steel factory buildings

K-hOME offers customized PEB factory building solutions. These solutions meet durable, economical, and local building standards.

Are you looking for a faster, more adaptable way to build your next manufacturing plant, warehouse, or logistics center? Today, speed to market is critical. Structural steel buildings offer a powerful solution, standing out as one of the fastest and most reliable construction systems available.

The inherent advantages of steel are clear: it provides exceptional strength, design flexibility, and rapid installation. These benefits directly help you accelerate your project timeline. Furthermore, a steel structure is uniquely adaptable, making future expansion straightforward as your business grows.

For businesses in manufacturing, processing, or storage, a custom-designed steel factory building is an ideal and strategic choice.

At K-HOME, we specialize in designing and manufacturing customized steel structure buildings that meet rigorous international standards. We understand the practical needs of clients across various sectors, including manufacturing, food processing, logistics, and heavy industry.

With years of experience serving a global clientele, we have become a trusted partner for businesses worldwide seeking efficient and reliable steel structure solutions.

What is a steel structure factory building? Guide to Its Definition, Types, and Core Advantages

In simple terms, a steel structure factory building is a modern construction that uses steel columns and beams as its primary load-bearing framework. The exterior is typically clad with insulated sandwich panels or corrugated steel sheets. Compared to traditional concrete buildings, it has become the preferred solution for industrial facilities like factories, warehouses, and workshops due to its exceptional strength, rapid construction speed, and high customizability.

Structure Type of Steel Structure Factory: The Portal Frame System

In industrial buildings, the portal frame is the most widely used and mature structural system. Originating in the United States, it has been continuously improved over nearly a century and has become a structural system with relatively complete design, fabrication, and construction standards.

Steel frame factory building‘s main advantages include:

- Structural Efficiency: Steel portal frame buildings have simple stress distribution and a clear force transmission path. They can achieve large spans and column-free structures, thereby maximizing the use of internal space.

- Short Construction Period: Standardized design and factory production mean that processing and on-site assembly speeds are typically more than 50% faster than traditional methods.

- Highly adaptable: Flexible design options include various configurations such as single-slope, multi-slope, and unequal spans to meet diverse needs.

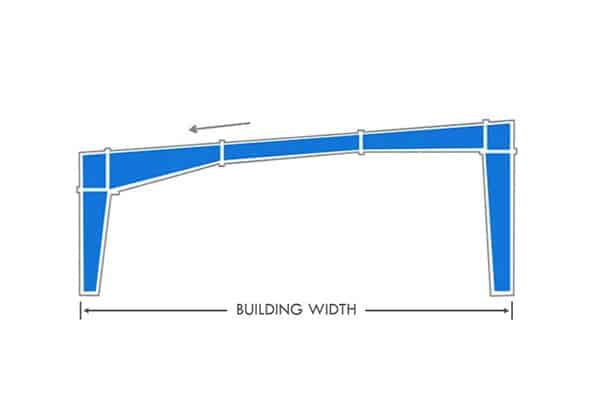

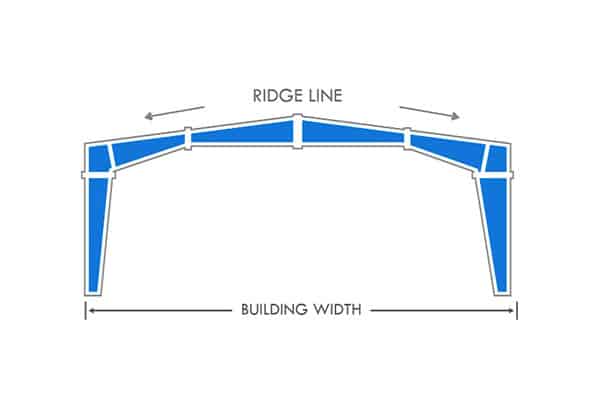

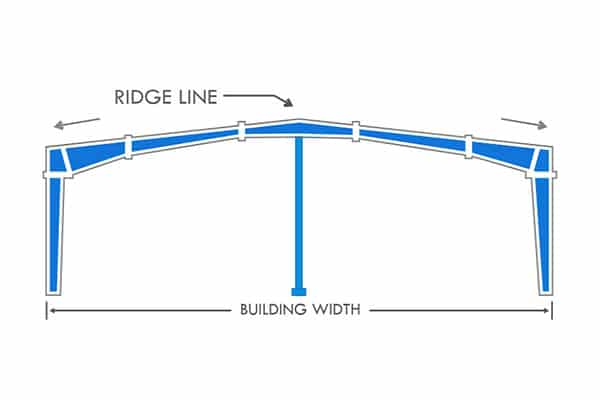

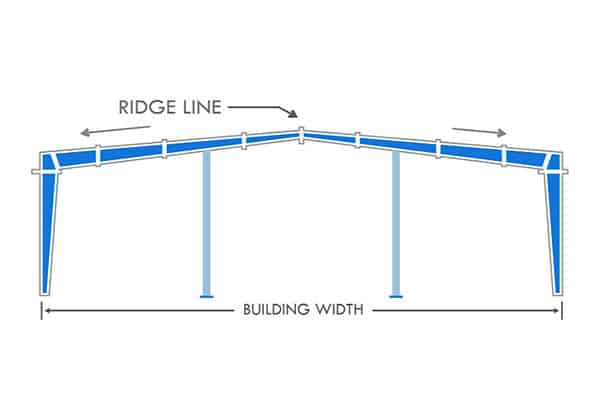

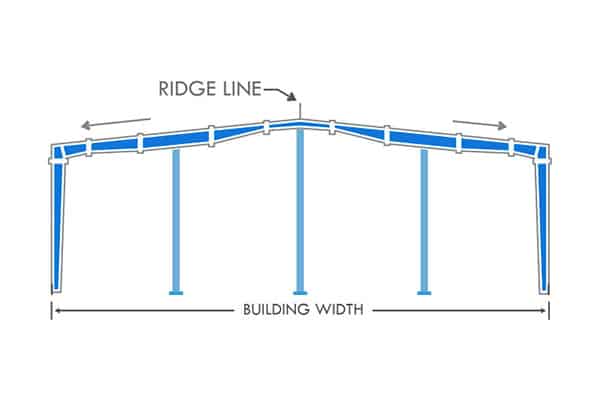

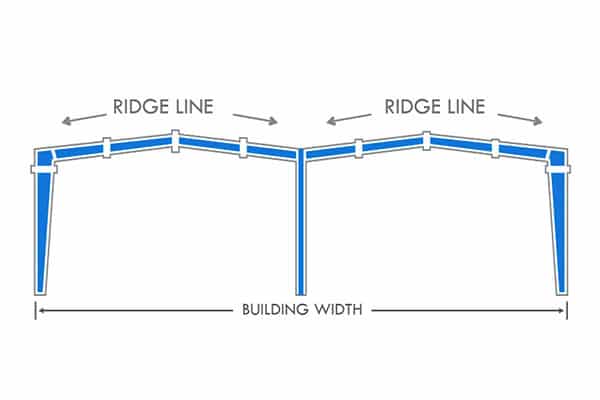

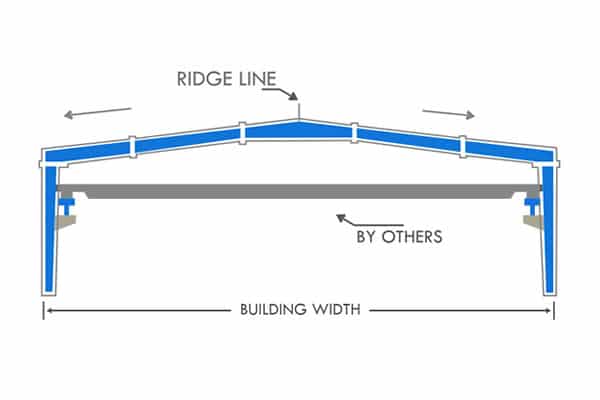

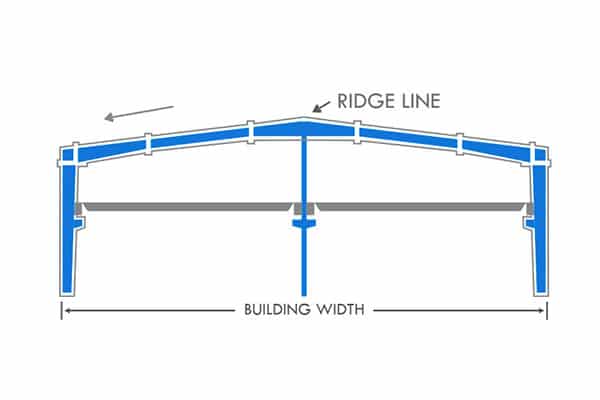

Portal Frame System – Single Span Single slope Portal Frame System – Single Span Double slope Portal Frame System – Double Span Double Slope Portal Frame System – Multi Span Portal Frame System – Multi Span Double Slope Portal Frame System – Multi Gable Portal Frame System – Clear Span with Crane Portal Frame System – Double Span with Crane

Why Choose Steel Structure for The Factory Building?

1、Superior overall performance: Steel structures comprehensively enhance the practicality, functionality, economy, and durability of factory buildings. It is not a single advantage, but a comprehensive solution.

2、Significant Economic Benefits:

- Reduced construction and material costs: The structural design is simpler, construction is more efficient, and it requires less building material.

- Lower life-cycle costs: Long service life and low maintenance requirements.

- High space utilization: Creates larger column-free spaces, facilitating the layout and control of process equipment, indirectly saving costs.

3、Sustainability and Environmental Friendliness:

- Reusable: Components can be reused multiple times after the building’s lifespan.

- Recyclable: Materials have high recycling value after dismantling, meeting environmental protection requirements.

4、Safety and Quality Combined: While pursuing economic efficiency, reasonable design ensures structural safety and the final building quality.

What are the components of a steel building factory? Key components and technical specifications

Each steel structure factory building is custom-designed to meet your unique needs. Its superior performance stems from a proven and reliable core component system. Understanding these key components will help you clearly plan your project and ensure that the solution precisely matches your budget and operational goals when communicating with our team.

A safe and efficient steel structure factory building mainly consists of the following five core systems:

1. Load Design

- Design Basis: This is the most crucial step, directly determining the structure and safety of the steel building. The design must strictly adhere to the wind load, snow load, seismic fortification level, and possible crane load specifications of the project site.

- Value Brought to You: Through scientific calculations, ensures your building maintains long-term durability and safety under both static load (structural self-weight) and live load (service load).

2. Foundation and Anchoring

- Composition: Custom-designed concrete foundation with pre-embedded anchor bolts, taking into account local geological conditions and the load requirements of the steel structure factory.

- Key Function: Ensures a secure connection between the superstructure and the ground, effectively resisting equipment vibration, wind loads, and other external forces, providing fundamental protection for the long-term safety of the building.

3. Primary Frame

- Composition: Steel columns and beams made of high-strength Q235 or Q355 steel.

- Key Parameters: Common column-free spans are 12–30 meters, and eaves heights are 6–12 meters.

- Value Brought to You: Creates open, barrier-free spaces, perfectly suited for large production line layouts, high-bay warehouse racking, or crane installation needs.

4. Secondary Frame

- Components: Includes C- or Z-shaped steel purlins, horizontal supports, and tie rods.

- Key Function: Not only does it support the roof and walls, but it also greatly enhances the overall structural stability and provides a solid foundation for the installation of doors, windows, and skylights.

5. Enclosure System(Roof & Wall System)

- Materials: Typically made of color-coated steel sheets or high-performance insulated sandwich panels (filled with EPS, PU, or fire-resistant rock wool).

- Key Parameters: Common thickness 50–150 mm.

- Value Brought to You: Directly determines the thermal insulation, sound insulation, and energy-saving effects of the factory building, creating a comfortable working environment and significantly reducing operational energy consumption.

| Component Structure | Material | Technical Parameters |

|---|---|---|

| Main Steel Structure | GJ / Q355B Steel | H-beam, Customized height according to building requirements |

| Secondary Steel Structure | Q235B; Paint or Hot Dip Gavalnized | H-beam, Spans range from 10 to 50 meters, depending on design |

| Roof System | Color Steel Type Roof Sheet / Sandwich Panel | Sandwich panel thickness: 50-150mm Customized size according to design |

| Wall System | Color Steel Type Roof Sheet / Sandwich Panel | Sandwich panel thickness: 50-150mm Customized size according to wall area |

| Window & Door | Color steel sliding door / electric rolling door Sliding Window | Door and window sizes are customized according to design |

| Fireproof Layer | Fire retardant coatings | Coating thickness (1-3mm) depends on the fire rating requirements |

| Drainage System | Color Steel &PVC | Downspout: Φ110 PVC Pipe Water Gutter: Color Steel 250x160x0.6mm |

| Installation Bolt | Q235B Anchor Bolt | M30x1200 / M24x900 |

| Installation Bolt | High-Strength Bolt | 10.9M20*75 |

| Installation Bolt | Common Bolt | 4.8M20x55 / 4.8M12x35 |

We welcome you to contact us with your project’s specific parameters and requirements. K-HOME’s engineering experts will provide you with a customized preliminary plan and design based on these core components.

Design Considerations for Specialized Factory Steel Structures

An exceptional steel structure factory building begins with a well-thought-out design. Poor design leads to cost overruns, wasted space, and inefficient operations. At K-HOME, we firmly believe that professional design is the cornerstone of controlling total project costs, maximizing building performance, and ensuring its long-term lifespan. We design every building based on the client’s project needs and local conditions.

Layout & Functional Planning

A disorganized layout leads to circuitous production processes, inefficient logistics, and wasted space. At KHOME, we conduct in-depth analyses of your production processes, equipment load, logistics flow, and warehousing needs. These plans ensure maximum space utilization, making daily operations more efficient and streamlined.

Span & Eave Height

Dense columns can divide space and limit the layout of large equipment and flexible production lines. Our designs optimize span (typically 12-30 meters) and eaves height (typically 6-12 meters) to create open, unobstructed, and continuous spaces for you. These spaces can accommodate assembly lines, maintenance areas, and high-bay racking, giving you the freedom to adjust your layout as needed based on market changes.

Crane Integration

For workshops requiring overhead cranes, the design incorporates crane runway beams, reinforced columns, and deflection control. These features ensure safety, structural stability, and smooth operation of crane systems.

Energy Efficiency

K-HOME integrates insulated wall and roof panels, natural ventilation, skylights, and environmental coatings. These energy-efficient solutions help reduce operating costs over the building’s lifecycle while maintaining a comfortable and safe working environment.

Future Expansion

The modular nature of a factory steel structure allows for fast extension, flexible space growth, and reconfiguration without damaging the existing structure. This adaptability is a major advantage for growing companies that may need to scale up operations in the future.

cost of steel workshop building

Many clients ask about the cost of a steel structure workshop building at the very beginning of a project. While the final price depends on specific design, size, and project requirements, the following ranges provide a general reference.

Price Reference (FOB China):

- Standard steel workshop: US$50–80 per m²

- With insulation panels or overhead cranes: US$70–120 per m²

- Heavy-duty or fully customised applications: US$120–200+ per m²

Factors Affecting the Cost:

Several key factors determine the final price of a steel structure workshop:

- Steel price and weight: The type and amount of steel used is the biggest cost driver. High-grade steel or larger structures naturally increase cost.

- Span and eave height: Wider spans and taller eaves require stronger beams and columns, which add to material and fabrication costs.

- Wall and roof insulation: Insulated sandwich panels for cold storage or food-processing facilities cost more than standard color-steel sheets.

- Crane requirements: Overhead cranes need reinforced columns, crane rails, and specialized engineering, which increase costs.

- Foundation design: Soil conditions, seismic zones, and heavy-load requirements affect concrete foundation complexity and cost.

- Location and environmental loads: Wind, snow, or other climate factors may require additional structural reinforcement.

- Additional features: Number of doors, windows, mezzanine floors, and internal partitions all impact total cost.

Applications of PEB Factory Buildings

Because of their flexibility, durability, and cost-effectiveness, PEB Factory Buildings are widely used across various industries. Their modular design and large clear spans make them suitable for both heavy industrial use and precise operational requirements.

Manufacturing Plants:

Factory steel structure buildings are ideal for manufacturing facilities due to their column-free space and adaptability. They are widely used for: Automotive parts production, Machinery assembly, Electronics manufacturing. The large clear spans allow easy installation of heavy machinery, assembly lines, and conveyors, enabling efficient workflow and operational flexibility.

Warehouses & Logistics Centers:

Steel structure buildings are perfect for modern warehousing and logistics needs. Common applications include: Distribution hubs, High-bay storage facilities, Cold chain storage warehouses. Insulated panels help maintain temperature control for cold storage, while the open floor plans allow flexible storage layouts and easy forklift operations.

Food Processing Industry:

The hygienic and easily maintained interior of a factory steel structure makes it suitable for food-grade facilities, such as: Flour mills, Grain processing workshops, Beverage or dairy plants. The design allows for integration of ventilation, drainage, and clean zones, meeting strict food safety standards.

Agriculture & Livestock:

Steel structures are also used in agricultural and livestock operations: Feed production facilities, Storage sheds for grains or equipment, Livestock processing workshops. Their durability and modularity make them suitable for expansion as production scales up.

The robust steel framework ensures long-term durability, while fast installation minimizes downtime and construction costs. With such versatility, factory steel structure buildings have become the backbone of modern industrial development. Their ability to combine strength, speed, flexibility, and cost-efficiency makes them an essential solution for growing businesses across multiple sectors.

- prefabricated steel warehouse for Auto Parts

- CNC workshop

- Steel bar production workshop

- steel production workshop

- Logistics Centers

- metal storage warehouse

- prefab warehouse

- Steel livestock farm

How to choose a reliable steel structure factory supplier?

Choosing a steel structure factory supplier is one of the most critical decisions for your project’s success. A reliable partner ensures building safety, cost control, and smooth project delivery, while a poor choice can lead to endless quality problems and disputes.

To help you make an informed decision, we have summarized the following 7 core evaluation criteria, based on K-HOME’s experience serving global clients.

Project Experience and Case Studies

Past cases are the most direct proof of a supplier’s capabilities. Especially projects in the same industry or with similar process complexity as yours can significantly reduce your project risks.

Technical Design and Engineering Support Capabilities

Excellent design is the cornerstone of cost control, optimized functionality, and guaranteed safety. Companies lacking technical depth will only offer generic solutions. At K-HOME, we can show you preliminary calculations considering local wind and snow loads. We also provide BIM modeling services to achieve visualized collaborative design, avoiding conflicts and rework during the construction phase.

Quality Control and Certification System

The quality of steel, welding processes, and coating treatments directly determine the building’s lifespan and safety. 4. Manufacturing Capacity and Project Performance Record: Strong factory capacity and a stable delivery record are guarantees for on-time project progress. You need to understand their factory’s annual capacity, main processing equipment, and ability to coordinate multiple projects simultaneously.

Transparent Pricing and Cost Structure

A vague quote is a major trap for cost overruns later on. You need to pay for a clear scope, not hidden risks. At K-HOME, we will provide you with a detailed quote, including material specifications, models, quantities, unit prices, and total prices.

Note: Be wary of quotes significantly below market levels, as this usually indicates shoddy workmanship or additional charges later.

Comprehensive Service Scope

Your chosen supplier not only provides high-quality steel structure materials but also full lifecycle services. We believe you need a partner who can provide a one-stop solution from design to delivery.

At K-HOME, we not only fully meet all the above standards but also strive to exceed your expectations. We view each project as a long-term partnership. Our global project experience, internationally standardized technical expertise, transparent pricing model, and full-cycle customer support are designed to ensure your investment yields long-term, stable returns.

why K-HOME Steel factory building?

As a professional PEB manufacturer, K-HOME is committed to providing you with high-quality, economical prefabricated steel structure buildings.

Committed to Creative Problem Solving

We tailor each building to your needs with the most professional, efficient and economical design.

Buy direct from the manufacturer

Steel structure buildings come from the source factory, carefully selected high-quality materials to ensure quality and durability. Factory direct delivery allows you to get prefabricated steel structure buildings at the best price.

Customer-centric service concept

We always work with customers with a people-oriented concept to understand not only what they want to build, but also what they want to achieve.

1000+

Delivered structure

60+

countries

15+

Experiences

Frequently Asked Questions

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.