Metal Shop Building in Bahamas

K-HOME provides Hurricane-Resistant steel building solutions – meeting the Bahamian climate, building standards, and customization

Building a Metal Shop Building in the Bahamas usually faces multiple problems and challenges. These issues include: extreme weather during the hurricane season, high-salt air throughout the year, and complex government approval processes, etc. Every link is of vital importance. A minor design mistake or material defect can lead to huge property losses and operational disruptions.

For this reason, what you need is not just a construction supplier, but an expert who is well-versed in the local building codes of the Bahamas and proficient in wind load engineering and anti-corrosion technology.

At K-HOME, we deeply understand all of this. Over the years, we have successfully delivered multiple PEB building projects in the Bahamas region. Each one strictly adheres to local regulations, smoothly passes government approval, and has withstood the tests of harsh environments. From wind load calculation to structural layout, we are always committed to high standards of engineering quality, ensuring that your steel building not only stands firm in storms but also remains reliable and long-lasting in daily operations.

Metal shop building withstands the harsh environment of the Bahamas

Project Overview:

|

Length |

45.720 meters (150ft) |

|

Width |

29.256 meters (96ft) |

|

Eave Height |

7meters(22.96ft) |

|

Span |

Single-span |

|

Function |

Furniture Store with the mezzanine office |

|

Overview |

This type of Metal Shop Building in Bahamas is used for furniture shop, which can also used for workshops, automotive repair shops, and storage facilities in the Bahamas. |

Design Considerations Based on the Bahamian Climate

In tropical maritime climates like the Bahamas, steel buildings must withstand multiple environmental challenges, including hurricane-force winds, high temperatures, and high-salt air.

Based on the specific environmental conditions and building codes of your project location, K-HOME focuses on core design elements such as hurricane-resistant construction, highly corrosion-resistant materials, and thermal insulation and ventilation. While ensuring structural durability and safety, we rigorously control construction costs, ensuring that each project is economical, reliable, and suitable for the unique climate of the Bahamas.

Through close communication with the client, this metal shop building Bahamas adopts the following design scheme:

Solutions for high wind speeds/hurricanes

The local climate requires buildings to be designed to withstand hurricanes up to 290 kilometers per hour (180 miles per hour).

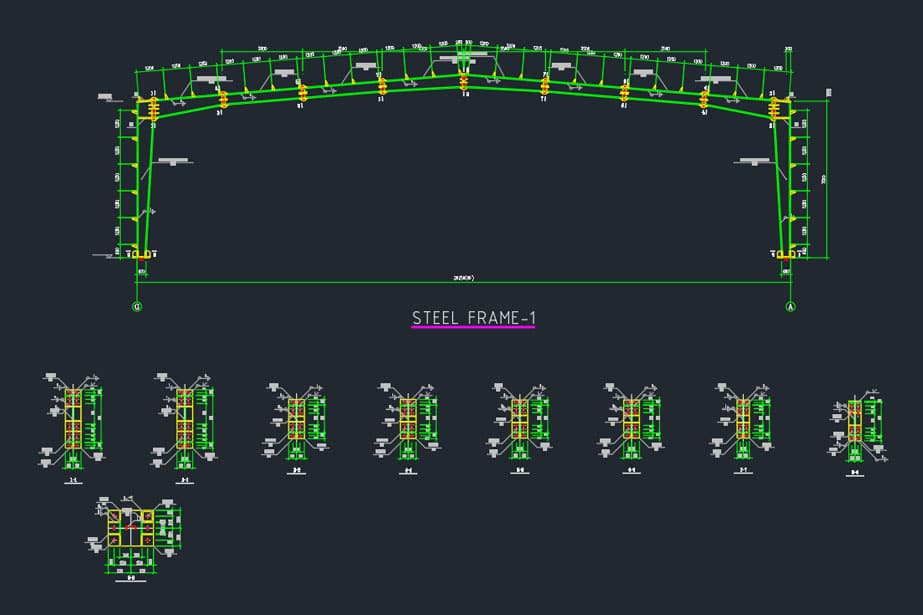

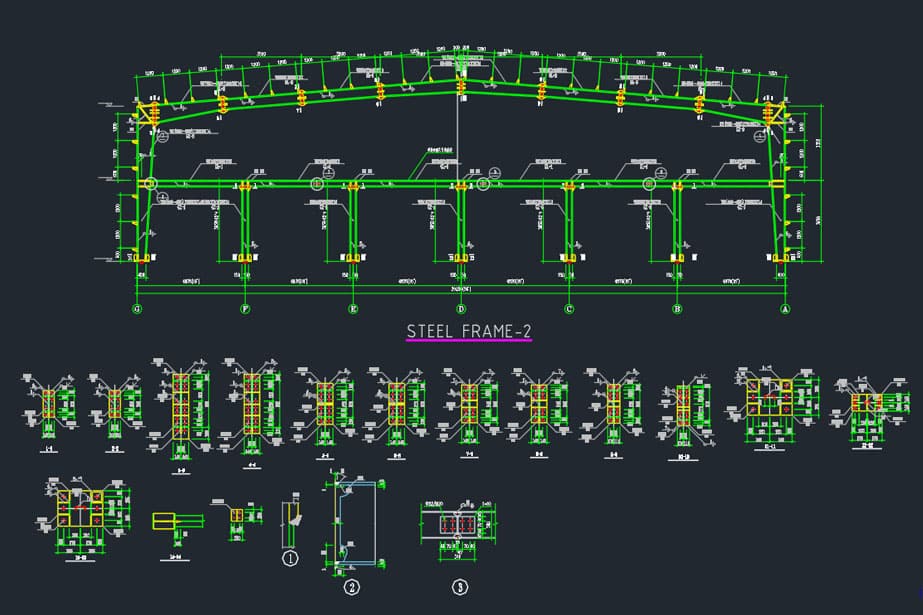

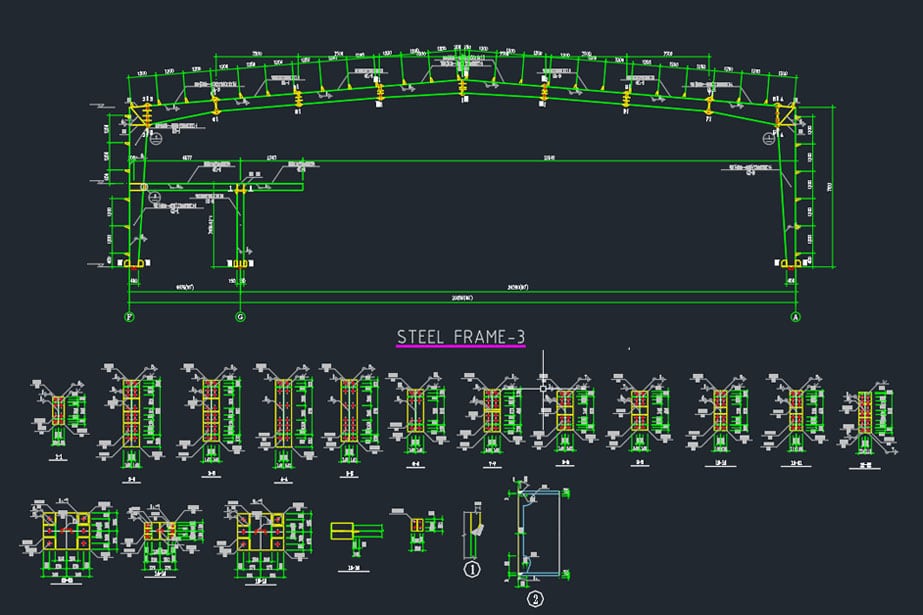

In response to this unique requirement, K-HOME’s technical team conducted structural calculations and verification, and ultimately decided to use a reinforced steel frame and a sturdy connecting structure to withstand such loads. The rigid frame not only has H-shaped steel columns, but also is designed with wind-resistant columns. The splicing of components adopts friction-type high-strength bolts of grade 10.9. The entire framework structure ensures the stability and safety of the building.

steel frame drawing

steel frame drawing steel frame drawing

steel frame drawing steel frame drawing

steel frame drawing steel frame design of metal shop building in Bahamas

steel frame design of metal shop building in Bahamas

Solutions for High Temperature & Humidity

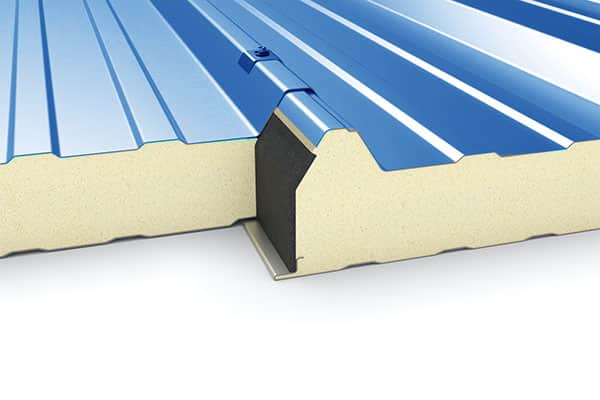

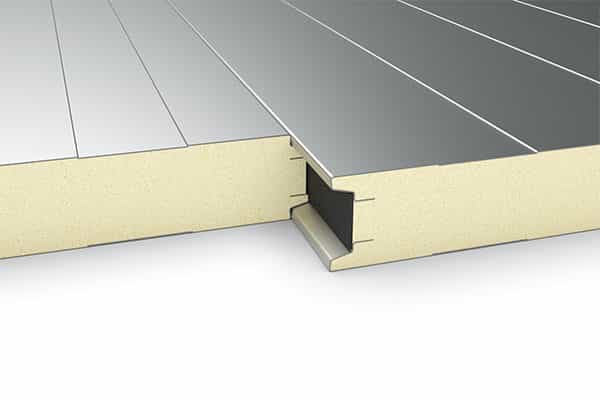

Roof and wall panels should have good insulation and anti-corrosion coatings. Using PU sealed rock wool / PU / PIR insulated sandwich panels can help maintain indoor comfort.

Salt Air Corrosion (Coastal Environment)

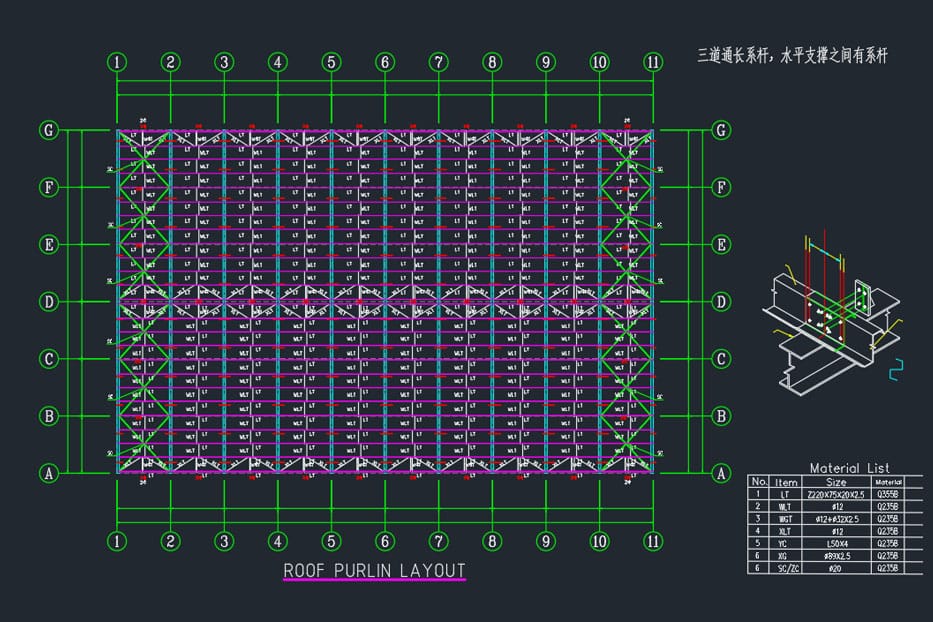

- The main steel frame and secondary frame should be Epoxy zinc-rich paint. Purlin should be 275g/m2 to avoid rusting.

- Hot-dip zinc-coated steel or Prepainted galvanized steel sheet with PE, PVDF painting is recommended to prevent rust and fade.

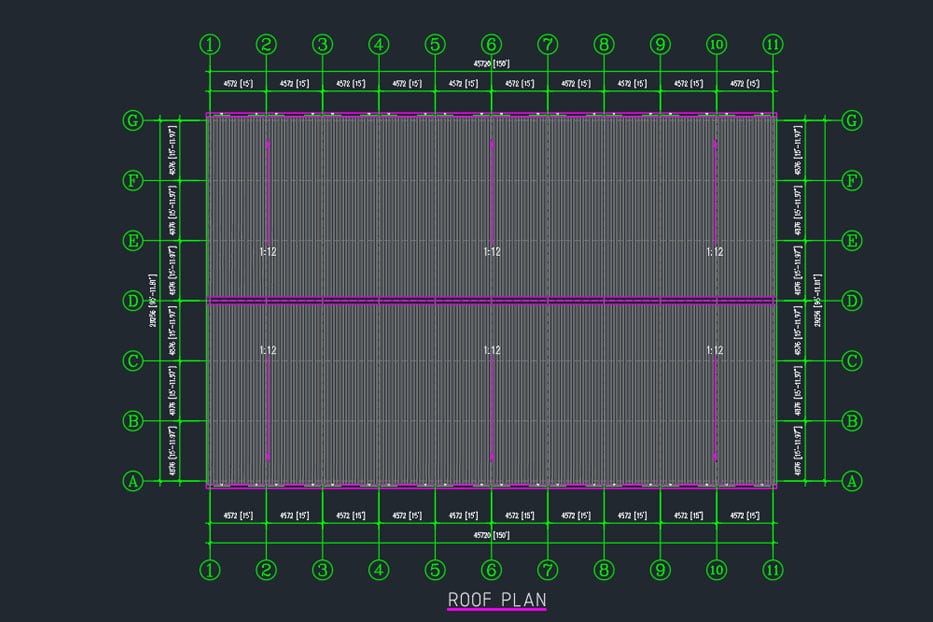

roof purlin layout

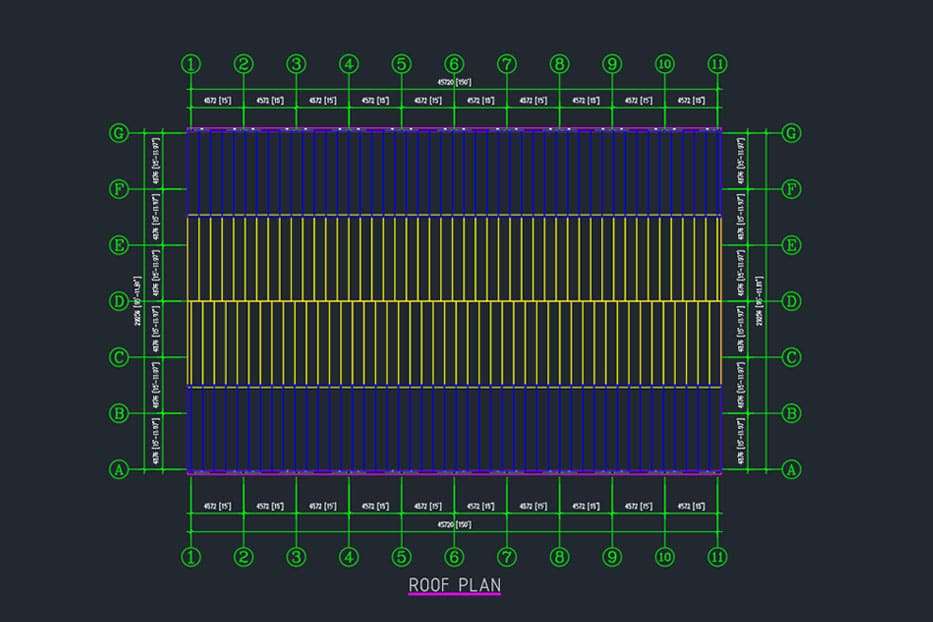

roof purlin layout roof panel layout

roof panel layout Roof slope ratio

Roof slope ratio

Rainfall

Roof slope and drainage systems(bigger galvanized gutter) are optimized to prevent water accumulation.

K-HOME ensures that every Metal Shop Building in Bahamas meets local environmental demands, providing durability, safety, and energy efficiency.

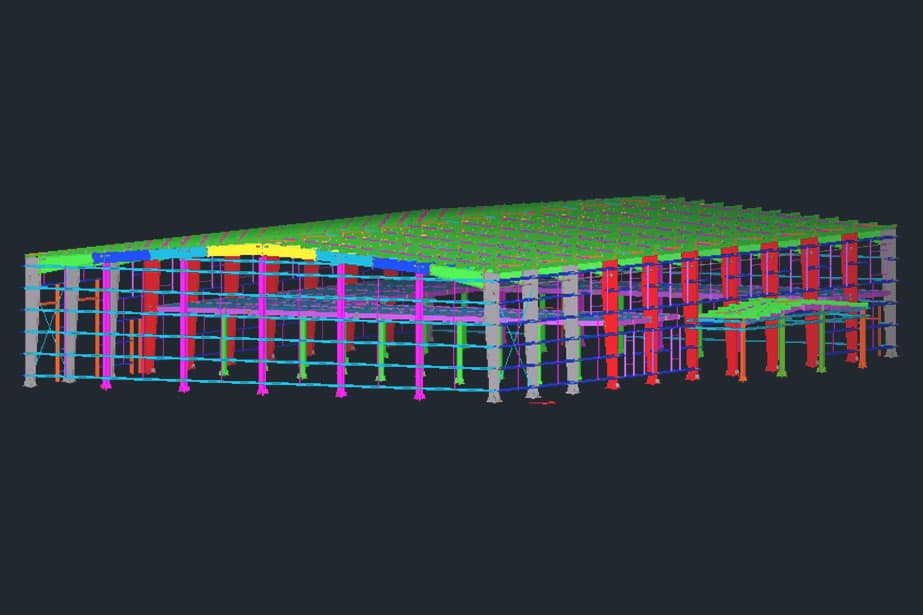

Structural System & Building Envelope for Metal Shop Building in Bahamas

- Main Structure: Q355B Beam and column H-beam welded steel with bolted connections with Epoxy zinc-rich paint

- Secondary Structure: Q235B Bracing system, and tie rods with Epoxy zinc-rich paint

- Wall & Roof Purlin: Q355B C/Z purlins with 275g/m2

- Roof Panels: Insulated 75mm PU sealed rock wool PU/PIR sandwich panels or corrugated metal sheets

- Wall Panels: Insulated 75mm PU sealed rock wool PU/PIR sandwich panels or corrugated metal sheets

- Doors: Roller shutter doors

- Windows: Aluminum hurricane-proof windows

- Foundation: Reinforced concrete isolated footing or strip foundation, customized per geotechnical report.

Your Best Steel Building partner in the Bahamas

Building a durable, efficient, and code-compliant steel structure building in the Bahamas presents unique challenges. From hurricane season to the high salt content of the air that accelerates corrosion, your investment requires expert solutions.

At K-HOME, we don’t just deliver the building; we provide peace of mind. With decades of experience in structural engineering tailored to the Caribbean climate, we handle everything from design and permitting to logistics and construction, ensuring your commercial building in the Bahamas is built to last.

You can send me a WhatsApp message (+86-18790630368), or send an e-mail (sales@khomechina.com) to leave your contact information. We will contact you as soon as possible.

Metal Shop Building Construction Process

The transformation from raw steel to a fully constructed steel shop building involves several critical stages:

Design and Engineering

At the beginning of each project, architects and structural engineers collaborate to produce detailed drawings and structural plans. These designs outline the dimensions, connection points, and load capacities of every steel component. Engineers also perform detailed calculations to account for environmental loads, such as: 1. Wind load 2.Snow and rain load 3.Roof live load 4.Thermal expansion

Material Procurement

Our experienced procurement team sources high-grade structural steel plates, beams, and columns, ensuring materials comply with international quality standards. All materials are inspected for structural integrity and quality before entering the fabrication workshop.

Fabrication

Fabrication is where raw steel becomes customized components for Metal Shop Building in Bahamas. Key steps include:

Cutting: Precision laser cutting ensures accurate dimensions.

Shaping: Steel is bent, punched, or rolled into required profiles.

Welding: We use J427 or J507 welding rods, which produce clean seams without cracks or defects—essential for maintaining structural integrity.

Surface Treatment: Shot blasting is applied to remove rust and meet Sa2.5 standards, enhancing surface roughness for improved paint adhesion.

Marking and Transportation

Each steel part is clearly marked and photographed, making site assembly efficient and foolproof. Our packaging process maximizes container space and minimizes shipping costs by planning the loading sequence in advance.

Advantages of Metal Shop Building in Bahamas

Fast and Efficient Construction

Since components are prefabricated in a controlled environment, on-site work is minimized, and buildings can be erected 30–50% faster than concrete structures. This efficiency is ideal for projects requiring rapid deployment.

Design Flexibility

Architects and structural engineers will make comprehensive designs at the start of the project together. Each steel component’s necessary dimensions, load capabilities, and connecting locations are outlined in these designs. Engineers must calculate things like wind loads,snow load, rain load, roof load, and thermal expansion to assure the structure’s stability.

Eco-Friendly and Sustainable

Steel is 100% recyclable and reusable. It produces less construction waste compared to traditional methods.

Lightweight steel frames require smaller foundations, lowering material consumption and reducing carbon footprint.

Cost-Effectiveness

Though steel material costs may initially appear higher, the overall project cost is often lower due to:

Faster construction

Lower labor requirements

Minimal long-term maintenance

Durability and longevity of the steel frame

Why Choose K-HOME for Your Pre-Engineered Building in Bahamas?

We have extensive local project experience and are familiar with approval processes and construction specifications. We provide professional drawings and competitive pricing. Our Bahamas projects consistently pass local government approvals. In addition, two production workshops ensure fast delivery. Comprehensive quality control includes shot blasting (Sa2.0–Sa2.5), high-quality welding, and a three-coat protective system (125–150μm), ensuring optimal performance in high-temperature and high-salt environments.

We provide clearly marked components, optimized packaging, and comprehensive logistics planning, significantly reducing on-site workload. Even inexperienced contractors can easily complete installation with our detailed installation drawings, 3D guidance, and comprehensive technical support.

K-HOME offers comprehensive services, including high-quality materials, free design, on-time delivery, and reliable after-sales service, ensuring a worry-free and effortless construction experience.

Frequently Asked Questions

Prefabricated Commercial Steel Buildings

Indoor Badminton Court

Learn More >>

Indoor Baseball Field

Learn More >>

Indoor Soccer Field

Learn More >>

Indoor Practice Facility

Learn More >>

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.