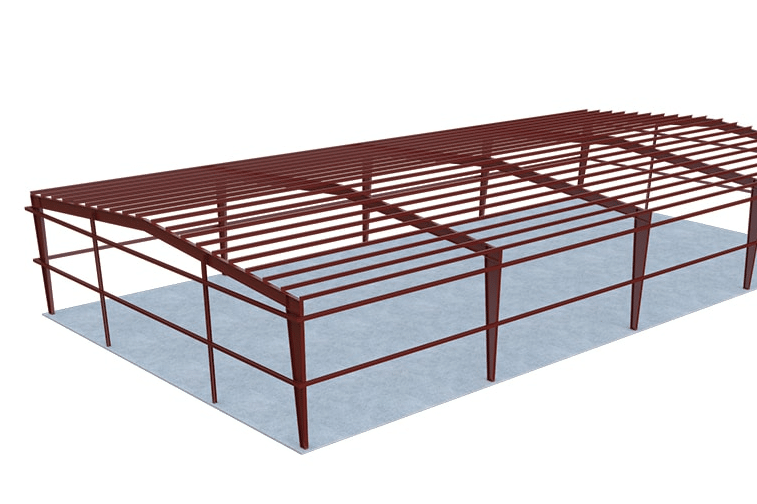

Steel Portal Frame Building is a traditional structural system. The upper main frame of this type of structure includes rigid frame inclined beams, rigid frame columns, supports, purlins, tie rods, gable frames, etc.

The steel structure of portal rigid frame light steel house has the characteristics of simple force, clear force transmission path, quick component production, easy factory processing, short construction period, etc., so it is widely used in industrial and civil buildings such as industrial, commercial, cultural and entertainment public facilities middle.

The steel structure of portal rigid frame light steel house originated in the United States and has experienced nearly a hundred years of development. It has now become a structural system with relatively complete design, production and construction standards.

The combination of beam-column unit components has various forms. The steel structure of single-span, double-span, or multi-span single- and double-sloping portal steel frames is more commonly used in the steel structure of single-story industrial buildings and civil buildings.

Types of Prefab Steel Farm Building

The Combination of Steel Portable Frame Building

Main Steel:

Beams, columns, platforms, crane beams are the main components. The main structure is the component that transmits the main load above. Just like the frame structure of civil construction,

Sub-Frame Steel

Beams, purlins, and corner braces. Those parts that do not transmit forces are named Sub-Frame.

Secondary Components:

Gutters, railings, braces, tie rods, those that do not transmit any force. But also very necessary, after using it, the building will be connected more tightly, which will extend the service life of the building.

Enclosure Parts:

Wall panels, roofs, doors and windows, ventilation equipment, etc. That you can change it anytime, even if it has broken, that won’t bring trouble to the durability of the whole structure.

The Structural Components of the steel Portable Steel Frame Building

Main Steel Structure

The main steel frame bears the strength of the entire building. If it is a big tree, it is equivalent to a tree trunk.

Roof Structure

Usually, a roof purlin above the roof frame and after that fixes the roof panel. Also need to use some bracing. And if you need an exhaust fan, a water gutter also needs to place on the roof.

Wall Structure

We will provide all wall layouts, also including the window or doors installation for you.

Floor Structure

Here share the anchor bolts layout with you. The Structural Layout of the Portable Steel Frame Building.

After the projects are confirmed, we will send you a detailed structure design like below, which shows the detail purlins, frame, bracing, etc.Even the 3D design for you could understand it easier.

The Main Principles Of The Bracing Placement Are As Follows:

- The distance between two horizontal supports should not be greater than 60 meters.

- The horizontal support of the roof should be set in the first or second compartment of the temperature range. When the end support is set in the second compartment, a rigid tie rod should be set at the corresponding position of the first compartment.

- Usually set in the first bay. Set in the first bay to directly and effectively transmit the gable load.

- Set in the second bay; add a set of tie rods.

- When the first bay is equipped with a gate, it is not suitable to set up the support between the columns. The support between the columns is set in the second bay, and the horizontal support corresponds to the position of the support between the columns.

Installation Step of Portal Steel Structure:

Column installation

In order to eliminate the influence of the error in the length of the column on the elevation of the column, before hoisting, measure 1 m down from the upper plane of the corbel as the cross-section of the theoretical elevation, and mark the obvious mark as a reference for adjusting the elevation of the column.

On the upper surface of the bottom plate of the column, mark the cross line of the vertical and horizontal axes passing through the center of the column, which is used as a reference for the installation and positioning of the column. When installing, align the cross line on the column with the cross line on the foundation, first use a level to correct the elevation of the column based on the mark on the theoretical elevation of the column, and then use cushion blocks to cushion and tighten the anchor screws.

Then use two theodolites to correct the verticality of the column from the two axis directions, and tighten the bolts with double nuts when the requirements are met. For a single column with an unstable structure, temporary protection measures can be taken with the help of wind cables. For columns designed with inter-column supports, the inter-column supports can be installed to enhance structural stability.

Crane beam installation

Before the crane beam is installed, it should be inspected, and can only be installed when the deformation does not exceed the limit. After a single piece of crane beam is hoisted in place, it should be bolted to the corbel in time and the connecting plate between the upper edge of the beam and the column should be connected, sighted, and adjusted with a spirit level and level instrument, and the bolts are tightened after meeting the requirements.

Roof beam installation

The roof beam should be inspected before the ground assembling. When the deformation of the component is not excessive, the friction surface of the high-strength bolt connection is free of debris and other debris, and the friction surface is flat and dry, it can be assembled on the ground.

When assembling, use non-oil gasket to pad up the components, and use wooden bars on both sides of the components to enhance stability. The roof beam is assembled with two columns as a unit. After the unit is spliced, it is necessary to check: ①The straightness of the beam; ②The spacing size of bolt holes connected with other components (such as columns). After the adjustment and inspection meet the requirements, tighten the high-strength bolts.

Sub-Frame and Accessory installation

The roof purlin and wall purlin are installed at the same time. Before installation of the purlin, check the deformation of the components, and deal with it if there is any over-limit, and remove the oil and sand on the surface of the components. Put several purlins as a group and hoist them together. After one span is installed, check the slope of the purlins. The straightness of the purlin is required to be controlled within the allowable deviation range, otherwise, it can be adjusted by connecting bolts (add gasket if necessary).

Re-inspection and adjustment, welding, paint repair:

After the hoisting is completed, all components are re-inspected and adjusted. After the design requirements are met, welding is carried out on-site, and the paint-damaged parts of the components are repaired.

Further Reading: Steel Structure Installation & Design

What should we know before we can design the steel Portable Frame Buildings?

Maximum Wind Resistance Coefficient, have a hurricane or not, and Snow load.

Should the building withstand more serious weather, it needs stronger. And meanwhile, the bigger size of the steel frame, the price will be higher.

Design Code

Different places have different requirements, not all places accept China’s design code to get installation permits. So this is very important.

These are the most important things that we need to face first, and there is still more need to check based on your actual project plan.

Recommended Reading

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.

About Author: K-HOME

K-home Steel Structure Co., Ltd covers an area of 120,000 square meters. We are engaged in the design, project budget, fabrication, and installation of PEB steel structures and sandwich panels with second-grade general contracting qualifications. Our products cover light steel structures, PEB buildings, low-cost prefab houses, container houses, C/Z steel, various models of color steel plate, PU sandwich panels, eps sandwich panels, rock wool sandwich panels, cold room panels, purification plates, and other construction materials.