Large-span Steel Building Kit Design (100×150)

Steel buildings can be designed and laid out flexibly to suit your needs. It can complete large-span and special-shaped houses. Generally speaking, steel structures can be made in many different sizes and shapes, but strictly speaking, according to the experience of engineers and designers, the design relatively speaking, is relatively standard, and the price without special styling is the most reasonable. Today, let’s take a look at the 100*150ft workshop, in which the steel structure is a very economical building.

Framing Detail, Application and Service

| Brand | General Steel | Application | Factory, Warehouse, Workshop, Office, Gymnasiums, etc. |

| Available Products | I-Beam, H-Beam, etc. | Project Coordinator | Included in |

| Colors Choice | White/Grey/Black/others | Civil Work | Excluded |

Base Building Includes and Popular Additions

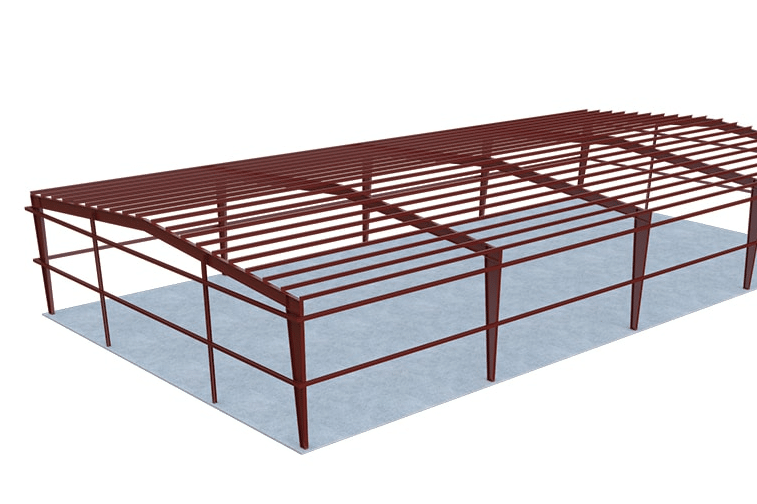

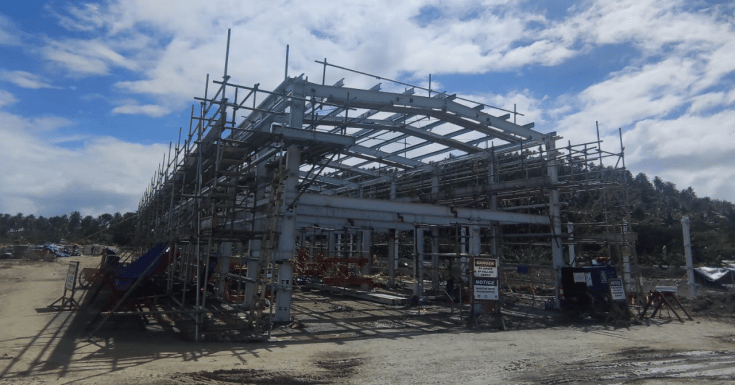

As you see from the photo, even if the building size is the same, the building package can be easily transformed into the specific design as you required, based on actual use. It can be used for large recreation halls, production factories, warehouses, etc.

The most basic building package includes the truss, steel column, purlin, secondary beam, tie bar and enclose sheet, etc.

The enclosure mostly uses 2 kinds of material, steel single sheet, and sandwich panel. The sandwich panel is thicker, and with insulation in between. The insulation in it, which has a thermal function, makes your house not that cold in winter and not that hot in summer, compared with a single steel sheet. And, the price of the sandwich panel is more expensive than the steel sheet.

Here show you the detailed structure of 100×150 steel buildings.

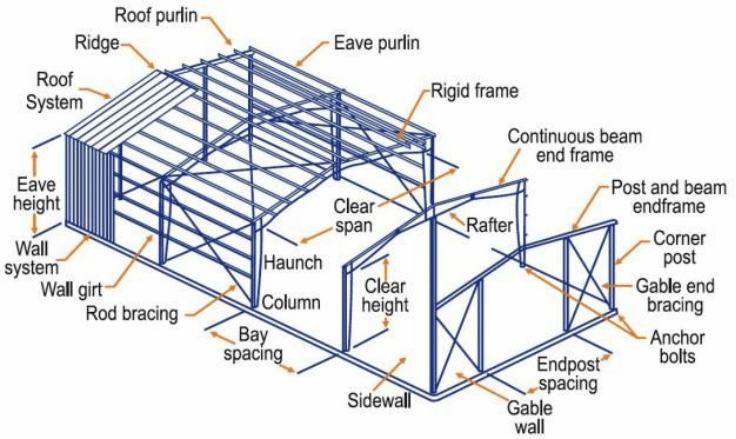

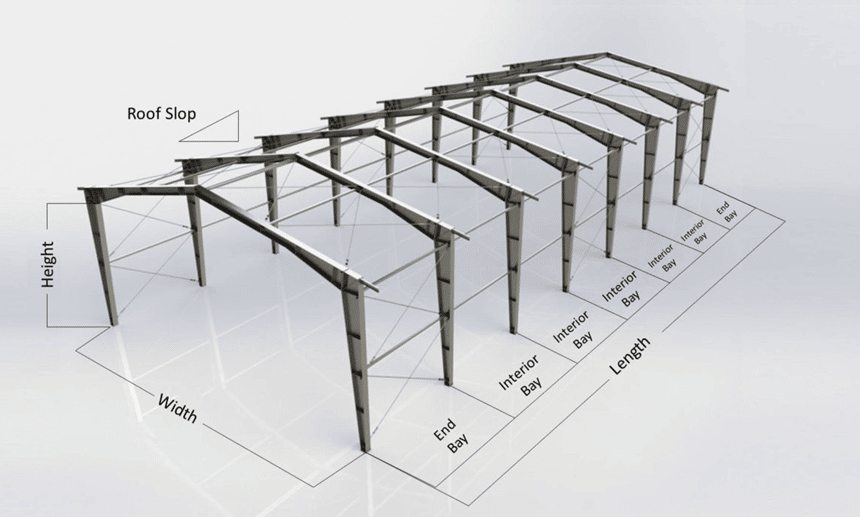

Primary frame of the 100×150 steel buildings Design

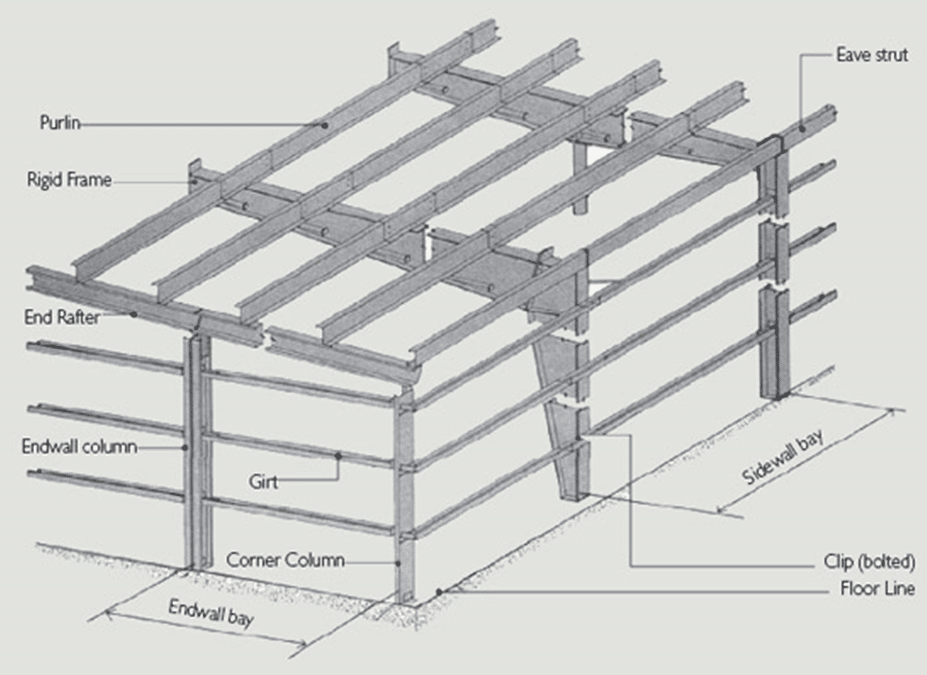

With solid H-Section/I-Section construction, the truss, and end wall frame that mainly items that could make the building stand up.

Secondary Framing

There are many secondary beams. To talk about how to place the secondary beams, to put it bluntly, they are placed between the main beams, and the trabeculae connecting the main beams are called secondary beams. Mainly are 2 parts, purlin, and girts.

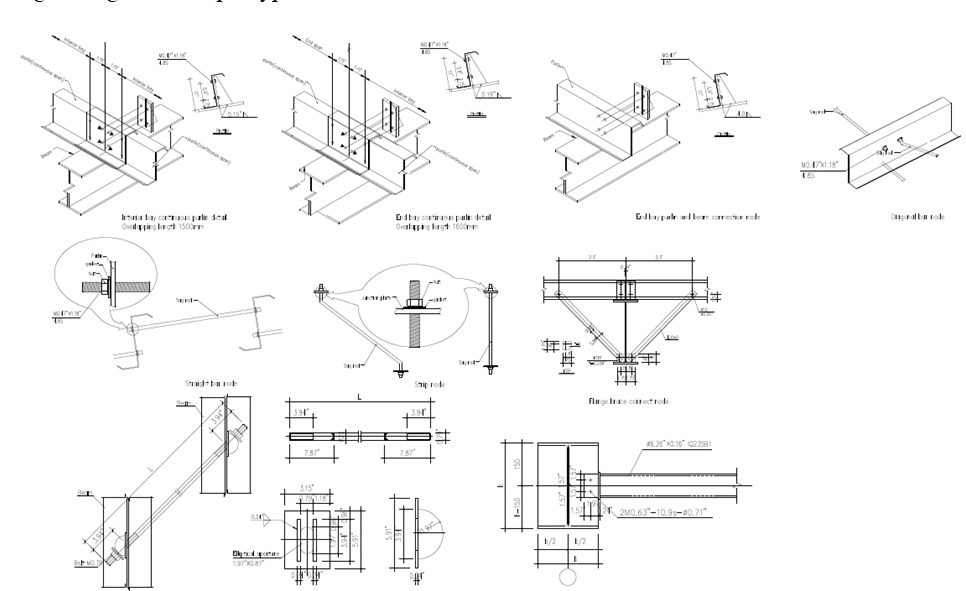

Fasteners & Bracing

Fasteners: A steel structure bolt is a kind of high-strength bolt and a kind of standard part, which is mainly used to connect the connection points of steel structure steel plate.

Steel structure bolts are divided into torsional shear type high-strength bolts and large hexagonal high-strength bolts.

The construction of steel structure bolts must be initially tightened and then finally tightened. The impact type electric wrench or torque adjustable electric wrench is required for the initial tightening of the steel structure bolts; while the final tightening of the steel structure bolts has strict requirements, the final tightening of the torsional shear steel structure bolts must be Use a torsion-scissor electric wrench, and a torque-type electric wrench must be used for the final tightening of the torque-type steel structure bolts.

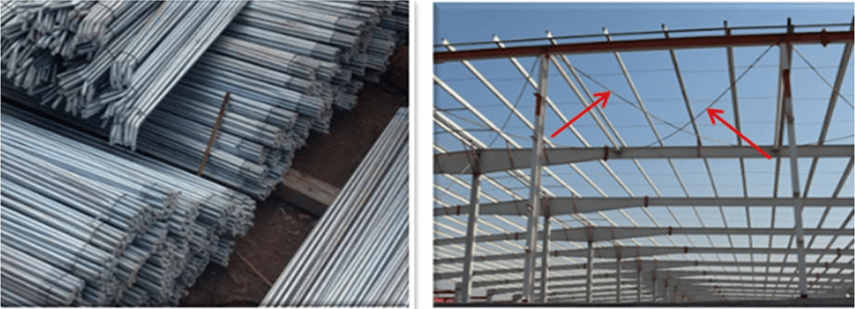

Bracing: The inter-column support of a steel structure is a connecting rod set between two adjacent columns to ensure the overall stability of the building structure, improve lateral stiffness and transmit longitudinal horizontal force.

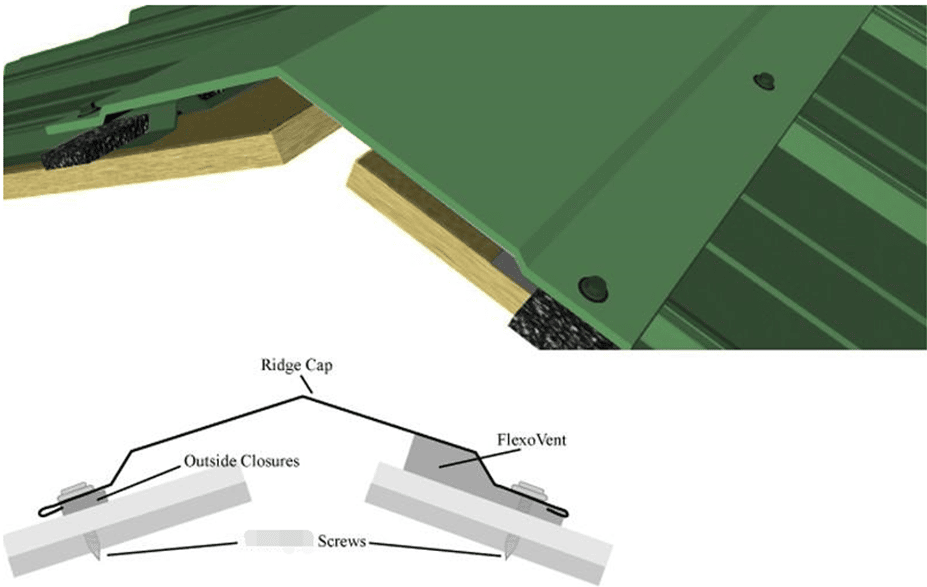

Sheeting and Ridge Cap

The ridge cap has an inner ridge cap and an outside ridge cap. They are put at the highest point of the roof, where the two roof panels overlap. The function is to prevent roof leaks

The ridge cap normally uses a colored steel plate, then bending it into a suitable size, usually choose the same material as the roof sheet, that will be more beautiful and suitable.

Window, Door, Ventilator

There are many options for doors and windows and ventilation systems of steel structures. The doors can have double doors, sliding doors, rolling doors, etc. to be customized according to your needs.

How to custom your needs

Base building + Components = Your Building

Should you need a prefabricated building, and an ideal PEB buildings manufacturer, you can freely check-up with K-Home, we are catering to the steel structure building for years, and have completed many different kinds of steel buildings. We will offer our best and most professional service for you until you find out what do you do with the PEB building.

Our professional engineer and the designer team could make sure all the built according to your specific requirement and detailed needs. Our QC team is doing their job very carefully, making sure all the components are qualified before it could leave our factory.

Our Services

- Advanced manufacturing capabilities.

Humanized production site management; high-efficiency production equipment; advanced production technology; high-quality production team; IS09001 quality certification system; professional on-site processing services - Years of experience, factory direct sales.

Manufacturers directly connect with customers, with no middlemen, transparent prices, and discounts for large quantities. - Efficient customer service capabilities.

Convenient integrated service model; fast delivery time; safe cargo transportation guarantee; high-quality product packaging services.

Other Steel Building Kits Design

Articles Selected for You

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.