Pre Engineered Building

Pre Engineered Metal Building / Pre Engineered Steel Buildings / Pre Engineered Building Structure / Pre-Engineered Heavy Steel Building / Pre Engineered Structures

What are the Pre Engineered Buildings?

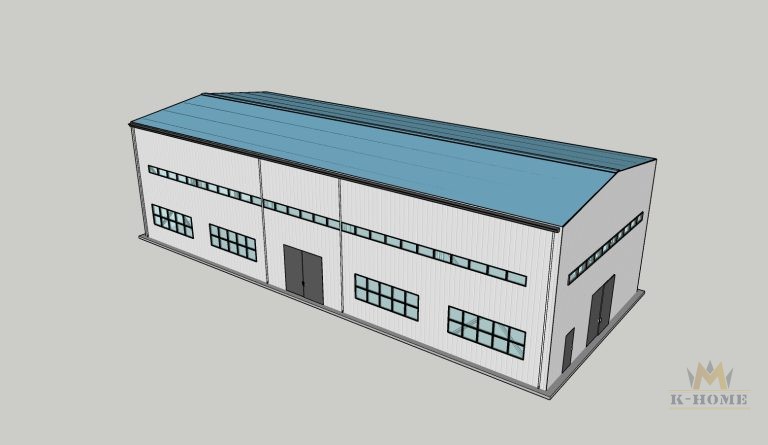

Pre-engineered buildings (PEBs) are structural systems that are designed and prefabricated before being transported to the construction site for assembly. Designed to precise specifications and built using precision-cut components, these structures are easily transported and assembled on-site, ensuring optimal performance and durability. K-HOME pre engineered building is known for their efficiency, cost-effectiveness, and versatility, providing a sustainable and practical solution to a variety of construction needs. PEBs offer many advantages over traditional construction methods. They can provide significant cost savings due to reduced labor requirements and shortened construction time. Their versatility makes them suitable for a wide range of applications, from industrial warehouses to commercial complexes and even residential buildings. Pre engineered buildings (PEBs) have revolutionized the construction industry, offering speed, efficiency, and customization that are often difficult to match with traditional construction methods.

WHY CHOOSE KHOME AS YOUR SUPPLIER?

K-HOME is one of the trusted pre engineered building suppliers in China. From structural design to installation, our team can handle various complex projects. You will receive a pre engineered building solution that best suits your needs.

You can send me a WhatsApp message (+86-18338952063), or send an email to leave your contact information. We will contact you as soon as possible.

The Advantages of Pre Engineered Buildings

PEBs offer numerous benefits that make them an ideal choice for domestic and international clients. Cost-effectiveness and time efficiency are paramount, with PEBs typically costing less and taking less time to build than traditional building methods. PEBs can reduce construction time by up to 50%. The prefabrication process allows for simultaneous site preparation and component fabrication, resulting in rapid on-site assembly. This efficiency translates into lower labor costs and minimal disruption to the surrounding environment. K-HOME leverages advanced manufacturing techniques to ensure fast delivery and installation, thereby increasing project feasibility.

PEBs offer compelling cost benefits. While the initial investment may be comparable to traditional construction, the shortened construction time, reduced maintenance costs, and energy efficiency translate into significant long-term savings. K-HOME’s economies of scale and efficient production processes further enhance cost-effectiveness for clients.

Durability is another key benefit. PEBs are designed to withstand harsh weather conditions, including strong winds, heavy snow, and seismic activity, making them ideal for areas prone to natural disasters. Additionally, PEBs offer easy expansion and relocation capabilities, allowing businesses to adapt to changing needs without significant disruption or cost.

Sustainability is another key aspect. pre engineered building protect the environment by reducing material waste, increasing energy efficiency, and using recycled materials. K-HOME, in particular, has adopted green building practices, incorporating sustainable materials and designs into its products. Environmental sustainability is also an important consideration in modern construction, and PEB fits in perfectly with green building practices. Using recyclable materials, energy-efficient design, and reducing waste during construction help lower the carbon footprint.

Pre Engineered Building Design

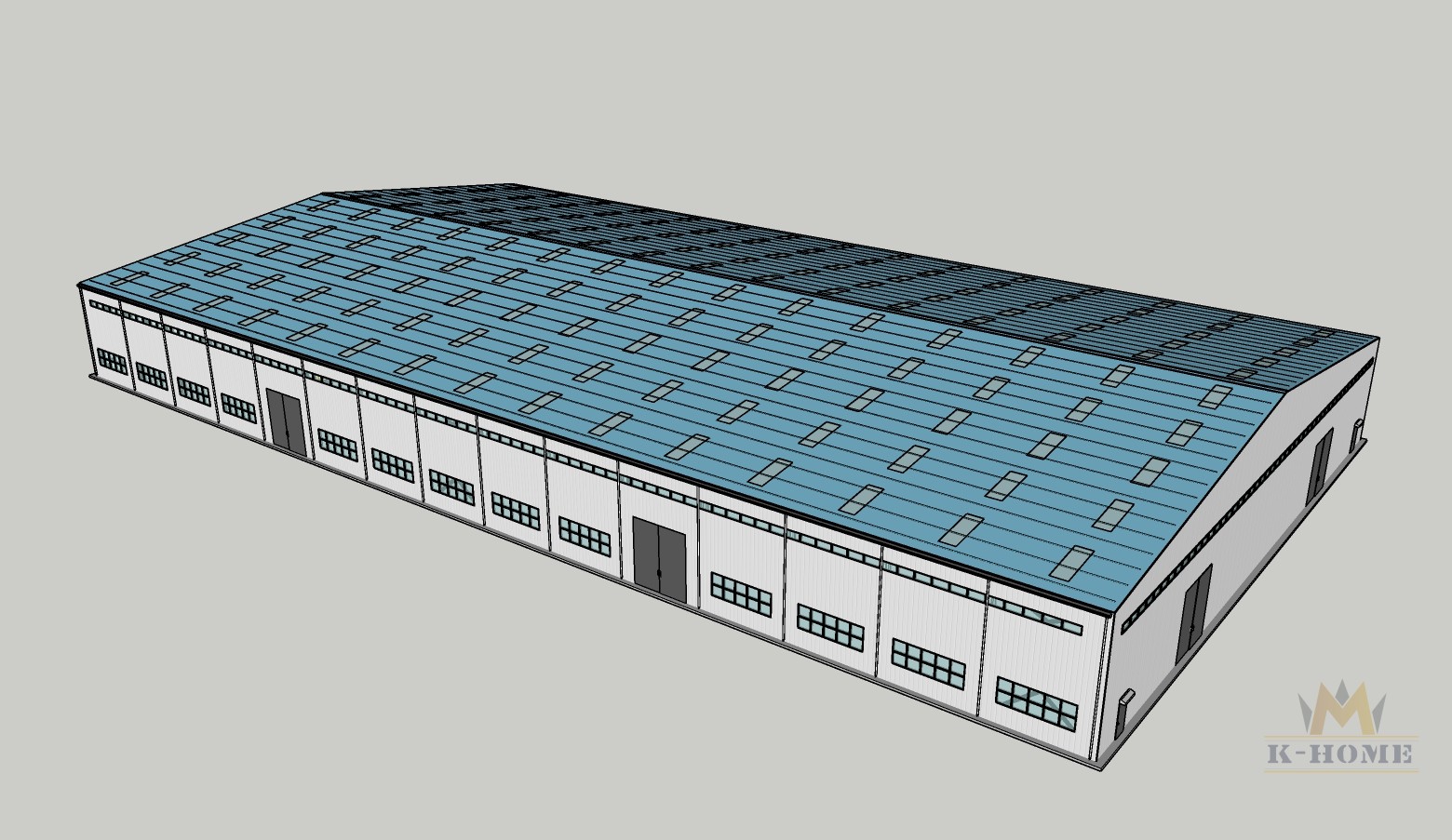

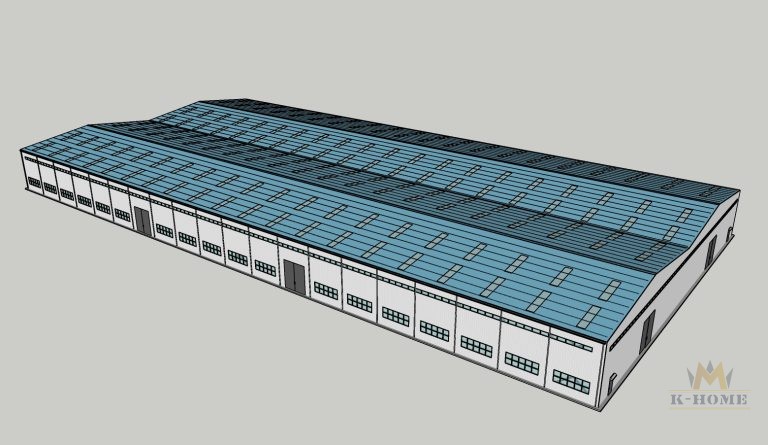

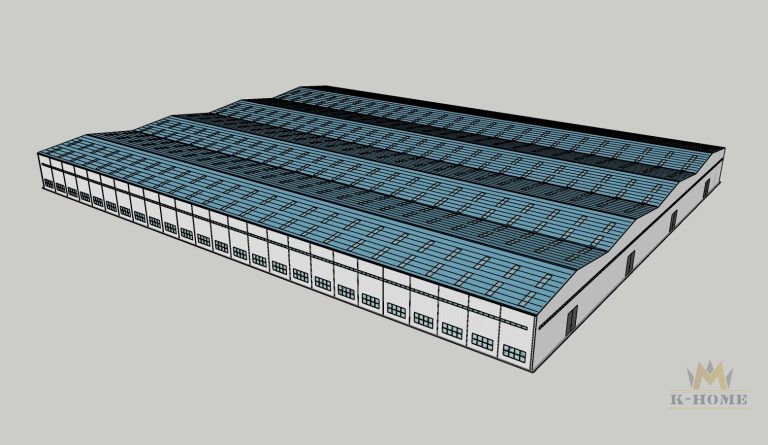

Pre engineered building design is an efficient building design and construction method that utilizes pre-designed, manufactured, and standardized components for rapid assembly and installation on site. One of the most important advantages of PEBs is their design flexibility. They can be customized to specific project requirements and are suitable for various applications from industrial warehouses to commercial complexes and even residential buildings. K-HOME can provide crane-supported pre engineered building with a reasonably optimized steel structure frame. Its design process usually includes steps such as demand analysis, preliminary design, in-depth design, factory production, and on-site installation, aiming to ensure the safety, durability, and functionality of the building.

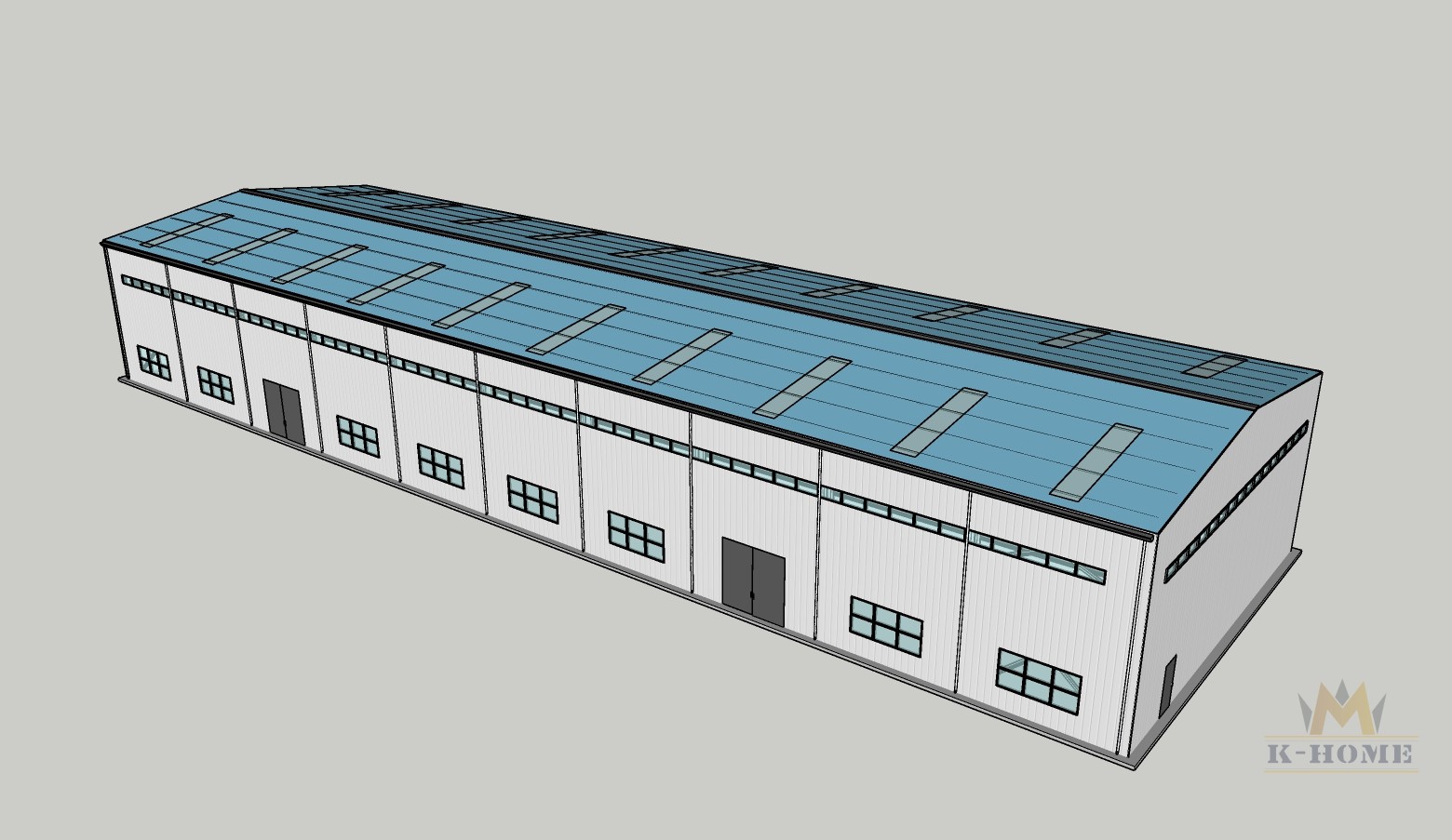

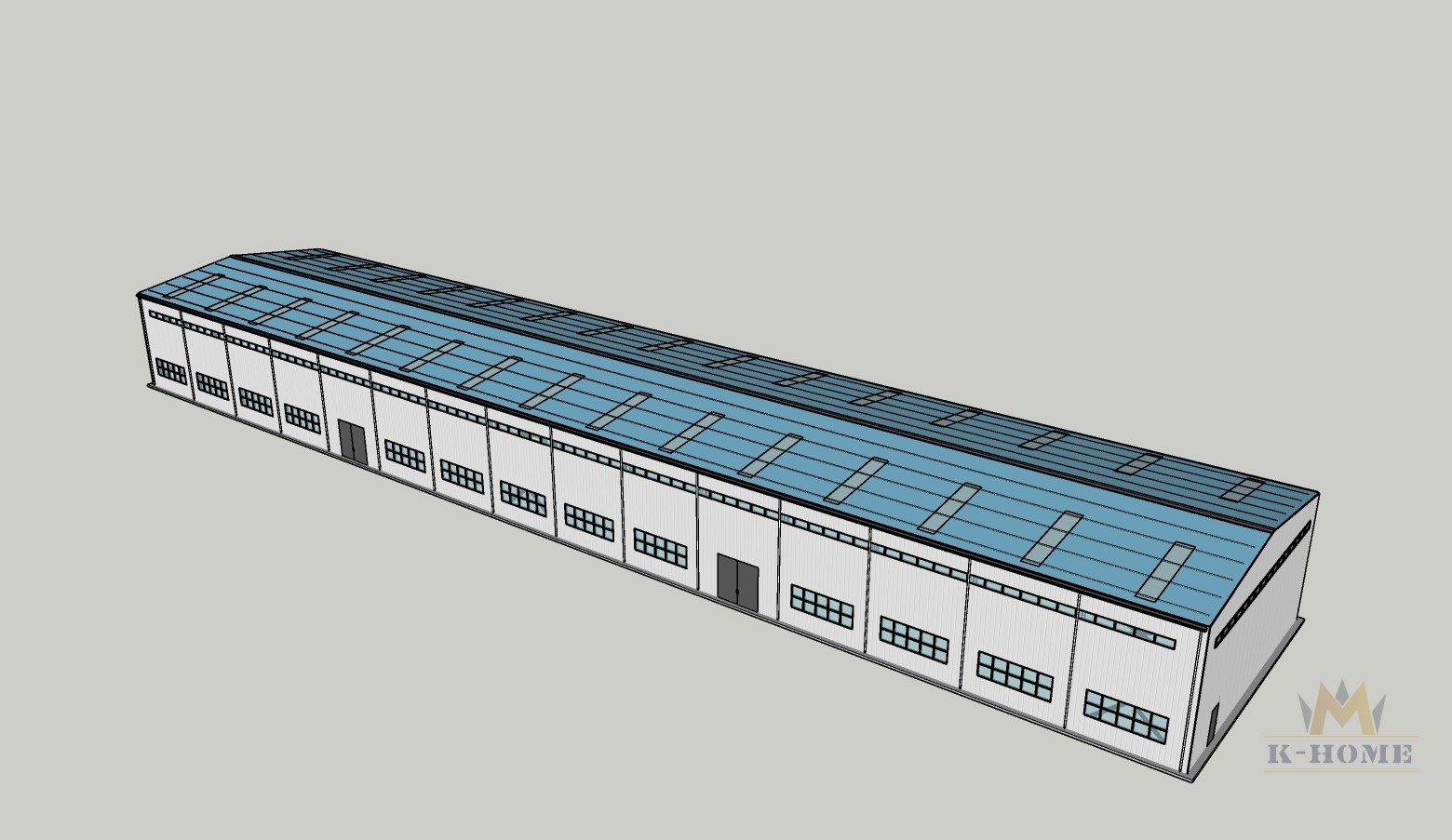

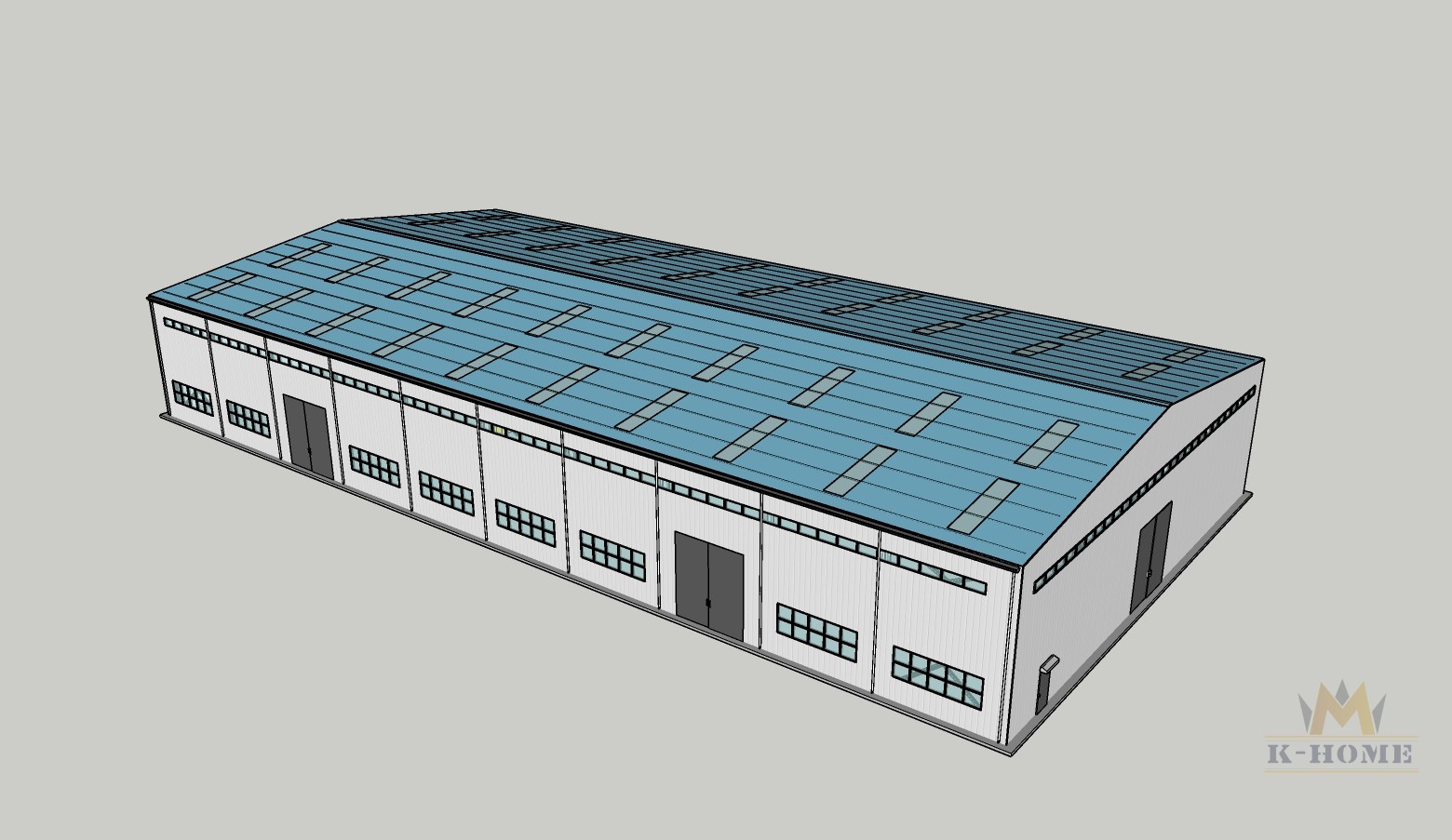

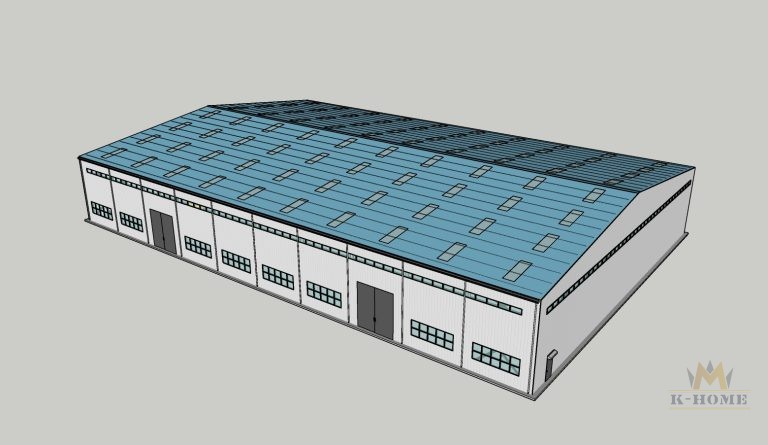

Pre Engineered Building kits

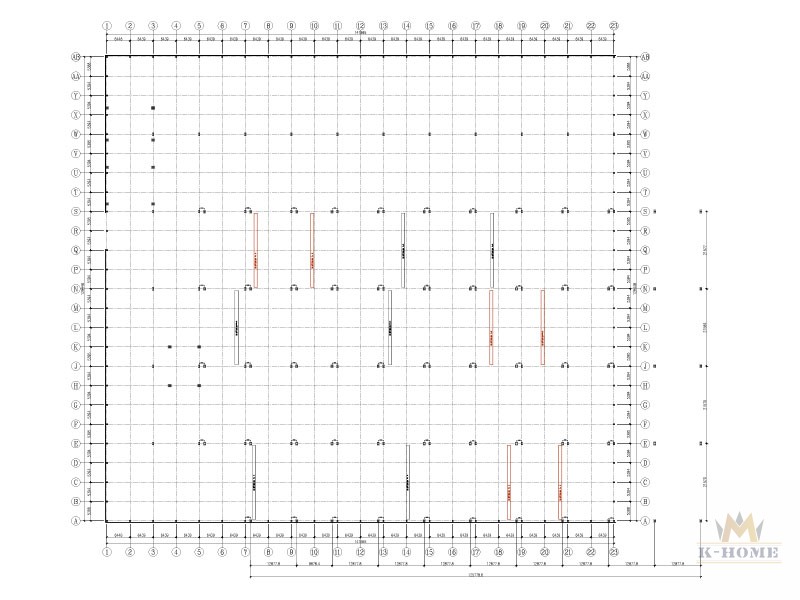

PEB provides a wide range of design flexibility. K-HOME works with customers to customize structures according to specific requirements, whether it is a warehouse, office space or retail store. Some commonly used pre engineered building kit sizes are listed below for your reference. You can click on the picture below to understand the steel usage and approximate layout. In fact, we understand that each project is unique, and we will customize it according to your actual needs, including building size, structural form, material selection, etc.

120×150 Steel Building (18000m²)

Pre Engineered Building Cost

Pre-Engineered Building Cost is affected by many factors, including but not limited to the following aspects:

- Building scale and complexity: The larger the building area and the more complex the structure, the higher the cost is usually.

- Material selection: The cost and performance of different materials vary greatly. Choosing the right material is crucial to controlling costs.

- Design and manufacturing costs: The design and manufacturing process of prefabricated buildings requires professional team and equipment support, and related costs are also an important part of the cost. K-HOME has its own team of professional engineers who can provide you with layout design and installation design, which can save you a lot of money, while saving docking time and reducing time costs.

- Transportation and installation costs: The transportation and on-site installation costs of prefabricated components also need to be taken into account. K-HOME always pays attention to freight fluctuations and tries its best to save you money. At the same time, we can provide you with detailed installation instructions to help you quickly complete the project installation.

As a professional prefabricated building manufacturer, K-HOME can provide detailed quotations and plans according to specific needs to help you better control costs and achieve building goals. K-HOME Pre-Engineered Building Design and its kits have significant advantages in reducing construction costs, improving construction efficiency and quality.

Pre Engineered Building Systems

Pre-Engineered Building Systems is an efficient building solution that integrates design, manufacturing, transportation, and on-site assembly. The Pre-Engineered Building Systems prefabricates major building components such as steel structure frames, enclosure systems, door, and window systems, etc. in factories and assembles them quickly on site, which greatly shortens the construction period and improves building quality and economic benefits.

Pre-engineered building systems are generally composed of the following main components and subsystems:

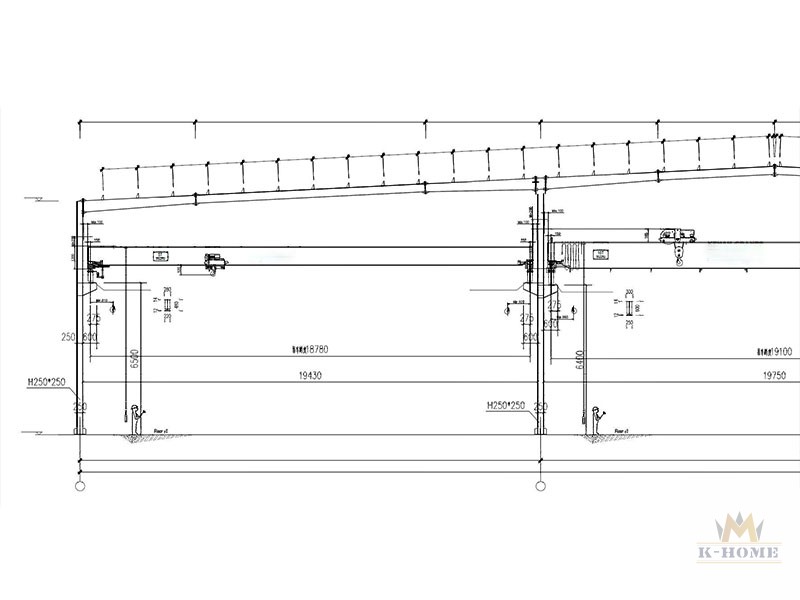

- Steel structure frame: As the main load-bearing structure of the building, it is composed of steel columns, steel beams, and other components with high strength and stability.

- Enclosure system: Including wall panels, roof panels, etc., used to enclose building space and provide insulation, heat insulation, waterproofing, and other functions.

- Door and window system: Doors and windows are customized according to building needs to meet lighting, ventilation, and safety requirements.

- Auxiliary systems: such as stairs, elevators, lighting, ventilation, etc., provide auxiliary functions of the building.

Pre Engineered Building Structure

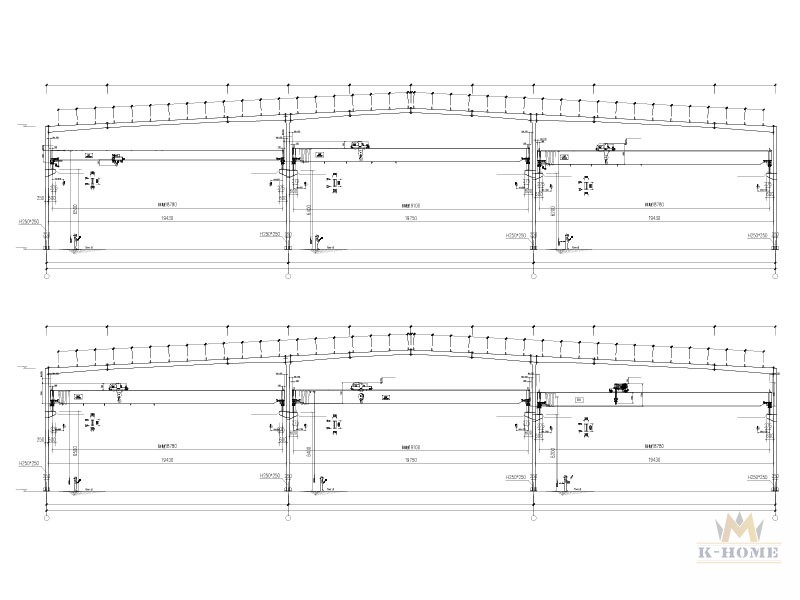

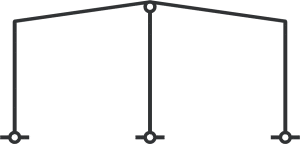

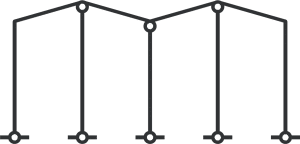

The main load-bearing structure of the pre engineeredbuilding Structure is composed of steel structure, which has the advantages of stable structure, fast construction, and controllable quality. Made of high-strength steel, it has excellent seismic resistance and bearing capacity. Usually, the column spacing is set to 6m, and the maximum clear span of the steel structure can be 30 meters. If it exceeds 30m, it is necessary to add supporting columns in the space to form a 2-span steel structure or a multi-span steel structure.

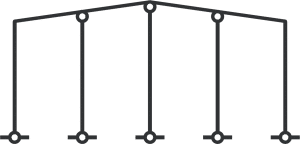

Single-span Double-sloped Roofs Double-span Double-sloped Roofs Multi-span Double-sloped Roofs Multi-span Multi Double-sloped Roofs

Pre Engineered Building Components

Pre-Engineered Building Components refer to the basic units that make up the structure of prefabricated engineeed buildings. These components are usually prefabricated in the factory according to the design drawings and specifications and assembled on-site. The quality of pre engineered building components directly affects the safety and durability of the entire building. Therefore, the quality of raw materials and the accuracy of processing technology need to be strictly controlled during the manufacturing process to ensure that the quality and performance of the components meet the design requirements.

Pre Engineered Building Insulation

Pre engineeed building insulation refers to the thermal insulation measures taken in pre engineered steel building systems. Its main purpose is to improve the energy efficiency of buildings, reduce energy consumption and operating costs, and improve indoor environmental comfort. Thermal insulation of pre engineered heavy buildings can be achieved by adding thermal insulation materials to the enclosure system components (such as wall panels and roof panels). K-HOME recommends that you use rock wool sandwich panels or polyurethane sandwich panels, which usually have lower thermal conductivity and higher thermal resistance values, and can effectively prevent heat transfer and loss.

Pre Engineered Buildings Manufacturer

K-HOME is a leading prefabricated industrial steel structure manufacturer, dedicated to providing top PEB solutions worldwide. K-HOME is not limited to providing pre engineered buildings themselves, but also provides related building materials, lifting equipment, overall planning services, etc. Committed to meeting customers’ diverse needs in the field of construction. From initial design consultation to after-sales service, K-HOME’s team of engineers and project managers ensure seamless communication and timely and effective resolution of customer issues.

Pre Engineered Building Construction

Acceptance stage: After the construction is completed, the building quality acceptance and performance testing are carried out. Ensure that the safety and functionality of the building meet the design requirements and relevant standards.

Throughout the construction stage, K-HOME is always ready to provide you with quality services. We provide not only the PEB steel structure products themselves but also our perfect services. Please contact us to learn more about what K-HOME can provide you.

Design phase: K-HOME will carry out exclusive architectural design and structural design according to your pre engineered building needs and functional requirements, and determine the overall plan and component specifications of the pre engineered steel building system. At the same time, your local geological environment and climate environment will be taken into account to ensure the safety of the structure. All design drawings will be carefully communicated and designed, and then strictly produced according to the drawings.

Manufacturing phase: Prefabricated components are processed and manufactured in the factory according to the design drawings and specifications. At this stage, K-HOME strictly controls the quality of raw materials and the accuracy of processing technology to ensure that the quality and performance of the components meet the design requirements and ensure that there are no errors in installation.

Transportation phase: K-HOME has different transportation channels, and detailed markings will be made before transportation to ensure that there will be no missing or wrong shipments. When you receive the goods, you can also clearly count all the goods. During the transportation of prefabricated components from the factory to the construction site, K-HOME pays great attention to the protection and fixation of the components to avoid damage and deformation.

Installation phase: Assemble and install prefabricated components at the construction site. This stage requires precise measurement and positioning according to the design requirements to ensure that the connection between the components is tight and stable. K-HOME will provide you with very detailed installation drawings to ensure that you can install smoothly.

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.