packing. We will plan in advance. The packing location of the parts and the maximum use space, as far as possible to reduce the number of packing for you, and reduce the cost of shipping.

Installation: Before you received the cargo, we’ll prepare and send a full set installation files, there are detailed house parts size, marks, also, I know you may the first time to do pre engineered building construction, we can custimized 3d installation guide for you. You don’t need to worry about the installation. What’s more, we have a professional pre engineered building construction team in Africa, so you have no language barriers and can save the cost.

Price: Our price is reasonable and moderate, the profit of this pre engineered building industry is relatively transparent, as we know, the price doesn’t only mean the good cost, it comes with a lot of service, like free professional design, good quality, delivery on time, installation guide, flexible payment term and after self-service. We should keep certain profit to ensure the business well and make sure the safety of capital of every customers.

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.