Prefab Metal Steel Workshop Building

Steel Structure Workshop Building

Single-story steel structure workshop Multi-storey steel structure workshop

K-home offering you 2 types of steel workshop: single-story and multi-story steel structure workshop building.

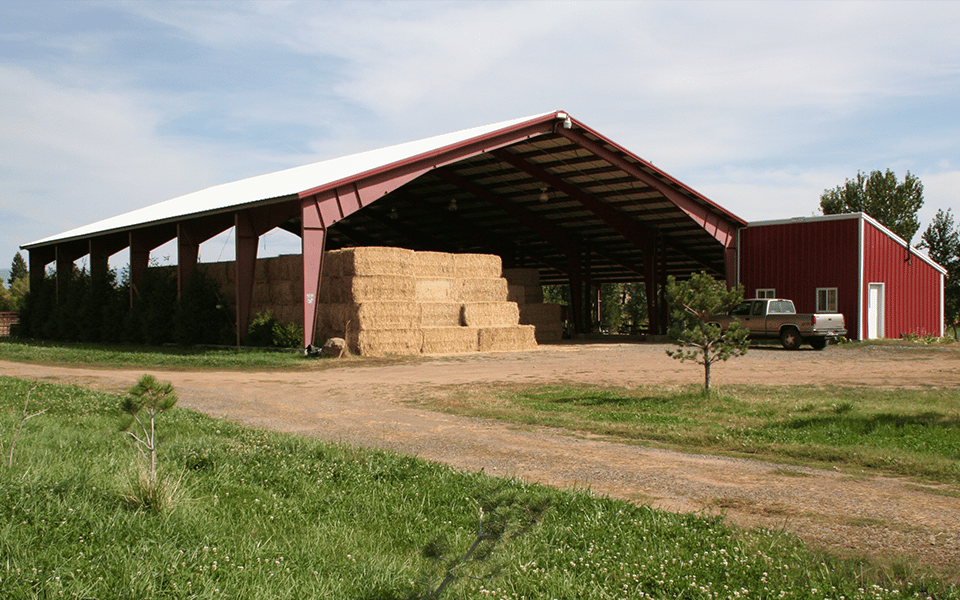

A single-story steel structure workshop building refers to an industrial factory building with one floor and a steel structure as the main body.

Single-story steel structure workshops are often used in large-scale machinery and equipment or factories with heavy lifting and transportation equipment, such as hardware and plastics, machinery and equipment, printing paper products, molds, and other industries. Color steel plates are generally used for exterior walls and roofs.

The elevation of the column top of a crane-free workshop is usually determined by the height of the largest production equipment and the net height required for use, installation, and maintenance.

The bottom floor of a multi-story steel structure workshop building is mostly used for arranging the workshops or raw material and finished product warehouses with frequent external transportation of raw materials, large equipment, and more water.

The top floor is mostly used for arranging larger workshops (such as processing and assembly workshops).

The rest of the floors are arranged according to the production line, and the floors are mainly connected by freight elevators, and the stairs should be arranged against the outer wall.

Related Industrial Metal Steel Buildings

The PEB Steel Building

The Other Additional Attachments

WHY CHOOSE KHOME AS YOUR SUPPLIER?

K-HOME is one of the trusted factory manufacturers in China. From structural design to installation, our team can handle various complex projects. You will receive a prefabricated structure solution that best suits your needs.

You can send me a WhatsApp message (+86-18338952063), or send an email to leave your contact information. We will contact you as soon as possible.

Our Steel Workshop Building Advantages

Durable Structure

The steel structure is made of steel, and when cold-formed steel is used in conjunction, it gives the steel structure engineering good stability and long service life.

High Strength

Steel structure engineering is characterized by high strength, lightweight, and high rigidity, so it is used to build large-span and high-height buildings. The material has good homogeneity and isotropy, which is an ideal elastomer.

Fast Construction

Steel structural components are pre-manufactured in the factory. and you can easily assemble on site. In this way, the speed is faster and the construction period can be reduced by about 40%.

Save cost

Due to the pre-production (reduction of manpower cost and raw material cost), the capital construction cost is reduced. that the

Environment Friendly

The raw materials can be recycled, which is conducive to environmental protection and sustainable development.

High degree of industrialization

It is suitable for mechanical processing. The various components that make up the steel structure are generally made in specialized processing plants and then transported to the site, where they are assembled and hoisted by welding and bolts.

FAQs ABOUT STEEL WORKSHOP

More Metal Building Kits

Articles Selected for You

Building FAQs

- How to Design Steel Building Components & Parts

- How Much Does a Steel Building Cost

- Pre-Construction Services

- What is a Steel Portal Framed Construction

- How to Read Structural Steel Drawings

Blogs Selected for You

- The Main Factors Affecting The Cost of Steel Structure Warehouse

- How Steel Buildings Help Reduce Environmental Impact

- How to Read Structural Steel Drawings

- Are Metal Buildings Cheaper Than Wood Buildings?

- Benefits of Metal Buildings For Agricultural Use

- Choosing the Right Location For Your Metal Building

- Making a Prefab Steel Church

- Passive Housing & Metal –Made for Each Other

- Uses for Metal Structures You May Not Have Known

- Why Do You Need a Prefabricated Home

- What Do You Need To Know Before Designing a Steel Structure Workshop?

- Why Should You Choose a Steel Frame Home Over a Wooden Frame Home

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.