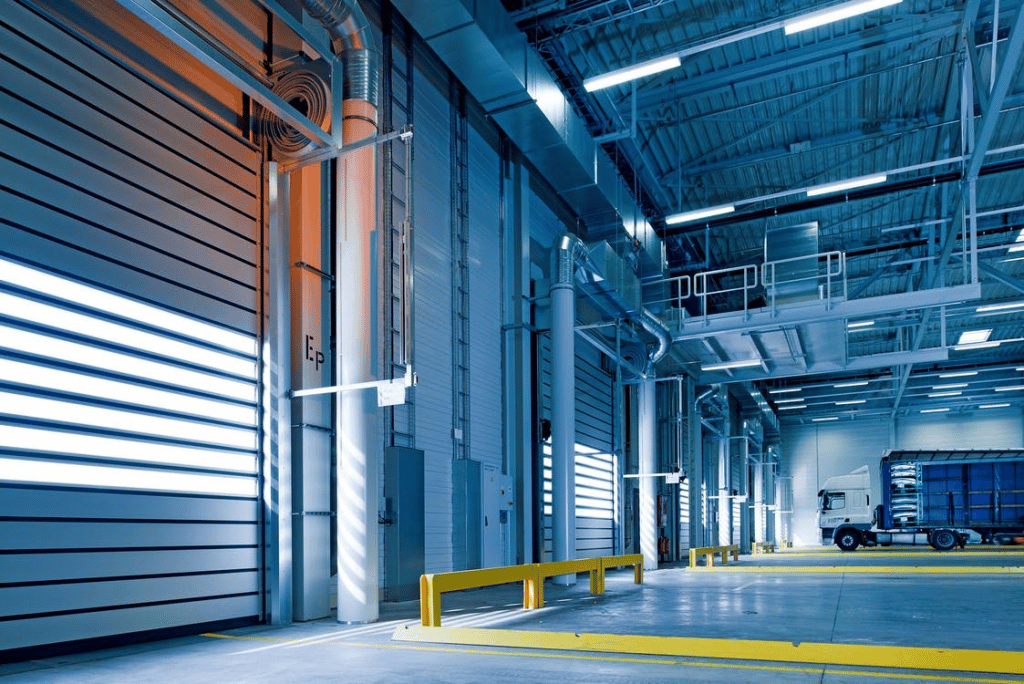

The steel warehouse building is warmly welcomed by people because the roof load is light, the cross-section of the components is small, the sampling is convenient, and the construction time is short. Due to this advantage, which saves time and cost to a great extent, steel warehouse building is more competitive.

Prefab Metal Warehouse: Design, Type, Cost

Raw material factor

Raw material factor Steel is the main frame of the steel warehouse building, accounting for about 70%-80% of the total cost of the steel warehouse building. The fluctuation of the market price of steel structure raw materials directly affects the cost of the steel warehouse building. The material and loading surface of the section steel, the thickness of the cladding and the price of the material vary greatly. The raw material of steel structure is the main factor affecting the cost of steel structure workshop.

In fact, for material procurement, the main thing is to control the price in the project cost. Due to the wide variety of materials in the construction market with different prices, how to choose the source of materials is very important. The supplier shall analyze the market material price and material price provided by the buyer, and negotiate with the owner to select a reasonable material procurement method to reduce the project procurement cost and improve the project economic benefits.

Factors of plant design

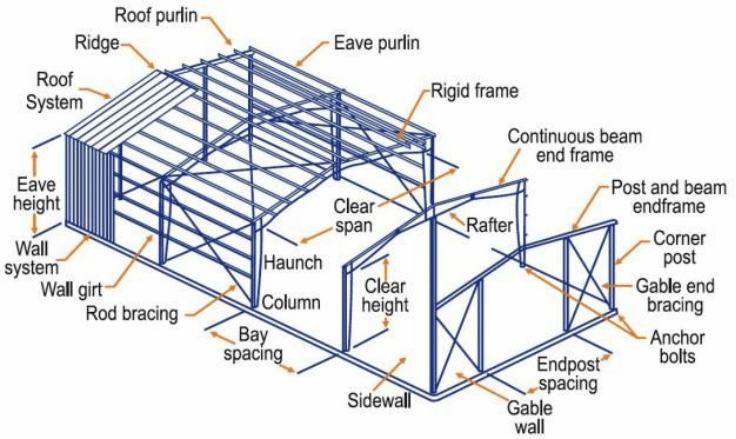

Factors of plant design, reasonable design of steel structure plant scheme is the key issue to control cost. The different design options of the plant directly affect the amount of steel used. In order to control the amount and cost of steel, the scheme of the steel structure workshop should be reasonably designed.

The base cost is closely related to the plant geology. The basic construction period is about 25% of the total construction period of the factory, and the cost also accounts for 15% of the total cost. Unqualified basic construction quality and improper selection of material quality will result in the failure of the steel structure workshop load to be well transmitted to the foundation, increasing the direct load force of the factory and increasing the dynamic load borne by the factory.

Learn More About Influences the Price/Cost of Steel Building

construction period and installation

The length of the construction period of the construction and installation factors is also a part of the cost of the steel structure workshop. Skilled installation technology is the main reason for the length of the construction period. The construction of structural workshop is a systematic project involving a wide range, many influencing factors, construction period, policy changes and a large amount of engineering.

Further Reading: Steel Structure Installation & Design

Other factors

The construction of a steel structure workshop is a systematic large-scale project, and labor costs, construction period, policy changes, and engineering quantities will all affect the cost of the steel structure workshop.

Recommended Reading

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.

About Author: K-HOME

K-home Steel Structure Co., Ltd covers an area of 120,000 square meters. We are engaged in the design, project budget, fabrication, and installation of PEB steel structures and sandwich panels with second-grade general contracting qualifications. Our products cover light steel structures, PEB buildings, low-cost prefab houses, container houses, C/Z steel, various models of color steel plate, PU sandwich panels, eps sandwich panels, rock wool sandwich panels, cold room panels, purification plates, and other construction materials.