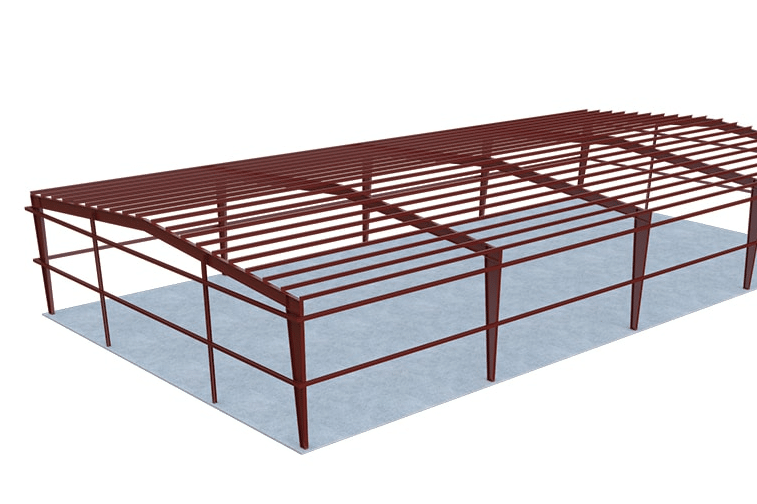

Steel Manufacturing Building

Industrial / Agricultural / Commercial Steel Buildings

Steel Manufacturing Building is a new type of building system, but it’s not new for most of us, which opens up the industry boundaries between the real estate industry, construction industry, and metallurgical industry, and integrates them into a new industrial system. This is the steel structure building system that is generally optimistic about the industry.

Compared with traditional concrete buildings, steel structure buildings replace reinforced concrete with steel plates or profiled steels, which have higher strength and better earthquake resistance. And because the components can be manufactured in factories and installed on-site, the construction period is greatly reduced. Due to the reusability of steel, it can greatly reduce construction waste and be greener and environmentally friendly, so it is widely used in industrial and civil buildings all over the world.

The application of steel structure buildings in high-rise and super high-rise buildings is becoming more and more mature, and it has gradually become the mainstream construction technology, which is the development direction of future buildings.

WHY CHOOSE KHOME AS YOUR SUPPLIER?

K-HOME is one of the trusted factory manufacturers in China. From structural design to installation, our team can handle various complex projects. You will receive a prefabricated structure solution that best suits your needs.

You can send me a WhatsApp message (+86-18338952063), or send an email to leave your contact information. We will contact you as soon as possible.

Description of Steel Manufacturing Building

The steel structure project is mainly based on the structure made just now. The characteristics of steel are high strength, light weight, good overall rigidity and strong deformation ability.

Materials of Steel Manufacturing Building

The stress-bearing components (columns, beams, etc.) of steel structure buildings are made of structural steel, which requires structural steel, welding rods, concrete, steel bars, brickwork, partition walls, etc., glass and other decorative materials. Buildings are designed first and then constructed. The characteristic of steel structure is that the steel components are all produced in the factory, and they are directly installed when they are shipped to the site.

- H-beam

The H steel is used for roof beams and steel columns, which are the biggest part in the building, and it bears the most pressure of the whole building. The thickness and the coating material need to be advice based on actual use.

- C,Z section steel

These two are mainly used to make purlins. The angles of Z-type purlins and C-type purlins are different. C-type purlins are 90 degrees, Z-type purlins are less than 90 degrees, about 60 to 75 degrees, and the load-bearing can be calculated to achieve Similarly, in the case of high sea freight, in order to reduce the number of boxes, we will use Z-shaped steel as much as possible, which will greatly reduce the number of the shipping container.

The thickness is widely chosen from 1.6mm-3.0mm, and all the steel purlin we will choose galvanized for you.

- Tie Rod and bracing

Those parts are sub- accessories that are used to tight the purlin and purlin, or purlin to beam helps the transfer the pressure from itself to the connected purlin or beam. These is small parts, but also very necessary.

- Roof and wall system

The roof and wall panel are usually chosen PPGI steel plate or sandwich panel. They all have different patterns, such as flat surfaces, corrugated, and different colors.

- Windows and doors

The window and door are various, have cheaper one and expensive one, the chosen based on your budget.

- Accessories

There are many things that need to use when assembling the building, such as bolts, nuts, structure glue, bending parts that are used on the connection area that prevent insects or water leaks into the house.

The advantage of the Steel Manufacturing Building

The building materials on the market are dazzling, and the choice of building materials determines the quality of the building. Steel structures are now widely used in large-span, super-high-rise, and super-heavy construction fields. Why are steel structures so popular? Let’s take a look at the advantages and disadvantages of steel structures.

- Short construction period

All the components are already fabricated inside the factory, they only need to be connected together by bolts and nuts, or slightly welded, compare with traditional brick and concrete buildings, the steel prefabricated building will save at least 70% on the construction period.

- Light weight

Compared with concrete and wood, steel structure has lighter weight and higher strength, which can greatly reduce the foundation cost. So it will show better on the seismic area.

- Environmental protect

In line with the national sustainable development strategy, low carbon, green, environmental protection, energy-saving, etc. are the industries supported by the state

Application of steel structure building

The steel structure is no stranger to us. In every corner of our life, as long as you pay a little attention, there will be steel structure buildings, such as warehouses, factories, dormitories, and so on.

Compared with traditional concrete, steel structure has obvious advantages in the construction period, energy-saving, and earthquake resistance. As a green and low-carbon building, it is in line with the current environmental protection concept.

Share This:

Related Projects

Blogs Selected for You

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.