Hurricane-Resistant Steel Shop Buildings in Bahamas

K-HOME provides high-demand steel building solutions – meeting the Bahamian climate, building standards, and customization

A steel structure building is a building made of steel as its main skeleton. We often encounter applications such as factory workshops, warehouses, exhibition halls, gas stations, parking garages, and cold storage. Its greatest strengths are its stable structure, fast installation, and large spans.

The steel manufacturing building we build are composed of several key components. The core is the primary structure, consisting of steel columns and beams, which support the weight of the entire building. Then there is the secondary structure, such as purlins, braces, and supports, which play a key role in stabilizing the structure and connecting various components. Next comes the enclosure system, primarily roof panels, wall panels, doors, and windows, which provide wind and rain protection, thermal insulation, and ensure indoor functionality. Finally, connectors, such as high-strength bolts and welds, securely connect all of these components, making the entire structure a cohesive whole.

| Component Structure | Material | Technical Parameters |

|---|---|---|

| Main Steel Structure | GJ / Q355B Steel | H-beam, Customized height according to building requirements |

| Secondary Steel Structure | Q235B; Paint or Hot Dip Gavalnized | H-beam, Spans range from 10 to 50 meters, depending on design |

| Roof System | Color Steel Type Roof Sheet / Sandwich Panel | Sandwich panel thickness: 50-150mm Customized size according to design |

| Wall System | Color Steel Type Roof Sheet / Sandwich Panel | Sandwich panel thickness: 50-150mm Customized size according to wall area |

| Window & Door | Color steel sliding door / electric rolling door Sliding Window | Door and window sizes are customized according to design |

| Fireproof Layer | Fire retardant coatings | Coating thickness (1-3mm) depends on the fire rating requirements |

| Drainage System | Color Steel &PVC | Downspout: Φ110 PVC Pipe Water Gutter: Color Steel 250x160x0.6mm |

| Installation Bolt | Q235B Anchor Bolt | M30x1200 / M24x900 |

| Installation Bolt | High-Strength Bolt | 10.9M20*75 |

| Installation Bolt | Common Bolt | 4.8M20x55 / 4.8M12x35 |

The structural requirements of different clients vary, and so do the structural types we recommend. The portal frame structure is our most commonly used and most cost-effective type, suitable for single-story, large-space buildings such as factories, warehouses, and workshops. If a client requires a larger space without obstructed interior columns, such as in a farm or exhibition hall, we recommend a truss structure or increase the cross-section of the steel beams to accommodate the required long spans.

PEB Steel structures offer significant advantages over traditional concrete buildings. For example, they are quick to install; many projects can be erected within weeks of delivery to the client’s site. Steel is also recyclable and reusable. Furthermore, the design is flexible, allowing for various layouts and structures to be tailored to the client’s needs.

Project Profile: – Versatile Commercial Steel Building Complex in the Bahamas

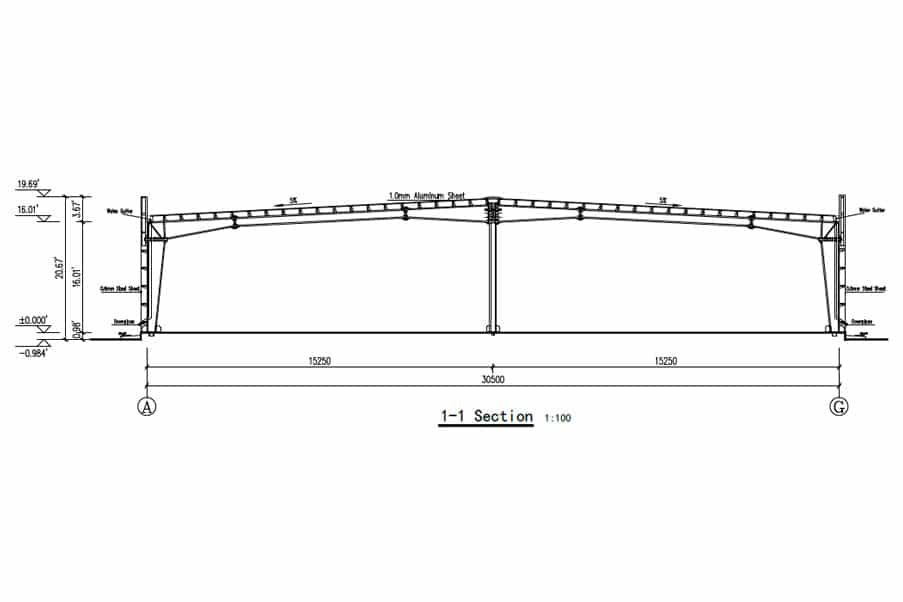

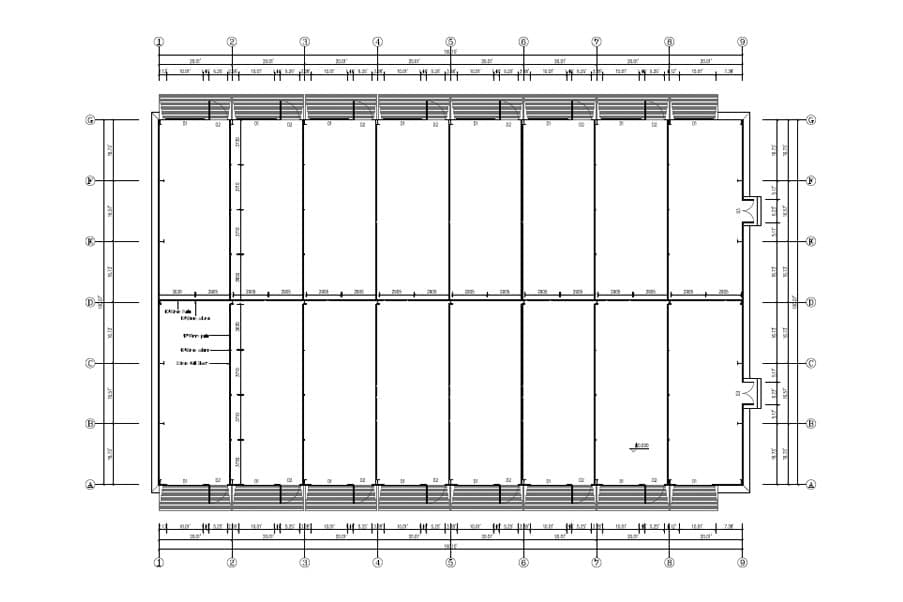

This is a steel shop building in the Bahamas. It covers an area of 1,500 square meters (16,145 square feet).

This steel building serves a dual purpose: it can be used as a solid retail space and generate income through rental units. Measuring 48.8 meters long and 30.5 meters wide, with an interior eaves height of 4.88 meters, it can accommodate a variety of commercial uses.

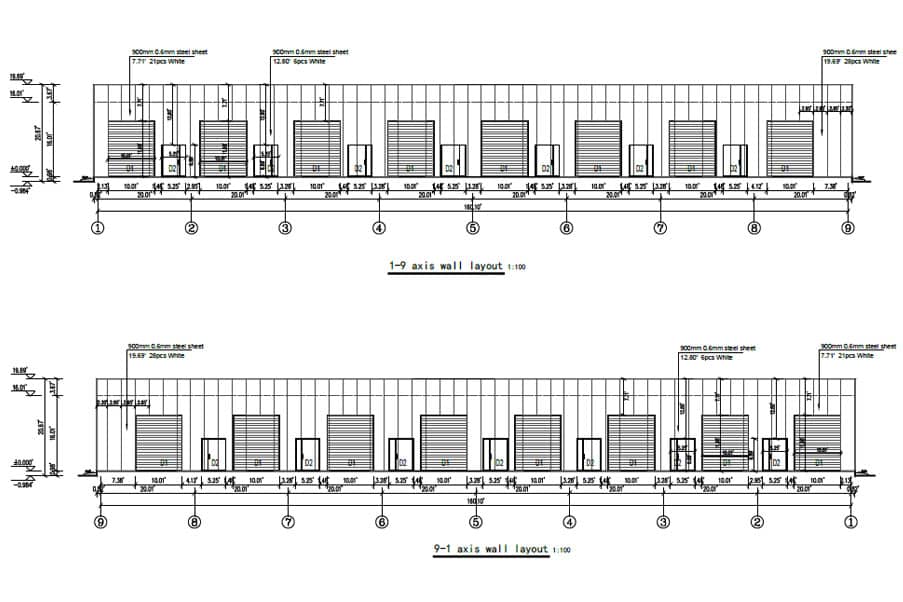

To meet the building’s dual-use requirements, full-height partition walls were designed between each steel column, creating independent and secure units. These partitions utilize the same high-quality, colored steel plate as the exterior walls, ensuring a consistent aesthetic and durability.

The roof system of the steel shop building is constructed using high-quality aluminum extrusions. This material offers excellent corrosion resistance in the harsh marine environment and excellent reflectivity, reducing heat gain and increasing energy efficiency—critical in tropical climates.

Project Challenges: Structural Engineering Design of a Steel Structure Shop in the Bahamas

The challenges we face in project design are: The client specified that the building must be able to withstand extreme wind speeds of up to 180 MPH (miles per hour)—a critical requirement for strong hurricanes in the Bahamas.

To meet this standard, our engineering team took the following precise measures:

- Accurate Wind Load Simulation: We used professional structural engineering software to accurately simulate and calculate local wind loads. Based on this, we scientifically determined the required steel specifications and content for each beam and column, ensuring the absolute safety and integrity of the entire structure in extreme weather conditions.

- Integrated drainage design: We innovatively adopted a parapet design with a built-in drainage system. This not only achieves a simple and beautiful building appearance, but also more efficiently organizes roof drainage, protecting the building’s exterior walls and foundation from rainwater erosion.

- Full Approval Drawing Service: We understand the complexities of local approval processes. To address this, we provide clients with a comprehensive, fully code-compliant structural drawing package, including: Anchor bolt details、Steel frame layout、Roof support and purlin layout, Wall layout, Steel frame structural details

It was precisely because the plan we submitted was accurately calculated, complete in details, and fully in compliance with specifications that the project drawings quickly passed the review of the customer’s government engineers, winning valuable time for the smooth start of the project.

Your Best Steel Building partner in the Bahamas

Building a durable, efficient, and code-compliant steel structure building in the Bahamas presents unique challenges. From hurricane season to the high salt content of the air that accelerates corrosion, your investment requires expert solutions.

At K-HOME, we don’t just deliver the building; we provide peace of mind. With decades of experience in structural engineering tailored to the Caribbean climate, we handle everything from design and permitting to logistics and construction, ensuring your commercial building in the Bahamas is built to last.

You can send me a WhatsApp message (+86-18790630368), or send an e-mail (sales@khomechina.com) to leave your contact information. We will contact you as soon as possible.

Steel structure building quotation analysis

A steel commercial structure project quote consists of several key components: the cost of the structural steel, the cost of wall panels, doors, and windows, labor processing fees, packaging and shipping costs, and special requirements, such as fire-retardant coatings, mezzanine floor slabs, and crane beams, all of which affect the price.

The most crucial factor is the amount of steel used. The larger the building, the longer the span, or the inclusion of mezzanines, cranes, or special load requirements, the more steel used in the main structure, and the higher the price. Then there are the steel specifications, such as Q235B or Q355B, and whether hot-dip galvanizing or conventional painting is used. If the client requires high corrosion resistance, we may recommend hot-dip galvanizing or anti-rust coating, and these costs should be clearly explained in advance.

When providing a quote to a client, we usually break it down and explain the cost of each component. For example, whether the color-coated steel plate thickness is 0.4mm or 0.5mm, and whether the door and window dimensions are larger, making it clear to the client will increase trust. If the customer has a limited budget, I will first ask him which configurations can be simplified, such as recommending a single-layer, moderate-span, simple-structured product to the customer, and help him adjust the solution to a more cost-effective one.

China’s reliable steel shop building manufacturer | K-HOME steel structure co, ltd

Production Capacity

We have two production workshops with large production capacity and short delivery cycles. Generally, our delivery cycle is approximately 20 days. If your order is urgent, we can work with our production team to shorten the production time to meet your requirements.

Professional Design Team

Our design team has over 10 years of experience, our projects span markets such as the Middle East, Southeast Asia, Africa, and South America, giving us a deep understanding of the regulations, material usage, and wind and rain protection requirements of various countries. For example, we factor in the high temperatures and strong winds of the Middle East, the humidity and rainfall of Southeast Asia, and the high material costs and tight budgets of Africa. We can design according to the load specifications of various countries (such as EN and GB standards) and quickly provide 2D drawings and 3D models to provide clients with a more intuitive understanding of the solutions.

Quality Control

- Confirmation of Installation Drawing Details: Before production, our design, procurement, production, and sales departments will hold a meeting to discuss the details of the installation drawings. The drawings are then sent to the customer for confirmation before the procurement process begins.

- Raw Material Quality Control: Raw Material Quality Control: Our raw materials are sourced from large steel mills, ensuring quality. We provide quality certificates for each batch. Upon arrival, our quality inspection department will conduct additional inspections based on the quality certificates to ensure quality.

Controlled Production Process

All production is conducted on an assembly line, with each step supervised and managed by professional personnel. Rust removal, welding, and painting are particularly important.

Rust Removal: The steel frame is shot blasted to Sa2.0 standard, improving workpiece roughness and paint adhesion.

Welding: We use J427 or J507 welding rods, ensuring welds are free of defects such as cracks or bulges.

Painting: Standard colors are white and gray. Three layers are applied: the first layer, the middle layer, and the surface layer. Depending on the local environment, the total thickness is approximately 125µm to 150µm.

Prefabricated Commercial Steel Buildings

Indoor Badminton Court

Learn More >>

Indoor Baseball Field

Learn More >>

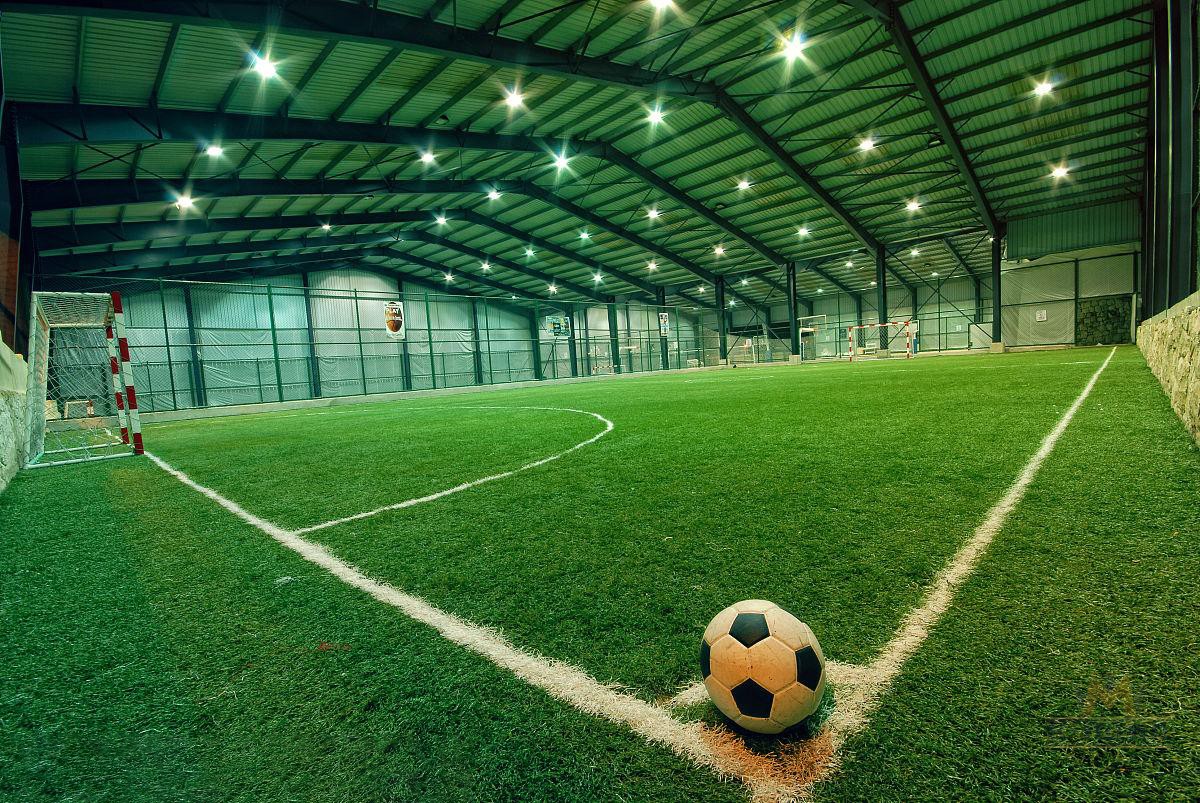

Indoor Soccer Field

Learn More >>

Indoor Practice Facility

Learn More >>

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.