Large-span steel structures are playing an increasingly important role in modern architecture and engineering. They utilize high-strength steel as a framework and are constructed using efficient connection and assembly methods. The ultimate goal is to simplify the need for vast spaces, achieving large-scale spatial volumes with few or no columns, while simultaneously considering aesthetics, durability, and economy.

What is a large span steel structure?

Generally, when the span of a spatial structure exceeds 20 to 30 meters and steel is used as the primary load-bearing system, regardless of its form (steel beams, steel arches, steel trusses, or steel space frames), it can be classified as a large-span steel structure.

Although specific engineering standards and design specifications may vary, their core characteristics remain consistent:

- First, steel is the primary structural material;

- Second, these structures minimize intermediate supports to maximize spatial coverage.

- Furthermore, large-span steel structures effectively reduce the impact of their own weight on the underlying space while retaining flexibility in layout and modification.

Prefab Metal Warehouse: Design, Type, Cost

Why Choose Large-span Steel Structure Buildings?

The choice of large-span steel structures stems primarily from the combined advantages of their materials and structural form. These advantages are specifically reflected in the following aspects:

- Superior Material Properties

Steel offers an excellent strength-to-weight ratio. That means that for the same weight, its strength and load-bearing capacity are significantly higher than traditional materials like concrete. This characteristic makes steel structures lightweight, allowing for large spans while effectively reducing the requirements for the foundation. Furthermore, steel possesses good plasticity and recyclability, facilitating factory prefabrication and aligning with green and sustainable development principles.

- Fast and Efficient Construction

Most steel components are prefabricated in factories and then transported to the site for assembly. Using methods like bolting or welding, construction proceeds quickly. This approach significantly shortens project timelines and reduces on-site work.

- Highly Flexible Space Design

The primary goal of large-span structures is to create open, column-free spaces. The high strength and flexibility of steel structures greatly facilitate the free division of internal spaces.Steel structures make this possible while allowing for easy future modifications. Whether rearranging interior layouts, adding spectator stands, or installing walkways, adjustments can be made flexibly and efficiently.

Common Types of Long Span Steel Structures

Long-span steel structures primarily achieve expansive column-free spaces through several classic forms. Each has its own characteristics and is suitable for different scenarios.

- Truss Structures

The truss in a truss structure refers to a truss beam, a type of latticed beam structure. This structure consists of straight members (diagonal web members and horizontal chords) connected at nodes to form triangular units. Truss structures are commonly used in public buildings such as large-span factories, exhibition halls, stadiums, and bridges. Because they are mostly used in roof structures, trusses are often also called roof trusses. Their main advantages include a clear load transfer path and high structural efficiency, making them very suitable for long-span, regular rectangular structures. Due to mature manufacturing technology, the construction and maintenance of truss structures are relatively simple.

- Space frame structure

This is a three-dimensional spatial structure composed of numerous members arranged in a grid. Its excellent overall stability and spatial stiffness allow it to adapt to various irregular planes and complex boundaries. At the same time, it also possesses a unique architectural aesthetic.

- Arches

Through continuous curved shapes, loads are transformed into axial pressure along the arch axis, thus achieving extremely large spans. Arches not only create spacious interiors, but their graceful curves often become the visual focal point of a building, and they also contribute to the optimization of acoustics and visual effects.

- Cable-Membrane Structures

Through continuous curved shapes, loads are transformed into axial pressure along the arch axis, thus achieving extremely large spans. Arches not only create spacious interiors, but their graceful curves often become the visual focal point of a building, and they also contribute to the optimization of acoustics and visual effects. Applications include: landscape architecture (stadium canopies), ecological architecture (botanical garden greenhouses), and temporary structures (large exhibition halls).

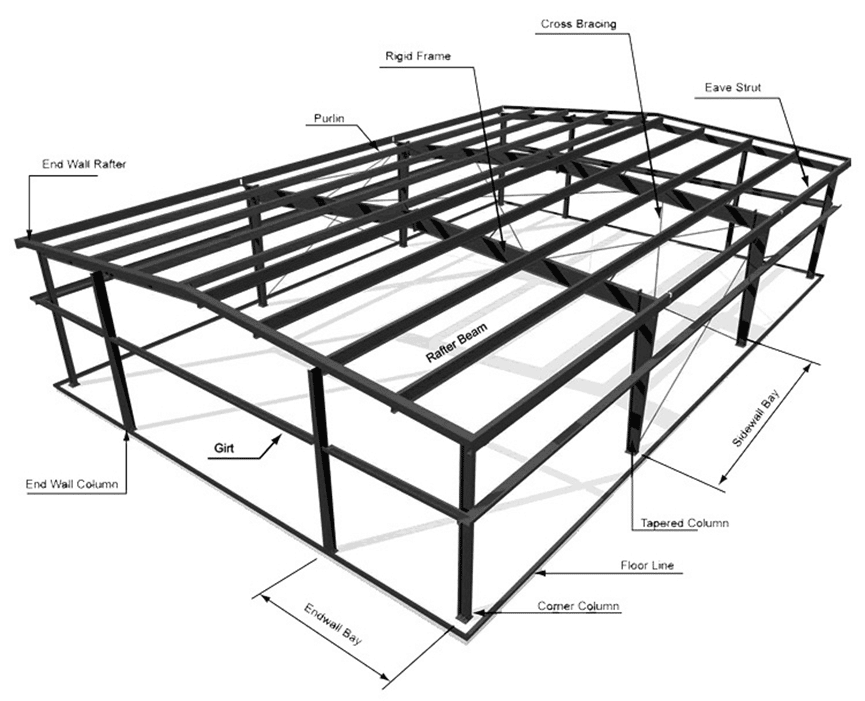

- Steel Portal Frame Structure (a cost-effective choice for small and medium-sized buildings)

A steel portal frame structure consists of a portal frame (H-shaped steel beam-column rigid joints), a purlin system (C/Z-shaped steel), and a bracing system, forming a planar load-bearing system. Its core advantage lies in its variable cross-section design—the beam and column cross-sections are optimized according to changes in internal forces, achieving efficient material utilization. The roof and walls use lightweight profiled steel sheets (self-weight only 0.1-0.3 kN/㎡). Foundation load is reduced by 40%-60% compared to concrete structures.

Truss Structures Arches Cable-Membrane Structures Steel Portal Frame Structure

Key Design Considerations

In practice, these systems are often combined to develop an optimal spatial framework tailored to project-specific requirements. As span increases, joint design complexity rises significantly. Thus, achieving an optimal balance among structural strength, stiffness, and manufacturability remains crucial to the successful design of large-span steel structures.

The Development History of Large Span Steel Structure Buildings

Ancient Rome had large-span buildings (such as ancient Roman buildings). Large-span structural buildings in modern times had made great achievements. For example, the machinery pavilion at the Paris World Exposition in 1889 used a three-hinged arched steel structure with a span of 115 meters.

At the beginning of the 20th century, the progress of metal materials and the development of reinforced concrete technology promoted the emergence of many new structural forms of large-span buildings.

For example, the Centennial Hall, built-in Breslau, Poland from 1912 to 1913, uses a reinforced concrete dome with a diameter of 65 meters and a covering area of 5,300 square meters. After the Second World War, large-span buildings saw new developments, with European countries, the United States, and Mexico developing the fastest.

The large span steel structure buildings of this period widely used various high-strength lightweight materials (such as alloy steel, special glass) and chemical synthetic materials, which reduced the weight of the large-span structure, and enabled the continuous appearance of novel spatial structures and the increasing coverage of the area.

The Characteristics of Large Span Steel Structure Buildings

- Increasing diversification and complexity of structural forms.

- The structural span is getting bigger and bigger, the steel grade is getting higher and higher, the steel plate thickness is getting thicker and thicker.

- Complex and diverse connection way styles.

- The number of components and cross-section types are increasing, making it more and more difficult to deepen the design.

- High require for machining accuracy.

Cost of Large-Span Steel Structures

The cost of large-span steel structures is not a fixed price. It varies greatly depending on factors such as raw materials, structural type, and construction conditions. For example:

- Size: Generally, the larger the building area, the lower the cost per unit area; the higher the building height, the higher the requirements for the structural load-bearing capacity and stability, and the higher the cost.

- Material Quality: Steel is also a key factor affecting cost. Ordinary carbon structural steel is relatively inexpensive, while high-quality high-strength steel is more expensive. Additionally, using high-quality protective coatings in the enclosure structure also increases costs.

- Design Complexity: For general portal steel structures, within a reasonable span range, economic feasibility can be balanced through structural design. Complex designs will increase costs.

- Geographical Location: Costs vary in different regions due to differences in labor costs, transportation costs, and market conditions. Costs in economically developed areas may be 10%-30% higher than in less developed areas.

- Construction Technology: Advanced construction technology may increase costs but also improves efficiency and lifespan.

- Location and Logistics: Logistics is also a significant cost factor. If the project location is relatively remote, the cost of ocean freight will increase. Furthermore, ocean freight costs also fluctuate with changes in the economic climate.

Further Reading: Steel Building Plans and Specifications

About K-HOME

——China steel Building Manufacturer

At k-home, we offer two main steel structure systems: frame structures and portal frame structures. K-Home’s engineering team conducts comprehensive assessments of each project’s specific needs, considering load requirements, functional requirements, and budget control, to recommend the most suitable steel frame solution for our clients. Our steel structure systems undergo rigorous calculations and physical testing to ensure that every building reaches its designed lifespan.

Design

Every designer in our team has at least 10 years of experience. You don’t have to worry about the unprofessional design affecting the safety of the building.

Mark and Transportation

In order to make you clear and reduce the site work, we meticulously mark each part with labels, and all parts will be planned in advance to reduce the number of packings for you

Manufacturing

Our factory has 2 production workshops with large production capacity and short delivery time. Generally, the lead time is around 15 days.

Detailed Installation

If this is the first time for you to install the steel building, our engineer will customize a 3D installation guide for you. You don’t need to worry about the installation.

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.

About Author: K-HOME

K-home Steel Structure Co., Ltd covers an area of 120,000 square meters. We are engaged in the design, project budget, fabrication, and installation of PEB steel structures and sandwich panels with second-grade general contracting qualifications. Our products cover light steel structures, PEB buildings, low-cost prefab houses, container houses, C/Z steel, various models of color steel plate, PU sandwich panels, eps sandwich panels, rock wool sandwich panels, cold room panels, purification plates, and other construction materials.