prefabricated Agricultural Steel Buildings

Poultry Farm, Chicken House, Horse Barn, Cow Barn, Livestock Building, storage Building, warehouse, Greenhouse, etc.

what is classed as an agricultural building?

In agricultural operations, agricultural buildings are required. An agricultural building is an architectural structure used for agricultural purposes. It is designed to house farm equipment, hay, grain, poultry, livestock, or other agricultural products. An agricultural building needs to be durable and meet the need to maximize the use of space. It needs to be cost-effective and easy to assemble. To meet your needs, prefabricated agricultural buildings using steel structures become the appropriate solution for modern farm operations compared to concrete structures and brick wall structures. Agricultural buildings need to cover many different needs and uses that can occur on agricultural property. These steel agricultural buildings may be used to store your new tractor, combine, or other farm equipment or they may be used to raise livestock and poultry, while you may also have a need to store grain.

Prefabricated agricultural building kits are highly versatile and can be customized to fit your site needs. So, no matter what kind of agricultural building you need, you can achieve it using prefabricated steel buildings. Whether it’s storage for hay, equipment, livestock, or farm vehicles, agricultural steel buildings provide maximum protection from various hazards. Therefore, steel buildings are widely used and preferred in agricultural buildings.

If you are looking for fast construction, low cost, and safe agricultural building, K-HOME is your best choice.

Advantages of Agricultural Steel Buildings

Fast Construction

The construction of the steel structure industrial building is rapid, and the emergency advantages are apparent, which can meet the sudden needs of the enterprise.

Environment friendly

The steel structure is dry construction, which can reduce the impact on the environment and nearby residents. It is much better than reinforced concrete buildings.

Low Cost

Steel structure can save construction costs and workers’ costs. The cost of a steel structure industrial building is 20% to 30% lower than a typical one, and it is more secure and stable.

Light Weight

The steel structure is lightweight, and the building materials used in walls and roofs are much lighter than concrete or terracotta. Also, the transportation cost will be much lower.

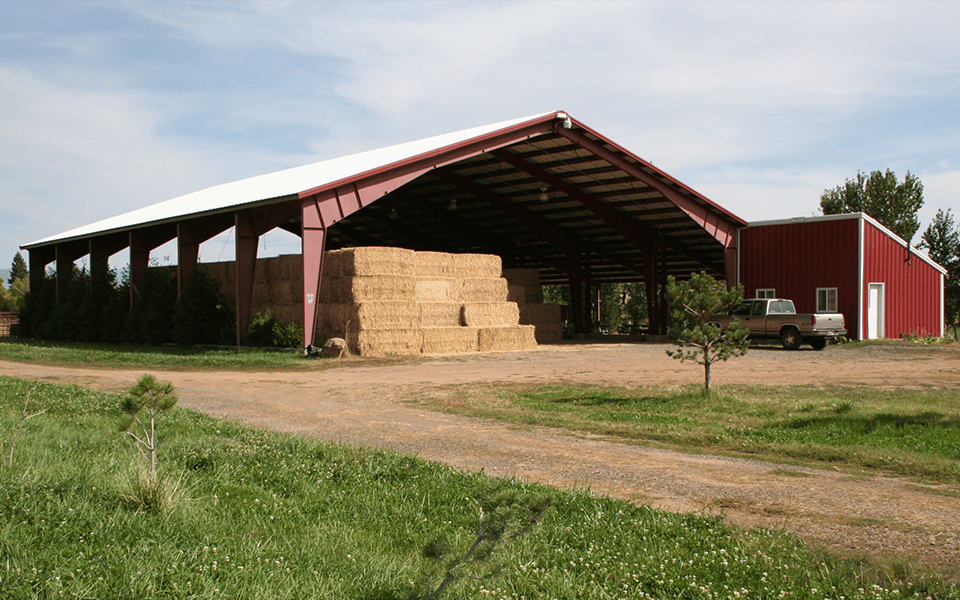

Agricultural machine& equipment storage buildings

Many pieces of farm equipment can be placed in the field, but most farmers prefer to store them in a separate space, especially machinery, to protect them from the elements. For agricultural landowners, their equipment is their livelihood, and protecting their tools is critical. Metal structures are strong and durable, and you can customize them in different widths and heights so that there will be enough space to accommodate your farm machinery and equipment. Prefabricated metal agricultural building kits can greatly reduce the cost of farm buildings while also providing a safer way to protect their equipment from weather and other disturbances.

Agricultural Metal Barns

A dry, wind, and rain-proof environment Barn are necessary for the agricultural building. The ruggedness and durability of metal barns make them a cost-effective and highly customizable option. They are designed to meet your specific local specifications for wind, snow, and seismic loads. And these structures are not susceptible to insect damage or rot, nor are they prone to warping and cracking like wood-frame buildings.

Steel livestock building

Maintaining the health of your livestock is crucial. As one of the most specialized manufacturers of prefabricated steel agricultural buildings, we could provide livestock buildings including cattle barns, horse barns, poultry houses, sheep pens, etc. Our prefabricated steel livestock buildings are quick and easy to install. Prefabricated agricultural buildings will meet the specific needs of the client and species being raised, including the construction site location, lighting, ventilation and insulation, and safety. Whether you raise cattle, sheep, hogs, or other livestock, our team can develop the most effective building designs that provide the ideal environment for raising livestock, protecting them from inclement weather and outside predators.

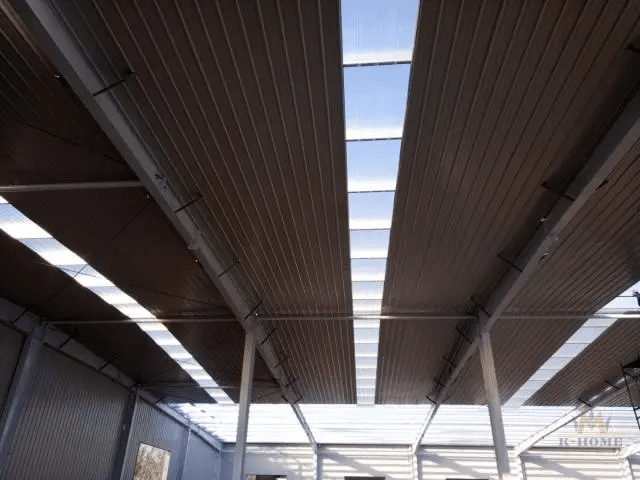

Steel Greenhouse

Many cash crops need adequate sunlight, temperature, and humidity to thrive. To ensure a good growing environment for plants, this means that growers need to find a space that is conducive to plant growth. Metal greenhouses offer growers another new way out. The steel structure serves as the frame and the polycarbonate as the roof panels. The combination of these two materials is the best choice for greenhouse sheds. Polycarbonate is used as wall panels, which means more sunlight to the plants, promoting space humidity and photosynthesis of the plants.

WHY CHOOSE KHOME AS YOUR SUPPLIER?

K-HOME is one of the trusted factory manufacturers in China. From structural design to installation, our team can handle various complex projects. You will receive a prefabricated structure solution that best suits your needs.

You can send me a WhatsApp message (+86-18338952063), or send an email to leave your contact information. We will contact you as soon as possible.

Prefabricated Agricultural Steel Building Structure

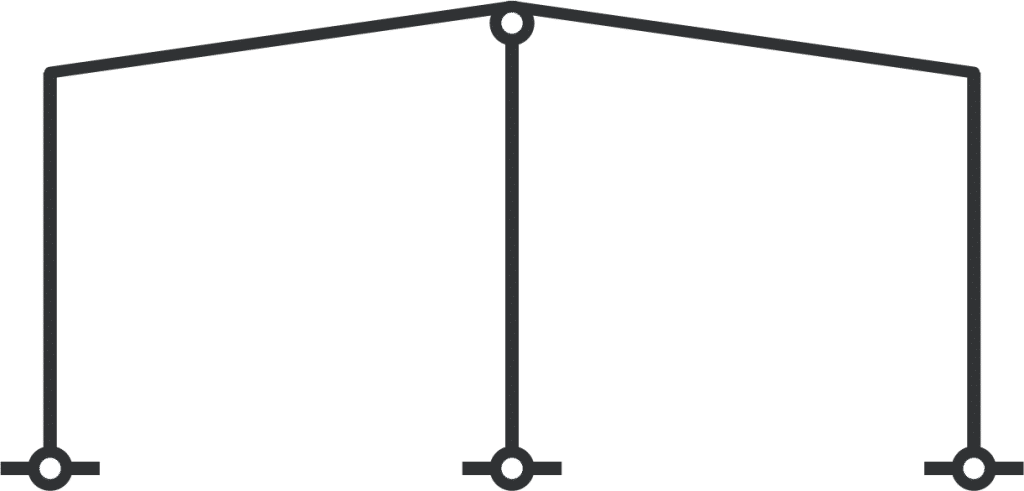

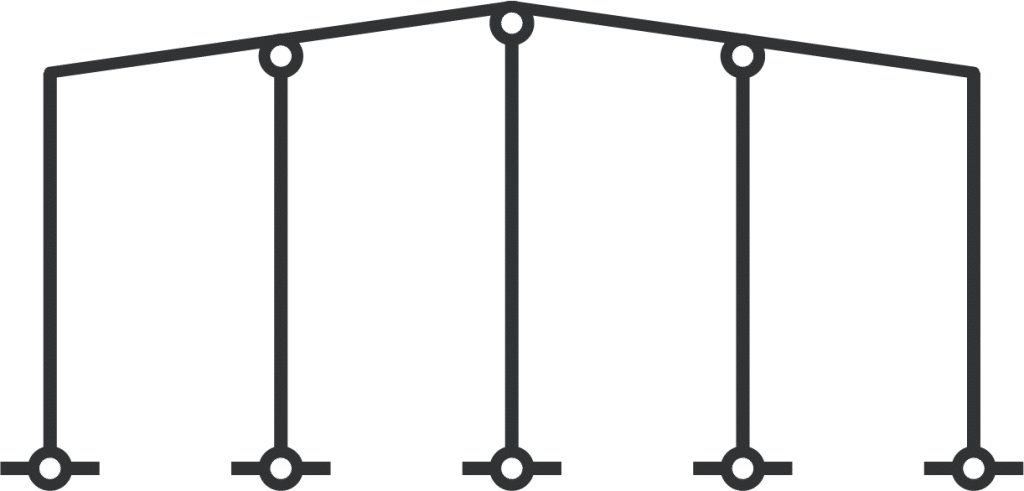

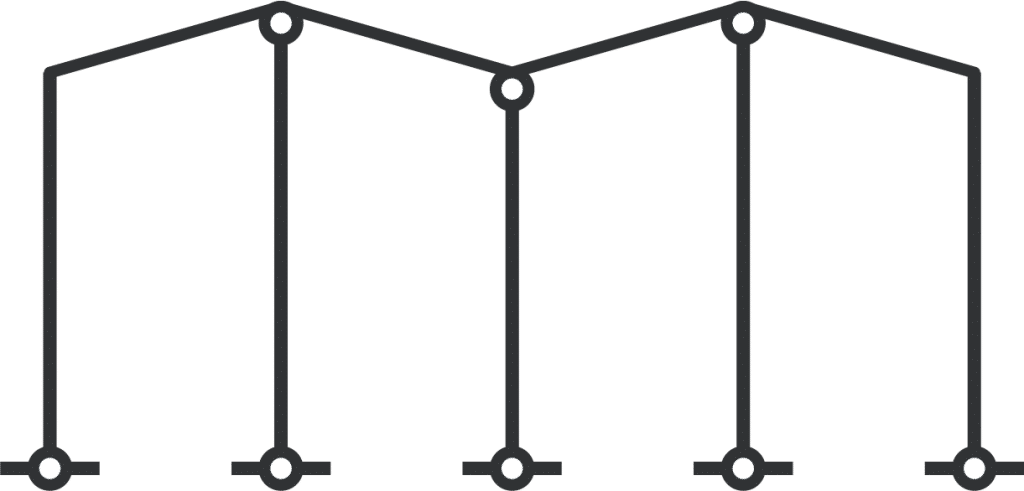

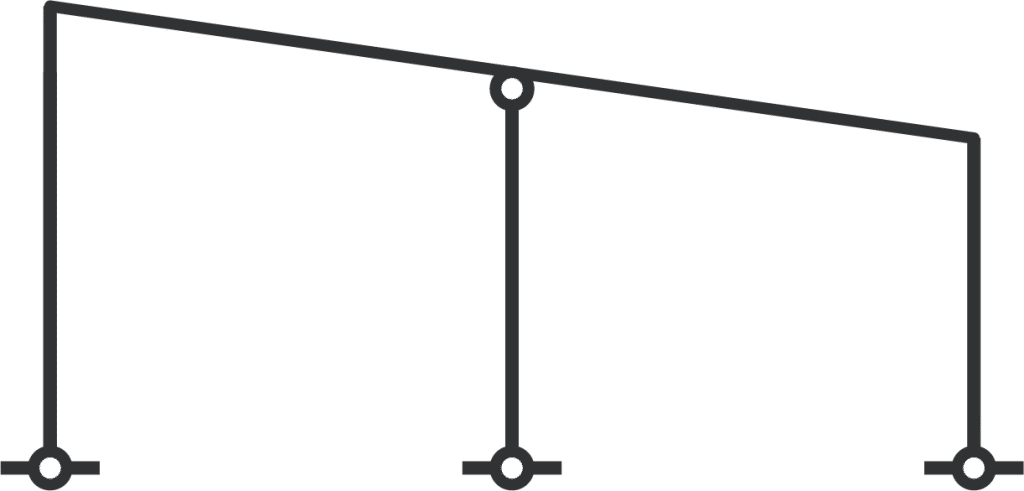

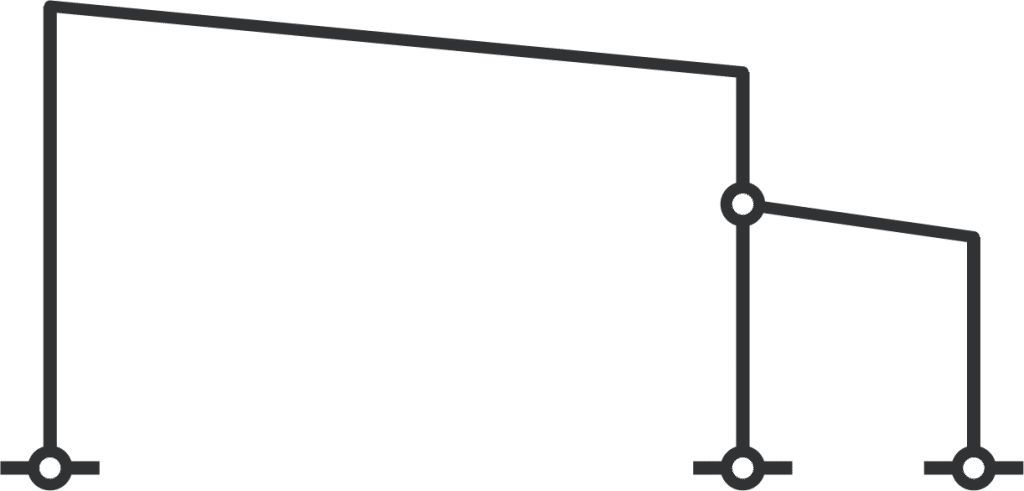

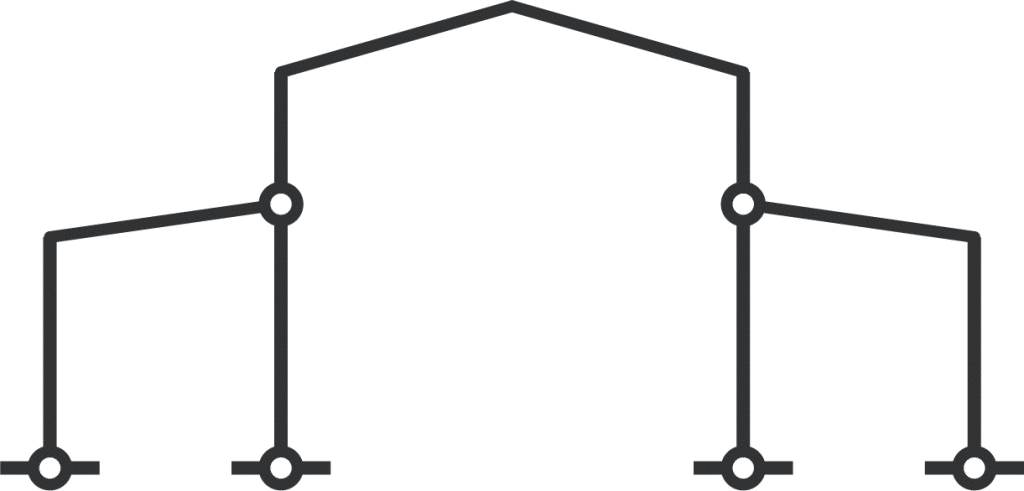

Prefabricated Portal Frame Steel Structure Types

Single-span Double-sloped Roofs Double-span Double-sloped Roofs Multi-span Double-sloped Roofs Multi-span Multi Double-sloped Roofs Single-span Overhanging Eaves Double-span Single-sloped Roofs High-low Span Single-sloped Roofs High-low Span Double-sloped Roofs

Roof System

- Roof panel: You can use steel plate or sandwich panel, it depends on your budget and the usage of your building.

- Skylight: The material is Transparent Fiberglass Plastic Roofing Tile, which can let sunlight into your building. It’s very common in prefabricated steel buildings.

- Ventilators: You can use a turbo ventilator or ridge ventilator.

- Roof beam: It includes a crane beam, and a floor secondary beam, both ends are connected to the main beam. The other beams connected are secondary beams, and the force transmission path is always secondary.

- The steel frame: The steel frame type is normally H-section Steel, and the material is Q235B and Q355B.

- Roof purlins: They sit between the roofing sheets and the roof beam, acting as a support for the sheet to ensure it is firmly attached and safely in place and transmits the roof load to the steel frame.

- Drainage system: Water gutter and downpipes.

- Small parts: Roof bracing, tie rod, and flashing.

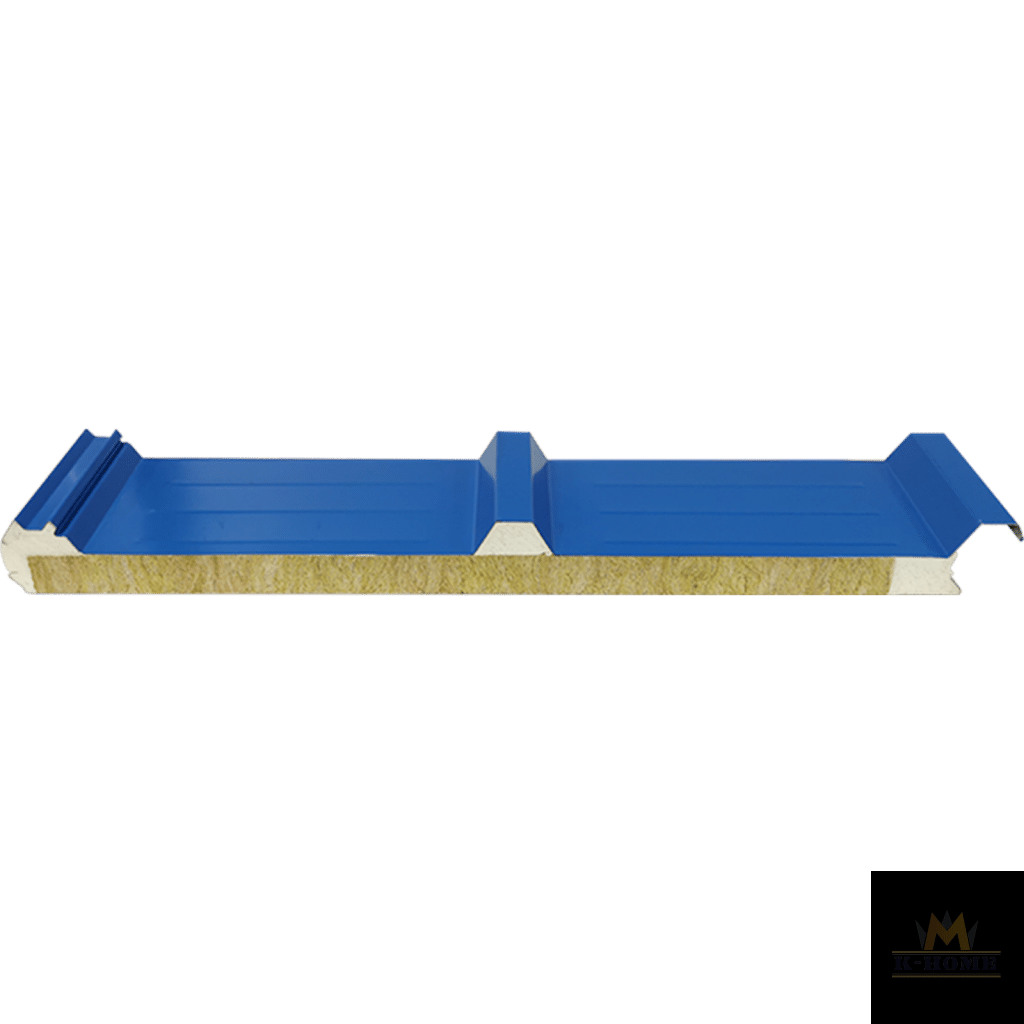

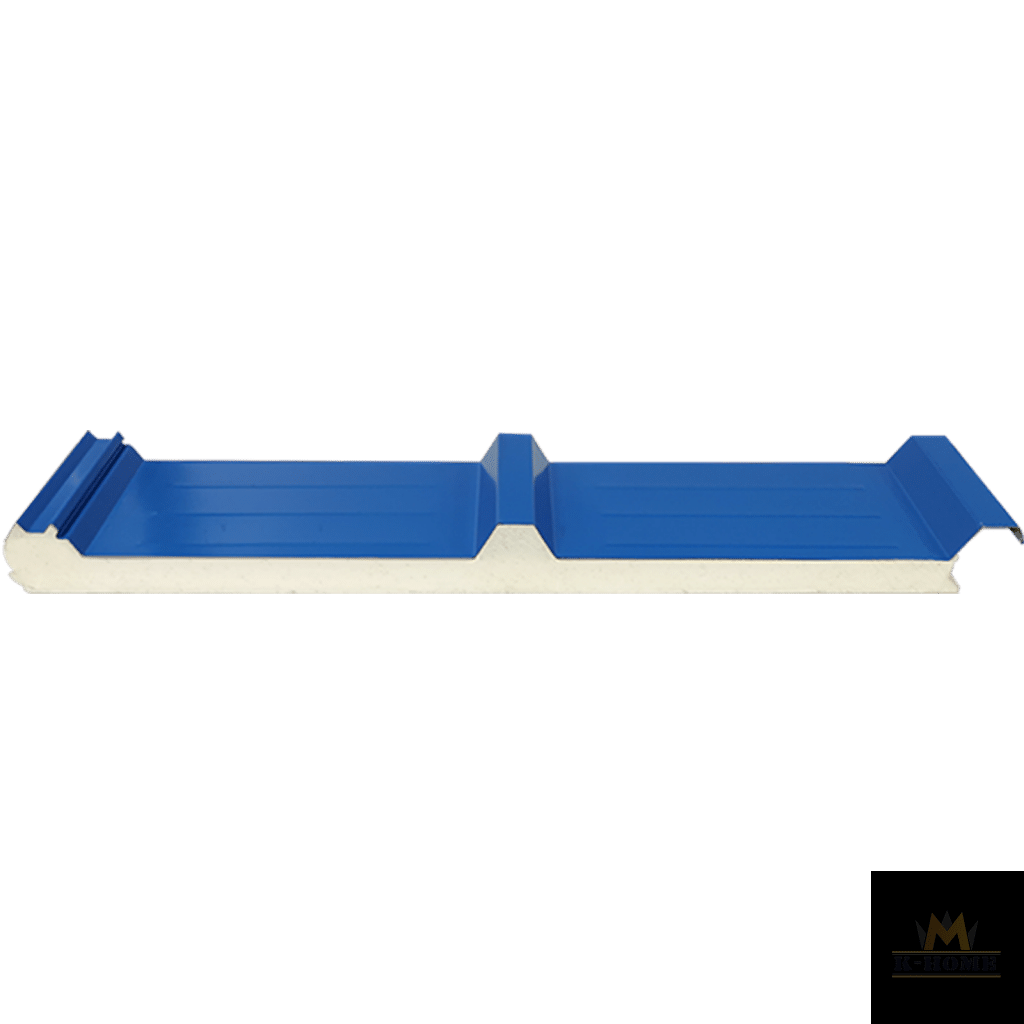

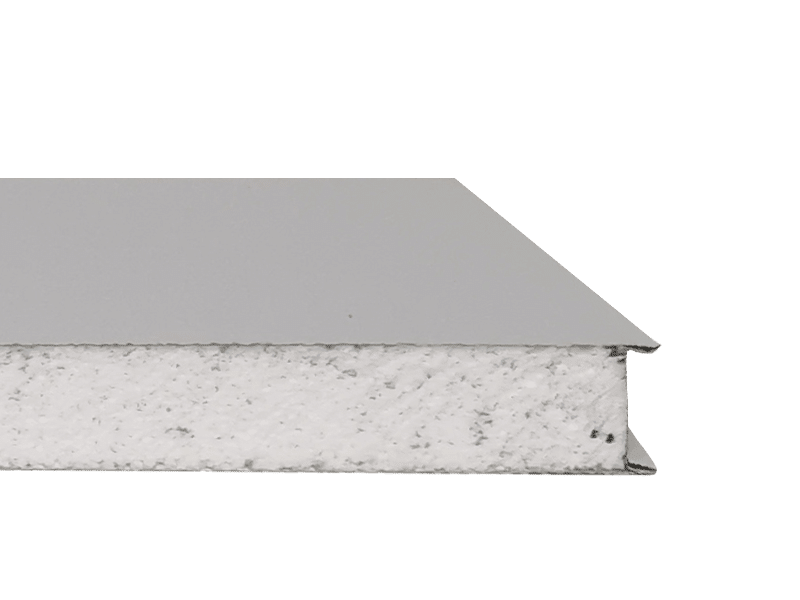

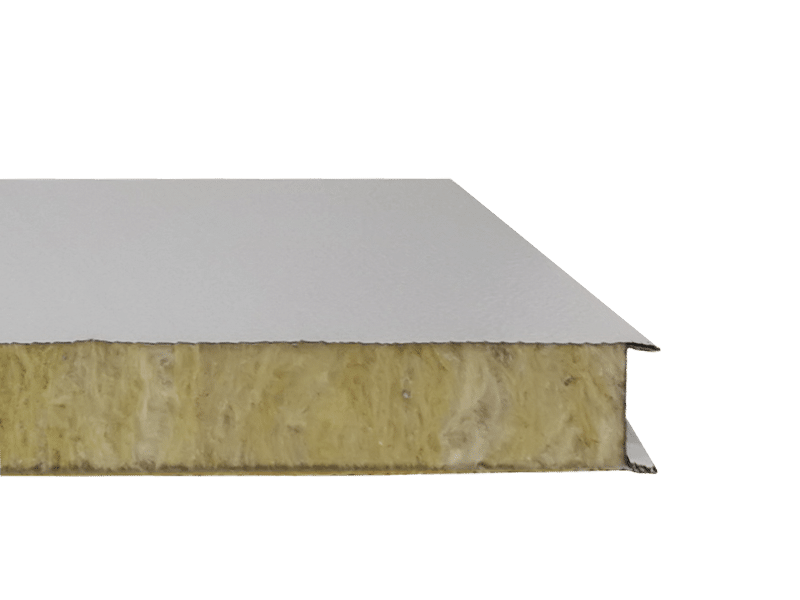

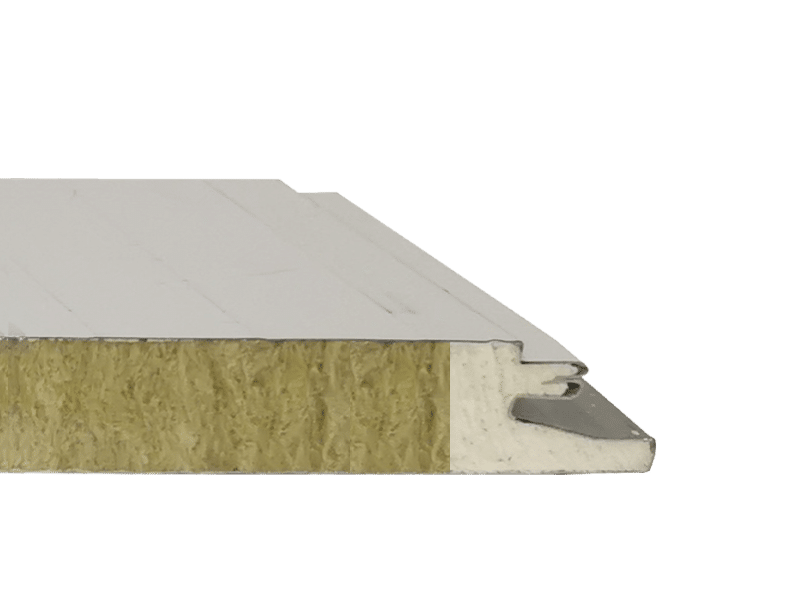

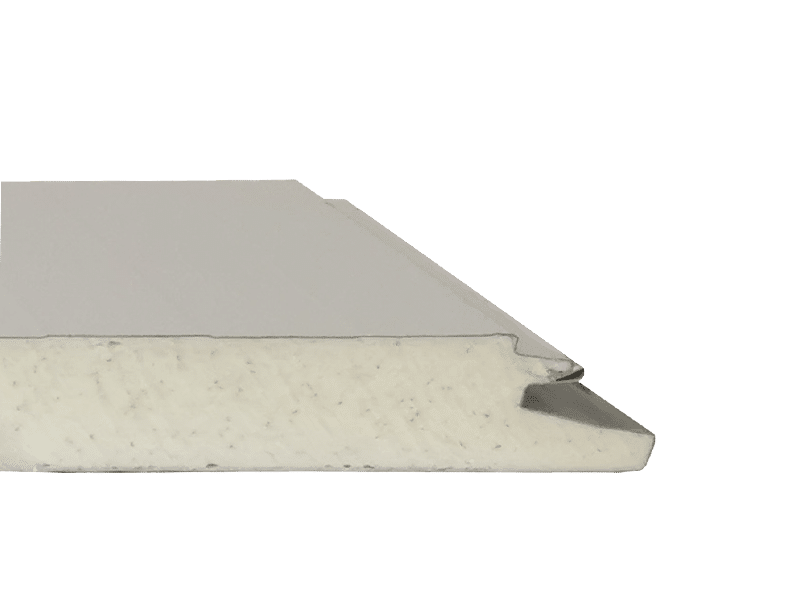

EPS Sandwich Roof Panel Rock Wool Sandwich Roof Panel PU Sealed Rock Wool Sandwich Roof Panel PU Sandwich Roof Panel

Wall System

- Wall panel: You can use steel plate or sandwich panel, it depends on your budget and the usage of your building.

- Wall purlins: For exporting, we will design Z-purlins to save shipping container space.

- Small parts: Column bracing, tie rod, flashing.

EPS Sandwich Panel Rock Wool Sandwich Panel PU Sealed Rock Wool Sandwich Panel PU Sandwich Panel

Judge the stress point of the foundation

In many construction projects, metal agricultural buildings, due to the different scales and uses of the buildings, the size, and nature of the loads on the structure are also different.

In addition, due to the geological structure of the location of the building, the building has a certain degree of uneven settlement. Therefore, in order to achieve the stability of the structure under different conditions, the basic form of the structure is selected differently.

When selecting the foundation of a steel structure building, the influence of these factors should be fully considered, and the geological conditions, soil quality, distribution, groundwater conditions, etc. should be systematically analyzed, and the work should be fully combined with the local reality.

Generally speaking, when the local quality conditions are good, the independent foundation form can be adopted. When the geological conditions are not ideal or the building requirements are high, pile foundations are usually used.

A pile foundation is an earlier and more mature form of foundation. It has the advantages of strong bearing capacity, a small settlement, and a uniform settlement. It can adapt to various engineering geological conditions, especially in building structures on weak foundations. Wide range of applications.

Adjust the form of the foundation.

How to carry out foundation construction when building a steel structure building?

In order to ensure the smooth progress of the construction of the steel structure project, the absolute stability of the foundation must be ensured.

A complete foundation is required to ensure the smooth progress of the steel structure project. It is also a prerequisite for safe use in the later period.

We can provide the one-stop solution for you, from design, manufacture, transportation to installation. Our technical team has more than 10 years of work experience in this steel structure design industry. They will make professional structural calculations on every project to make sure the safety of the structure. A good design is also helpful for saving costs and installation.

Our technologically adaptable professionals utilize the latest designing software and bring forth client-specific structures featuring assurance of aesthetics and compliance to the architectural standards. Before production, we will also make a detailed structural drawing and production drawing (including the size and quantity of each component, as well as the connection method), to ensure that after you receive the goods, there will be no missing components, and you can install each part correctly.

We did over 100+ projects, Please contact us to see more awesome projects.

Our Process

1. Design

K-Home is a comprehensive company that can provide one professional design. From Architectural drawings, steel structure layout, the installation guide layout, etc.

Every designer in our team has at least 10 years experience. You don’t have to worry about the unprofessional design affecting the safety of the building.

A professional design can help you save costs because we clearly know how to adjust and give you the most cost-effective solution, few companies will do this.

2. Manufacturing

Our factory has 2 production workshops with large production capacity and short delivery time. Generally, the lead time is around 15 days. All production is an assembly line, and each link is responsible and controlled by professional personnel. The important things are rust removal, welding, and painting.

Rust Remove: The steel frame uses shot blasting to remove the rust, reaching the Sa2.0 standard, Improve the roughness of the workpiece and the adhesion of the paint.

Welding: welding rod we choose is a J427welding rod or J507welding rod, they can make welding seam without defects.

Painting: The standard color of the paint is white and gray(customizable). There are 3 layers in total, the first layer, the middle layer, and the face layer, the total paint thickness is around 125μm~150μm based on the local environment.

3. Mark and Transportation

K-Home attaches great importance to mark, transportation, and packaging. Although there are many parts, in order to make you clear and reduce the site work, we mark each part with labels and take photos.

In addition, K-Home has rich experience in packing. the packing location of the parts will be planned in advance and the maximum usable space, as far as possible to reduce the number of packings for you and reduce the cost of shipping.

4. Detailed Installation Service

Before you received the cargo, a full set of installation files will be sent to you. You can download our sample installation file below for your reference. There are detailed house parts sizes, and marks.

Also, If this is the first time you to install the steel building, our engineer will customize a 3d installation guide for you. You don’t need to worry about the installation.

More Metal Building Kits

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.