Professional & Trusted Steel Fabrication Workshop Design & Construction

Specialized steel fabrication workshop offering high-quality steel cutting, welding, and assembly services for construction and engineering needs.

Steel Fabrication Workshop Beginner’s Guide: From Design to Construction

More and more customers are beginning to attach importance to the design of steel fabrication workshops—a critical asset for modern manufacturing. A reasonable steel fabrication workshop space design can not only optimize production processes but also rationally allocate resources, improve efficiency, and simplify factory management. This enables managers to adjust equipment layouts timely manner, aligning with the core goals of a high-performance steel fabrication workshop.

Before Project Start: Understand the Core of Steel Structure Fabrication Procedure

Before starting a steel fabrication workshop project, understanding the core procedure is vital. Whether you’re planning a new facility or upgrading an existing one, clarifying steps like design, material selection, and compliance ensures your steel fabrication workshop meets both current needs and future scalability.

- Material Preparation and Collection

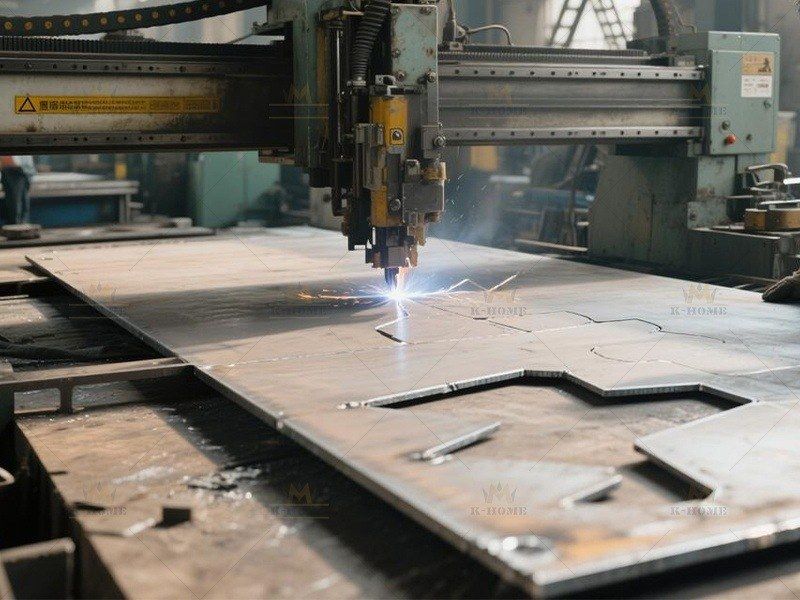

Select steel and auxiliary materials that meet standards, have clear sources, and complete quality certificates. Conduct strict inspection before warehousing to eliminate unqualified products. Store materials in categories in separate areas to avoid adverse environmental impacts, arrange the material collection area for subsequent transportation and production, and ensure relevant equipment and machinery are ready for use in follow-up production. - Steel Cutting

Cut steel plates or steel sections (e.g., H-beams, U-beams) per design drawings: trim excess parts from profiles; assemble composite steel after cutting. Modern technologies like lasers and plasmas are adopted to ensure precision. Recheck dimensions post-cutting and reject non-conforming parts. - Press Forming

Press and shape components such as metal panels and partitions according to design requirements. The forming process changes the original shape of the steel billet by applying high pressure. After pressing, carefully check the size and precision of parts and compare them with the design drawings. - Welding Parts into Assemblies

Use dedicated automatic welding systems to assemble steel parts into complete assemblies, ensuring optimal precision and quality. Automatic welding achieves uniform, neat, and durable welds, guarantees firm connections between parts, and minimizes errors caused by human factors. After welding, fully inspect the welding quality, straightness, and angle of the assemblies; only proceed to the next production step if they meet all technical standards. - Structural Adjustment

Use specialized straightening machines to straighten the welded assemblies to eliminate warping, ensuring the flatness and standard angle of the assemblies. Then, use specialized measuring rulers to check the flatness and verticality of the structure. - Connector Installation & Finishing Welding

Use bolts, rivets, etc. to connect structural parts; bolts must be tightened with special tools as required. Before welding, check the size and position of sub-components, then weld brackets, stiffeners, etc., to the steel structure. After welding, inspect the strength and shape of all welds, and correct any issues promptly. - Surface Cleaning

Use a shot blasting system to clean the entire surface of the assemblies, thoroughly removing dirt, rust, and slag that affect welding quality and paint color. The cleaned surface must remain dry, clean, rough, and flat. - Applying Protective Paint

First, apply 1-2 coats of anti-rust primer as the structural base, then spray a specialized polyurethane coating that meets thickness standards. The paint protects the structure from environmental factors and extends its service life. - Inspection Before Packaging and Transportation

Conduct a comprehensive inspection of all assemblies before packaging and storage. Carefully protect the steel structure to avoid scratches and heavy impacts, then safely transport it to the installation site.

Special Considerations for the Fabrication Procedure of Steel Structure Workshops

Trusted Steel Fabrication Workshop – Fast & Reliable Metal Services

As a professional steel structure manufacturer, K-HOME has a complete and scientific design and delivery process, ensuring each project is safe, compliant, reliable in quality, and delivered on time. Our design strictly adheres to the national standard Code for Design of Steel Structures (GB50017-2017), and at the same time, we combine customers’ actual needs to provide them with the most suitable solutions.

Step 1: In-depth Communication on Workshop Details & Preliminary Scheme Design

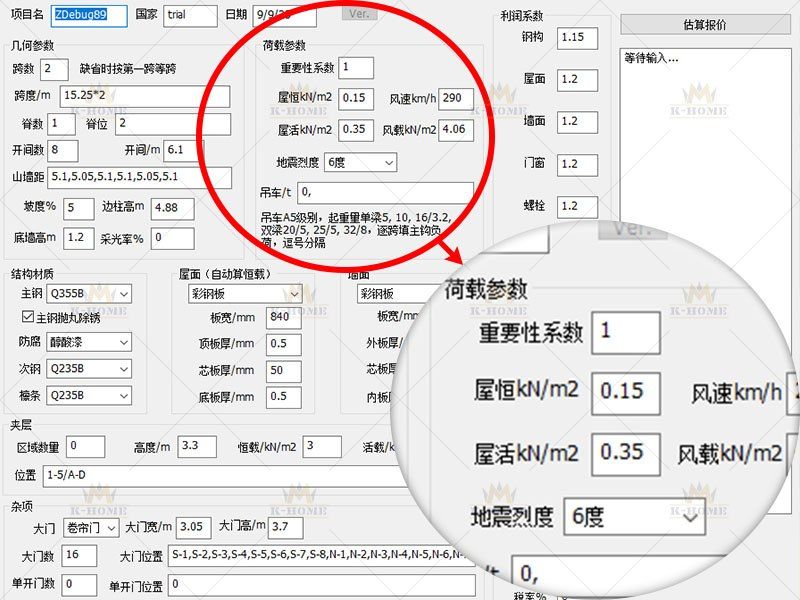

First, in the preliminary stage, we will conduct in-depth communication with the client to fully understand the project requirements and architectural and environmental factors—such as wind force, rainfall, snowfall, and seismic intensity. This information is directly related to the scientific validity and applicability of the design scheme.

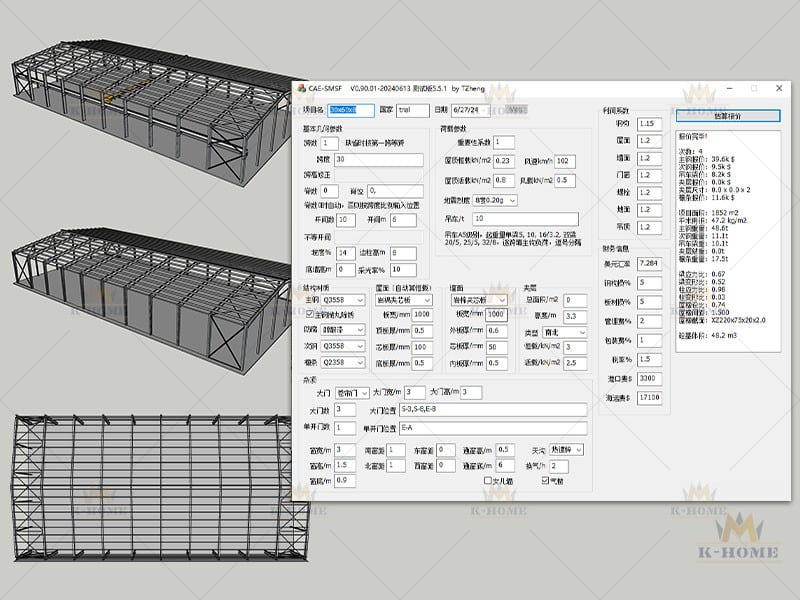

After the communication, the designer will initiate the preliminary scheme design, confirming the steel type, structural form, and specific dimensions. Subsequently, our R&D and design team will conduct force calculations in accordance with relevant specifications, ensuring the stability and safety of the steel structure from the source.

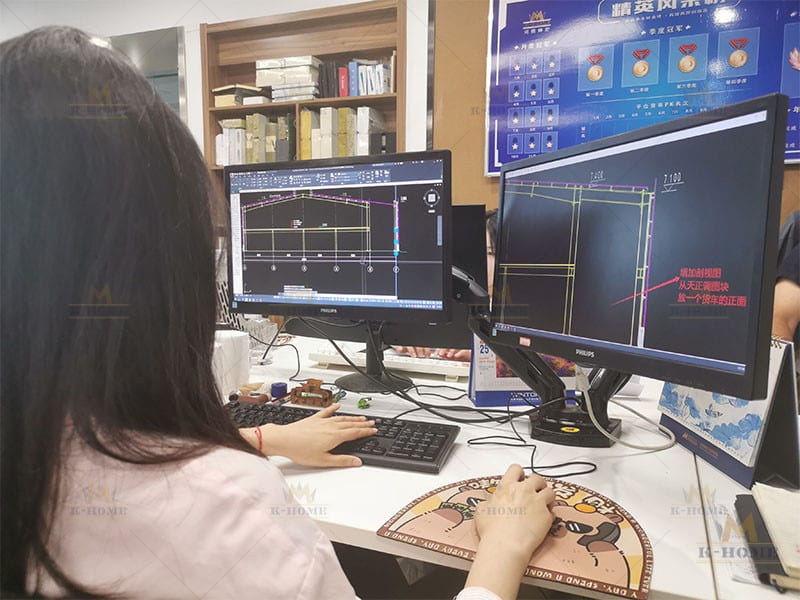

Step 2: Steel structure workshop Scheme Drawing, Verification & Quotation

After the design scheme is finalized, the engineering team will conduct a strict review, carefully verifying the calculation data and drawing details to ensure the finalized scheme fully complies with the standards of the client’s target country and the actual construction requirements.

Upon passing the review, we will provide the client with a detailed quotation sheet based on the design scheme and material costs. The quotation covers expenses of all links, including production, packaging, and transportation, allowing the client to understand the cost composition of their project fully.

Step 3: Standardized Production & Packaging

After the client confirms the quotation, we will officially enter the production phase and simultaneously prepare relevant technical documents and construction drawings to ensure workers can smoothly carry out production and manufacturing. Upon completion of production, all steel structure components will be packaged in strict accordance with standard procedures, fully preparing for the subsequent shipment and transportation.

Step 4: Shipment Coordination and Logistics Follow-up

During transportation, our order follow-up specialists will fully coordinate container loading and transportation arrangements. We will track logistics progress in real time, maintain close communication with the client, and ensure the goods arrive safely and on time. Upon arrival of the goods at the port, the client only needs to complete customs clearance and pickup procedures per local regulations—keeping the entire process efficient and smooth.

In addition, to help the client better understand the product installation process, we will provide detailed installation videos and drawings. If the client requires technical support, we can also dispatch engineers to the site for assistance, ensuring a seamless installation process.

We not only attach great importance to design and production quality, but also strive for excellence in every link from quotation to logistics. We are committed to providing the client with high-quality services that fully guarantee the quality of steel structure buildings, and to creating safe and durable steel structure buildings.

WHY CHOOSE KHOME AS YOUR SUPPLIER?

K-HOME is one of the trusted factory manufacturers in China. From structural design to installation, our team can handle various complex projects. You will receive a prefabricated structure solution that best suits your needs.

You can send me a WhatsApp message (+86-18790630368), or send an e-mail (sales@khomechina.com) to leave your contact information. We will contact you as soon as possible.

Our Overseas Steel Structure Project Capabilities & Support System

To date, we have completed projects in over 65 countries across Southeast Asia, the Middle East, Africa, Europe, and South America. For efficient execution, we’ve established systematically trained professional installation teams in Ethiopia, Kenya, Saudi Arabia, etc.—they know local construction conditions and specs well, ensuring precise control of project progress and quality.

If clients have special project needs, we can quickly dispatch experienced engineers from our China headquarters to the site. With solid expertise and overseas project experience, these engineers provide comprehensive support from technical guidance to on-site coordination.

Overseas demand for steel structures continues to rise, but building standards vary greatly by country. To address this, we align with global authorities like the American Institute of Steel Construction (AISC) , which sets industry-leading standards for steel fabrication workshop design. We also reference the American Welding Society (AWS) for certification guidelines, ensuring our welding processes meet rigorous global benchmarks.

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.