This Guideline(instruction) is long. You could use the quick link below, and jump to the part you like.

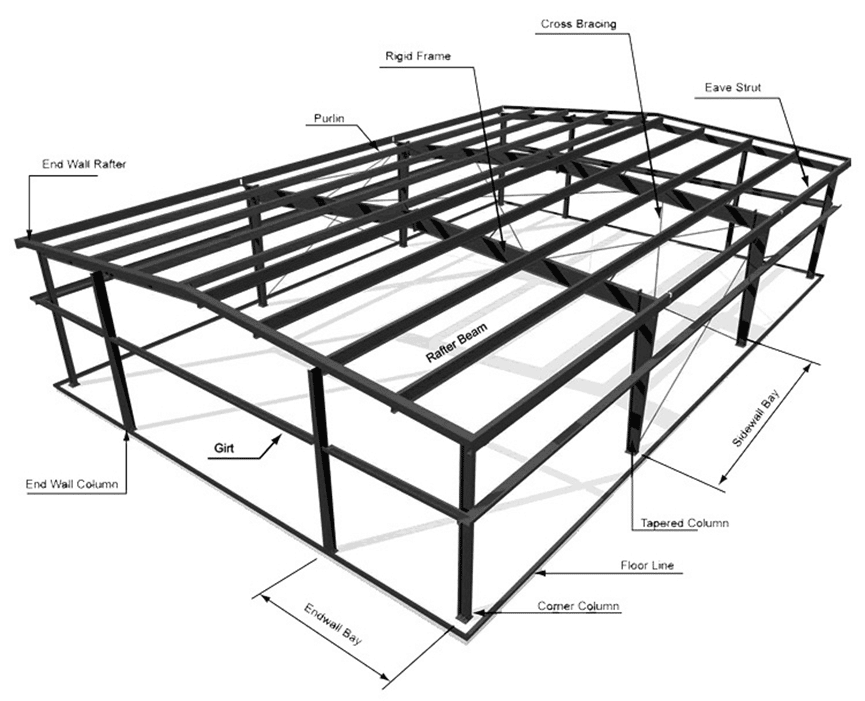

Components

Select Relevant Components

One of K-home’s customized building design processes is to choose the right building accessories, which will make your building more practical and personalized. The categories of architectural components are mainly divided into five major parts: including structural design, shadow and light, architectural passage, color selection, and common functions.

Please see the following table for the general configuration of each part:

| Structural Design | Shadow And Light | Building Access | Enclosure Systems | Function |

|---|---|---|---|---|

| Steel Mezzanine | Skylight | Combination Door | Roof, Wall Color | Drain And Downspout |

| Portal Frame | 1′-4′ Door Overhang | Walking Gate | Wall Panel Materials | Insulation |

| Frame Opening | Peripheral Overhang | Shutter Doors | Roof Panel | Turbofan |

| Main Frame End Wall | Translucent Tile | Bi-Fold Door | Color Steel Sheet | Ridge Vent |

| Crane Systems | Window | Louver Vent |

Maintenance System

The enclosure system can play a decorative and protective role on the steel structure, and has the functions of heat insulation, waterproofing, heat preservation, and noise reduction. Profiled steel plate building materials are widely used in the enclosure system of light steel structure factory buildings. The profiled steel plate has a variety of plate types. In addition to satisfying structural functions and architectural performance functions, it is also necessary to consider its economic efficiency. Therefore, the following factors should be considered comprehensively to choose what kind of board type building materials.

Strength Factor

Strength is the primary consideration in choosing the plate type. The plate type is closely related to the mechanical properties of its section. It has to bear external loads such as wind, thunder, and rain. Generally speaking, the wave crest is high, and its cross-section moment of penetration is large; the wave crest is dense, the ribs are many, the base plate is thick, and its strength is also high, but the amount of steel used is also larger. At the same time, the spacing of the purlins must be considered. The larger the spacing, the higher the requirements for the strength of the steel plate.

Single Slope Length

The greater the span of the steel structure plant’s house panel, the greater the difficulty of construction. At this time, the roof overlap method is often adopted. Its shortcoming is that there is a hidden danger of water leakage at the overlap point, so try to choose not to overlap the roof. When a color steel roof with a single slope of more than 50m, the influence of temperature must also be considered.

The current popular domestic practice is to use sliding bearings for the support between the profiled plate and the purlin, and evenly distribute the thermal expansion and contraction of the color plate and synchronize the expansion and contraction, so that the huge temperature stress can be relieved by appropriate expansion and contraction, and avoid Due to the destructive effects of temperature stress on the deformation, extrusion, and cracking of the outer roof panel, the use of the overall system is ensured.

In addition, the longer the single slope, the higher the requirements for the peak of the roof slab, the stronger the drainage capacity of the drainage channel, and the higher the requirement for its own strength. This must be carefully selected through calculations.

Slope Factor

The “Technical Specification for Steel Structures of Portal Frame Light Buildings” stipulates that the roof slope of portal frame light buildings should be 1/20~1/8, and the larger value should be used in areas with more rain.

In the engineering design, some design units did not consider the actual situation, and the designers did not understand the local rainfall and snow, which caused the roof slope design to be too slow and the gutter cross-sectional area to be too small.

As a result, the roof slopes of many projects are too small, and roof rainwater cannot be discharged to the gutter in time, causing water in the roof area and causing roof water seepage, or the gutter returning water due to snow and ice in the gutter. But it is not that the larger the slope, the better, the larger the slope, the greater the force component along the direction of the plate shape, and the easier it is to form a slippage phenomenon. When encountering heavy rain and snow, the roof will be deformed and damaged.

The Specifications And Quality Requirements Of Plate-Shaped Building Materials

The commonly used steel materials for steel structure construction are hot-dip galvanized steel sheet, hot-dip galvanized steel sheet, galvanized steel sheet plus durable polyester resin (HDP) baking varnish, galvanized steel sheet plus fluorocarbon resin (PVDF), etc. Customers usually use aluminum-zinc color steel plates or aluminum-plated steel plates.

When choosing a substrate, the thickness and manufacturer should be selected according to the use requirements and functional requirements. If the thickness of the hot-dip galvanizing layer is thick, the required cost will be slightly higher. The thickness of the profiled steel plate should not be too thin, preferably 0.4~0.8mm.

The color plate of the roof outer panel is too thin. After a period of use, the outer panel will corrode. Deformation due to temperature, the pressure of snow on the board, etc. cause the gap between the boards to increase.

Further Reading: Steel Building Plans and Specifications

Common Wallboard Characteristics

- Profiled steel plate: non-combustible, 15min fire resistance limit.

- Polystyrene sandwich panel: oxygen index ≥30%, foam plastic bulk density ≥15kg/m3, thermal conductivity ≤0.041W/m·k, due to poor flame retardancy, regular projects are rarely used now.

- Rigid polyurethane sandwich panel: Class B1 building material, foam plastic bulk density ≥30kg/m3, thermal conductivity ≤0.027W/m·k, higher strength, more beautiful appearance, and higher cost. Polyurethane rigid foam is currently a better building insulation material, with low thermal conductivity, good load resistance, high bending strength, no water absorption, no rot, no insect bites, relatively good flame retardancy, and temperature resistance The scope is large.

- Phenolic resin insulation board: In recent years, phenolic sandwich metal boards have been used in experiments on the market, which have good fire resistance and strong heat insulation. The disadvantage is that they have relatively poor adhesion to metal plates and are brittle.

- Rock wool sandwich board or glass wool board: belongs to inorganic material, non-combustible, thickness ≥80mm, fire resistance limit ≥60min, thickness <80mm, fire resistance limit ≥30min, bulk density ≥100kg/m3, thermal conductivity ≤0.044W /m·k. The advantage is that the fireproof performance is the best, but the disadvantage is that the rock wool board is self-heavy, and the on-site installation of the glass wool board is more complicated.

The Aesthetics Of The Wall Panel Appearance

The appearance of the building is mainly selected based on the use and usage habits of the building. For example, color-coated panels for construction usually choose medium and low gloss. You can also customize the color of the color panels according to your company’s logo color to further unify the image and style, achieve the purpose of distinctive features and promote the company.

Precautions

Please confirm with your local municipality whether the color you choose for the steel structure needs to be approved before construction. Our team has been involved in many projects. If you need assistance in recommending matching colors, please contact your project coordinator at K-home.

Further Reading(Steel Structure)

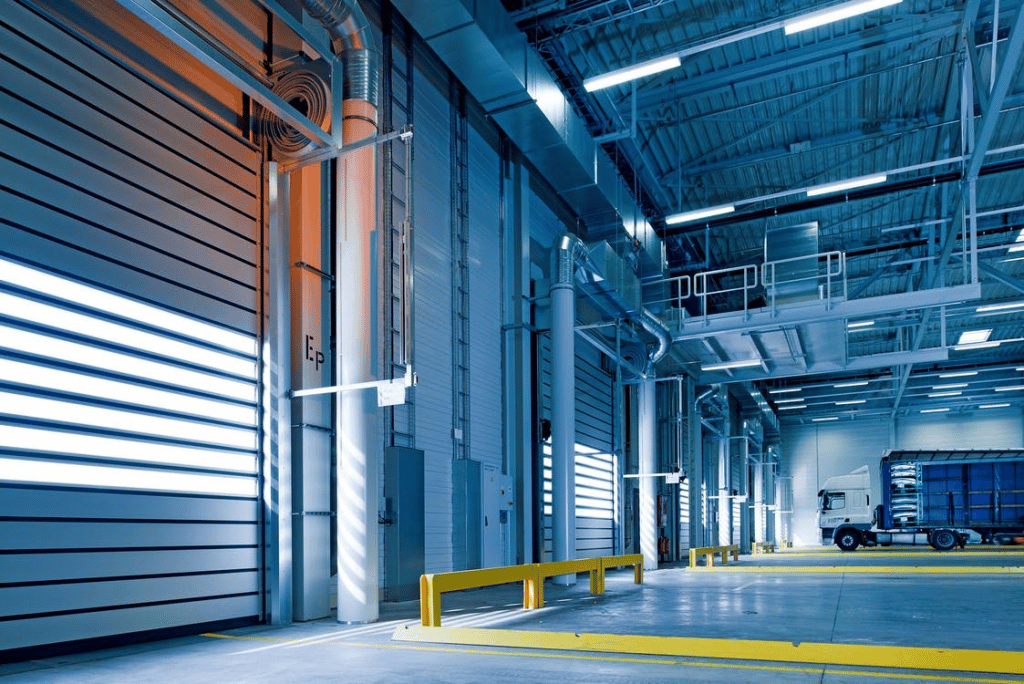

Insulations

The steel structure factory building is different from the brick-concrete structure factory building. Because its main constituent material is steel, the heat conduction speed of steel is fast. Especially in the hot summer, after the roof of the steel structure factory building is exposed to the sun, the temperature can rise to above 60℃. After the heat is transferred to the room, the temperature will be very high, which will have a great impact on the production personnel. So how can the insulation temperature of the steel structure factory be reduced?

The best way to insulate steel structure workshop is: steel structure workshop insulation.

It can isolate most of the solar radiation and conduct heat, reducing the greenhouse effect in the room. Thereby

greatly reducing the temperature of the workshop and improving the environment of the steel structure workshop.

The thermal insulation performance is determined by the following factors:

- The reflection ability of the metal roof layer to heat radiation;

- The raw material, density and thickness of the insulation cotton;

- The humidity of the insulation cotton, the connection method of the metal roof panel and the underlying structure (to prevent the “cold bridge” phenomenon).

So we can take the following two ways:

1. Spray high-efficiency heat insulation reflective paint on the outside of the steel structure roof

This product has excellent thermal insulation performance and can be coated with a thickness of 0.25mm on various surfaces such as metal, concrete, gray wall, wooden structure surface, asbestos tile, plastic, glass fiber reinforced plastic, rubber, etc. The effect is equivalent to 250px-375px glass The effect of cotton, it can reflect 99.5% infrared, 92.5% visible light, the highest sound insulation effect is 68%, and the average sound insulation effect is more than 50%.

Features of heat-insulating reflective coating: Class A fireproof, completely non-combustible. Non-toxic, safe, long-lasting and durable, with a service life of more than 15 years. If this method is used, the construction is convenient, the original roof is not damaged, and the aging of the roof can be prevented. After construction and before construction, the maximum temperature difference between the panel surface can reach 20℃, the indoor temperature difference can reach 8-10℃, and the energy consumption of steel structure workshop can be drastically reduced by 30-70%.

In addition, setting vents on the roof of the steel structure workshop can also appropriately reduce indoor temperature.

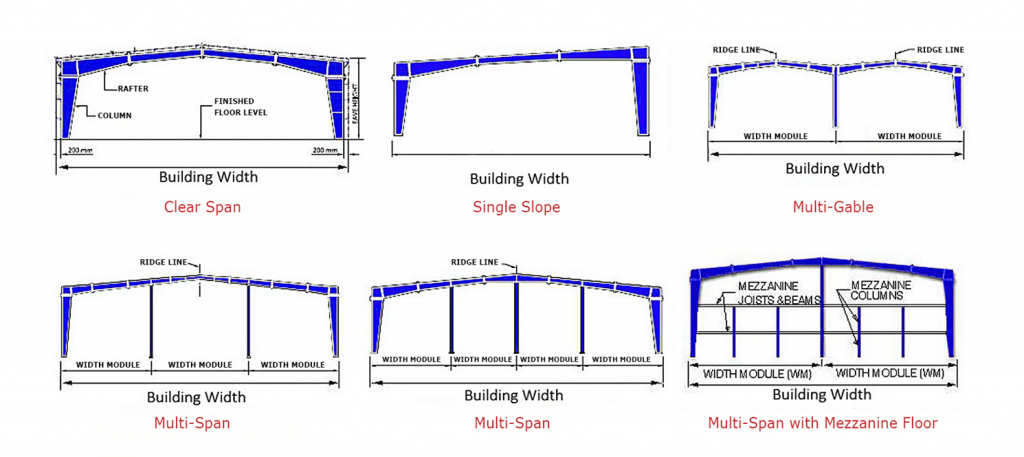

Portal Frame Options

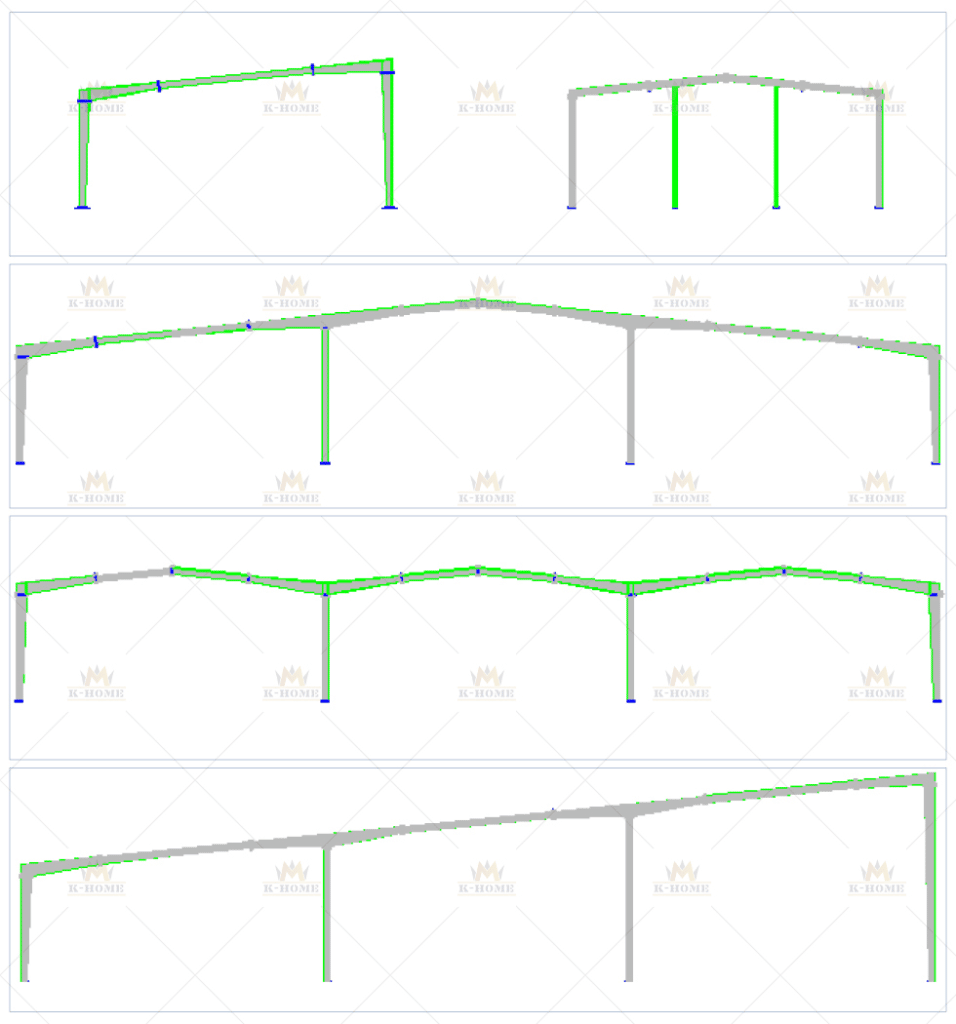

1. Clear Span

Features: The clear span design is a design without pillars, maximizes the use of space, and is very suitable for factories and warehouses that use forklifts and other vehicles in buildings. Span size: 32~ 82 feet.

2. Multi-Span

The modular inflexible frame can undertake gable or single slope patterns and helps offer a couple of spans on wider homes. This body fashion may be very inexpensive, with a span of 30 to eighty ft and a construction width of 60 to three hundred feet.

3. Unmarried Slope

The unmarried-slope rigid body may be very appropriate for purchasing department shops or strip malls with drainage regulations. This fashion of framework is also conducive to future growth. Because of the effective use of tapered participants and excessive-strength steel, the frame could be very low-priced and maximize the to be had clearance in the building.

4. Multi Gable

Tapered beams are very appropriate for steel buildings with a width of 60-70 ft and are designed to maximize the use of internal area and small crane assist structures. Thanks to the straight column, the inner finish can be effortlessly installed.

Steel Buildings Design & Customization Options

Determine The Design Requirements Of Steel Structures:

Before we get in touch, please prepare the following information, you will get a more accurate design and quotation. Or you could tell us your thought, and let us do the work:)

- Size: length*width*height in meters

- Wind speed: _____km/hour

- Snow load: ____kn/m2

- Roof and wall materials: EPS/rock wool/glass fiber cotton/PU sandwich panel/corrugated board?

- Do you need lighting, roof ventilation, etc.?

- Uses: warehouses, workshops, hangars, halls, sheds?

- Is there a crane system?

FAQs

Recommended Reading

Contact Us >>

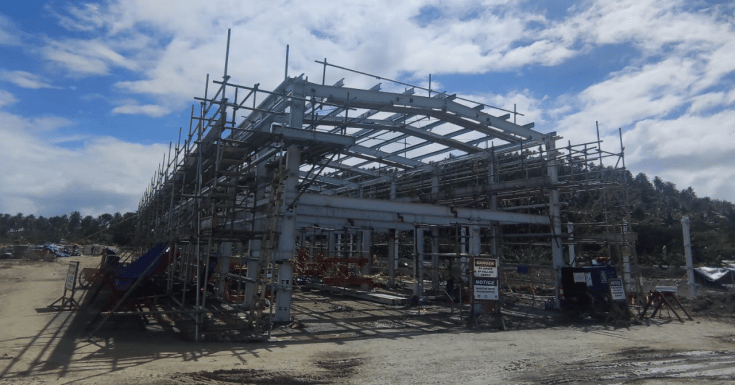

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.

About Author: K-HOME

K-home Steel Structure Co., Ltd covers an area of 120,000 square meters. We are engaged in the design, project budget, fabrication, and installation of PEB steel structures and sandwich panels with second-grade general contracting qualifications. Our products cover light steel structures, PEB buildings, low-cost prefab houses, container houses, C/Z steel, various models of color steel plate, PU sandwich panels, eps sandwich panels, rock wool sandwich panels, cold room panels, purification plates, and other construction materials.