Pre Engineered Metal Buildings

Pre Engineered Buildings / Pre Engineered Steel Buildings / Pre Engineered Building Structure / Pre-Engineered Heavy Steel Building / Pre Engineered Structures

What Is The Pre Engineered Metal Building?

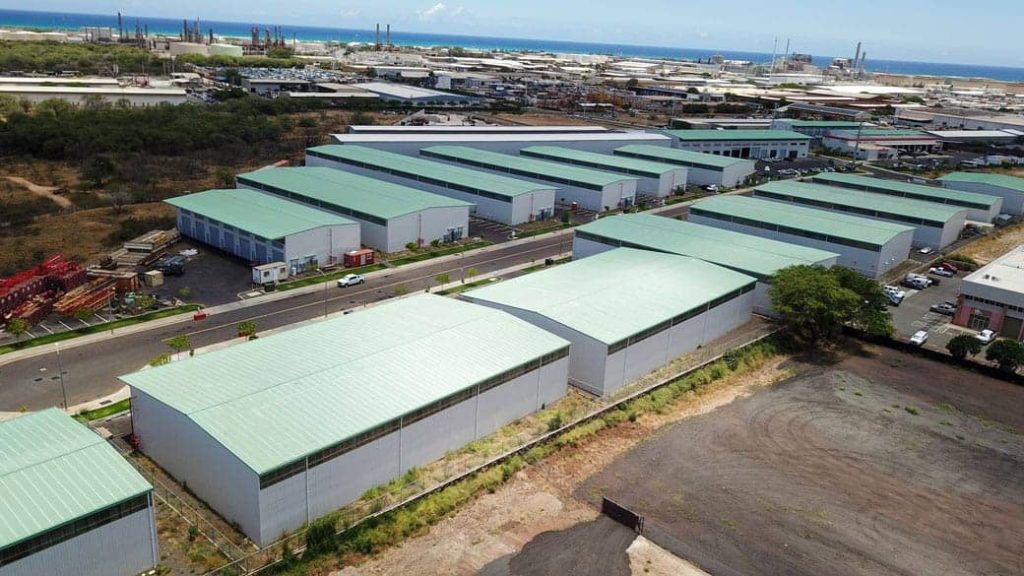

Pre Engineered metal buildings are components, including roof, wall, and frame are pre-manufactured inside the factory and then sent to your construction site by shipping container, the building needs to be assembled on your construction site, that’s why it is named the Pre-Engineered Building (PEB). Pre-engineered metal buildings, as contemporary architectural solutions, offer numerous benefits, it is more cost-effective, customizable, and quick to build and erect than traditional cement brick buildings. Their application has become increasingly prevalent in the current construction industry. If you are considering building a pre engineered metal building, please get in touch with K-HOME for reference designs and quotes

WHY CHOOSE KHOME AS YOUR SUPPLIER?

K-HOME is one of the trusted pre engineered metal building suppliers in China. From structural design to installation, our team can handle various complex projects. You will receive a pre engineered building solution that best suits your needs.

You can send me a WhatsApp message (+86-18338952063), or send an email to leave your contact information. We will contact you as soon as possible.

The Main Structure of Pre Engineered Metal Buildings

The main structure of industrial metal buildings usually includes the following parts:

Steel Beams and Steel Columns: The primary load-bearing elements of pre engineered metal buildings consist of steel beams and steel columns, which typically utilize H-shaped or I-shaped. High-strength steel is commonly employed as the material to guarantee structural integrity and stability. Typical methods for connecting steel beams and steel columns include welding and high-strength bolt connections, among others.

Support System: To improve the overall stability of the PEB steel structure, pre-engineered metal buildings typically incorporate a support system that includes column and roof supports, among others. This support system may consist of cross supports, tie rods, and similar components, with materials generally consistent with those used for steel beams and columns.

Roof and Wall System: The roof and walls of PEBs may be constructed using lightweight materials, including colored steel plates and sandwich panels, which offer excellent thermal insulation, heat retention, and waterproof capabilities.

Foundation: The foundation is an important part of the pre engineered metal buildings, usually using an independent foundation or strip foundation. The design of the foundation needs to consider factors such as the load transmitted from the superstructure and geological conditions.

What Affects the Cost of Pre Engineered Metal Buildings?

Pre engineered metal buildings serve as efficient, cost-effective, and adaptable structures, offering extensive potential applications across diverse sectors. The cost of pre engineered metal buildings will be affected by many factors, such as material prices, design requirements, construction conditions, geographical location, etc., so it is difficult to give a definite specific cost figure.

Material costs constitute a significant portion of the overall expenses, encompassing the prices of prefabricated components such as steel and wall panels. Additionally, labor costs, transportation expenses, foundation engineering costs, as well as fire and corrosion treatment costs, among other related expenditures, will also influence the total cost of pre engineered heavy steel buildings.

It is important to recognize that the costs associated with steel structure buildings may vary over time and according to market conditions, with regional price differences also being a factor. Therefore, a thorough analysis and evaluation should be conducted based on the specific circumstances during the actual construction process. Please contact us to get your quotation.

Pre Engineered Metal Building Design

Load calculation: Various loads need to be accurately calculated before pre engineered metal building design, including dead loads (structure self-weight, roof, and wall material weight, etc.) and live loads (personnel, equipment, snow load, wind load, etc.). According to different use functions and regions, the load values are determined in accordance with relevant specifications.

Structural Analysis: Our engineer will use professional software to conduct a force analysis on the pre engineered metal buildings. Evaluate the strength, stiffness, stability, and other essential criteria of the structure to ascertain the appropriate dimensions and cross-sectional shapes of the components.

Earthquake-Resistant Design: Implement earthquake-resistant design principles in accordance with the seismic fortification level pertinent to the building’s location. Effectively establish earthquake-resistant lines to guarantee structural integrity during seismic events.

Pre Engineered Metal Building kits

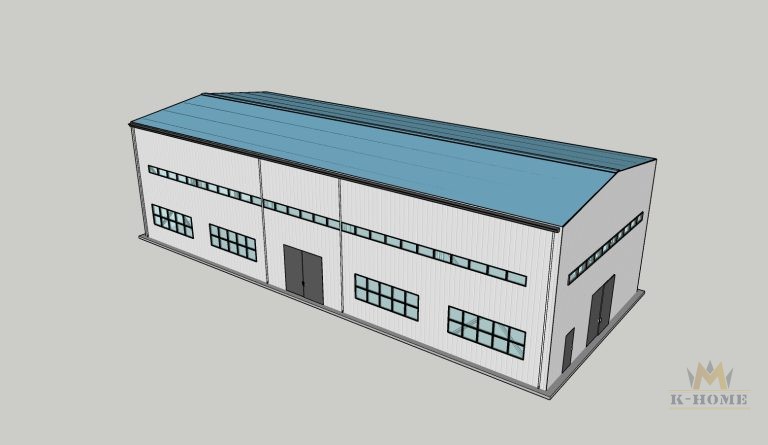

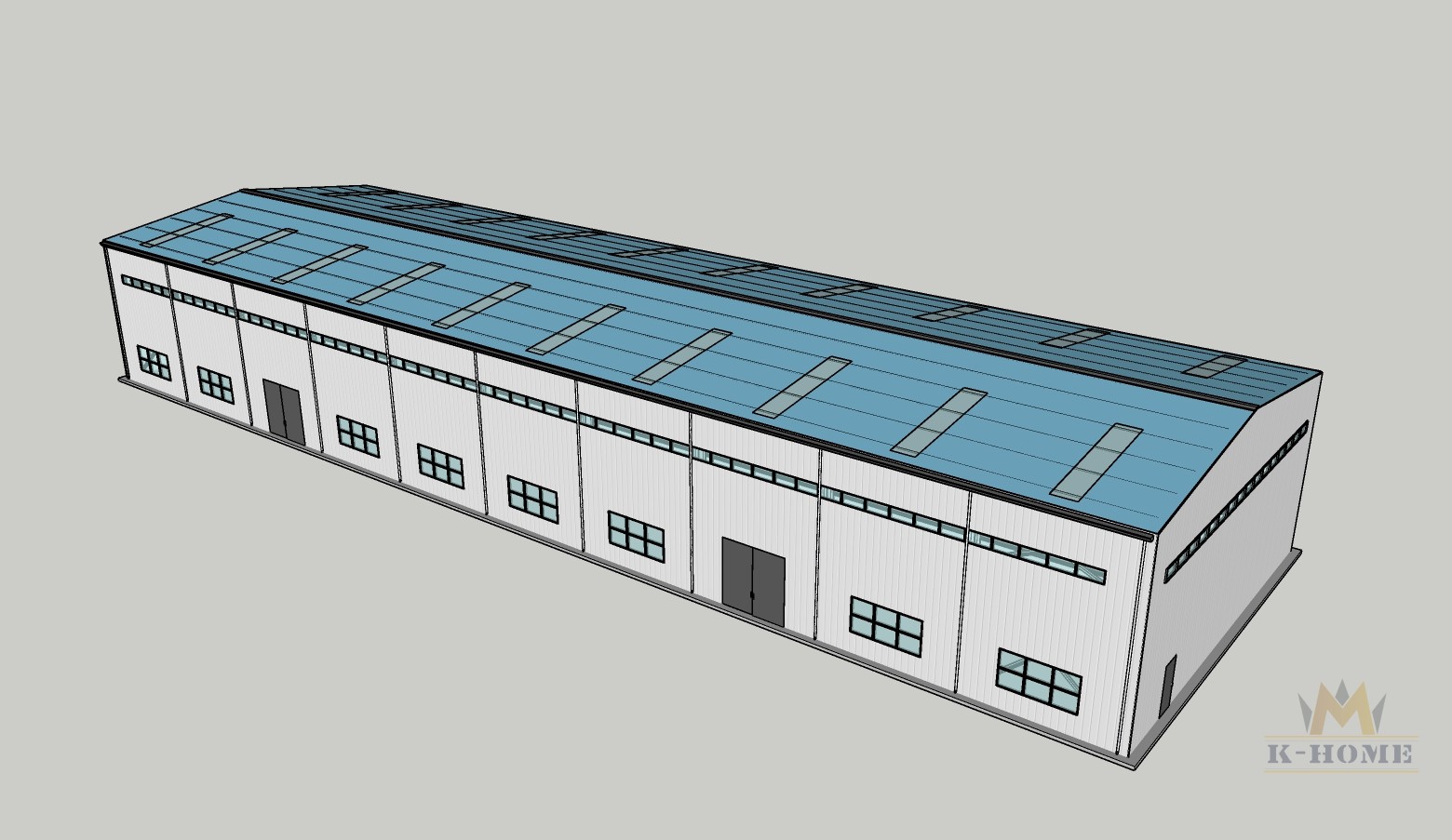

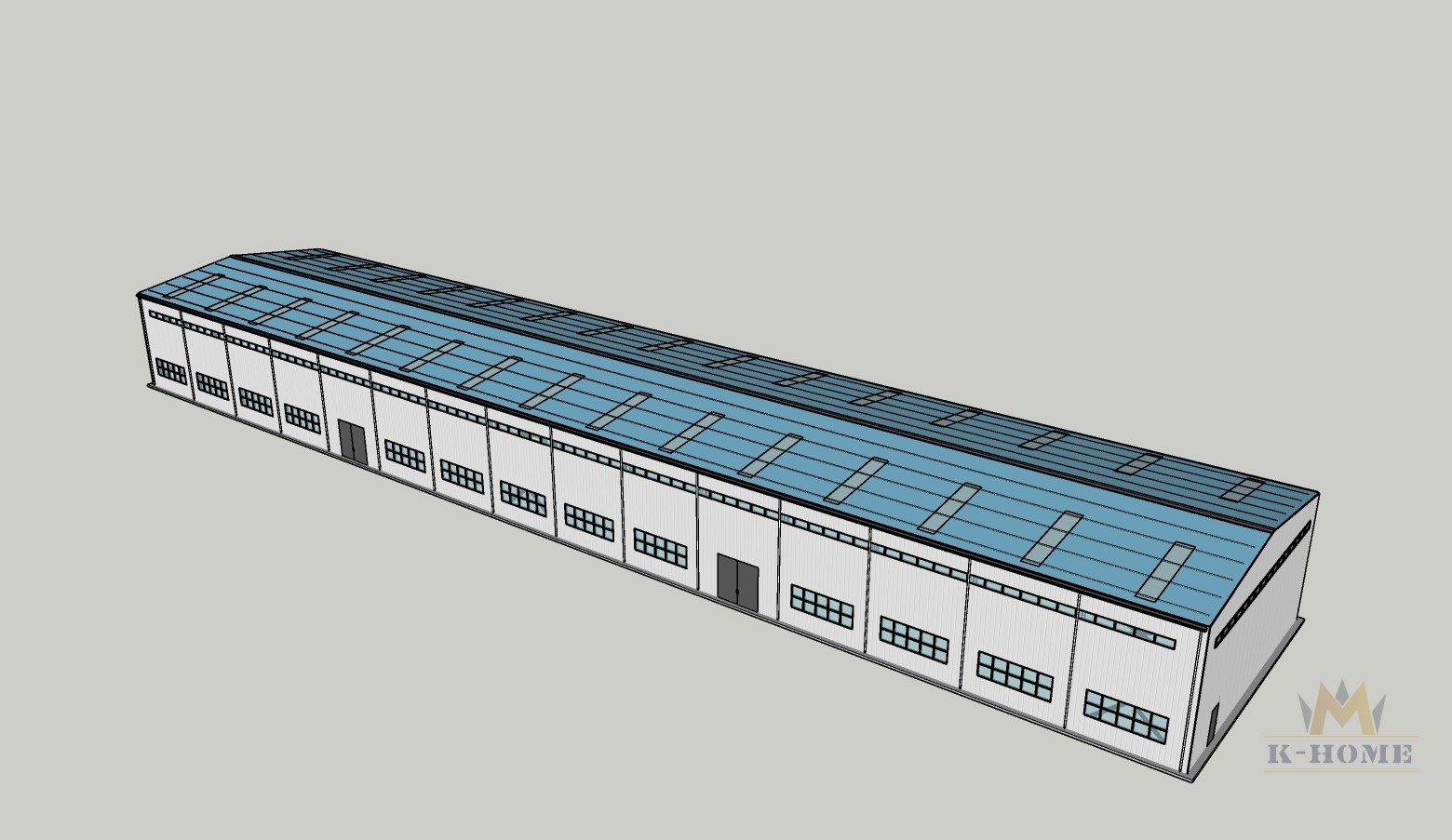

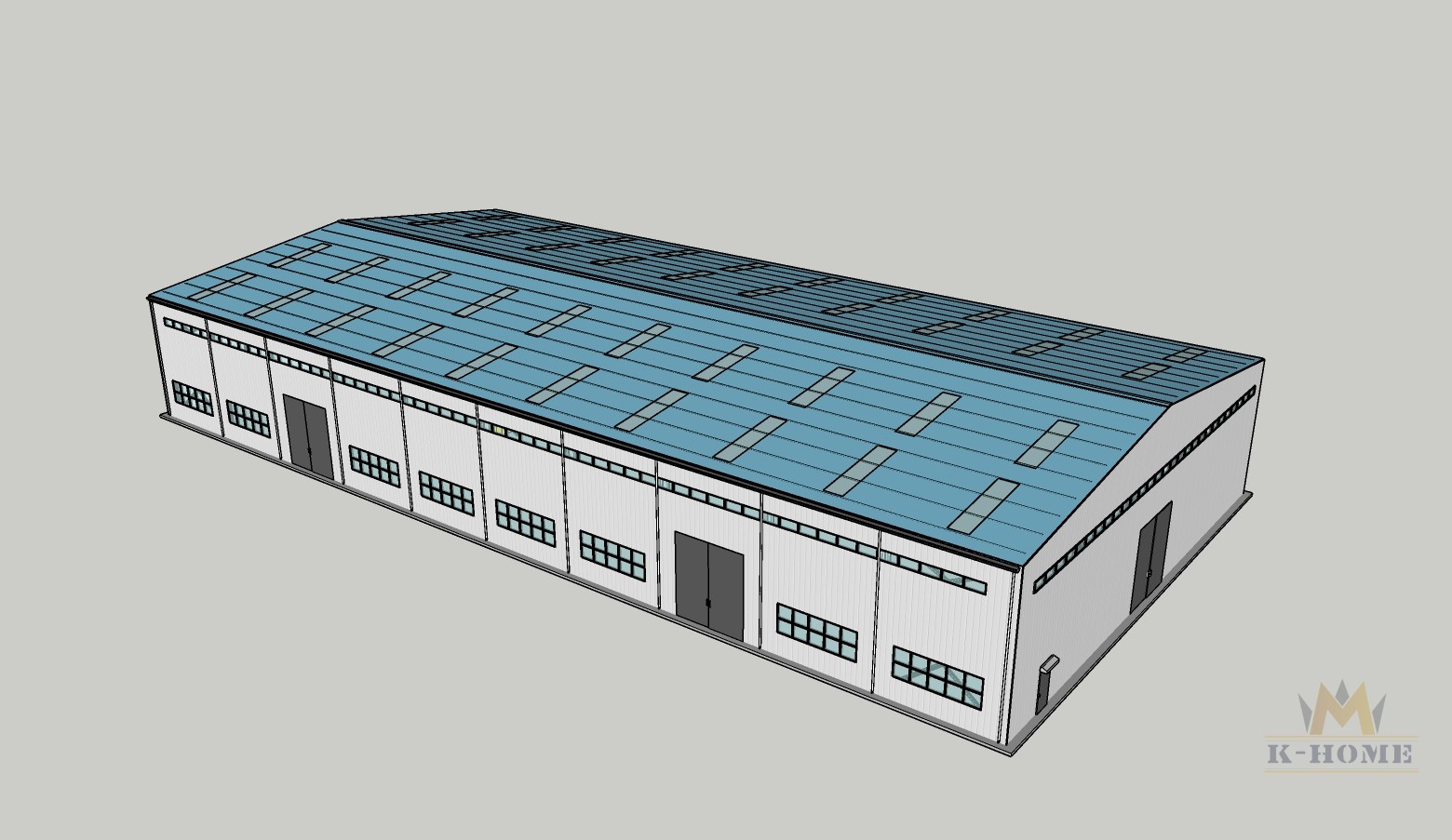

PEB provides a wide range of design flexibility. K-HOME works with customers to customize structures according to specific requirements, whether it is a warehouse, office space or retail store. Some commonly used pre engineered steel building kit sizes are listed below for your reference. You can click on the picture below to understand the steel usage and approximate layout. In fact, we understand that each project is unique, and we will customize it according to your actual needs, including building size, structural form, material selection, etc.

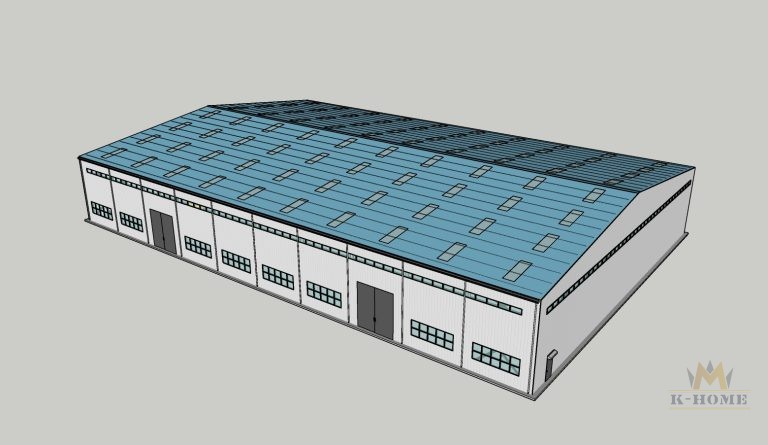

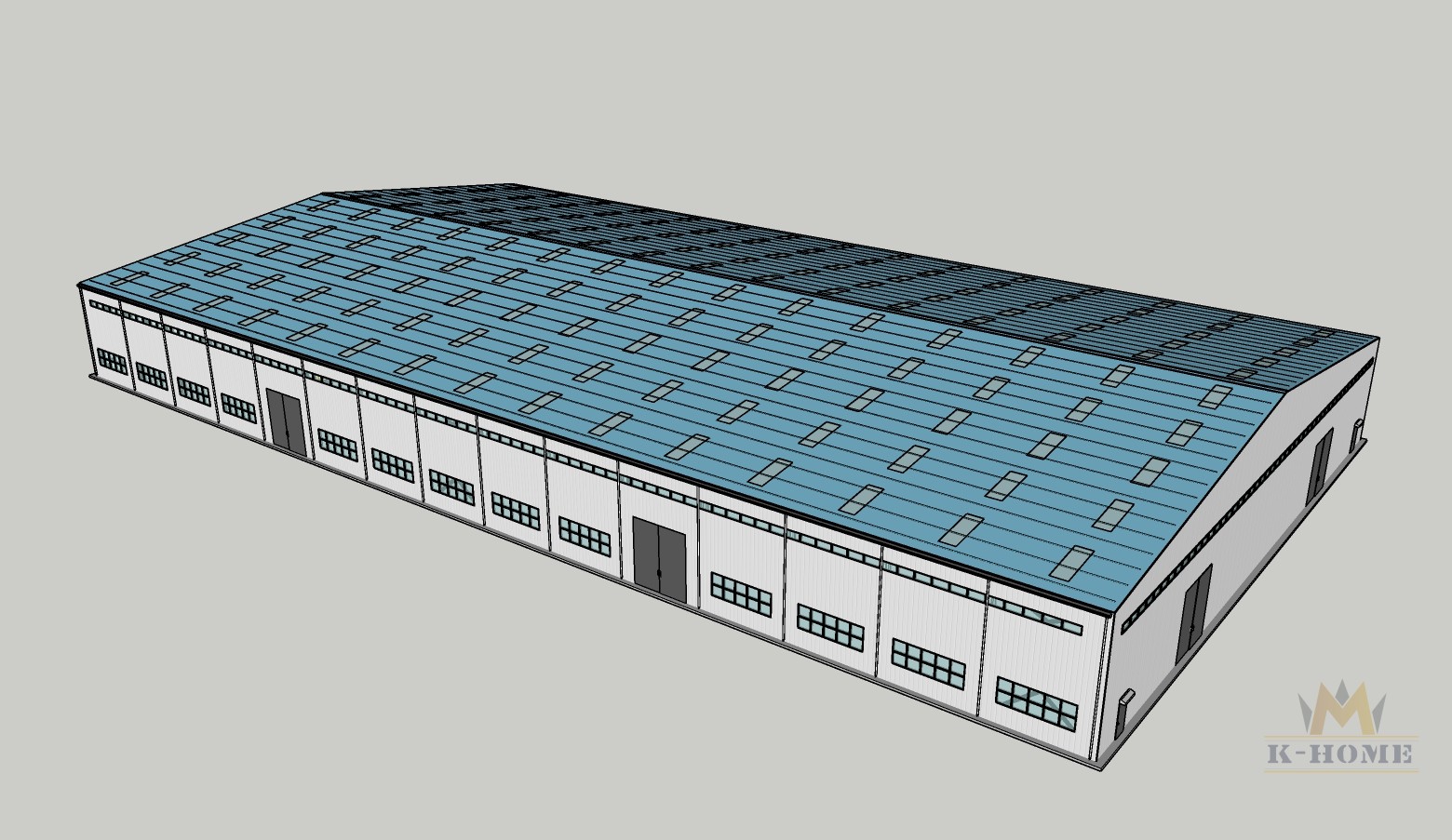

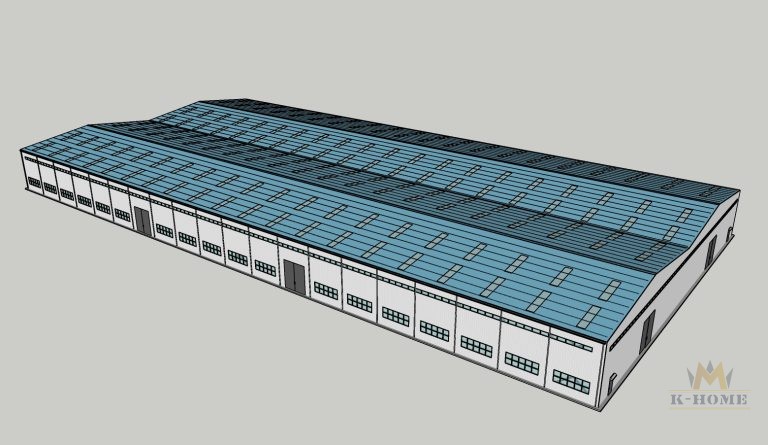

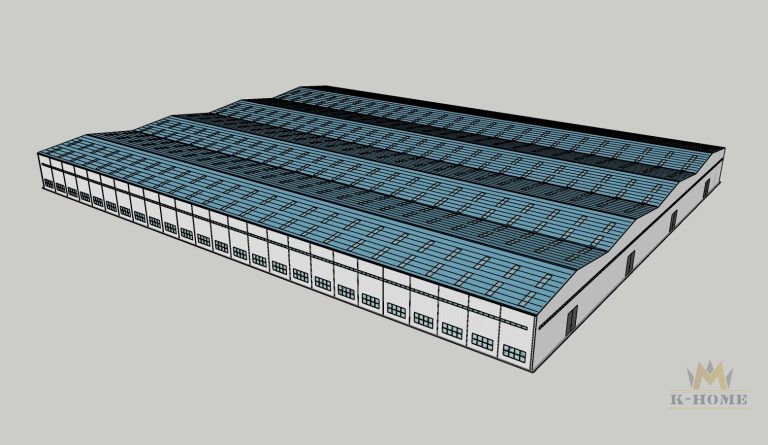

120×150 Steel Building (18000m²)

Pre Engineered Buildings Manufacturer

K-HOME is a leading prefabricated industrial steel structure manufacturer, dedicated to providing top PEB solutions worldwide. K-HOME is not limited to providing pre engineered buildings themselves, but also provides related building materials, lifting equipment, overall planning services, etc. Committed to meeting customers’ diverse needs in the field of construction. From initial design consultation to after-sales service, K-HOME’s team of engineers and project managers ensure seamless communication and timely and effective resolution of customer issues.

Pre Engineered Metal Building Construction

Foundation construction: Before foundation construction, detailed geological surveys are required to understand the distribution of soil layers, groundwater conditions, etc. Ensure that the foundation can withstand the loads of the superstructure and meet the settlement requirements. If the foundation conditions are poor, such as thick soft soil layers and insufficient bearing capacity, foundation treatment is required. Common foundation treatment methods include replacement filling, strong tamping, pile foundation, etc.

Component prefabrication: Manufacture prefabricated steel beams, columns, supports, and additional components in the factory following design specifications, while performing quality inspections. Ensure that the pre engineered steel building components’ dimensional precision and quality adhere to established standards.

Transportation and stacking: Use appropriate transportation methods to transport prefabricated components to the construction site and stack them reasonably. Pay attention to protecting the components to avoid deformation and damage during transportation and stacking.

Installation preparation: Clean up the construction site and install temporary supports scaffolding and other facilities. Measure and layout to determine the installation position and elevation of the components.

Installation of steel beams and steel columns: Usually, cranes are used to lift steel beams and steel columns and install them according to the designed position. During the pre engineered metal building installation process, pay attention to adjusting the verticality and horizontality of the components to ensure installation accuracy.

Installation of support system: After the installation of steel beams and steel columns, install the support system in time to enhance the stability of the structure.

Installation of roof and wall systems: Install the roof and wall panels in sequence, paying attention to the overlap and sealing of the panels.

Inspection and acceptance: After the pre engineered metal buildings installation is completed, conduct a comprehensive inspection of the structure, including the connection, verticality, horizontality, and sealing of the roof and wall. Subsequent construction can only be carried out after acceptance.

Pre Engineered Metal Buildings Application Fields

Industrial plants: Pre engineered metal buildings are widely used in the industrial field, such as factory steel structure workshops, prefabricated steel warehouses, steel crane building etc. It can meet the requirements of large span and high space, and is convenient for equipment layout and production process organization.

Logistics warehouse: It is used for buildings such as logistics centers and supply chain warehouses, with good bearing capacity and space utilization. It can easily set up shelves and loading and unloading equipment.

Commercial buildings: Such as supermarkets, shopping malls, etc., with simple and beautiful shapes, fast construction speed, and can be put into use as soon as possible.

Indoor stadiums: Some small indoor complex stadiums use pre engineered metal buildings, which can provide a large column-free space to meet the needs of sports activities.

Agricultural buildings: For example, breeding plants, greenhouses, etc., have the advantages of low cost and convenient construction.

Advantages Of Pre Engineered Metal Buildings

Fast construction speed: Prefabricated pre engineered metal buildings components are produced in the factory and then transported to the site for installation, which greatly shortens the construction period. Compared with the traditional on-site construction method, pre engineered metal buildings reduces the on-site operation time and can complete the project construction faster.

Easy to control quality: Factory production can more strictly control the quality of pre engineered metal buildings components, and the standardized production process helps to ensure the dimensional accuracy and quality stability of components, and reduce quality problems in on-site construction.

Light weight: The light steel structure system is lighter than the traditional concrete structure. It can effectively utilize the building space, reduce the building volume, make the pre engineered metal buildings more simple and beautiful, and also reduce the cost of the foundation.

Simple force and clear force transmission path: The structural design is relatively simple, and the force conditions can be clearly analyzed and calculated to ensure the safety and stability of the pre engineered metal buildings structure.

Flexible column grid layout: The column grid can be flexibly arranged according to different usage requirements and pre engineered metal building functions, providing greater spatial layout freedom to meet various special processes and usage requirements.

Significant overall economic advantages: While the initial investment for pre engineered steel buildings may be considerable, factors such as rapid construction timelines, reduced foundation expenses, and lower maintenance costs contribute to substantial economic benefits throughout the project’s entire life cycle.

Excellent seismic resilience: Pre engineered metal buildings exhibit commendable ductility and energy dissipation capabilities, allowing them to absorb and distribute energy during seismic events, thereby enhancing the overall seismic resistance of the structures.

Strong environmental sustainability: Pre engineered metal buildings are recyclable, aligning with sustainable development principles and minimizing the depletion of natural resources. Additionally, the construction process generates minimal waste, resulting in reduced environmental impact.

Optimal space efficiency: The expansive structural design offers ample internal space, free of columns, facilitating efficient equipment arrangement and production workflow, while also allowing for effective functional division and layout.

High level of industrialization: The manufacturing, processing, and installation of components are highly industrialized, enabling standardized and large-scale production, which enhances both efficiency and quality.

Easy and straightforward installation: The construction process involves minimal on-site welding, primarily utilizing bolt connections or other rapid assembly methods, simplifying installation and reducing labor costs and construction complexity.

Versatile roof slope options: By judiciously selecting the roof slope, it is possible to conserve steel resources while simultaneously fulfilling drainage requirements and aesthetic considerations.

Robust adaptability: Should renovations or expansions be necessary in the future, the structure can be easily modified, allowing for adjustments and the addition of pre engineered metal buildings components to meet evolving needs.

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.