Steel structure building is one of the common structural forms in modern construction engineering. As a new type of building form, steel structure buildings are simple in force and fast in construction. Widely used in industrial, commercial, public facilities and other buildings.

At the same time, the technical requirements for installing steel structure buildings are becoming more and more specific and standardized. Understanding the installation technical requirements of steel structure projects can strengthen the technical application and management of steel structure projects and ensure the safety and reliability of the entire steel structure project.

Further Reading: Steel Structure Installation & Design

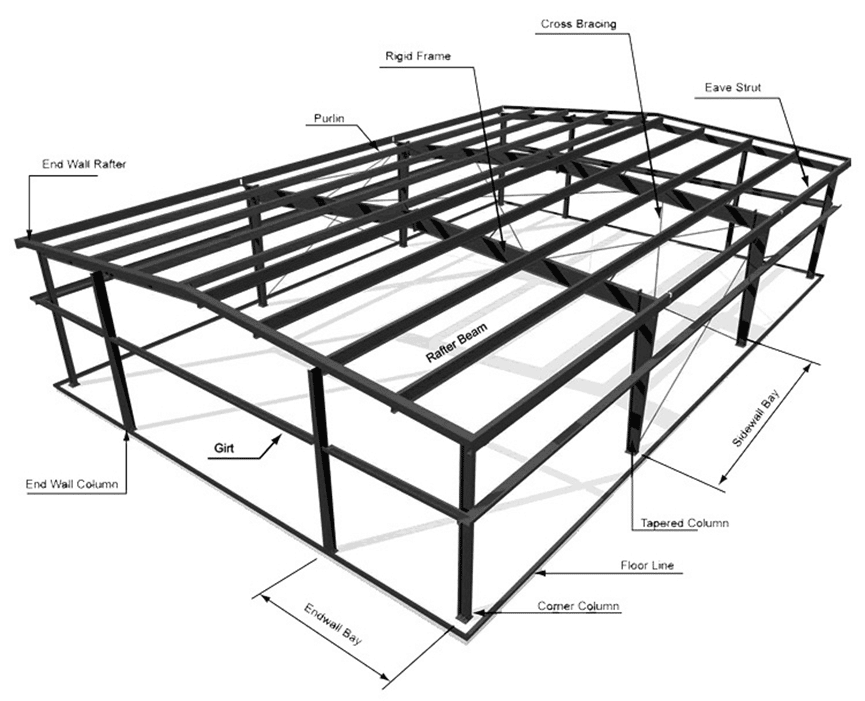

Single-layer steel structure building installation

Single-span structures should be hoisted in the sequence from one side of the span to the other, the middle to either end or both ends to the middle. For multi-span structures, it is advisable to hoist the main span first and then the auxiliary span; when multiple cranes work together, they can also be hoisted at the same time. The single-story portal rigid frame steel structure should be installed in the order of columns, connecting beams, column supports, hanging beams, roof trusses, purlins, roof supports, and roof panels.

During the installation of the portal frame structure, it is necessary to install temporary pillars or cable wind ropes in time to form a stable spatial structure system before the installation can be carried out. The stable space structure system should be able to withstand the influence of the structure’s own weight, wind load, snow load, earthquake action, installation load and impact load during the hoisting process.

Multi-layers steel structure building installation

The installation of multi-layers and super high-rise steel structures should be installed in multiple flow sections. The division of flow sections should meet the following requirements:

Steel structure installation

Preparations before installation

- Check the technical information such as entry materials, quality certificates, design changes, drawings, etc.

- Implement and deepen the construction organization design, and make preparations before lifting

- Master the external environment before and after installation, such as wind, temperature, wind and snow, sunshine, etc.

- Joint review and self-review of drawings

- Basic acceptance

- Pad setting

- The grouting mortar adopts non-shrinking micro-expansion mortar, and it is one grade higher than the basic concrete.

Further Reading: Steel Building Plans and Specifications

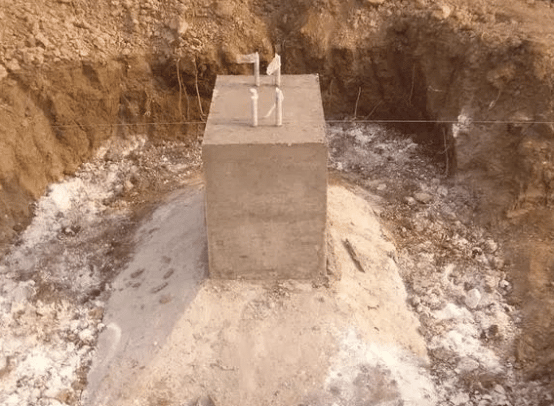

Pre-embedded anchor bolts

First, assemble the anchor bolts into groups according to the design size; make a “template” according to the design size, and mark the position of the axis; when pre-embedding, put the assembled anchor bolts into the supported concrete template, and put the Put the “template” on the assembled anchor bolts, use the theodolite and level to position the template, and then use an electric welding machine to fix the anchor bolts with the steel bars and the concrete template.

When fixing, ensure that the anchor bolts and the concrete template relative position.

Problems that should be paid attention to when pouring concrete: Before concrete pouring, tarpaulin must be wrapped around the screw buckle of the bolt to protect the screw buckle, and then untied when the steel structure is installed.

During the concrete pouring process, try to avoid stepping on the formwork, and the vibrating rod should try to avoid directly touching the bolts, especially the screws. After the concrete is poured, send someone to check the elevation of the column top, and those that do not meet the requirements should be rectified before the initial setting of the concrete. After the concrete is poured, the position of the anchor bolts should be recalibrated before the initial setting.

Column of steel installation

- Foundation excavation

- Cushion pouring

- Basic steel bar binding

- Steel plate welding embedded parts

- Steel plate and embedded parts rust removal and anticorrosion

- Steel plate and embedded parts installation and fixation

- Foundation formwork installation

- Foundation concrete pouring

- Steel column anti-corrosion and rust removal painting

- Steel column and steel plate welding and installation

- Foundation concrete secondary pouring – Steel column brushing and top coating

- Inspection

Installation of inter-column supports

Both ends of the support between columns are welded to steel columns and beams through round steel.

Crane beam installation

It should be carried out after the first alignment of the column support installation, the installation sequence starts from the span with the column support, and the crane beam after hoisting should be temporarily fixed.

The correction of the crane beam should be carried out after the roof system components are installed and permanently connected, and the allowable deviation should comply with the corresponding regulations. Its elevation can be adjusted by adjusting the thickness of the backing plate under the column bottom plate.

The connection between the lower flange of the crane girder and the column corbel shall comply with the corresponding regulations. The installation of the crane beam and the auxiliary truss should be assembled and hoisted as a whole, and its lateral bending, twisting and verticality should meet the regulations.

Steel frame assembly

Roofing works

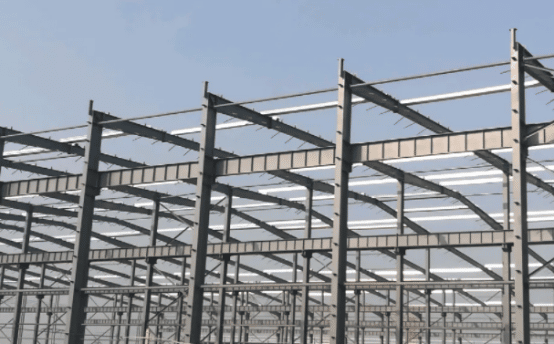

Check the C-type purlins that enter the site, and replace the purlins with excessive geometric dimensions or serious deformation during transportation.

When the purlin is installed, it must be perpendicular to the ridgeline to ensure that the purlin is in a plane. First install the ridge purlin, weld the ridge stay, and then install the purlin and the roof hole reinforcement purlin in turn. When installing the downslope purlin, you must install the pull The purlin should be leveled and tightened to ensure that the purlin is not twisted and deformed, and the pressure wing of the purlin can be effectively prevented from being unstable.

For the roof panels that enter the site, check the geometric size, quantity, color, etc., and if there are serious defects such as serious deformation during transportation, coating scratches, etc., they will be replaced at the site.

Set the installation reference line, the reference line is set on the vertical line of the gable end ridgeline, and according to this reference line, mark the effective coverage width positioning line of each or several profiled steel plates in the transverse direction of the purlin, and arrange the plates according to The drawings are laid in sequence, and the position should be adjusted while laying, and the roof should be installed first.

When laying profiled steel plates on the roof, temporary pedestrian boards should be set up on the profiled steel plates. Construction workers must wear soft-soled shoes and must not gather. Temporary plates should be installed in the places where the profiled steel plates are frequently traveled.

The connection between roof ridge plate, flashing plate and roof profiled steel plate shall be lap joint, and its lap length shall not be less than 200mm. The lap length of the joint shall not be less than 60 mm, and the distance between the connectors shall not be greater than 250 mm. Fill the lap joint with sealant.

The installation of the gutter board should pay attention to the longitudinal slope.

Wall panel installation

The installation of wall purlins (wall beams) must pull down the vertical line from the top to ensure that the wall purlins are on a flat plane, and then install the wall purlins and the hole reinforcement purlins in sequence.

The inspection of the wall panel is the same as that of the roof panel.

Set the installation reference line and draw the exact position of the door and window openings to facilitate the trimming of the wall panel. The installation reference line of the profiled steel plate on the wall is set on the vertical line 200 mm away from the gable yang angle line, and according to this Baseline, marking the effective coverage width line of the corner block wall panel section on the wall purlin.

The connection of the wall panel adopts self-tapping screws to connect with the wall purlin. Make holes on the wall profiled plate, cut the edge according to the size of the hole, and then install it. Click here to download construction technical data for free.

The lap joints between the flashing panels, between the angle panels, and between the flashing panels, angle panels and profiled steel plates must be provided with waterproof sealing materials as required. , The lap joint of the gable flashing board and the ridge board must first install the gable flashing board, and then install the ridge board.

Recommended Reading

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.

About Author: K-HOME

K-home Steel Structure Co., Ltd covers an area of 120,000 square meters. We are engaged in the design, project budget, fabrication, and installation of PEB steel structures and sandwich panels with second-grade general contracting qualifications. Our products cover light steel structures, PEB buildings, low-cost prefab houses, container houses, C/Z steel, various models of color steel plate, PU sandwich panels, eps sandwich panels, rock wool sandwich panels, cold room panels, purification plates, and other construction materials.