1. The Structural System Used In The Design Of The Steel Structure Workshop

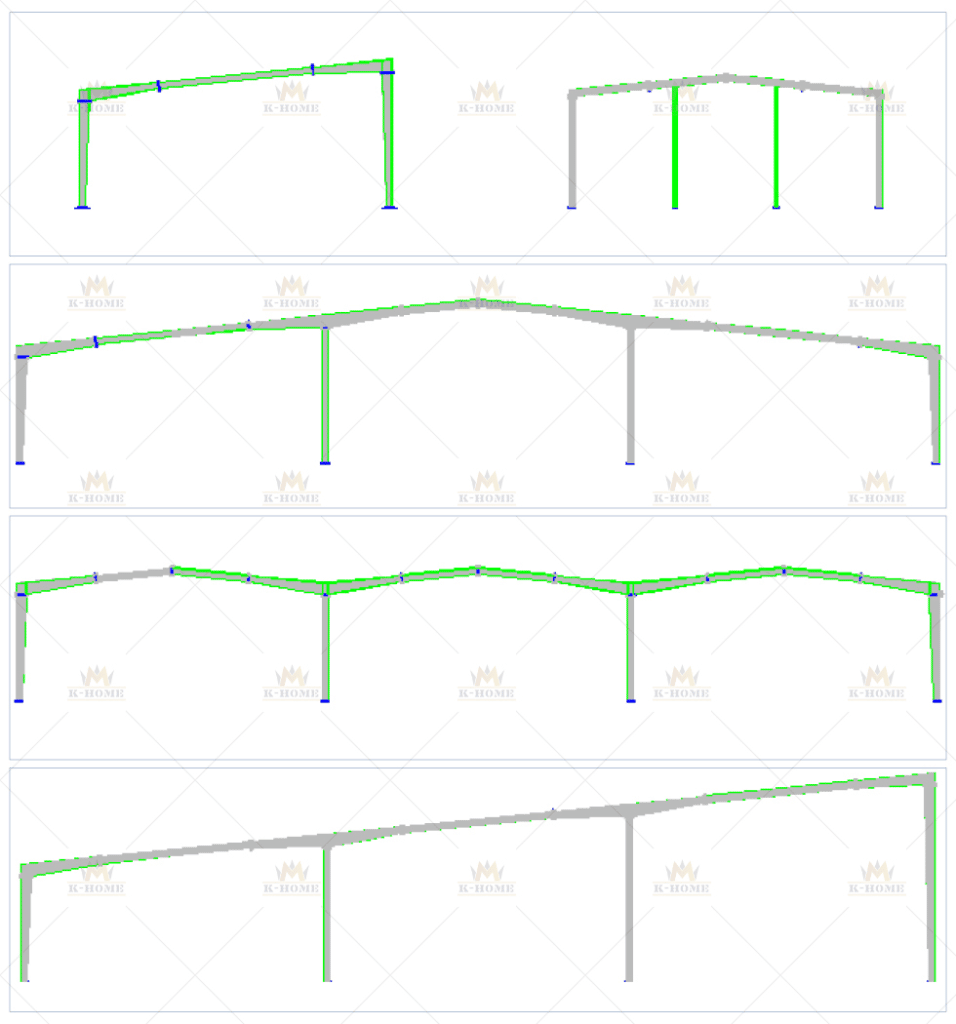

Due to the requirements of the process layout, the steel structure workshop generally requires a large space, and the frame structure is usually used, but the frame shear structure can also be used when the number of layers is large and the process conditions permit.

The principle of structural arrangement is: try to make the column grid symmetrical and evenly arranged, so that the center of stiffness of the house is close to the center of mass, so as to reduce the space torsion of the house, and the structural system requires simplicity, rules, and clear force transmission.

Avoid concave corners and shrinkage with stress concentration and sudden deformation, as well as overhang and adduction with excessive vertical changes, and strive to maintain no or less sudden changes in stiffness along the vertical direction.

Further Reading: Steel Structure Installation & Design

2. Fire Protection Design Of Steel Structure Workshop

The fire resistance of steel structure industrial plants is very poor.

- When the steel is heated above 100 °C, the tensile strength of the steel decreases and the plasticity increases with the increase in temperature;

- when the temperature is about 250 °C, the tensile strength of the steel increases slightly. , while the plasticity is reduced, and the phenomenon of blue brittleness occurs;

- when the temperature exceeds 250 °C, the steel exhibits a creep phenomenon;

- when the temperature reaches 500 °C, the strength of the steel decreases to a very low level, so the steel structure collapses.

Therefore, the steel structure must be designed for thermal insulation and fire protection.

Correctly define the fire hazard category of building products and reasonably determine the fire resistance level of the building.

According to the “Code for Fire Protection Design of Buildings”, the fire hazard of plant production is divided into five categories: A, B, C, D, and E. If determined If the project is of secondary fire resistance level, it should be protected by adding fire-resistant paint in strict accordance with the secondary fire resistance level, so that the steel components meet the fire resistance limit requirements of the secondary fire resistance level.

When designing, an appropriate fire protection method for steel structure should be selected to effectively protect the steel structure, that is, the fire resistance limit of the steel structure should be increased to the value specified in the specification to prevent the steel components from deforming and slumping in case of fire.

At present, the most common method to protect the steel structure workshop is to coat the steel structure with a fireproof coating on its surface. When a fire occurs, it acts as a fire-resistant and heat-insulating protective layer, which effectively improves the fire resistance limit of the steel structure and meets the requirements of the current national standards.

When using fire retardant coatings, attention should be paid to the mutual matching of the fire retardant coatings and the underlying anti-corrosion coatings, and should not have chemical reactions with the underlying anti-corrosion coatings, so as not to affect the anti-corrosion and fire-resistant effects.

When designing, we must select the most appropriate fire protection method through scientific comparison according to the requirements of different buildings on the fire resistance limit of components to achieve economic and safety requirements.

In the design of steel structure buildings, the fire compartments of the buildings should be reasonably divided, and the area of each fire compartment should be strictly controlled. At the same time, it is necessary to control the number of evacuation openings and the evacuation distance of each partition. Safety exits refer to evacuation stairs that meet the requirements of fire protection regulations, and doors that lead directly to the outdoor ground level or safe area.

Due to the weaknesses of the steel structure building itself, we should fully consider the factors of personnel evacuation in the design, and comprehensively consider the personnel density index and the characteristics of the steel structure building, and strengthen the design requirements for safe evacuation routes, evacuation distances, and evacuation widths. Set up evacuation signs scientifically, so that people can be quickly evacuated to a safe area, thereby greatly reducing casualties and loss of people’s property.

Further Reading(Steel Structure)

3. Anti-Corrosion Design Of Steel Structure Workshop

The surface of the steel structure will corrode when it is directly exposed to the atmosphere. When there is an aggressive medium in the air of the steel structure workshop or the steel structure is in a humid environment, the corrosion of the steel structure workshop will be more obvious and serious.

The corrosion of the steel structure will not only reduce the cross-section of the component but also cause rust pits on the surface of the steel component. When the component is stressed, it will cause stress concentration and premature failure of the structure.

Therefore, enough attention should be paid to the rust prevention of steel structure workshop components, and corresponding countermeasures and measures should be taken in terms of general layout, process layout, material selection, etc. according to the corrosive medium and environmental conditions of the workshop to ensure the safety of the workshop structure.

In order to prevent the metal surface from rusting, anti-rust and anti-corrosion coatings are often used to protect it.

Therefore, the anti-corrosion coating can effectively shield the erosion of water vapor, oxygen, chloride ions, etc., and play a role in physical rust prevention only when it has the conditions of compactness, strong hydrophobicity, good adhesion, high resistance or sufficient thickness of the coating.

Under the action of the natural atmospheric medium, the general indoor steel structure requires a coating thickness of 100 μm, that is, two primers and two topcoats. For open-air steel structures or steel structures under the action of industrial atmospheric media, the total thickness of the paint film is required to be 150 μm to 200 μm.

Steel structures in acid environments require the use of chlorosulfonated acid-proof paints. The part below the ground of the steel column should be wrapped with concrete not less than C20, and the thickness of the protective layer should not be less than 50mm.

Prefab Steel Structure Workshop: Design, Type, Cost

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.

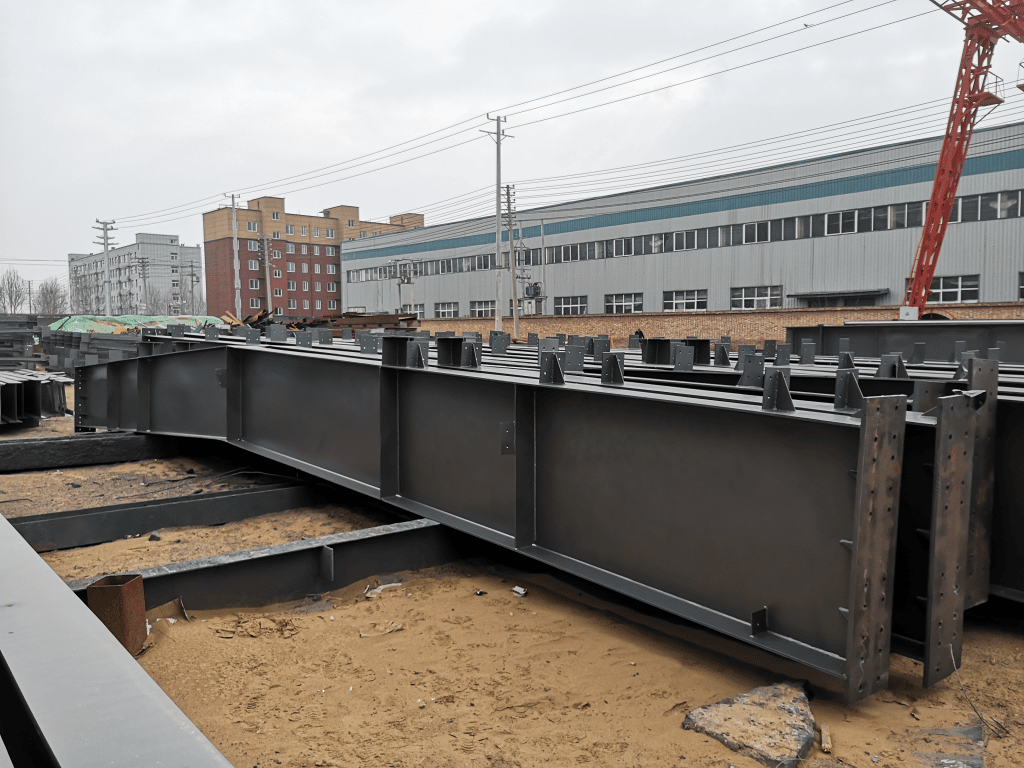

About Author: K-HOME

K-home Steel Structure Co., Ltd covers an area of 120,000 square meters. We are engaged in the design, project budget, fabrication, and installation of PEB steel structures and sandwich panels with second-grade general contracting qualifications. Our products cover light steel structures, PEB buildings, low-cost prefab houses, container houses, C/Z steel, various models of color steel plate, PU sandwich panels, eps sandwich panels, rock wool sandwich panels, cold room panels, purification plates, and other construction materials.