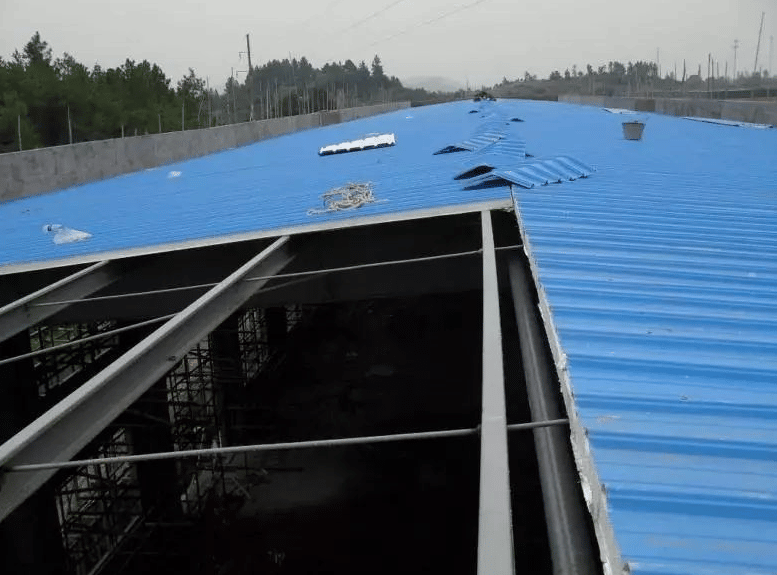

Steel structure workshops are basically composed of steel structure frames and roofs of different materials. In the design of steel structure workshops, not only should the steel structure be well designed but also the design of the factory floor. Only a reasonable roof design can ensure the steel structure. The normal use and safety of various functions of the plant. The following are the matters that must be paid attention to in the design of the steel structure factory roof.

Anti-seepage

Prevents rainwater from flowing from outside to metal roof panels. Rainwater enters metal roofs mainly through laps or seams. In order to achieve the anti-seepage function, it is necessary to use the sealing gasket of the screw mouth to hide and fix it, and then overlap or weld it with the sealing rubber plate.

Fire Protection

In the event of a fire, the metal roofing material will not burn, and the flame will not penetrate the metal roofing sheet.

Wind pressure resistance: It can resist large local wind pressure, and the metal roof panel will not be broken by negative wind pressure. The wind resistance performance is related to the buckling force of the metal roof panel and the fixed seat, and the density of the fixed seat.

Sound Insulation: Prevents sound from passing from outside to inside or from inside to outside. The metal roof layer is filled with sound insulation material (usually filled with insulating wool). The sound insulation effect is expressed by the sound intensity difference on both sides of the metal roof. The sound insulation effect is related to the density and thickness of the sound insulation material. It should be noted that the sound insulation effect of sound insulation materials for different frequencies is different.

Ventilation

indoor and outdoor air exchange. The vents are mounted on the metal roof.

Moisture-proof

Prevent the condensation of water vapor at the bottom and metal roof layer, and drain the water vapor in the metal roof layer. The solution is to fill the metal roof layer with thermal insulation cotton, apply a waterproof membrane on the metal roof bottom plate, and set up ventilation nodes on the metal roof plate.

Bearing

Bear construction load, rain, dust, snow pressure, and maintenance load. The load-bearing performance of the metal roof panel is related to the section characteristics of the panel type, the strength and thickness of the material, the force transmission method, and the spacing of the purlins (auxiliary purlins).

Lightning Protection

lead the lightning strike to the ground to prevent the lightning strike from penetrating the metal roof and entering the room.

Insulation

Prevent heat transfer on both sides of the metal roof, so that the indoor temperature is stable. The thermal insulation function is achieved by filling thermal insulation materials (commonly used glass wool and rock wool) under the metal roof panel. The insulation effect is expressed by the U value, and the unit is W/M2K. The thermal insulation performance of the thermal insulation cotton is mainly determined by the following factors: the raw material, density, and thickness of the thermal insulation cotton; the humidity of the thermal insulation cotton, the connection method between the metal roof panel and the substructure (to prevent the “cold bridge” phenomenon); the heat of the metal roof The ability to recycle radiation.

Lighting

Improve indoor lighting through skylights during the day and save energy. In the specific position where the light panel or lighting glass is arranged on the metal roof, the coordination of the service life of the skylight and the metal roof panel should be considered, and waterproof treatment should be done on the connection between the skylight and the metal roof panel.

Beautiful appearance

The metal roof has a good texture and pleasant color.

Control thermal expansion and contraction: Control the shrinkage displacement and shrinkage direction of the metal roof panel. Ensure that in areas with large temperature differences, the metal roof panel will not be damaged due to stress caused by thermal expansion and contraction.

Avalanche Protection

Metal roofs in snowfall areas are mounted on snow barriers to prevent sudden snow slips.

Icicles: Prevents rain and snow from forming icicles on the cornice.

Prefab Steel Structure Workshop: Design, Type, Cost

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.

About Author: K-HOME

K-home Steel Structure Co., Ltd covers an area of 120,000 square meters. We are engaged in the design, project budget, fabrication, and installation of PEB steel structures and sandwich panels with second-grade general contracting qualifications. Our products cover light steel structures, PEB buildings, low-cost prefab houses, container houses, C/Z steel, various models of color steel plate, PU sandwich panels, eps sandwich panels, rock wool sandwich panels, cold room panels, purification plates, and other construction materials.