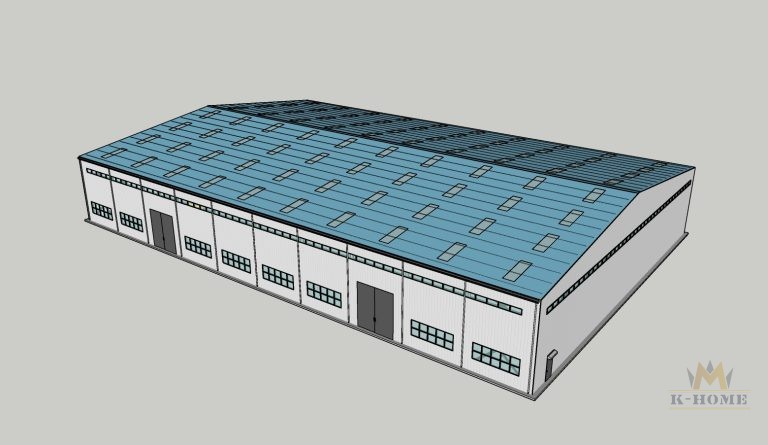

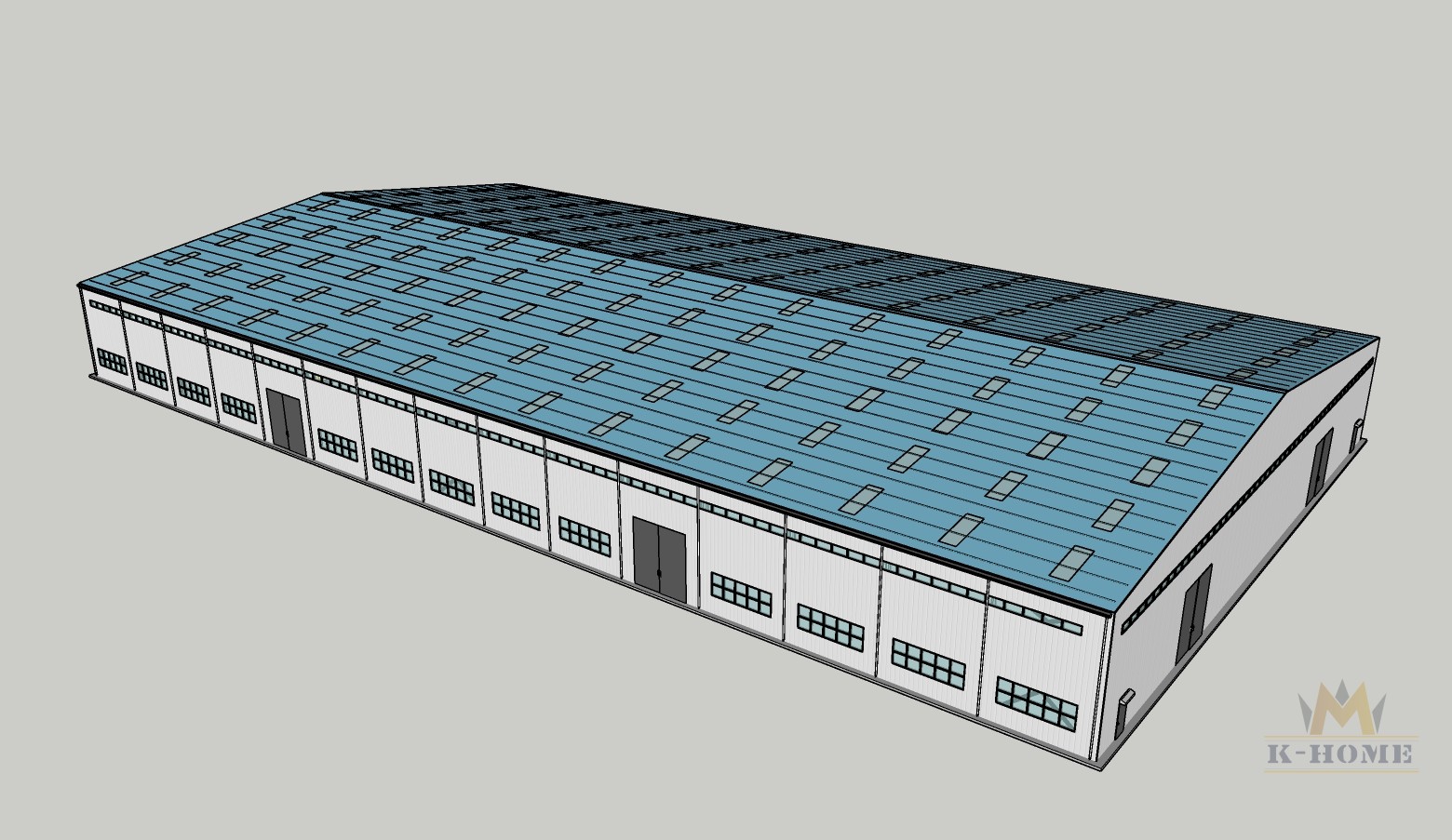

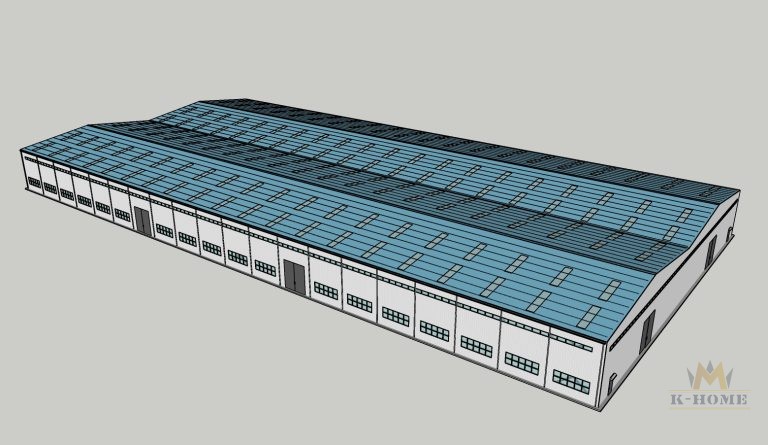

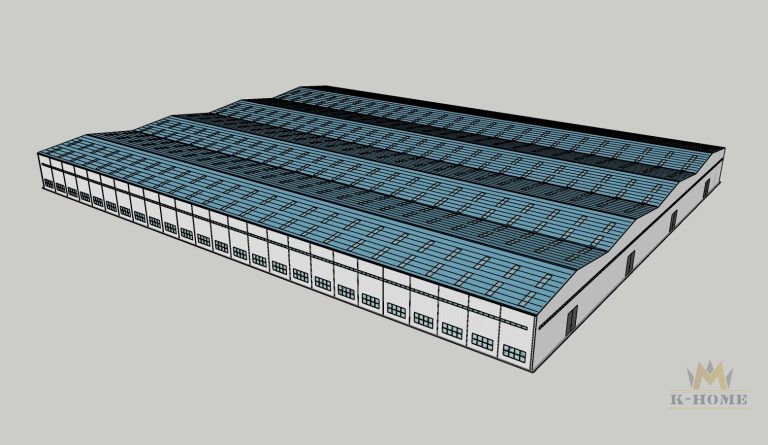

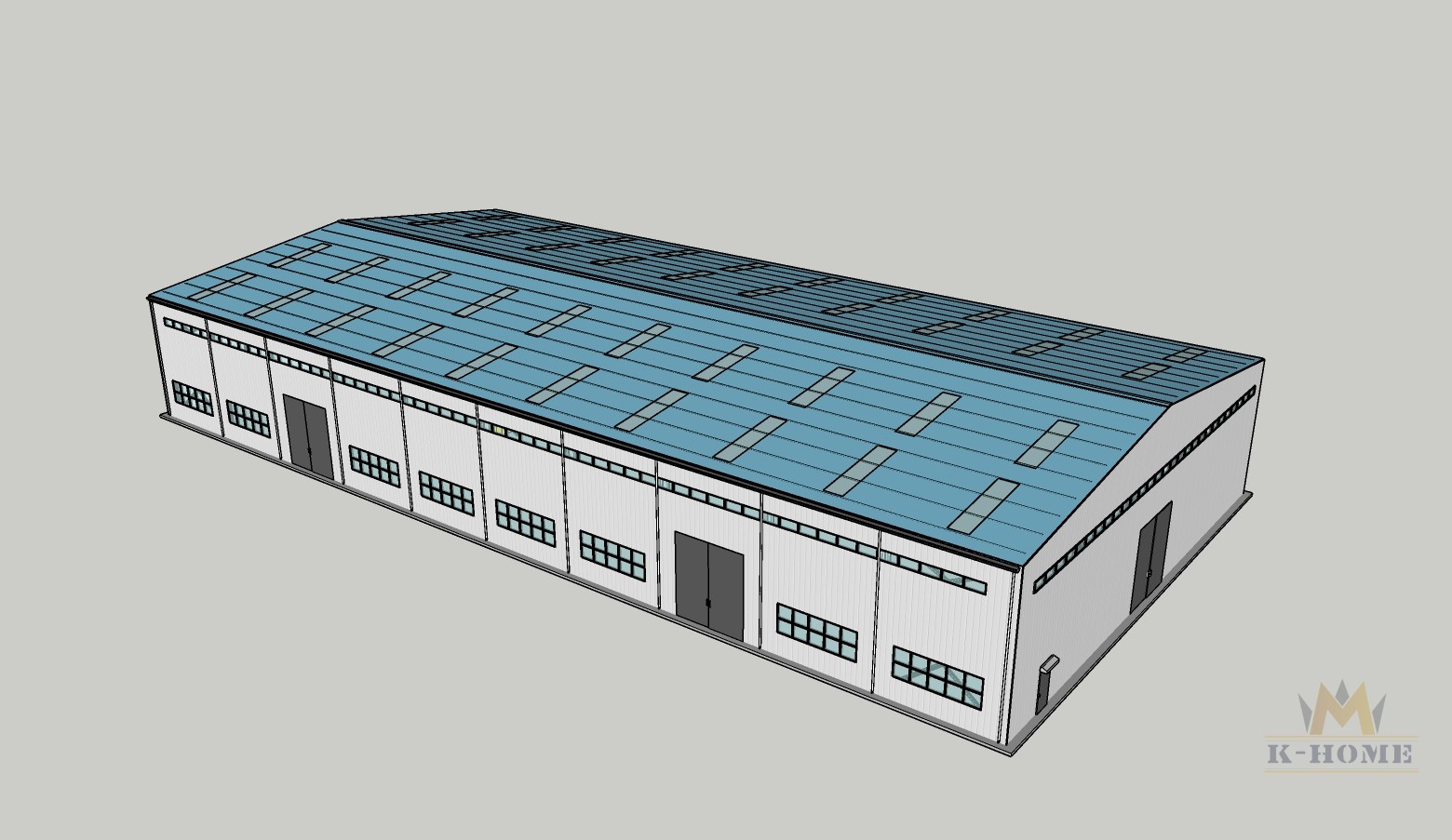

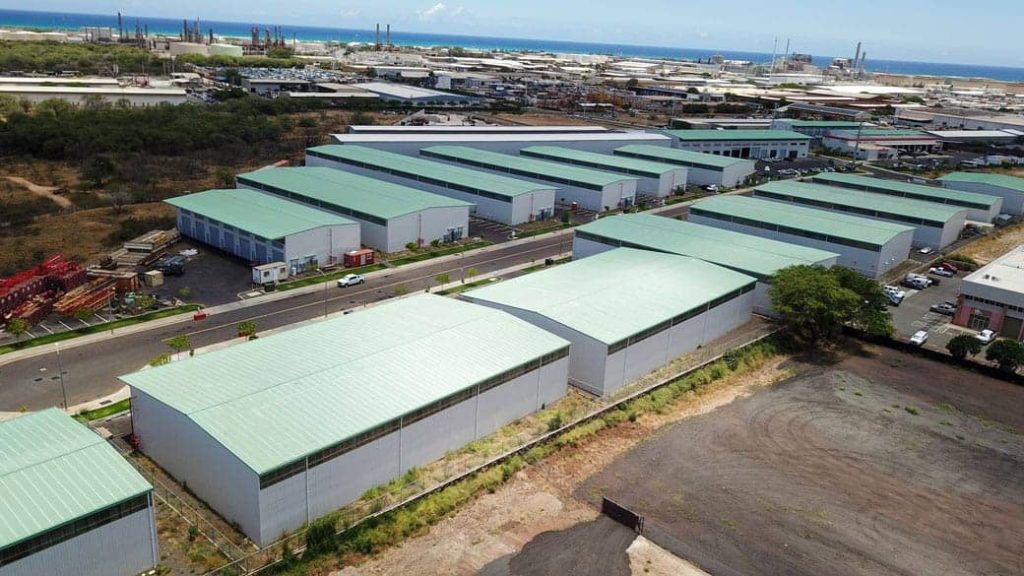

Production Workshop Steel Building in Tanzania

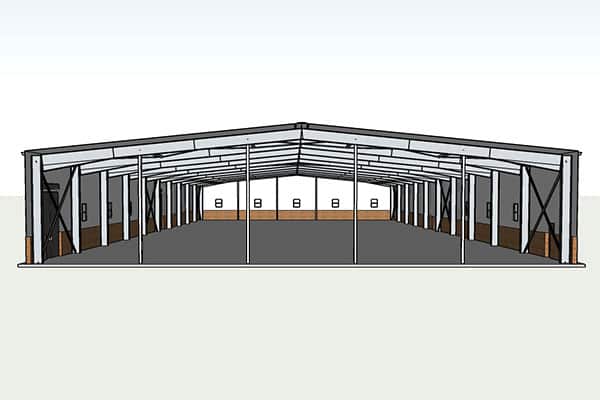

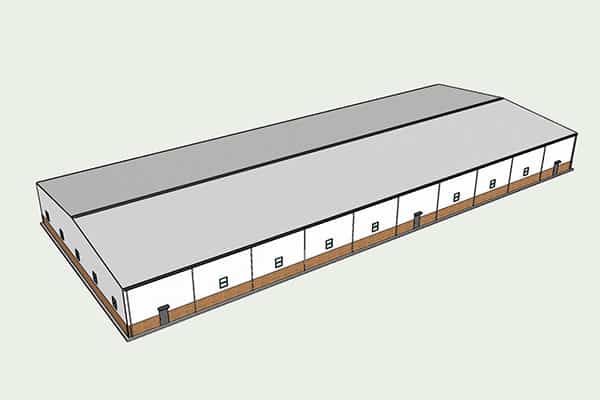

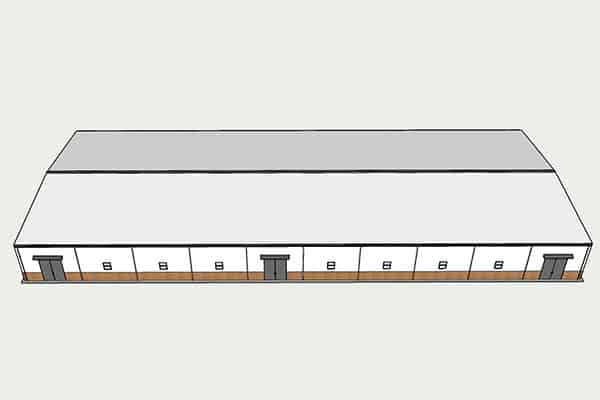

A prefabricated workshop steel building in Tanzania, designed and manufactured by K-Home, has been installed and is now operational. We designed the steel structure for food production. The production equipment was imported from Italy. The prefabricated steel structure was designed to suit the internal equipment layout. The advantages of steel structures include spacious interiors, allowing for the use of large production equipment, and ample raw material storage to ensure continuous production.

project overview

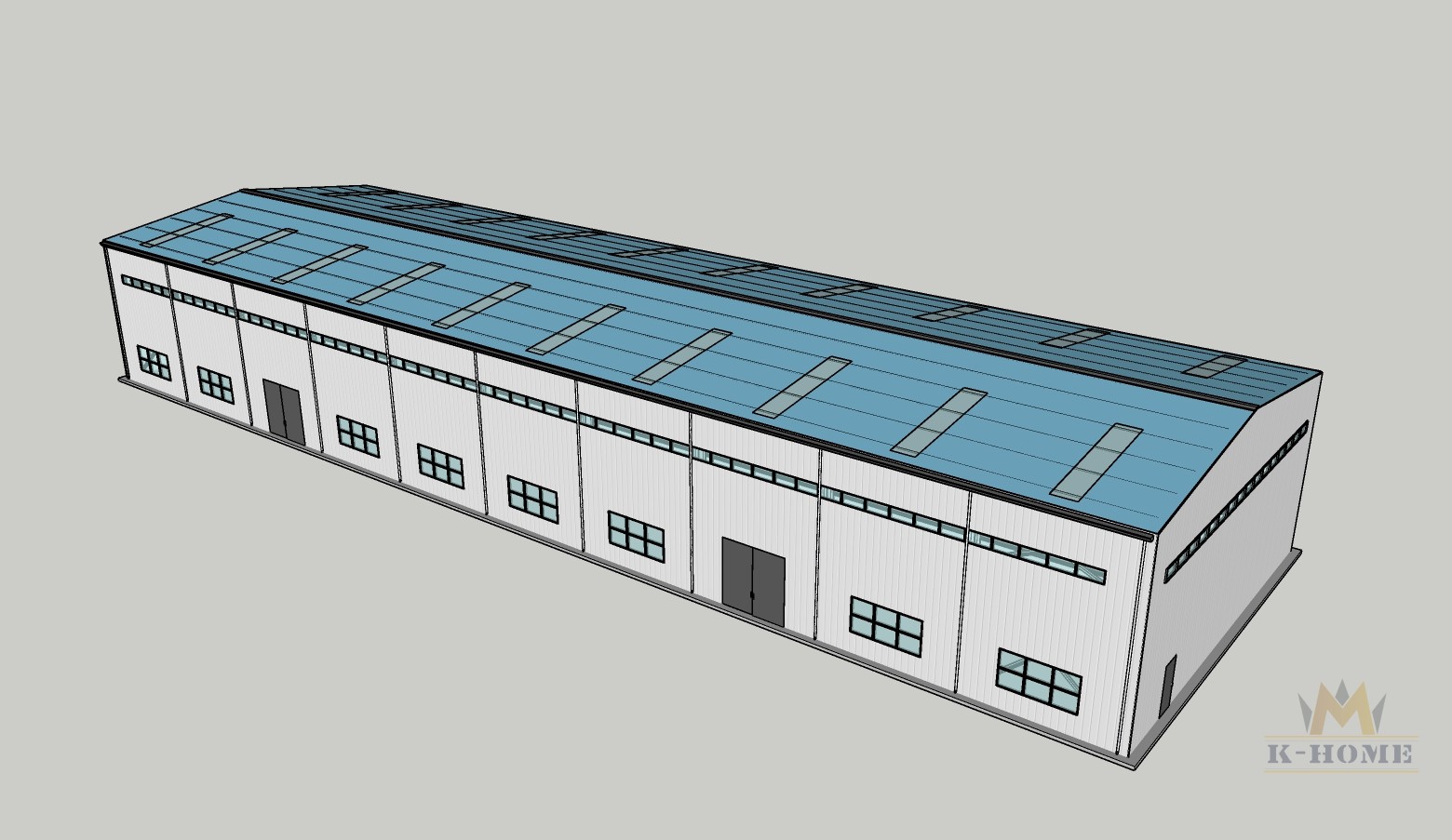

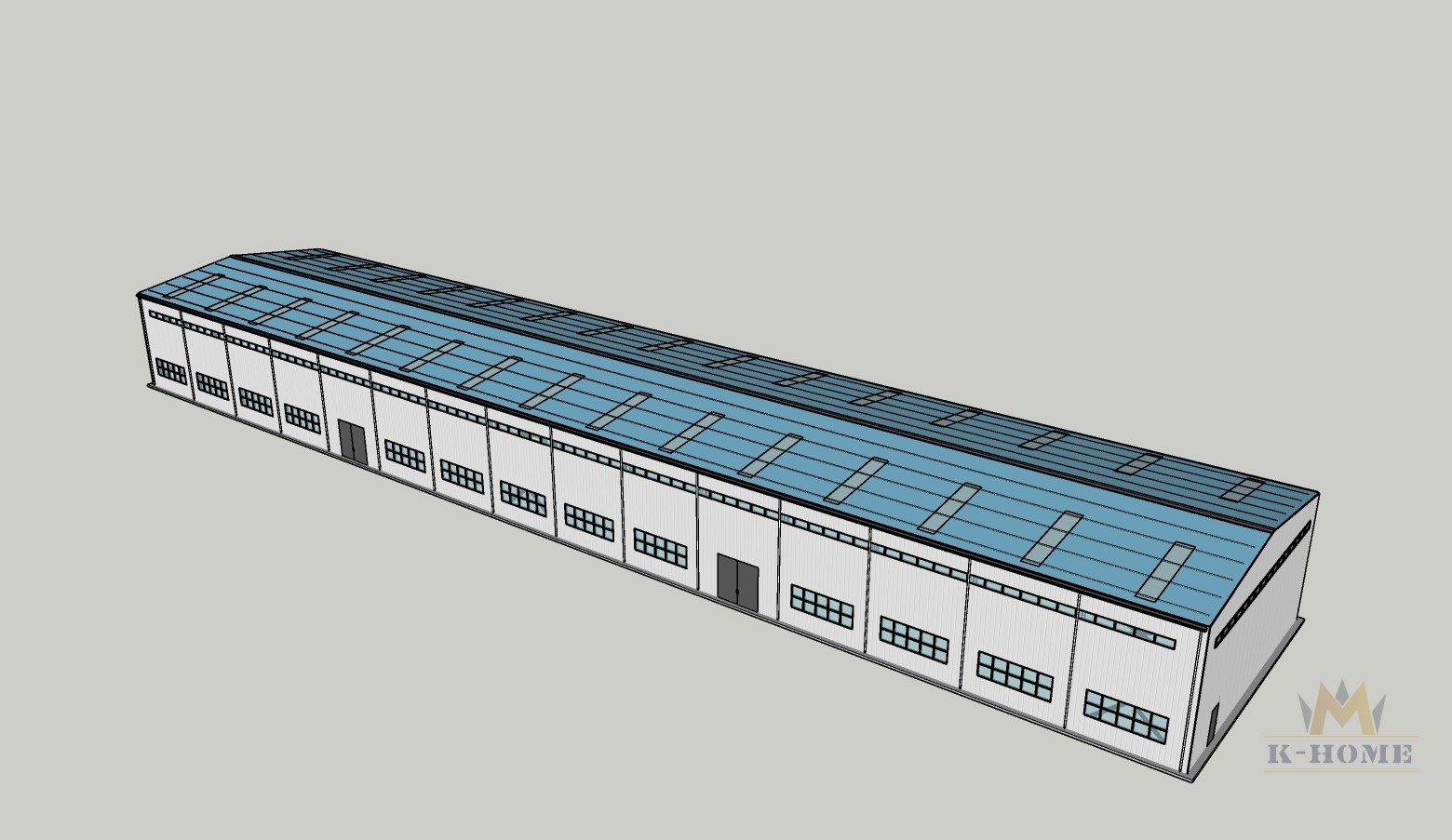

The steel structure of the production workshop is 30 meters wide, providing ample space for various production operations. Its 75-meter span allows for an open layout, eliminating the need for excessive internal support. The workshop is 6 meters long, accommodating large production lines. The eaves are 7 meters high, designed to accommodate equipment installation and material handling.

The raw materials and finished products are relatively light, so there is no need to design a crane. Only use forklifts to meet internal cargo handling. The steel structure building can be designed with a large span, and there is no column inside, which greatly improves the utilization rate of the prefab workshop building’s internal space.

Tailored Design of a Production Workshop Steel Building in Tanzania

Our steel structure buildings are designed based on local environmental characteristics and customer needs.

Tanzania experiences different wet and dry seasons due to its tropical environment. All year long, the average temperature is quite high, and strong winds are common, particularly during the rainy season.

In response to the client’s description of Tanzania’s climate characteristics and the requirements for a food – production steel structure factory, our design and construction approach is meticulously planned to meet local needs, ensure safety, and adhere to the specific demands of food production.

1. Structural Design to Fulfill Safety and Local Needs

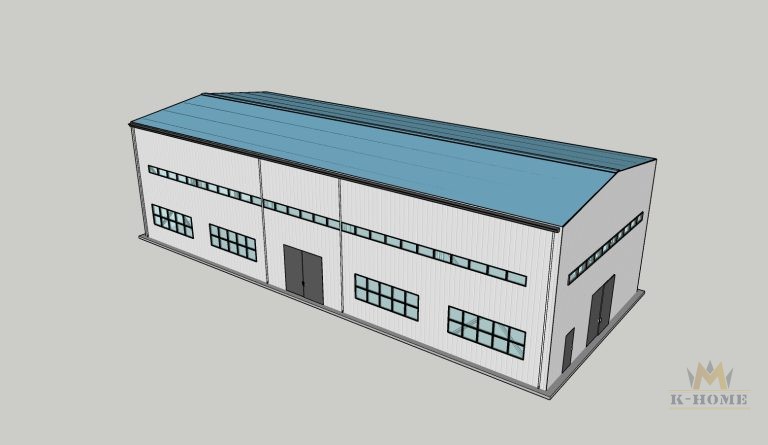

Given Tanzania’s environment, which includes intense rainfall and wind, particularly during the rainy season, the factory’s structural design is crucial. Our erection blueprint and structural design plan are made to endure these severe weather conditions. High-strength steel, which can withstand the forces of powerful winds, is used in the design of the major and secondary structures. Given Tanzania’s regular high rains, it is imperative that the trim and flashing be placed and chosen properly to minimize water seepage. High-quality anchor bolts and fasteners also guarantee that the entire structure stays sturdy in the face of severe rain and wind. This design not only meets safety requirements but also caters to the long – term use of the food production facility, protecting the valuable equipment and products inside.

2. Temperature Resistance

Temperature management is essential for food production since Tanzania is in the tropics, where average yearly temperatures are high. We made a calculated decision by selecting insulated sandwich panels for the roof and walls that are 75 mm thick. Because of their superior thermal insulation qualities, these panels may successfully lessen the amount of heat that enters the plant from the outside. This keeps the building’s interior temperature somewhat constant, which is necessary for the production and storage of food. Appropriate temperature regulation for food items may guarantee product quality and stop spoiling.

3. Drainage System

An effective drainage system is essential in Tanzania due to the country’s regular heavy rainfall. With a 1:10 roof pitch, we have built a gutter and downspout system. Rainwater may swiftly go from the roof into the gutters and subsequently via the downspouts because to its slope. A properly operating drainage system keeps water from collecting on the roof, which over time may cause structural damage. Standing water in a food manufacturing facility may also serve as a haven for pests and germs, which is unacceptable for the safety of the food. As a result, this drainage design helps to provide a clean production environment in addition to protecting the building.

4. Ventilation

Ventilation is crucial for a food production factory, especially in a hot and often humid climate like Tanzania’s. Our ventilation design includes roll – up doors, man doors, and sliding or casement aluminum windows. The roll – up doors can be opened wide to allow for large – scale ventilation when needed, such as during the cleaning of the factory or when there is a need for rapid air exchange. Man doors provide regular access and also contribute to air circulation. Fresh air may enter and stale air can depart through aluminum sliding or casement windows that can be adjusted according on the weather. In addition to guaranteeing the quality of the food items, adequate ventilation makes the factory more comfortable and hygienic for the workers by removing heat, moisture, and smells.

In conclusion, we have taken into consideration the local climate, safety regulations, and the particular requirements of food production in the design and construction of the steel structure factory for food production in Tanzania. We have no doubt that this plant will provide long-term benefits to the customer.

Your best steel workshop building partner in Tanzania

High – Quality Materials:K-HOMEsteel structure uses high – quality steel materials that meet international standards. These materials have high strength and good corrosion resistance, ensuring the long – term durability of the building.

Customizable Design: K-HOME can provide customized design solutions according to the specific requirements of the client. Whether it is the size, layout, or function of the building, K – Home can design a steel building that meets the needs of the production workshop in Tanzania.

Cost – Effectiveness: Compared with other building materials and construction methods, K – Home steel structure is more cost – effective. The pre – fabricated components can be produced in the factory and quickly assembled on – site, reducing the construction time and labor costs.

Professional Technical Support: K-HOME has a professional team of engineers and technicians who can provide technical support throughout the project, from design to construction and after – sales service.

You can send me a WhatsApp message (+86-18790630368), or send an e-mail (sales@khomechina.com) to leave your contact information. We will contact you as soon as possible.

K – Home Steel Structure Design Process

Consultation

The design process starts with an initial consultation with the client. The K – Home team will understand the client’s requirements, including the size, function, and budget of the production workshop. They will also collect information about the local climate, soil conditions, and other relevant factors in Tanzania.

Conceptual Design

Based on the information collected, the K – Home design team will develop a conceptual design. This design will include the overall layout, structural system, and enclosure system of the steel building. The conceptual design will be presented to the client for review and feedback.

Detailed Design

After the client approves the conceptual design, the K – Home team will carry out a detailed design. This includes the calculation of structural loads, the selection of materials, and the design of all components. The detailed design drawings will be produced, which will be used for the production of pre – fabricated components in the factory.

Review and Approval

The detailed design will be reviewed by the client and relevant local authorities in Tanzania. Any necessary modifications will be made based on the review comments. Once the design is approved, the production of components can start.

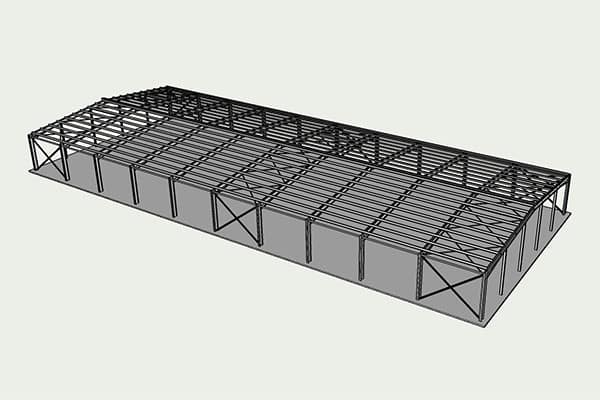

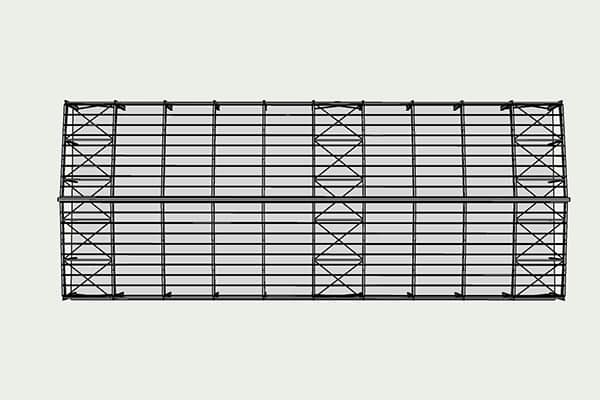

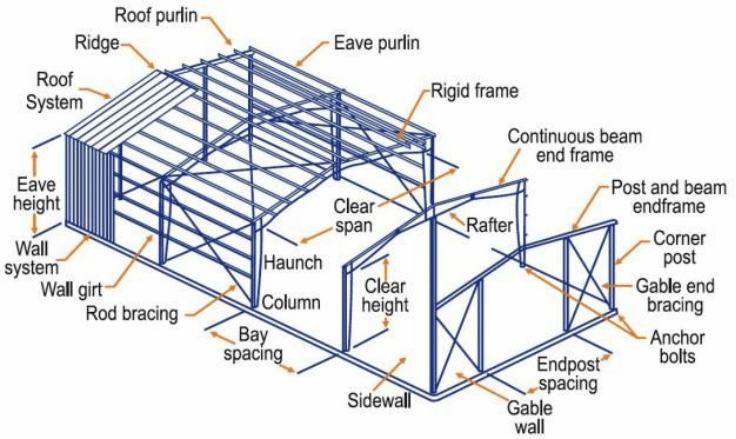

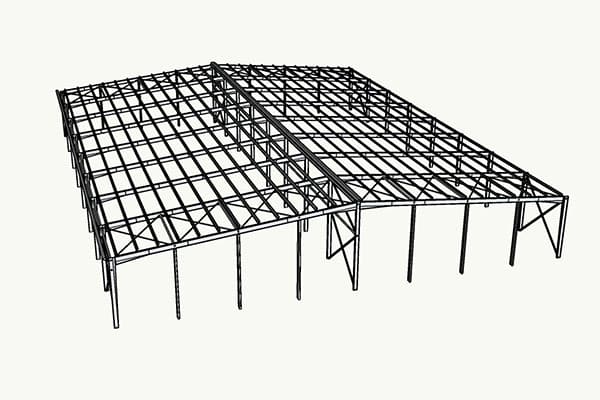

Structural System of Prefabricated Steel Structure Workshop

The factory adopts a professional prefabricated steel structure system, which is both durable and cost-effective:

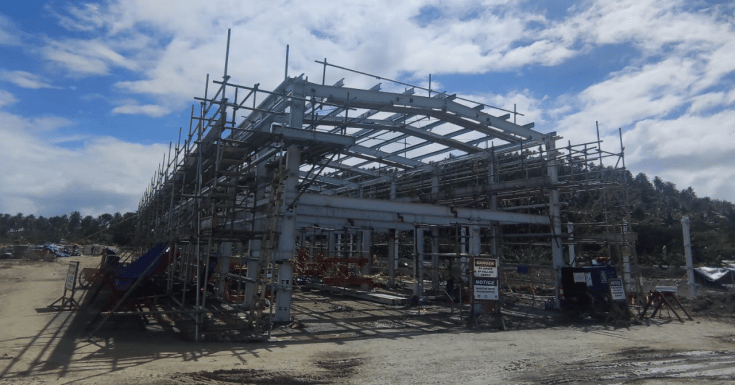

Reinforced cement concrete foundation with embedded anchor bolts to firmly connect the main steel columns, ensuring overall stability even under high wind loads.

It is worth noting that the foundation structure of steel buildings in each region is different, and designers need to calculate based on local geological conditions and load requirements, and then issue a specific construction plan.

The steel columns and beams, the structural core of the entire building, are constructed from Q355B-grade hot-rolled H-shaped steel, offering high strength and excellent load-bearing performance. All components are shot-peened to effectively enhance the steel’s surface adhesion, providing a uniform and stable foundation for the anti-corrosion coating, significantly improving the building’s corrosion resistance and service life in harsh environments.

Q355B steel purlins (C/Z-section), tie bars, wall and roof bracing to guarantee stability and optimize load distribution.

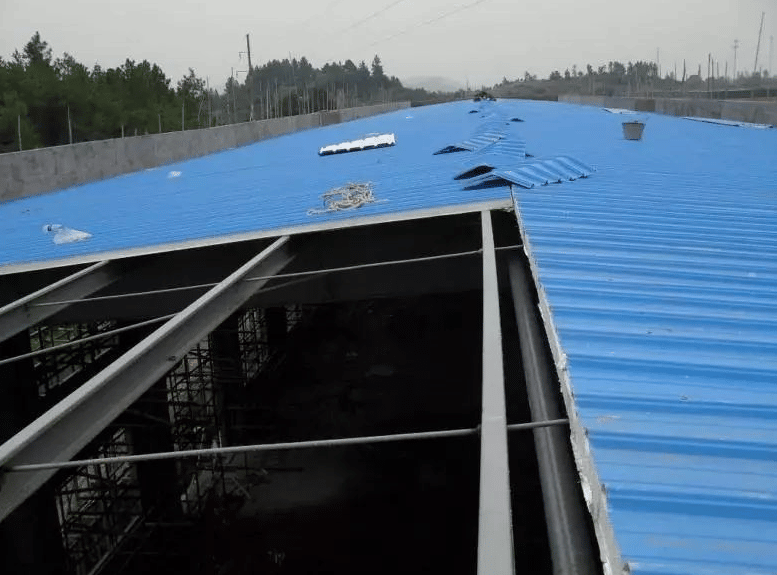

Double-layer roof panels with ventilation skylight for insulation and airflow; ridge ventilators and rainwater drainage systems designed for local climate conditions.

0.4mm single-layer color steel sheets with thicker zinc coating, providing enhanced resistance to corrosive chemical vapors from resin production.

Factors affecting the steel workshop building kits cost

The cost of prefabricated steel workshop kits depends on multiple variables. Here is a detailed explanation of the main cost drivers:

Building Size (Length × Width × Height) – The larger the structure, the more steel and panels required, directly affecting total cost. Taller buildings may need heavier sections and stronger bracing systems.

Project Location & Climate Loads – High wind zones or coastal areas require stronger columns, thicker bracing, and additional anchoring. Hot climates may require insulation, while high rainfall areas may need improved drainage and anti-rust coatings.

Building Function & Equipment – If cranes are required, crane beams and columns must be reinforced. If the building is used for storage, ventilation requirements may differ from production workshops.

Material Selection – Q355B steel vs. Q235B, single-layer vs. sandwich panels, thickness of galvanized coating, and type of roof insulation all influence the final price.

Design Complexity & Customization – Adding mezzanines, office spaces, partitions, skylights, or customized color schemes will increase costs but provide better functionality.

Logistics & Installation – Transport distance and site conditions (flat land vs. sloped land) also impact the total cost, as well as whether the client needs on-site installation support.

By analyzing these factors carefully, K-HOME can recommend the most cost-effective steel structure solution without compromising quality and safety.

popular steel building workshop sizes

120×150 Steel Workshop Building (18000m²)

Frequently Asked Questions

Recommended Reading

Related project

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.