Promising market for steel structures in the Philippines

In recent years, the Philippines has vigorously developed infrastructure and attracted foreign investment to build steel plants, aiming to achieve self-sufficiency in steel by 2030.

However, infrastructure construction in the Philippines, especially road and rail transport, is far less than that of other major countries in Southeast Asia. The cost of transportation and logistics virtually restricts the economic development and industrial upgrading of the Philippines. Compared with other countries in Southeast Asia, the Philippines is at a disadvantage in international competitiveness.

The improvement of infrastructure is a necessary condition for the transformation of the Philippine industry. In the past few decades, the investment in infrastructure in the Philippines has been less than 5% of the GDP. Poor infrastructure in the Philippines also means that the construction industry has a bright future.

The industry in the Philippines is underdeveloped. There are a few heavy industries such as steel, metallurgy, and machine manufacturing. The production capacity and technical level are in a backward position in the world. There is a lack of a large-scale smelting industry in the country. still at a low level.

Due to the lack of domestic steel mills in the Philippines and insufficient capacity supply, the growing demand for steel has long been dependent on imports, which stimulates local steel mills in the Philippines to actively expand production, and on the other hand, creates opportunities for foreign investment to build factories in the Philippines.

Check our Case study

64×90 Metal Workshop Building

Prefab Warehouse Philippines

Advantages of Using Steel structures in the Philippines

1. Strong Structure to Resist Harsh Weather

The steel structure house is very safe and can withstand earthquakes of 9 degrees. It can prevent typhoon level 12, and the roof bears 1.5 meters of snow. This is because the steel structure is light, strong, and has good rigidity and toughness. The construction speed of steel frame buildings is very fast. Generally, the construction period of a 500-square-meter house is within 1 month.

This is because the parts of the prefabricated steel structure house are all produced in the factory, and they can be assembled directly after being transported to the steel structure construction site, so the time-consuming is very short.

2. Short Delivery Time, Ready for Immediate Use

The production of steel structure buildings has a high degree of industrialization and mechanization, and a high degree of commercialization. The main materials required for building a house are all produced in factories, and the raw materials are processed by mechanical equipment, which has high efficiency, low cost, and good quality assurance.

Most of this equipment is imported from foreign advanced technology, and the new housing products of many large enterprises are of international quality.

3. Recyclable Material, Friendly to the Environment

80% of the materials of steel frame structure houses can be recycled. From the perspective of the main material, the steel will not grow insects or become deadwood with the passage of time and can be recycled and reused after being dismantled for several years, which is very environmentally friendly and very economical.

The service life of the main structure of the steel structure house is 90 years, which is 3 times that of the traditional house. Light steel houses have good durability and are very cost-effective.

4. Demountable Design, Easy for Repeat Use

The pre-engineered steel structure building is movable. If it encounters demolition, the prefab steel structure can be divided into many parts, which can be re-installed after being transported to a new location. Because these parts are connected together by screws and connectors, installation and disassembly are very simple.

Steel structure buildings are beautiful and diverse in shape, and houses of various styles are carefully designed by designers, and there are many styles to choose from.

When do you need Steel Structure Building?

1. Large-span Structure

The larger the structural span, the greater the proportion of self-weight in the load, and reducing the self-weight of the structure will bring obvious economic benefits. The advantages of high strength and lightweight steel structures are just suitable for long-span structures, so steel structures have been widely used in long-span space structures and long-span bridge structures.

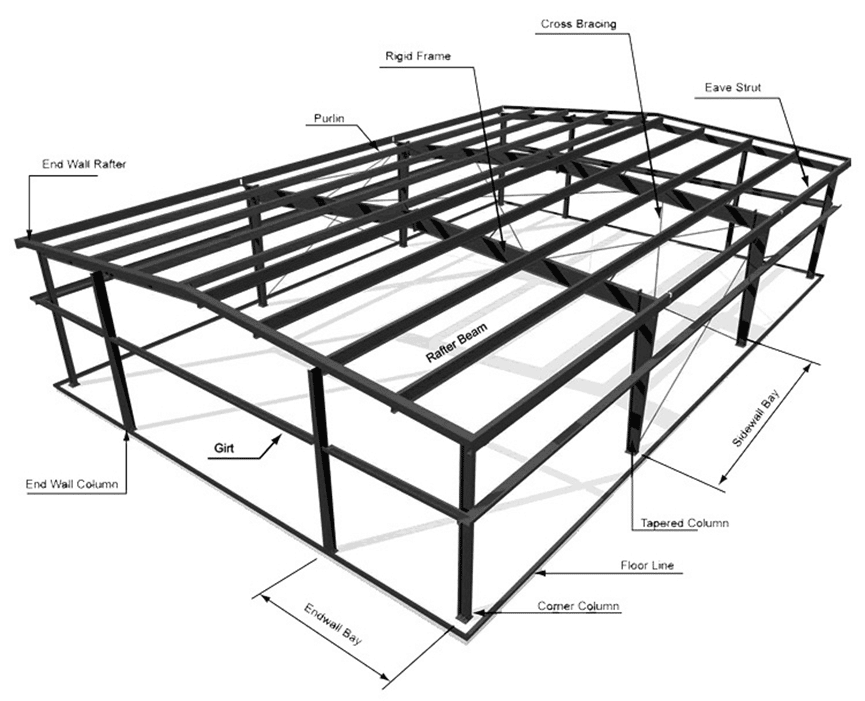

The structural forms used are space truss, grid frame, reticulated shell, suspension cable (including cable-stayed system), string beam, solid web or lattice arch, frame, etc.

2. Industrial Workshop

The main load-bearing skeleton of the workshop with a large crane or heavy work is mostly steel structure. Most of the structural forms are portal rigid frames or bent frames composed of steel roof trusses and stepped columns, and there are also structural forms that use mesh frames as roofs.

3. Structures Affected by Dynamic Loads

Due to the good toughness of steel, workshops with large forging hammers or other equipment that generate power are often made of steel even if the roof truss span is not large. For structures with high seismic capacity requirements, steel structures are also suitable.

4. Multi-storey and High-rise buildings

Due to the excellent comprehensive benefit index of steel structure, it has also been widely used in multi- and high-rise civil buildings in recent years. Its structural forms mainly include multi-layer frame, frame-support structure, frame tube, suspension, giant frame, and so on.

5. Towering Structure

Tall structures include towers and mast structures, such as towers for high-voltage transmission lines, towers, and masts for broadcasting, communications and television launches, rocket (satellite) launch towers, etc.

6. Detachable Structure

The steel structure is not only light in weight, but can also be connected by bolts or other means that are easy to disassemble and assemble, so it is very suitable for structures that need to be relocated, such as construction sites, oil fields, and skeletons of production and living rooms that require field operations. Formwork and brackets for reinforced concrete structure construction and scaffolding for building construction are also made of steel.

Learn More About Influences the Price/Cost of Steel Building

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.

About Author: K-HOME

K-home Steel Structure Co., Ltd covers an area of 120,000 square meters. We are engaged in the design, project budget, fabrication, and installation of PEB steel structures and sandwich panels with second-grade general contracting qualifications. Our products cover light steel structures, PEB buildings, low-cost prefab houses, container houses, C/Z steel, various models of color steel plate, PU sandwich panels, eps sandwich panels, rock wool sandwich panels, cold room panels, purification plates, and other construction materials.