Steel Structure Workshop in Tanzania

steel Resin Factory in Tanzania – Built for Tanzanian Conditions

K-HOME’s steel structure workshop Tanzania is tailored to the climate of Tanzania and other parts of Africa. Responding to the hot, rainy, and humid local climate, all building structures utilize corrosion-resistant galvanized steel, supplemented with a high-performance anti-corrosion coating system. This treatment ensures the steel building has a long service life and extremely low maintenance costs in harsh environments.

K-HOME has extensive project experience in numerous African countries, including Mozambique, Kenya, Ghana, and Guyana. We are proficient in steel structure workshop design that complies with national regulations and efficiently obtains government approvals. We also possess mature international logistics capabilities and reliable local construction partners. K-HOME provides clients with a one-stop solution from design and production to transportation and installation, ensuring the smooth implementation of projects in Tanzania and throughout Africa.

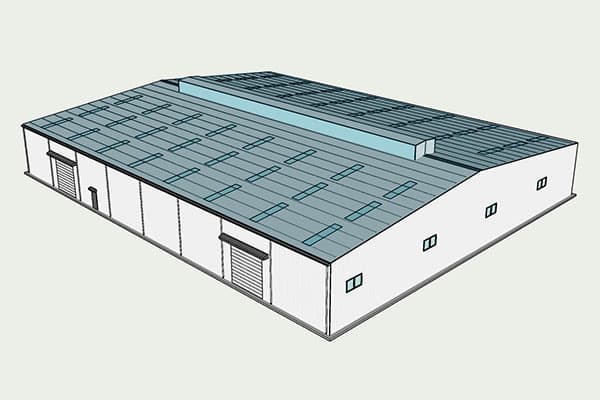

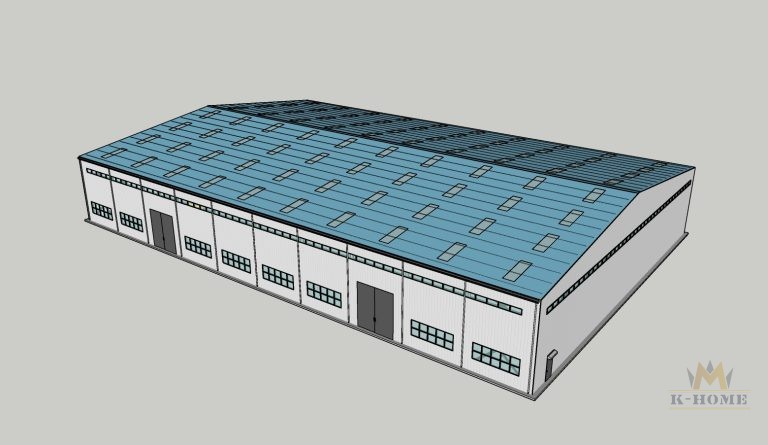

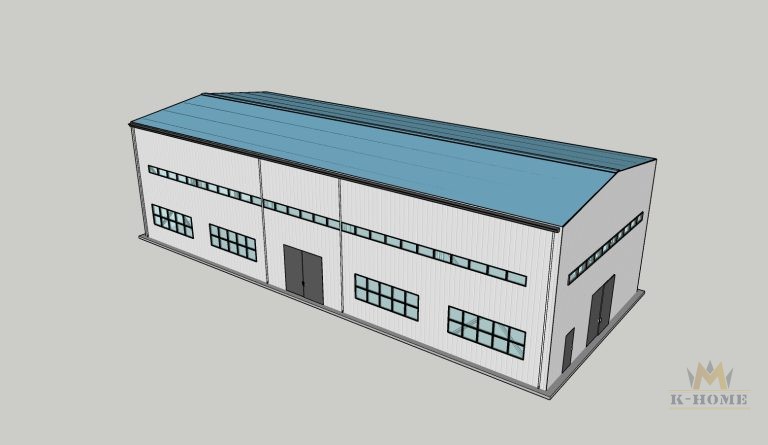

Steel Structure Workshop Solution – Resin Factory Project in Tanzania

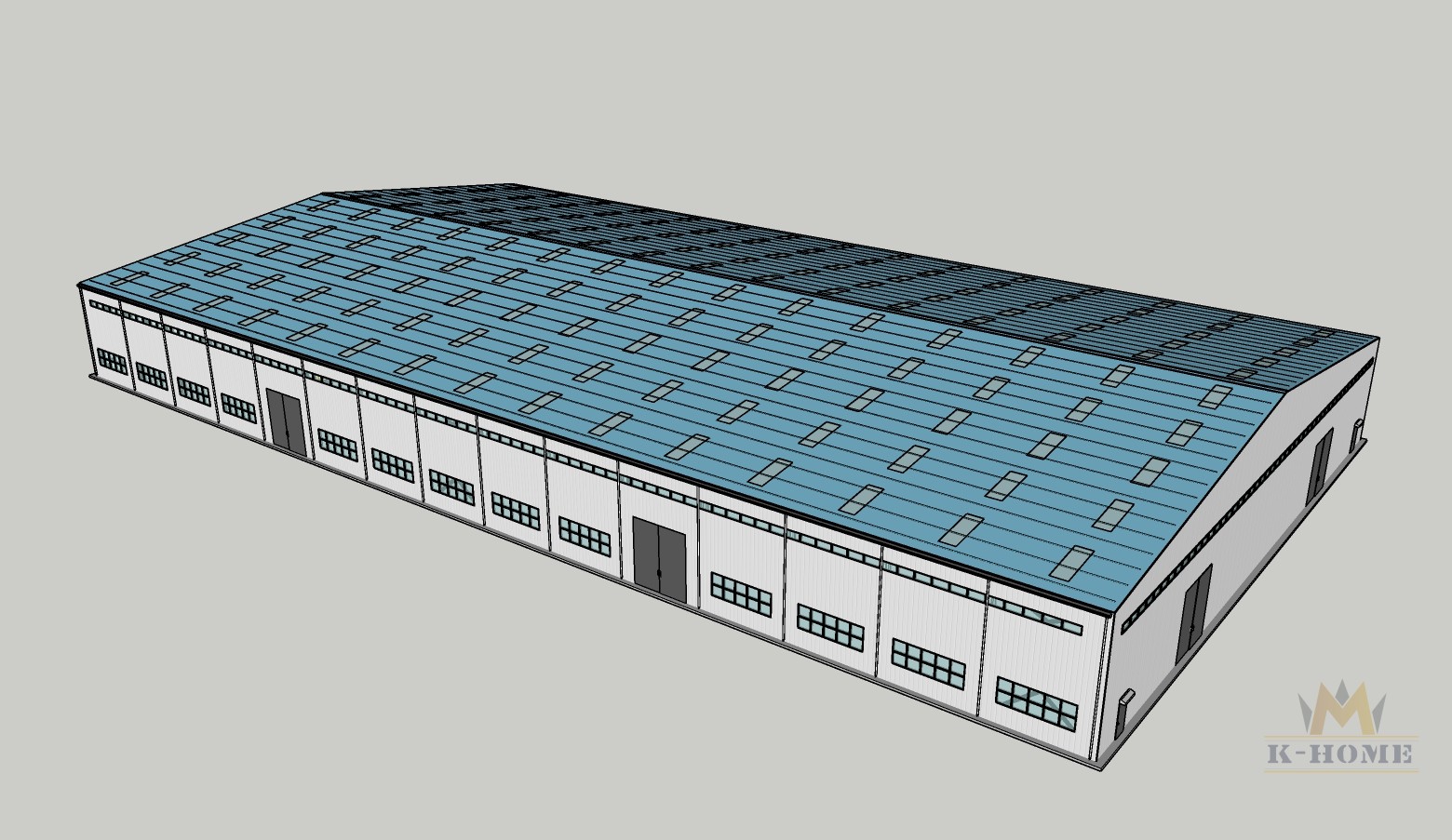

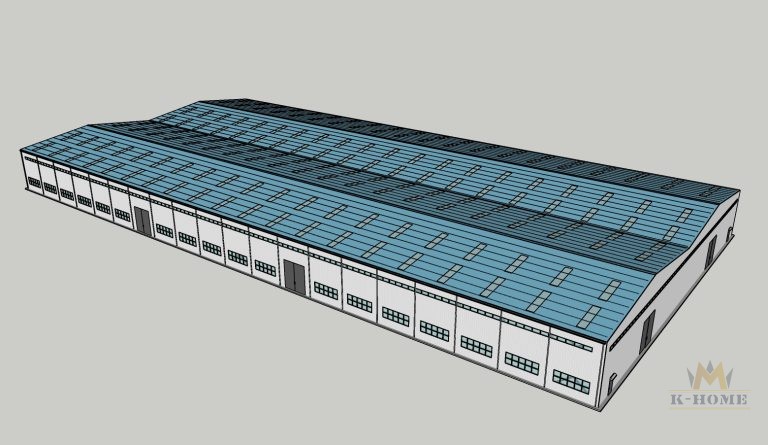

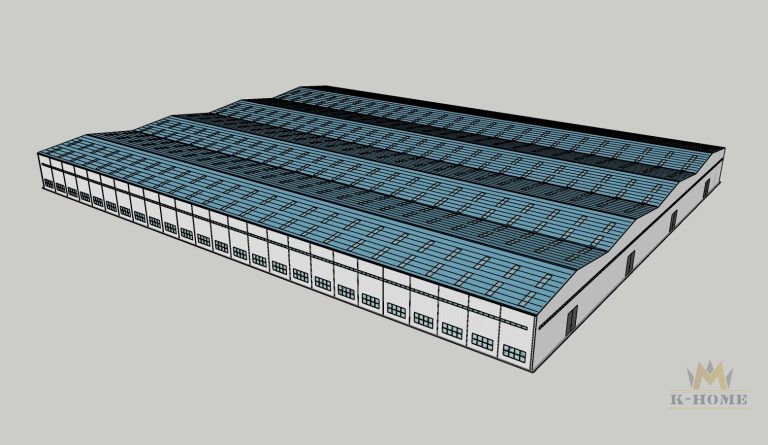

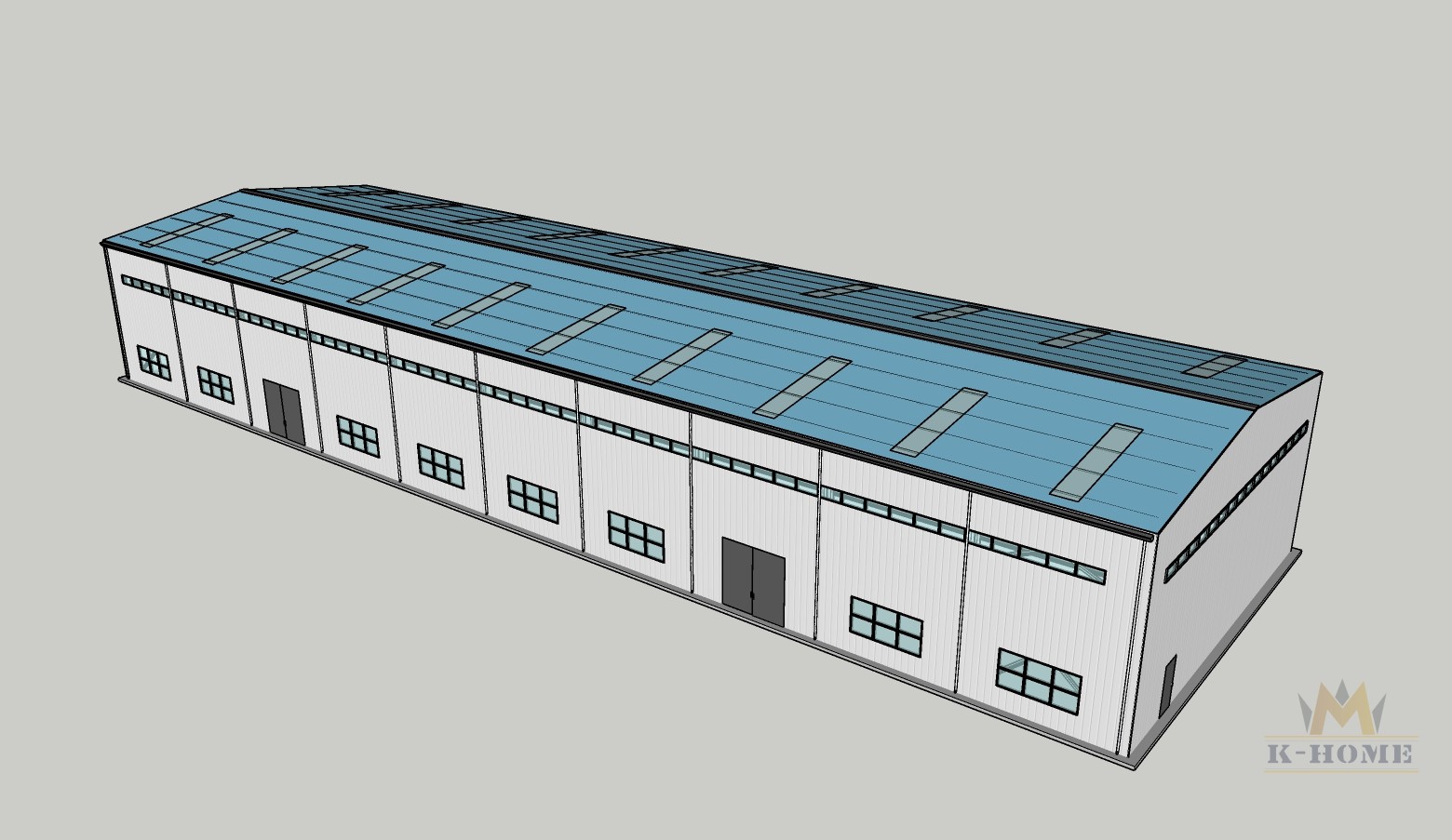

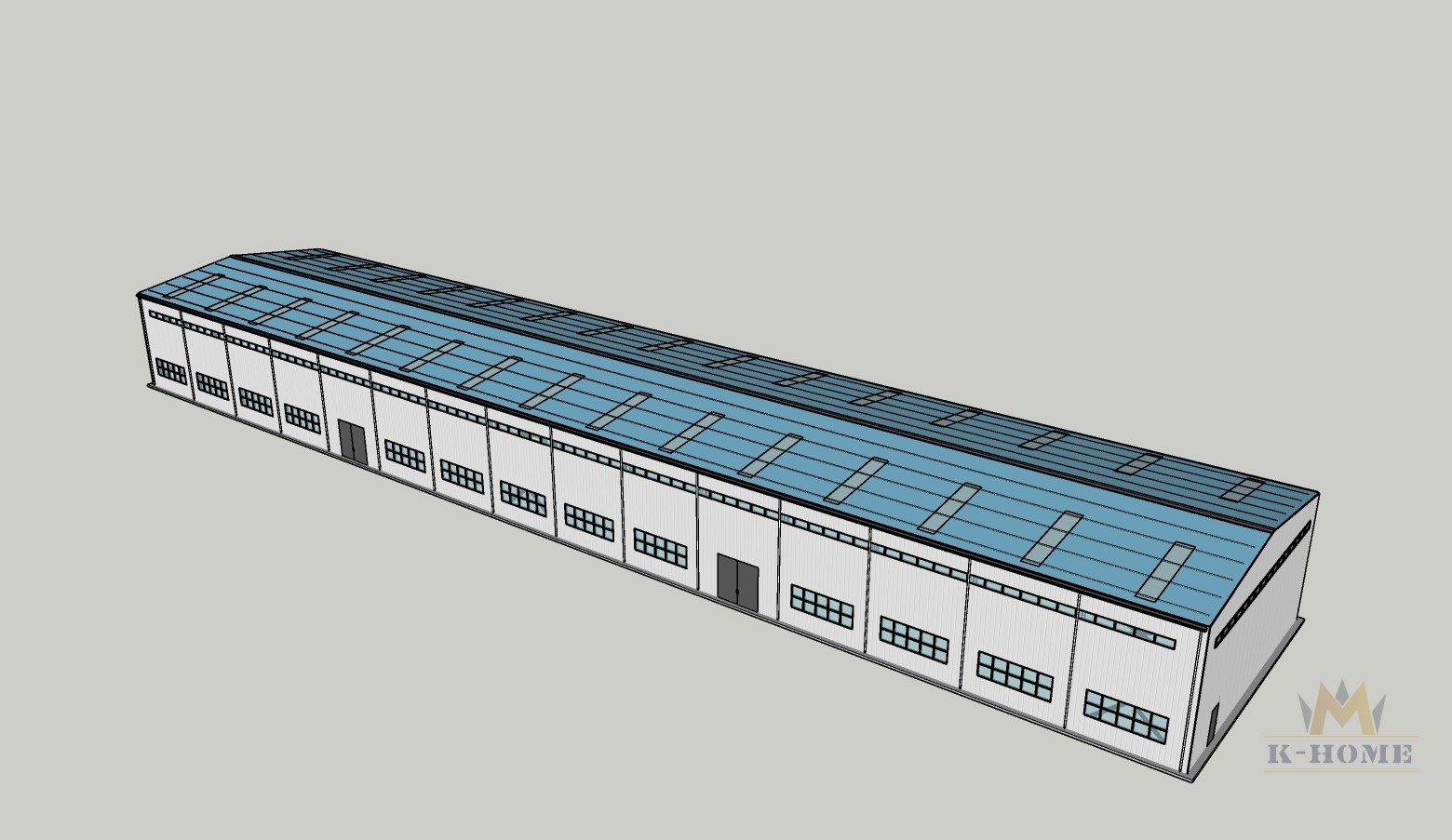

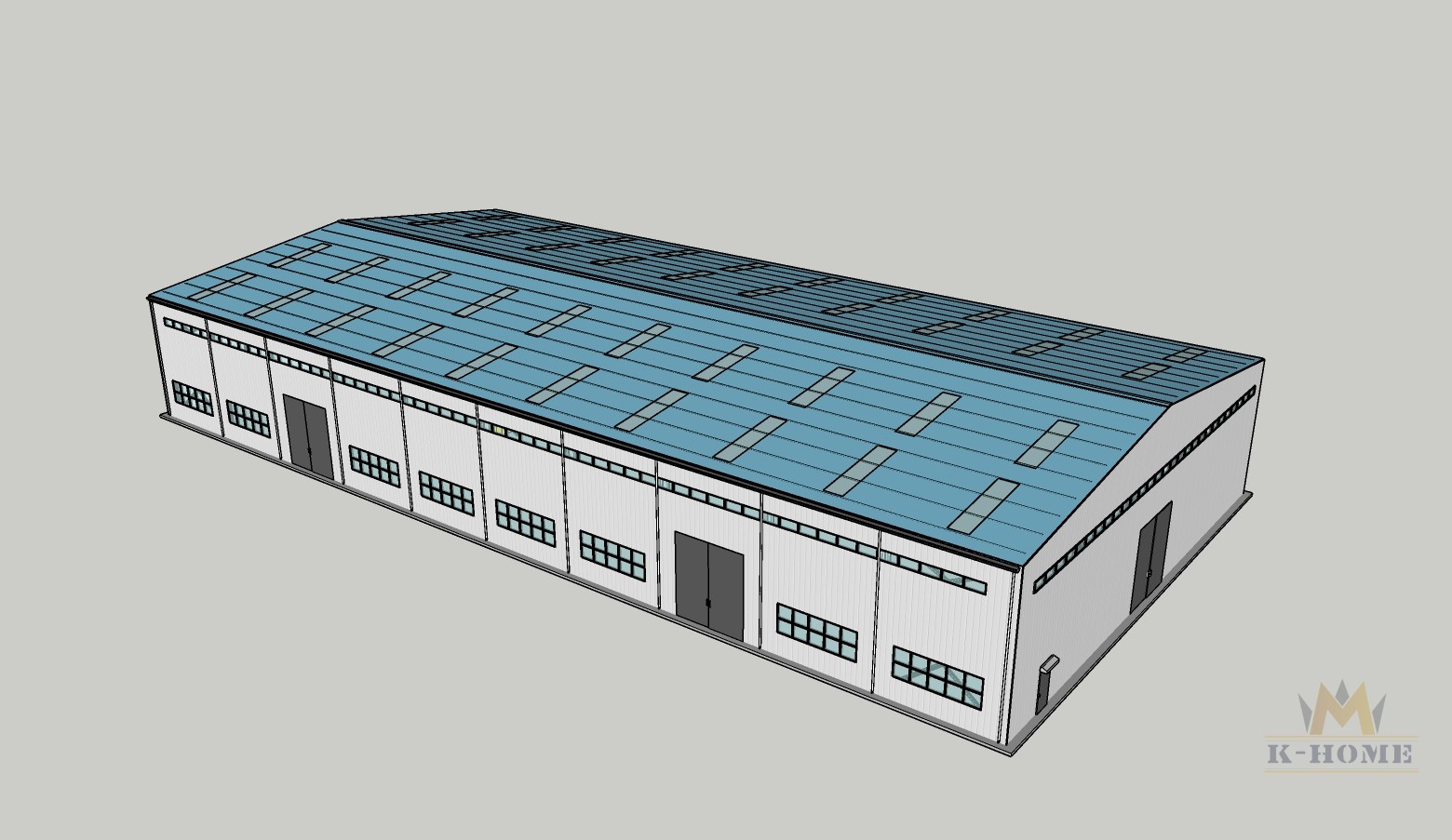

This project is a steel structure workshop designed for a resin production factory in Tanzania. The main workshop measures 40m in width, 20m in span, 50m in length, with an eave height of 6m. There is no overhead crane inside the building, and the workshop is mainly used for production and storage of resin products.

In addition to the main factory building, the project also includes several supporting facilities: a steel structure office building for administration and meetings, staff accommodation for on-site workers, a canteen to improve daily welfare, and a machine storage shed for equipment protection. By integrating these functional areas into one comprehensive industrial factory complex, K-HOME ensures smooth production workflow, better working conditions, and improved efficiency.

Since the client’s factory produces resin, which involves a certain level of corrosiveness, K-HOME designed a special anti-corrosion solution with upgraded galvanized cladding and double-layer roofing system to ensure long-term durability and safety.

Steel Resin Factory Building Design: Considering Tanzanian Climate Conditions

Tanzania has a tropical savanna climate, characterized by high temperatures throughout the year and distinct rainy and dry seasons. When designing an industrial warehouse building in Tanzania, the following environmental factors must be considered:

- Wind speed and wind load: Strong winds in coastal and inland areas require a stable and wind-resistant structural system.

- High temperature: Long-term heat resistance must be guaranteed by both materials and building design.

- Humidity and rainfall: High humidity requires a reliable anti-corrosion design.

- Ventilation and insulation: Critical for safe resin production and a comfortable working environment.

To meet these requirements, K-HOME adopted a double-layer roof design to improve thermal insulation. A ventilation skylight was added to the roof, enhancing natural airflow and preventing heat accumulation inside the workshop. The roof and wall panels are made of thicker galvanized color steel sheets, which provide strong protection against corrosion and ensure building stability in hot and humid climates.

Your best steel workshop building partner in Tanzania

K-HOME is one of the trusted factory manufacturers in China. From structural design to installation, our team can handle various complex projects. You will receive a prefabricated structure solution that best suits your needs.

You can send me a WhatsApp message (+86-18790630368), or send an e-mail (sales@khomechina.com) to leave your contact information. We will contact you as soon as possible.

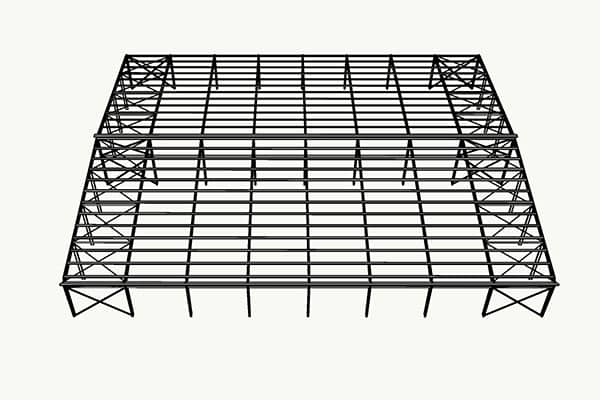

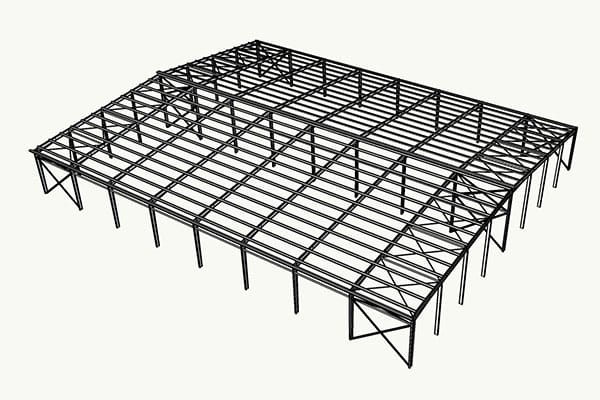

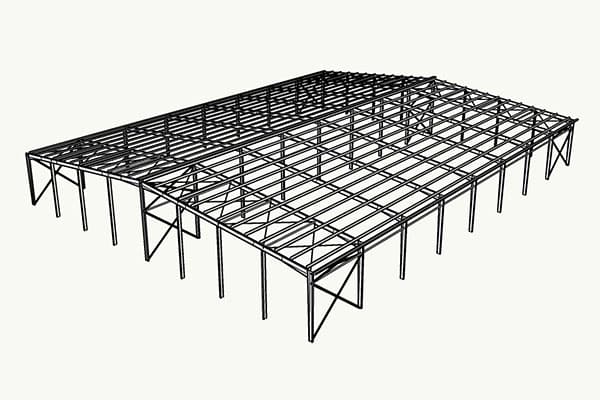

Structural System of Prefabricated Steel Structure Workshop

The factory adopts a professional prefabricated steel structure system, which is both durable and cost-effective:

Reinforced cement concrete foundation with embedded anchor bolts to firmly connect the main steel columns, ensuring overall stability even under high wind loads.

It is worth noting that the foundation structure of steel buildings in each region is different, and designers need to calculate based on local geological conditions and load requirements, and then issue a specific construction plan.

The steel columns and beams, the structural core of the entire building, are constructed from Q355B-grade hot-rolled H-shaped steel, offering high strength and excellent load-bearing performance. All components are shot-peened to effectively enhance the steel’s surface adhesion, providing a uniform and stable foundation for the anti-corrosion coating, significantly improving the building’s corrosion resistance and service life in harsh environments.

Q355B steel purlins (C/Z-section), tie bars, wall and roof bracing to guarantee stability and optimize load distribution.

Double-layer roof panels with ventilation skylight for insulation and airflow; ridge ventilators and rainwater drainage systems designed for local climate conditions.

0.4mm single-layer color steel sheets with thicker zinc coating, providing enhanced resistance to corrosive chemical vapors from resin production.

Factors affecting the steel structure workshop cost

The cost of a prefabricated steel workshop depends on multiple variables. Here is a detailed explanation of the main cost drivers:

Building Size (Length × Width × Height) – The larger the structure, the more steel and panels required, directly affecting total cost. Taller buildings may need heavier sections and stronger bracing systems.

Project Location & Climate Loads – High wind zones or coastal areas require stronger columns, thicker bracing, and additional anchoring. Hot climates may require insulation, while high rainfall areas may need improved drainage and anti-rust coatings.

Building Function & Equipment – If cranes are required, crane beams and columns must be reinforced. If the building is used for storage, ventilation requirements may differ from production workshops.

Material Selection – Q355B steel vs. Q235B, single-layer vs. sandwich panels, thickness of galvanized coating, and type of roof insulation all influence the final price.

Design Complexity & Customization – Adding mezzanines, office spaces, partitions, skylights, or customized color schemes will increase costs but provide better functionality.

Logistics & Installation – Transport distance and site conditions (flat land vs. sloped land) also impact the total cost, as well as whether the client needs on-site installation support.

By analyzing these factors carefully, K-HOME can recommend the most cost-effective steel structure solution without compromising quality and safety.

popular steel building workshop sizes

120×150 Steel Workshop Building (18000m²)

Frequently Asked Questions

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.