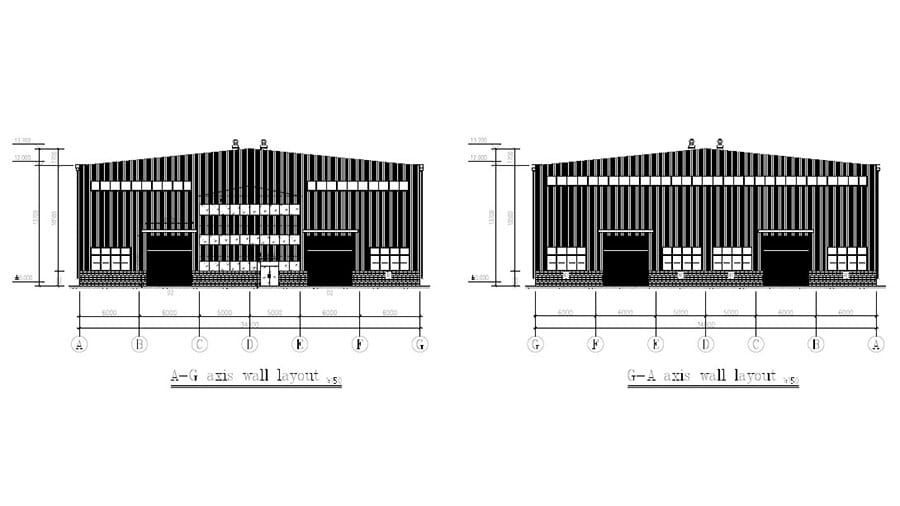

Steel Frame Workshop in Mexico

We provide customized steel structure solutions for worldwide customers

Steel structure buildings are used in various industries. Compared with traditional concrete buildings, steel frame buildings use section steel instead of reinforced concrete, which gives them higher strength and better seismic resistance. Moreover, since the building components are produced in factories and installed on-site, the construction period is significantly shortened. Additionally, as steel can be reused, construction waste is greatly reduced, making steel structure buildings more environmentally friendly.

Project Overview – Steel Frame Workshop in Mexico

In August 2024, K-home received an inquiry from a Mexican client. With the expansion of their business scale, they needed to extend a steel frame workshop and warehouse, equipping it with an office. After getting in touch with the client, he provided more details: due to the tight land area of the factory, the new building must not exceed 110m in length and 50m in width; more importantly, sufficient width of passages must be reserved around the building to meet the needs of large freight trucks for entry, exit and U-turn. Meanwhile, an independent construction space must be reserved for a 3-story office building to ensure that it is next to the production and storage areas but does not interfere with each other.

Based on the basic requirements from the client, our design team drew multiple versions of plane sketches combined with the actual situation of the site. The sketches not only marked the approximate outline of the building and the reserved width of the passages, but also initially divided the estimated areas of the workshop and warehouse, and marked the reserved location of the office building, so that the client could intuitively understand the layout idea.

After we sent the plane sketches to the client, he put forward several adjustment suggestions based on his own production process and storage needs. In the following two weeks, we had multiple rounds of communication and revisions around the design details: from the division of the internal functional areas of the building, to the accurate calculation of the passage width, and then to the preliminary planning of the functional layout of each floor of the office building. Finally, the dimensions of the steel frame workshop were determined by 88m x 34m x 12m (L*W*H). The interior is divided into two spans by a partition wall, each with a width of 17 meters; the supporting office building is built next to this building, with dimensions of 10m (length) × 10m (width) × 9m (height, 3 floors in total, each with a floor height of 3 meters).

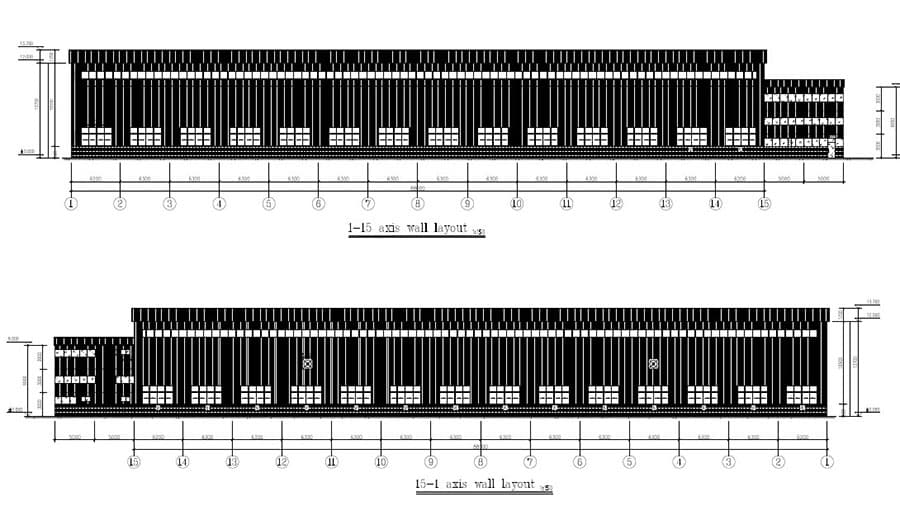

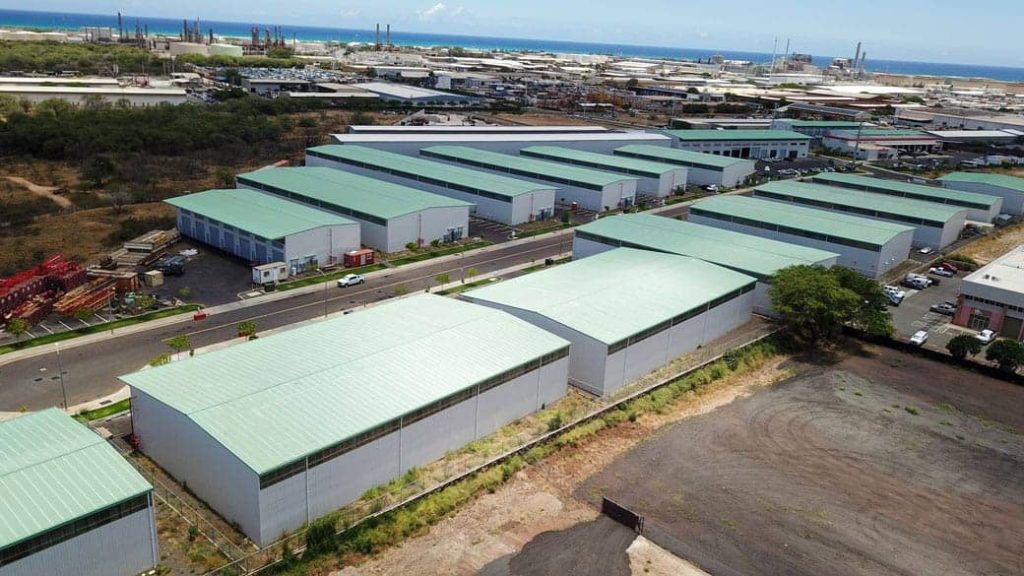

Steel Frame Workshop in Mexico Floor Plan

Your Best Partner For Steel Structure Building in Mexico

K-HOME is one of the trusted factory manufacturers in China. From structural design to installation, our team can handle various complex projects. You will receive a prefabricated structure solution that best suits your needs.

You can send me a WhatsApp message (+86-18790630368), or send an e-mail (sales@khomechina.com) to leave your contact information. We will contact you as soon as possible.

Challenges of Prefabricated Steel Structure Design in Mexico

This project is located in Monclova, Mexico. The area has a typical hot semi-arid climate. Winters here are mild and comfortable, posing no special challenges to the building structure; however, high temperatures frequently occur in summer, with the maximum temperature exceeding 40°C. Moreover, due to the terrain, there is a high risk of sudden flooding. These core challenges must be taken into account when designing the steel structure.

To address potential damage to the building caused by sudden floods, we have incorporated flood prevention design at the bottom of the building’s enclosure wall – using a 1.5m-high solid brick wall structure. This can effectively prevent floodwater from pouring into the building, avoiding damage to production equipment and stored materials due to water accumulation. At the same time, the brick wall has high compressive strength, which can resist accidental external impacts (such as incorrect collisions by forklifts and freight vehicles in the factory area). Additionally, the dense wall structure can also be effectively anti-theft, achieving the dual functions of “flood prevention + protection”.

In the design of the roof and wall structures, considering the high summer temperatures, composite sandwich panels with excellent thermal insulation performance would be the ideal choice. However, due to the client’s limited budget, color steel single sheets with higher cost-effectiveness were finally selected. Meanwhile, supporting design measures have been taken to make up for their thermal insulation shortcomings and ensure the production comfort inside the workshop under high-temperature conditions. The specific measures are as follows:

- Increase window quantity: Additional windows are installed. The windows adopt a sliding design, with a single size of 4m × 2.4m, and the distance between adjacent windows is controlled within 4m. This measure not only increases natural daylighting and reduces energy consumption, but also forms a convective ventilation channel, accelerating indoor air circulation and lowering the indoor temperature.

- Configuration of industrial fans: Two large industrial fans are installed on the walls. By generating large-area air flow (with a wind speed of up to 2-3m/s), they accelerate the evaporation of human sweat, creating a cool and comfortable working environment for workshop operators.

- Installation of roof ventilators: A row of roof ventilators is evenly arranged along the ridge direction on the roof, with a single ventilator air volume of 1000m³/h. The ventilators can quickly exchange indoor and outdoor air, realizing 24-hour uninterrupted natural ventilation and achieving both energy-saving and cooling effects.

- Upgrade of roof structure: To address the insufficient thermal insulation of color steel single sheets, we have optimized the roof structure into a composite system of “color steel single sheet + 75mm glass wool insulation layer”. This improves the solar reflectance, reduces heat absorption by the roof, and effectively alleviates the problem of high indoor temperatures in summer.

Structural System and Enclosure Structure

According to the span, height and load characteristics of a building, there are various types of steel structure systems for selection. Common types include:

- Portal rigid frame: Suitable for single-story workshops and warehouses (span: 15-30m, column spacing: 6-9m);

- Steel frame structure: Suitable for multi-story office buildings and hotels (height: ≤100m, column spacing: 8-12m);

- Spatial steel structure: Such as grid structures and lattice shells (suitable for large-span venues, span: ≥30m), and trusses (suitable for exhibition halls and corridors);

- Light steel structure: Suitable for low-rise residences and temporary buildings (with small component sections and light self-weight).

For this Mexico project, the economical and practical portal rigid frame was finally selected as the structural system.

- Steel Frame: Considering safety and economy, Q235B H-section steel was used for the main steel frame of this project. Shot blasting and alkyd paint spraying were applied to extend its service life. Q235B steel was also used for the secondary steel and purlins, which were treated with hot-dip galvanizing for moisture and corrosion resistance.

- Enclosure: Both the roof and walls adopted 0.5mm-thick color steel single sheets, and an insulation layer was added to the roof.

4 Steps to Complete Steel Frame Workshop Design

The design process of steel frame workshops includes steps such as defining design objectives and building functions, making architectural drawings, conducting structural calculations, and finally creating construction drawings. These steps ensure the structure’s safety, functionality and economy. The design process is as follows:

- Define Design Objectives and Building Functions: Clarify the building’s purpose, dimensions, load requirements, environmental conditions, and expected service life.

- Make Architectural Drawings: After confirming all details, our designers will draw preliminary architectural drawings (including floor plans and elevations) for the client’s confirmation. Based on the drawings, many clients will put forward adjustment suggestions. After multiple revisions, the final version of the architectural drawing will be confirmed.

- Conduct Structural Calculations: After the architectural drawings are confirmed, our structural engineer will perform structural calculations based on various applied loads (including dead loads, live loads, wind loads, snow loads, etc.). They will confirm the appropriate steel materials and component types, design joint connection methods, and calculate the project quantity accordingly to ensure the safety of the building structure.

- Draw Construction Drawings: After the order is confirmed, our engineers will draw a complete and clear set of construction drawings, such as foundation drawing, layout plans, component details, joint details, purlin layout drawings, wall panel and roof panel layout drawings, to guide factory processing and on-site construction.

Factors Affecting Steel Structure Building Price

Raw Material Prices:

The price of raw materials has a significant impact on the construction cost of steel frame workshop. Therefore, fluctuations in steel prices always lead to changes in the overall price of steel structure buildings.

External Loads

External loads determine the size and strength of the steel structure. The greater the load, the more steel is used in the building. In particular, if a structure bears wind loads or snow loads (both essentially static loads), it should use more steel than other buildings constructed at the same time.

Span of The Steel Frame

The larger the span of the steel frame, the more steel is used. A width exceeding 30m is considered a large width. If the steel frame has a large span and no central columns, the steel consumption will also increase.

Structure

If a steel frame workshop is equipped with cranes or mezzanines, it needs to meet the relevant requirements for crane safety and safe operation. When calculating the design strength of steel columns, the size of the columns is usually increased, and equal cross-sections are used. This will increase the steel consumption of the building to support greater weight.

Steel warehouse building supplier – providing customized solutions for demanding customers

The steel structure buildings provided by K-home are architectural solutions designed to meet various needs. We supply all the components required for building construction, including main steel frames, support systems, purlins, wall girders, bolts, self-tapping screws, etc., which are suitable for construction projects of different scales and purposes. In addition, our steel structure buildings are equipped with rolling shutter doors, windows, color steel roofs and wall panels. You can choose the appearance and functional configuration according to your personal preferences.

K-home will provide you with comprehensive 24-hour installation services, including suggestions, support and objective guidance. After delivery, we will provide detailed installation drawings, and if necessary, we can also send engineers to the site for installation guidance. Whether it is an industrial warehouse or a production workshop, you can easily complete the construction of the steel structure with our help.

K-home will provide highly customized services according to customer needs and local usage environment, such as column spacing design, span distribution, internal layout, enclosure selection, crane configuration, etc.

A professional steel structure company provides much more than just steel beams; they offer complete solutions to turn ideas into a fully functional building. We believe that K-home’s services can enable you to find your most satisfactory solution with peace of mind.

Frequently Asked Questions

Related Industrial Steel Buildings

More Metal Building Kits

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.