Steel Construction Buildings & Solutions

K-HOME: Your Go-To for Steel Structure Construction Worldwide

Why is steel construction building superior to traditional building methods?

Traditional cement and brick structures suffer from long construction periods and high costs, whereas modern steel structure buildings offer greater value per square meter: faster installation, lower lifecycle costs, and resistance to extreme weather conditions.

K-HOME specializes in providing pre-engineered steel structures for warehouses, workshops, and agricultural greenhouses. From design to commissioning, the entire process takes only a few weeks, far shorter than the months or even years required for traditional construction.

Our advantages are clear: lightweight steel frames optimized by precision algorithms reduce material waste by 15%, and factory-preassembled components enable simple bolted installation, avoiding on-site delays and budget overruns. The delivered certified steel structures can directly withstand hurricanes, heavy snow, and corrosive marine air.

In a real customer case, an auto parts client in Nigeria reduced their construction period by 70% after adopting our K-HOME steel structure building kits. They completed SONCAP certification simultaneously during customs clearance, while competitors using traditional concrete construction were still waiting for permits at that time.

Steel Construction Building: More Than Just a Building

Steel structure construction has become the backbone of modern industrial and commercial projects, thanks to its durability, flexibility, and adaptability. But successful projects rely on more than just strong steel—it takes understanding global markets, navigating complex regulations, and designing with cost in mind.

For businesses expanding into regions like Africa, the challenge often lies in balancing quality with practicality: building structures that stand up to local conditions, clearing customs without delays, and keeping budgets in check. That’s where a focus on integrated solutions matters—blending reliable steel construction with the support needed to turn plans into reality, from concept to completion.

Versatile Steel Structure Building Options for Every Need

Steel structure construction thrives on versatility, with options tailored to fit specific operational demands.

Portal Frame Steel Buildings

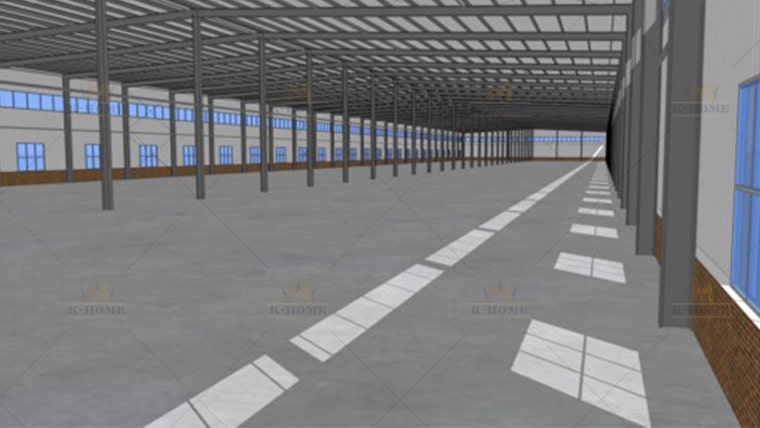

Portal steel frames are a staple in industrial and agricultural settings, valued for their ability to create wide, unobstructed spaces. Whether used as warehouses, workshop floors, or storage areas, they’re designed to maximize usable space without sacrificing strength. Steel sheds, similarly, excel in adaptability—ideal for crop storage, equipment housing, or temporary facilities. Both are prefabricated with precision, ensuring on-site assembly is efficient and minimizes disruption.

Industrial Steel Buildings & Container-Based Buildings

Industrial steel structures are engineered for heavy use, supporting manufacturing lines, logistics hubs, and production facilities. Their modular design allows for easy expansion, growing alongside business needs. For projects requiring speed or mobility, container-based steel structures offer a smart solution—pre-fitted for use as offices, worker accommodations, or small-scale storage, with the same durability as larger steel builds.

Simplifying Global Trade: K-HOME’s Certification Support for Steel-Structure Buildings

Exporting steel structures to international markets often hinges on navigating complex certification requirements—a hurdle that can delay projects and inflate costs. K-HOME removes this barrier by integrating certification support into our steel structure construction services.

Expertise in Regional Requirements

From Kenya’s PVOC and Cameroon’s COC to Nigeria’s PC+SONCAP, and ECTN tracking for West African nations like Benin and Mali, navigating these certifications requires on-the-ground knowledge. The key is syncing certification work with construction: preparing documents as the steel structure takes shape, so paperwork is ready the moment production wraps. This alignment avoids last-minute rushes and keeps projects on track.

Attention to Detail in Documentation

Every certification file needs precision—from material specifications to compliance statements. Thorough reviews catch discrepancies early, ensuring documents meet local standards. This level of care has helped hundreds of projects clear customs smoothly, turning potential hurdles into non-issues.

Get your free steel structure project quote within 24 hours!

K-HOME Steel Structure Buildings: Standardized Design, Full-Process Control, Comprehensive Quality Service

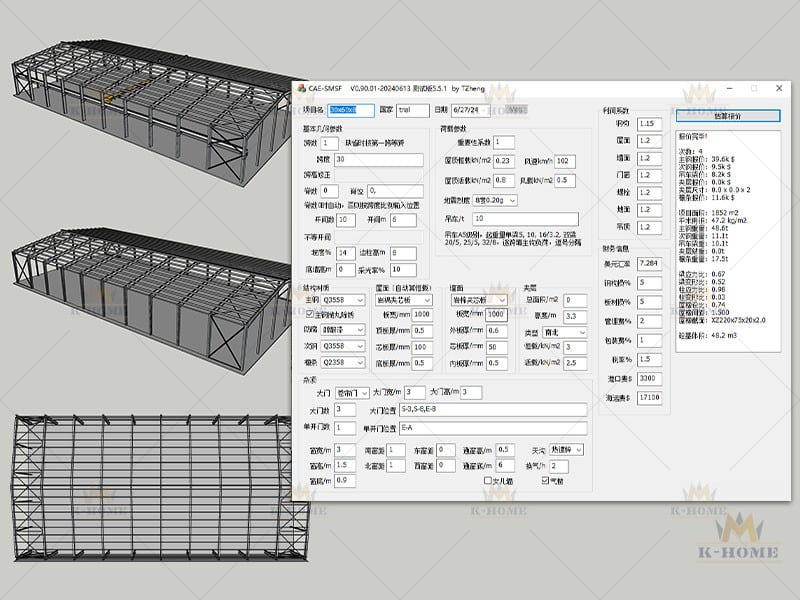

As a professional steel structure manufacturer, K-HOME boasts a complete and scientific design and delivery process, ensuring every project is safe, reliable in quality, and completed on time. Our designs strictly adhere to the national standard Code for Design of Steel Structures (GB50017-2017) and are tailored to actual needs to provide clients with the most suitable solutions.

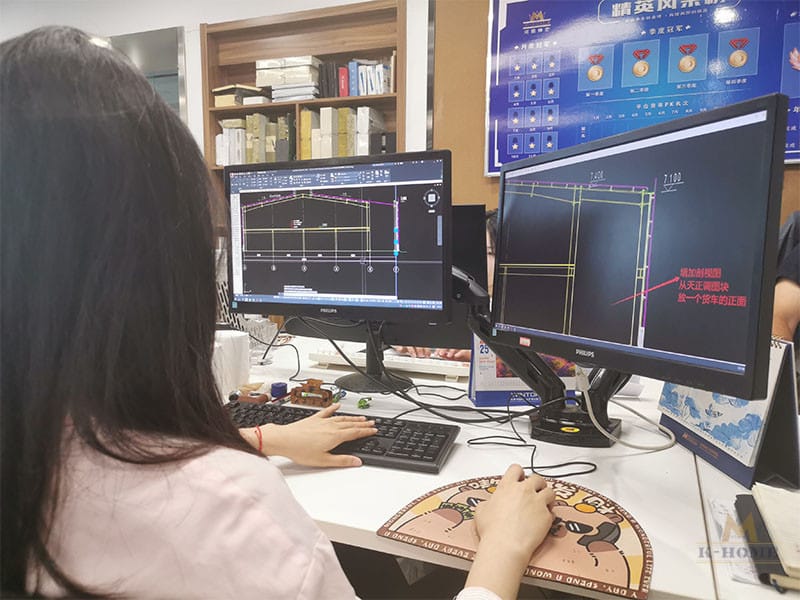

First, we communicate in detail with clients to understand project requirements and building environments—such as wind force, rainfall, snowfall, and seismic intensity—all of which directly influence the design scheme. Next, our designers develop preliminary plans, determining steel types, structural forms, and dimensions. They then conduct stress calculations in accordance with standards to ensure structural stability and safety.

Once the design is finalized, a professional team conducts rigorous reviews, checking calculations and drawing details to ensure compliance with standards and construction requirements. After approval, we provide clients with a detailed quotation based on the design scheme and material costs, covering all expenses, including production, packaging, and transportation, to facilitate a comprehensive understanding of costs. Upon confirmation of the quotation, we proceed to the production phase while preparing relevant technical documents and construction drawings to ensure precise manufacturing in the factory. After production, products are packaged to standard and prepared for shipment.

For ocean freight, K-HOME coordinates container loading and transportation arrangements. We closely track logistics status and maintain communication with clients to ensure goods arrive safely and on time. Upon arrival, clients only need to complete customs clearance and pickup procedures in accordance with local regulations, making the entire process efficient and smooth.

In addition, to help clients better understand product installation, we provide detailed installation videos and drawings. If clients require technical support, we can also dispatch engineers to assist on-site, ensuring hassle-free installation.

In summary, K-HOME not only emphasizes design and production quality but also pays attention to every link from quotation to logistics. We are committed to providing clients with comprehensive quality services and creating safe, durable steel structure buildings.

Showcase of Client Cases

Need Help?

Please let me know your requirements, such as project location, usage, L*W*H, and additional options. Or we can make a quote based on your drawings.

Why Choose Expertise for Your Steel Structure Project

A standout steel structure project brings together quality, compliance, and cost control. It’s about more than just construction—it’s understanding the full project lifecycle: knowing the structure’s purpose, ensuring smooth transportation, and keeping costs on track.

Whether you’re building a warehouse, a shed, or a production facility, partnering with a team that has both construction skills and international trade experience is key. Such a team ensures your steel structure isn’t just strong and durable, but also a real asset to your business—delivered on time and within budget.