Steel Manufacturing Buildings in Ethiopia

Steel structure Manufacturing Buildings solutions speed construction, reduce costs, and are designed for Ethiopia’s climate.

Ethiopia is rapidly becoming a manufacturing hub in East Africa, offering unprecedented opportunities for global investors. Building a modern, efficient steel manufacturing building in Ethiopia presents unique challenges, from complying with local building codes and managing seasonal rainfall to reliable international logistics solutions and expert technical guidance.

So, choosing the right construction partner is a critical first step in ensuring the smooth implementation and long-term stability of your project.

With deep roots in the African market and a deep understanding of both its opportunities and complexities, K-HOME is committed to providing you with durable steel manufacturing plant building solutions designed specifically for Ethiopia.

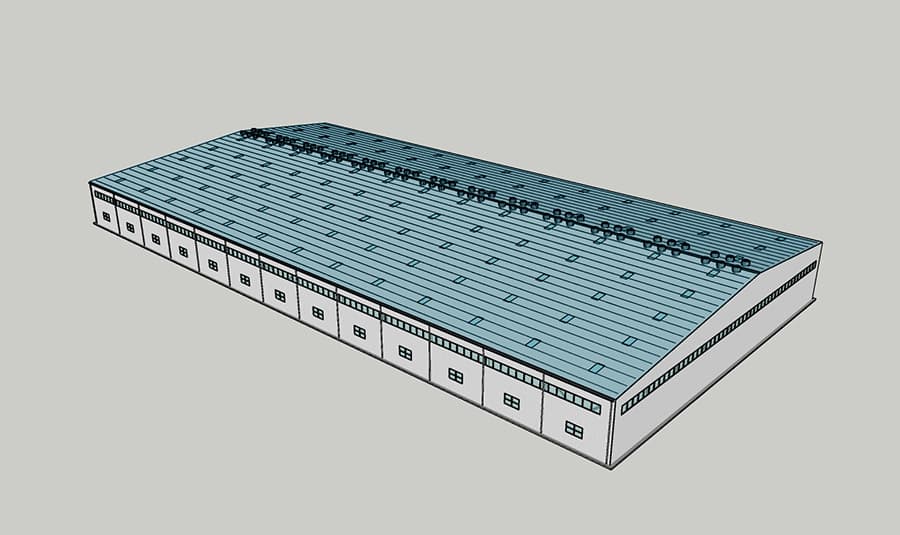

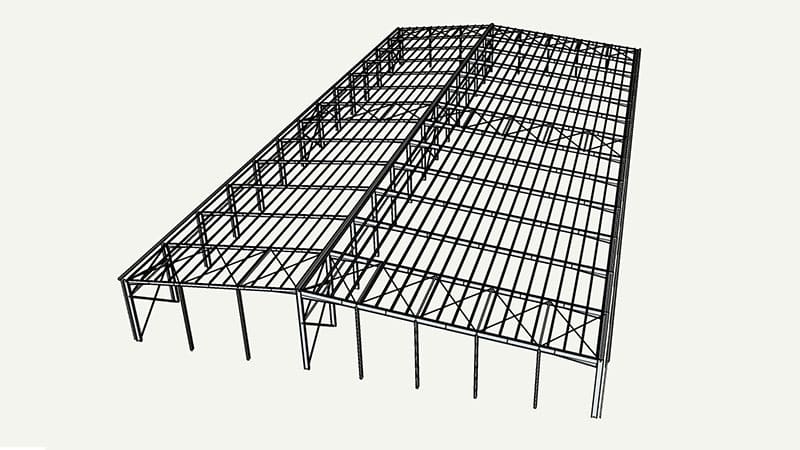

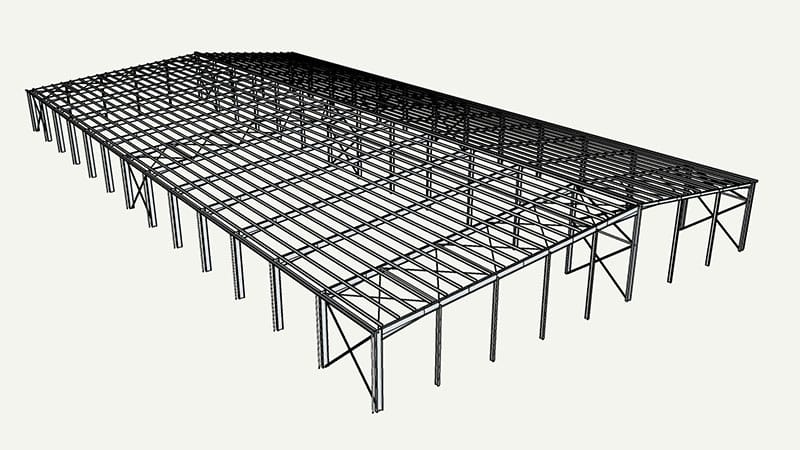

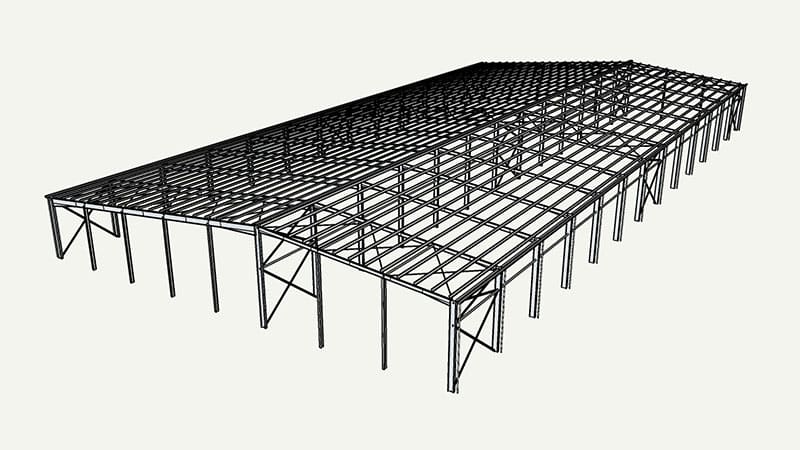

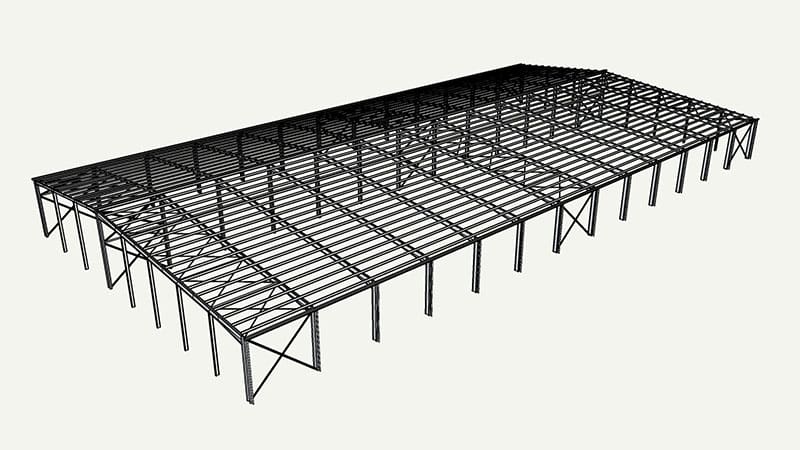

Below is an analysis of the projects we built for Ethiopia

Steel Manufacturing Buildings in Ethiopia – Project Background

Our client is a high-quality aluminum profile manufacturing enterprise that is committed to investing in and establishing a steel manufacturing building in Ethiopia. Their core requirement is to build a modern production workshop with a total area of 5,000 square meters. The specific specifications are as follows:

|

Dimensions |

L100 m x W 50 m x H 8 m |

|

function |

Production and processing of aluminum profiles. |

|

layout |

Large production line (85 meters x 18 meters) and small production line (15 meters x 5 meters). The large production line needs to be 2.5 meters away from the wall, optimizing the production process and personnel movement. The distance between the two production lines is 4 meters to ensure unobstructed transportation channels for raw materials and finished products. |

|

Initial requirements |

Walls and roof use galvanized single tiles. The crane system is not installed for the time being. |

In response to this specific and precise requirement, the project team of K-HOME promptly acted and began to plan a solution that not only met the production needs, but also could perfectly adapt to the climate of Ethiopia while providing customers with a professional and most cost-effective steel structure building solution.

3 Key Design Elements: Addressing the Climate Challenges in Ethiopia

Although Ethiopia is located in the tropics, its high altitude gives it a unique climate environment. When designing this project, the structural designer of K-HOME focused on the following climate factors:

Wind Load

In some areas of Ethiopia, especially during the dry season, strong gusts of wind occur. Our design strictly follows local building codes and international standards, and accurately calculates the basic wind pressure. By increasing the specifications of structural components, optimizing the spacing of purlins and wall beams, and using high-strength connectors, we ensure the stability and safety of the entire steel manufacturing buildings structure under strong winds, preventing structural damage or roof damage caused by wind-induced vibrations.

Rainfall & Drainage

The rainfall in the rainy season in Ethiopia is concentrated and heavy. For this steel manufacturing building, we designed a double-slope roof with a large slope (generally recommended to be no less than 10%), and planned an efficient gutter and downpipe system to ensure that the rainwater can be quickly and effectively drained, preventing water accumulation inside the house and fundamentally eliminating the risk of leakage.

Ventilation & Heat Dissipation

The production equipment in the steel manufacturing buildings generate a large amount of heat, and due to the high temperature in the area, good ventilation is extremely important. In our plan, we suggest installing ventilators at the high point of the roof. By utilizing the principle of thermal pressure ventilation, we can continuously discharge hot air and industrial waste gases, while introducing cooler outdoor air, creating air convection, significantly reducing the indoor temperature, improving the working environment for workers, and reducing the energy consumption of air conditioning.

Through the above targeted design, K-HOME has not merely created an architectural shell; rather, it has constructed a production space that is in harmony with the local environment and highly energy-efficient.

Structure System Overview of Steel Structure Manufacturing Buildings in Ethiopia

For this 5,000-square-meter steel manufacturing buildings, K-HOME has adopted a mature and cost-effective light steel structure system.

Primary Structure

The H-shaped steel is used as the beams and columns of the portal frame. The steel columns and beams of steel manufacturing buildings are selected with different specifications of H-shaped steel based on the force calculation to ensure the overall stiffness and strength. All steel components are made of Q355B high-strength steel, which are factory-prepared and processed. They have high precision and stable quality.

Secondary Structure

Roof System: The roof system of steel manufacturing buildings employs high-strength Z-shaped cold-formed thin-walled steel purlins, with the density determined based on wind pressure and snow load (even though snowfall is rare in Ethiopia, other loads need to be considered). These steel purlins provide solid support for the roof panels.

Wall System: The wall system of steel manufacturing buildings also uses Z-shaped steel wall beams, arranged in layers. They are not only used to fix the wall panels but can also serve as support points for equipment that may be installed in the future.

Compared to C-shaped steel purlins, Z-shaped steel purlins occupy less space during transportation and effectively save shipping costs for customers while maintaining structural strength.

Enclosure System

Roof and Wall: In strict accordance with customer requirements, 0.4mm thick galvanized single tiles are used, with the base plate being galvanized steel. They have excellent corrosion resistance and durability. Customers can choose different colors and coatings based on aesthetics and budget.

Insulation and Heat Retention (Optional)

Given the high temperatures in the area, we strongly recommend installing a glass wool insulation layer between the roof panels and purlins, effectively blocking heat transfer and creating a more comfortable production environment.

- insulation materinal – glass wool

- insulation treatment of the roof

- insulation treatment of the roof

- insulation treatment of the roof

Connection and Sealing

The panels are fixed using self-tapping and self-drilling screws. All joint areas of the panels are sealed with weatherproof sealant to ensure the airtightness and watertightness of the entire enclosure system.

Foundation System

Design a reinforced concrete independent foundation. Our structural designers will provide precise foundation drawings, including foundation dimensions, reinforcement details, positions and elevations of embedded bolts, to guide the local construction team in carrying out the foundation work, ensuring a precise connection with the upper steel structure.

Your best steel manufacturing buildings partner in Ethiopia

K-HOME is one of the trusted factory manufacturers in China. From structural design to installation, our team can handle various complex projects. You will receive a prefabricated structure solution that best suits your needs.

You can send me a WhatsApp message (+86-18790630368), or send an e-mail (sales@khomechina.com) to leave your contact information. We will contact you as soon as possible.

K-HOME Steel Manufacturing Buildings Design and Construction Process

We offer a clear and transparent project process, allowing you to understand every step clearly:

1. Demand Communication: You provide the initial requirements (such as size, purpose, layout, design specifications, etc.).

2. Scheme Design and Quotation: Our designers conduct the initial scheme design and provide detailed quotations.

3. Technical Deepening and Signing: After both parties confirm, structural calculations and detailed construction drawings are carried out, and a formal contract is signed.

4. Factory Production: After the drawings are confirmed, raw materials are purchased and put into factory production.

5. Transportation: After the product is produced, the loading of steel manufacturing buildings components and sea transportation are arranged.

6. Foundation Construction: At the same time, the local construction team conducts foundation construction according to the drawings.

7. On-site Installation: After the steel manufacturing buildings components arrive at the site, we will provide detailed construction drawings, and your installation team can carry out a quick and efficient installation.

8. Completion Acceptance: After the installation of steel manufacturing buildings is completed, a final acceptance is conducted, and the product is delivered for use.

Steel Manufacturing Buildings Price Information and Influencing Factors

The price of steel manufacturing buildings is not a fixed value but is determined by multiple factors. The initial estimated price range for a 5,000-square-meter steel workshop is usually between $35 and $50 per square meter, and the total price needs to be determined based on the final plan.

The main influencing factors include:

- Raw material prices: The international steel market price is the main cost variable.

- Design complexity: Span, height, presence of cranes, special joints, local climate (wind speed, earthquakes, snow load) etc. all affect the amount of steel used.

- Enclosure system selection: The price difference between single tiles and sandwich panels is significant; the thickness of the panels and the type of coating also affect the price.

- Transportation costs: Shipping costs from China to Ethiopia and local transportation costs.

- Local taxes: Import duties and value-added taxes in Ethiopia, etc.

- Foundation conditions: Different geological conditions will result in different foundation costs.

We promise to provide detailed itemized quotations, so that you can clearly see where each expense goes.

Best Steel Manufacturing Buildings supplier in China | K-HOME

K-HOME is a reliable steel manufacturing building supplier in China. A prefabricated steel structure production workshop is specially designed for the Ethiopian market. Our buildings offer long spans, durability and cost-effectiveness. We have successfully delivered projects across Ethiopia. Additionally, we have collaborated with trusted local installation partners to ensure a smooth and successful construction process.

Professional Design: Professional Structural Design Team

K-HOME has an experienced team of professional structural engineers who are proficient in international and local design standards. Your project will receive technical support from the very beginning of the concept stage, ensuring that the structural design is safe, economical, compliant, and can perfectly adapt to your process requirements. Professional design of steel structure buildings can not only precisely match your project needs, but also optimize the design while ensuring the structural safety and durability, and saving you a lot of project time and management costs.

After-sales Service: Local Agent in Ethiopia and Professional Installation Team

This is the decisive advantage that distinguishes K-HOME from other competitors. We have long-term cooperative local agencies and professional installation teams in Ethiopia. The local team is proficient in language and culture, ensuring that your needs are accurately understood and conveyed. At the same time, our installation team has undergone strict training by K-HOME and is proficient in installation techniques and standards, ensuring the speed, quality, and safety of the steel manufacturing buildings, saving you a lot of project time and management costs. You no longer need to worry about finding a reliable construction team.

Reliable Quality

K-HOME has established a full-process quality control system from raw materials to the final product delivery. We mainly use high-strength steel produced by large Chinese steel mills, and all materials have traceable material certificates. The production process of steel manufacturing buildings employs a complete set of CNC equipment (such as CNC cutting, automatic assembly, gantry welding, and shot blasting for rust removal), ensuring that the processing accuracy of the components reaches the millimeter level. The surface treatment adopts high-quality galvanizing or spraying processes, providing excellent corrosion resistance and effectively coping with the complex environment in Ethiopia. What we deliver is not just a simple pile of steel, but a meticulously polished industrial art piece, ensuring that your building operates stably for decades.

Rapid Delivery

Time is equivalent to cost, especially for enterprises that are eager to start production. The prefabricated production model of K-HOME steel manufacturing buildings is the key to ensuring the construction schedule. All steel components are produced simultaneously in the factory, unaffected by weather conditions, and the quality is more controllable. At the same time, foundation construction can be carried out simultaneously at the project site. This “factory and site parallel” model can shorten the total construction period by at least 50% compared to traditional concrete buildings. A 5,000-square-meter standard workshop, from design to installation completion, usually only takes 3-4 months. We can provide a clear project schedule, allowing you to have an accurate expectation of the entire investment cycle and achieve investment returns faster.

Frequently Asked Questions

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.