No matter what kind of building, a load-bearing skeleton supporting the entire building quality is required during the construction process. Steel structure building is a structure composed of steel materials on the mainframe, which is one of the types of building structure. Steel structure buildings are mainly composed of steel beams, steel columns, steel trusses, and other components made of section steel and steel plates. Steel structure components or parts are usually connected by welds, bolts, or rivets(Types Of Connections In Steel Structures).

Steel structure buildings meet the needs of modern buildings. It is possible to construct some large-span, heavy-load structural buildings, which are not available in concrete houses. Because the steel structure is lightweight, high-strength, quick build, and short construction. It is widely used in warehouses, workshops, garages, large factories, gyms, super high-rise buildings and other fields.

Steel Structure Detail for Steel Frame System:

Frame Structure

A frame structure is a three-dimensional load-bearing system composed of steel beams and columns connected by welding or bolting. It evenly distributes lateral and vertical load-bearing capacity. It features high tensile strength, light weight, and excellent ductility. This structure’s modular construction reduces construction time by 30%-50%.

This type of frame structure is primarily used in multi-story or high-rise office buildings and commercial complexes. Its horizontal arrangement provides resistance to wind loads and earthquakes, while longitudinal support components ensure overall structural stability.

Portal Frame Structure

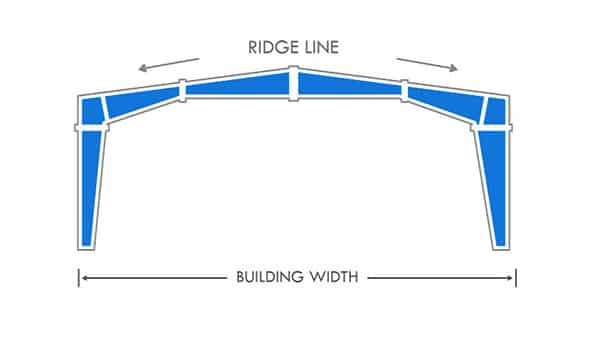

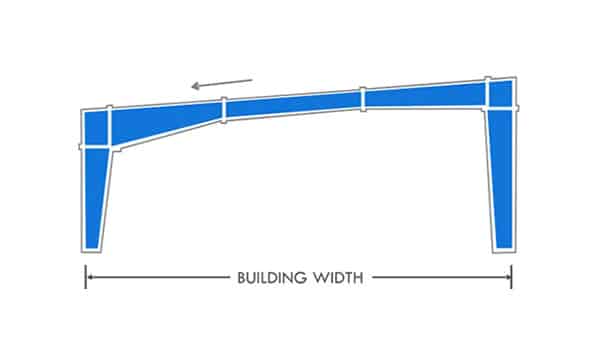

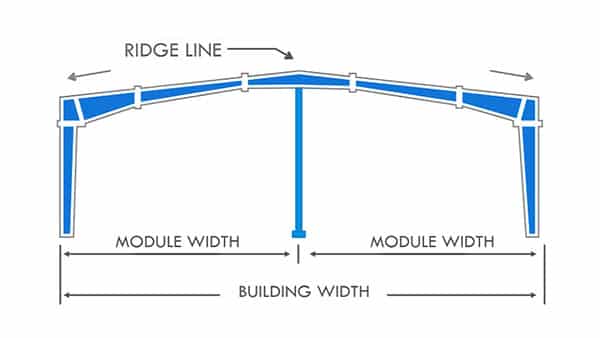

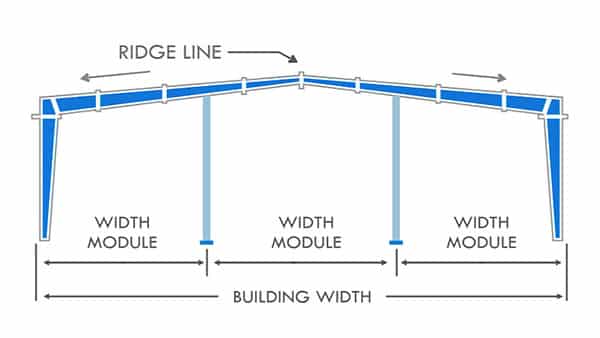

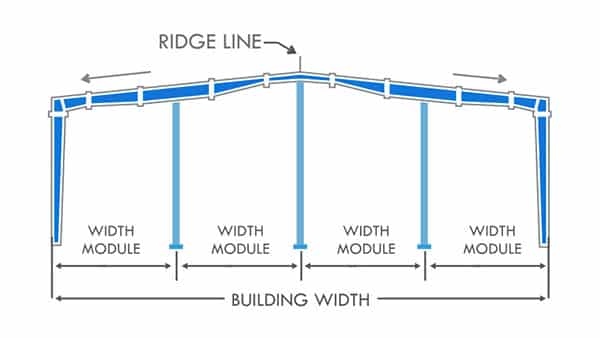

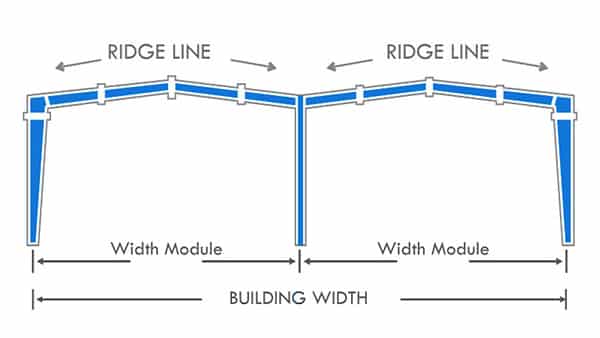

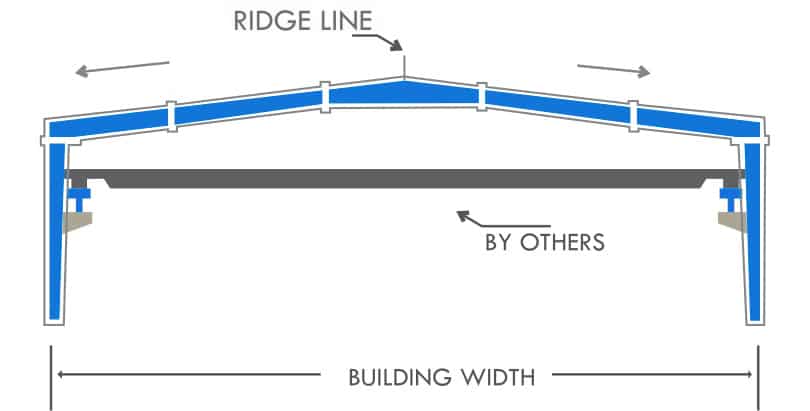

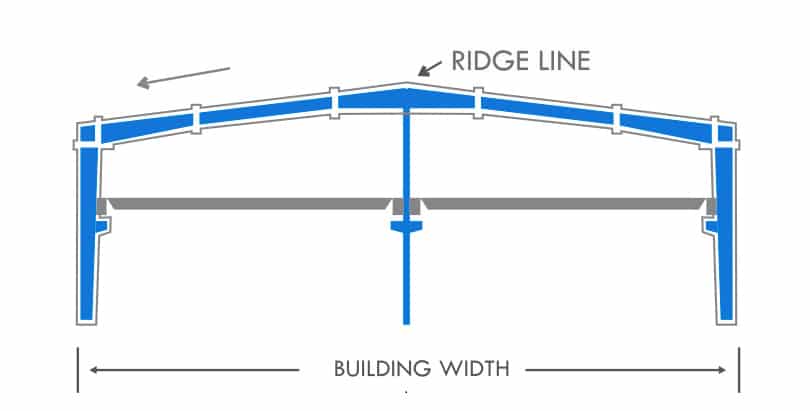

A portal steel structure is a common steel building type. Its primary load-bearing structure is composed of steel beams and columns, resulting in a “gate”-shaped exterior. Depending on whether a crane is available, portal steel structures can be categorized as lightweight without a crane or heavy with a crane. Structural forms can also include single-span, double-span, and multi-span structures, as well as those with overhangs and adjoining roofs.

The ideal span for portal frames ranges from 12 to 48 meters. If columns vary in width, their outer sides should be aligned. The frame height is determined by the required clear height within the building, typically ranging from 4.5 to 9 meters. Furthermore, the longitudinal temperature range should be limited to less than 300 meters, and the transverse temperature range to less than 150 meters. However, these temperature ranges can be relaxed with sufficient calculations.

Portal steel structure is a common form of large-span buildings such as industrial plants and warehouses.

single-span portal steel frame single-span portal steel frame double-span double slope portal steel frame multi-span double slope portal steel frame multi-span double slope portal steel frame multi-span multi-slope portal steel frame Single Span portal frame with Crane multi-span portal frame with crane

1. The single-span steel structure

A single-span structure, often referred to as a “clear-span portal frame,” is a building structure with two rows of columns supporting a single main beam, forming a single span. This type of structure is suitable for single-span factories, with an economically reasonable span typically ranging from 9 to 36 meters. When spans exceed 36 meters, the economics of the structure decline significantly, and a more suitable structural form is recommended.

The design layout of a single-span steel factory building should be rationally and rationally zoning functions based on the actual usable area. Due to the large overall area of the factory building, the division of usable areas must comprehensively consider personnel flow, natural ventilation, and the rational layout and reservation of fire escape routes to ensure that the space meets both production needs and safety regulations.

2. The double-span steel structure

A double-span steel structure consists of two adjacent single-span structures, sharing a row of steel columns to form a continuous spatial frame. Compared to single-span structures, double-span structures offer greater span flexibility, accommodating larger space requirements. They also offer improved seismic performance, as the two adjacent spans provide mutual support, enhancing overall stability.

Double-span steel factory buildings have a wider range of applications, particularly in production scenarios requiring large space, high flexibility, and strong seismic resistance. However, compared to single-span factories, double-span factories may be more difficult and costly to construct.

3. The multi-span steel structure

Multi-span steel structure also refers to large-span steel structure, which is a multi-span steel structure with a large horizontal span and needs to be supported by multiple steel columns and steel beams.

The floors of multi-span steel structure workshops are generally not very high. Its lighting design is similar to common scientific research laboratory buildings, etc., and mostly uses fluorescent lighting schemes.

The production plants of machinery processing, metallurgy, textile, and other industries are generally single-story industrial buildings, and according to the needs of production, they are more multi-span single-story industrial plants, that is, multi-span plants arranged next to each other in parallel. The needs can be the same or different.

The span and height of the workshop are the main factors considered in the lighting design of the workshop. In addition, according to the continuity of industrial production and the needs of product transportation between work sections, most industrial plants are equipped with cranes, which can have a light lifting weight of 3 to 5 tons, and a large crane can reach hundreds of tons.

Therefore, factory lighting is usually realized by lamps installed on the roof truss. The top of the factory building is usually high, and most of them are steel structure frames. When decorating, fire protection, ventilation, and central air conditioning must be designed first, because these are the necessary hardware facilities in the decoration of the factory.

Steel Structure Details – Span Selection

The span of a steel structure refers to the distance between its two ends, typically the span of a beam or overhang. It’s a crucial indicator of a structure’s strength and stability, determining its ability to withstand the design loads. It also significantly impacts its cost and construction difficulty.

The span of steel structure buildings generally follows the common practice of general building modulus. The multiples of three meters are 18 meters, 21 meters, etc., but if there are special needs, it is also possible to set the modulus size, but the upper components are purchased. It’s not a common component, it needs to be customized.

In steel structure projects, the span between two adjacent longitudinal positioning axes is noted by the design icon. A large-span steel structure refers to a span above (24m). The positioning axis should coincide with the main grid axis. The distance between the positioning lines should conform to the modulus size to determine the position and elevation of structures or components.

The following factors should be considered when determining the appropriate span of a steel structure:

- Load requirements: The span of a steel structure must be determined based on the magnitude and type of the design load to ensure the safety and stability of the steel structure.

- Material selection: The span of a steel structure beam must be determined based on the strength and stiffness of the material to ensure the load-bearing capacity of the steel structure.

- Design standards: The span of a steel structure must be calculated and determined in accordance with relevant design specifications and standards to ensure a reasonable and safe design.

- Project conditions: When determining the span of a steel structure, specific project conditions, such as construction conditions and space limitations, must also be considered.

Steel Structure Details – Column Distance

There are many influencing factors that determine the column distance and suitable spacing of the steel frame. For example, the number of foundations of portal steel structure buildings will affect the column distance. The number of concrete foundations has a greater impact on the overall project cost.

Generally speaking, a 9m column distance will greatly reduce the number of foundation works than a 6m column distance. It also impacts the construction period. The number of components will be reduced if the column spacing is large, which is beneficial to reduce transportation costs.

And it also reduces the number of hoisting works and shortens the construction period. The reduction in the number of concrete foundations will also help shorten the construction period and help the owner to use it as soon as possible.

Steel Structure Detail-Roof slope

Roof slope frame structure: A building roof with a slope greater than or equal to 10° and less than 75°. The slope of the sloping roof varies greatly.

The rules for roofs are as follows:

- The roof with a single slope span greater than 9m should be used for structural slope finding, and the slope should not be less than 3%.

- When looking for slopes with materials, light materials or insulation layers can be used to find slopes, and the slope should be 2%.

- The longitudinal slope of the gutter and eaves shall not be less than 1%, and the water drop at the bottom of the gutter shall not exceed 200mm; the drainage of the gutter and eaves shall not flow through deformation joints and firewalls.

Steel Structure Detail-Steel Structure Components

Steel columns: As one of the primary load-bearing components of a steel structure, they support the weight of the entire structure. The size and number of steel columns can vary depending on specific needs to accommodate different building designs and load requirements.

Steel beams: The primary horizontal members connecting steel columns, used to support and transfer loads. They are typically constructed from I-beams or other steel sections, offering excellent bending resistance. The length and cross-sectional dimensions of the beams are determined by the span, load, and support requirements.

Supports and Ties: Rigid supports are constructed from hot-rolled steel sections, typically angle steel. Flexible supports are constructed from round steel. Ties are compression-bearing round steel tubes, forming a closed load-bearing system with the supports.

Roof Purlins and Wall Beams: Typically constructed from C-section steel or Z-section steel. They bear the forces transmitted from the roof and wall panels and transmit these forces to the columns and beams.

Joints: The points in a steel structure where components intersect or connect. The design and construction of joints are crucial to the stability and safety of the entire structure. Joints are often reinforced with components such as reinforcing plates and pads to increase their load-bearing capacity and stability.

In the construction of steel structures, these components are rationally arranged and connected to form a stable and safe overall structure. It should be noted that the type and number of components in a steel structure may vary depending on the specific design and application.

Steel Structure Design

K – Home Steel Structure Design Process:

Consultation

The design process starts with an initial consultation with the client. The K – Home team will understand the client’s requirements, including the size, function, and budget of the production workshop. They will also collect information about the local climate, soil conditions, and other relevant factors in Tanzania.

Conceptual Design

Based on the information collected, the K – Home design team will develop a conceptual design. This design will include the overall layout, structural system, and enclosure system of the steel building. The conceptual design will be presented to the client for review and feedback.

Detailed Design

After the client approves the conceptual design, the K – Home team will carry out a detailed design. This includes the calculation of structural loads, the selection of materials, and the design of all components. The detailed design drawings will be produced, which will be used for the production of pre – fabricated components in the factory.

Review and Approval

The detailed design will be reviewed by the client and relevant local authorities in Tanzania. Any necessary modifications will be made based on the review comments. Once the design is approved, the production of components can start.

The Characteristics of Steel Structure:

1. High material strength

Although the bulk density of steel is larger, its strength is much higher. Compared with other building materials, the ratio of bulk density to yield point of steel is the smallest.

2. Lightweight

The steel content of the main structure of a steel structure building is usually around 25KG/-80KG, and the weight of the color-profiled steel plate is less than 10KG. The self-weight of the steel structure house is only 1/8-1/3 of the concrete structure, which can greatly reduce the cost of the foundation.

3. Safe and reliable

The steel is texture, isotropy, large elastic modulus, good plasticity, and toughness. It is calculated according to this steel structure house. Accurate and reliable.

4. Industrialized production

It can be mass-produced in batches with high manufacturing accuracy. The construction method of factory manufacturing and site installation can greatly shorten the construction period and improve economic benefits.

5. Beautiful

The enclosure of the steel structure BUILDING is made of color-profiled steel plates, and the service life is 30 years without fading and corrosion. Due to the diversity of the color steel plate, the lines of the building are clear, the look is comfortable, and it is easier to shape.

6. Reuse

The mainframe of the steel structure building is connected by high-strength bolts, and the enclosure plate is connected by self-tapping screws. It is convenient to dismantle.

7. Good seismic performance

As the main load-bearing component of a steel structure building is steel structure, its toughness and elasticity are relatively large. The shear and torsion resistance of purlins and the support between columns and beams greatly enhance the stability of the overall structure.

8. Wide application range

Steel structure buildings are suitable for all kinds of industrial plants, warehouses, supermarkets, high-rise buildings, etc.

Further Reading: Steel Structure Installation & Design

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.

About Author: K-HOME

K-home Steel Structure Co., Ltd covers an area of 120,000 square meters. We are engaged in the design, project budget, fabrication, and installation of PEB steel structures and sandwich panels with second-grade general contracting qualifications. Our products cover light steel structures, PEB buildings, low-cost prefab houses, container houses, C/Z steel, various models of color steel plate, PU sandwich panels, eps sandwich panels, rock wool sandwich panels, cold room panels, purification plates, and other construction materials.