The characteristics of Steel Workshop Structure are overall stiffness and seismic performance are good, its construction speed is fast, its weight is light, and its bearing capacity is high. In the workshop structure design, according to its characteristics, the role of steel structure can be better played by making use of its strengths and avoiding weaknesses. Now, a few problems in the design of industrial steel structure workshops are briefly explained.

Further Reading: Steel Structure Installation & Design

Thermal Insulation And Fire Protection

Steel has high thermal conductivity, and its thermal conductivity is 50w (m.°C).

- When the temperature reaches 100°C or more, its tensile strength will decrease and its plasticity will increase;

- when the temperature reaches 250°C, the tensile strength of steel will be reduced.

- When the temperature reaches 500 °C, the strength of the steel decreases to a very low level, which will cause the steel structure to collapse.

Therefore, when the ambient temperature of the steel structure reaches above 150 °C, it is necessary to do thermal insulation and fire protection design.

The general practice is: the outer side of the steel structure is covered with refractory bricks, concrete or hard fireproof boards. Or the steel structure should be brushed with thick coating type fireproof coating, and the thickness should be calculated according to the “Technical Regulations for Fireproof Coatings for Steel Structures”.

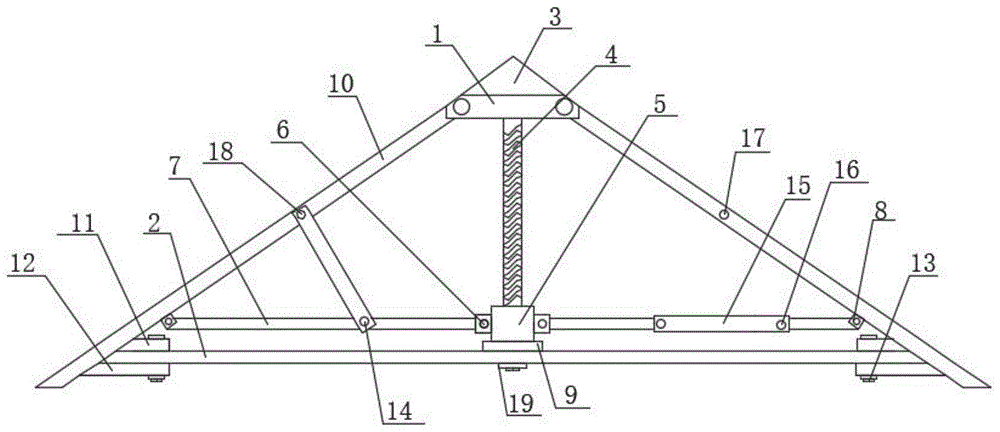

Roof Support System Design

The layout of the roof support system should be determined according to the span, height, column network layout, roof structure, crane tonnage and seismic fortification intensity of the area. In general, the roof structure with or without purlin system should be provided with vertical support; in the system without purlin, the large roof panel is welded with the roof truss at three points, which can play the role of upper chord support but considering the limitations of construction conditions and Installation required.

Regardless of whether there is a purlin or a roof without a purlin system, the top chord of the roof truss and the top chord of the skylight frame shall be provided with top chord lateral supports. Longitudinal horizontal supports shall be provided for workshops with a roof truss spacing of not less than 12m or where there are super heavy bridge cranes in the workshop or large vibration equipment in the workshop.

The drainage and waterproof design of the roof should be considered in the roof design. The minimum roof slope is 5%. In areas with heavy snow, the slope should be appropriately increased.

The length of a single-slope roof mainly depends on the temperature difference in the area and the maximum water head height formed by rainfall. According to the engineering design experience, the length of the single-slope roof should be controlled within 70m.

At present, there are two commonly used methods of steel structure roofing on the market:

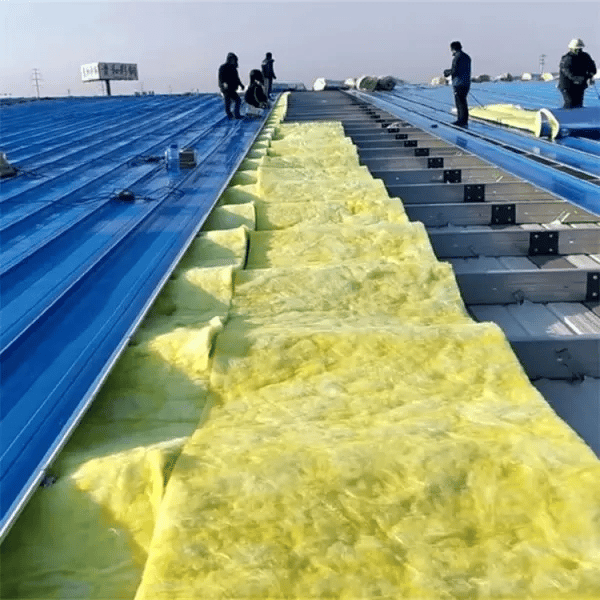

- Rigid roof: double-layer color profiled steel plate with insulation cotton inside;

- Composite flexible roof: composed of roof color steel plate inner plate, gas barrier, thermal insulation layer, roll material waterproof layer.

Setting Of Temperature Expansion Joints

The temperature change will cause the deformation of the steel structure workshop, causing the structure to generate temperature stress. When the plane size of the workshop is large, in order to avoid the generation of large temperature stress, temperature expansion joints should be set in the longitudinal and horizontal directions of the workshop, and the length of the section can be adjusted.

Execute according to steel structure specification. Temperature expansion joints are generally treated by setting up double columns, and rolling bearings can be set at the roof truss support for longitudinal temperature expansion joints.

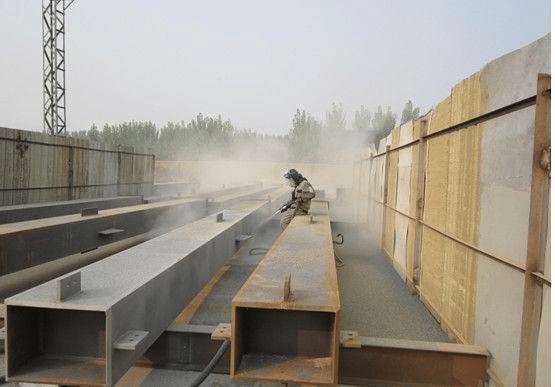

Anti-Rust Treatment

The surface of the steel structure will corrode when it is directly exposed to the atmosphere. When there is a corrosive medium in the air of the steel structure workshop or the steel structure is in a humid environment, the corrosion of the steel structure workshop will be more obvious and serious.

The corrosion of the steel structure will not only reduce the cross-section of the component but also cause rust pits on the surface of the steel component. When the component is stressed, it will cause stress concentration and cause the structure to fail prematurely.

Therefore, enough attention should be paid to the rust prevention of steel structure workshop components, and corresponding countermeasures and measures should be taken in terms of general layout, process layout, material selection, etc.

According to the corrosive medium and environmental conditions of the workshop to ensure the safety of the workshop structure. Safety. Generally, anti-corrosion primers and topcoats are often used for the anti-corrosion of steel structures.

The number and thickness of coating layers are often determined according to the use environment and coating properties. Under the action of a natural atmospheric medium, the general indoor steel structure requires a coating thickness of 100 μm, that is two primers and two topcoats.

For open-air steel structures or steel structures under the action of industrial atmospheric media, the total thickness of the paint film is required to be 150 μm to 200 μm. And the steel structure in the acid environment requires the use of chlorosulfonated acid-proof paint.

The part below the ground of the steel column should be wrapped with concrete not less than C20, and the thickness of the protective layer should not be less than 50mm.

Facade Design

The building of a light steel structures mainly has the following four characteristics: scale, line, color and change.

The façade of the steel structure workshop is mainly determined by the process layout. While meeting the requirements of the process, the façade is simple and grand, and the nodes are as simple and unified as possible.

The color-profiled steel plate makes the building of the light steel workshop appear light and rich in color, which is obviously better than the heavy and single structure of the traditional reinforced concrete structure.

In the design of light steel workshops, jumping colors and cool colors are often used, focusing on the main entrances and exits, outer gutters, and edge flooding, which not only reflects the grandeur of the modern workshop but also enriches the façade effect.

For the traditional reinforced concrete structure workshop, the exterior walls are maintained as brick masonry, and the exterior decoration is paint or face bricks, supplemented by ribbons.

Due to the unsatisfactory effect of lighting windows on the concrete roof, a large number of lighting windows are usually set on the walls during design. But this is not the case for the steel structure workshop with the maintenance wall made of color-profiled steel plates.

Lines are the most unique feature of the architectural style of light steel structures. The uniform lines are either horizontal or vertical, making the light steel structure buildings full of smooth metal texture, reflecting a strong modern industrial atmosphere.

If a large number of lighting windows are installed on the wall, the line shape of the wall will be destroyed. At the same time, the light steel structure roof can use a large number of roof lighting panels, the lighting is uniform, and the ventilation problem of the workshop can be solved at the same time.

Conclusion

In a word, the design of the steel structure workshop should be based on its characteristics. The building structure design should be carried out according to its characteristics so that the design is safe, reliable, economical, reasonable and beautiful.

Prefab Steel Structure Workshop: Design, Type, Cost

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.

About Author: K-HOME

K-home Steel Structure Co., Ltd covers an area of 120,000 square meters. We are engaged in the design, project budget, fabrication, and installation of PEB steel structures and sandwich panels with second-grade general contracting qualifications. Our products cover light steel structures, PEB buildings, low-cost prefab houses, container houses, C/Z steel, various models of color steel plate, PU sandwich panels, eps sandwich panels, rock wool sandwich panels, cold room panels, purification plates, and other construction materials.