Steel Workshop Kit Design(82×190)

The PEB steel workshop is hailed as a “green industrial building”. It has the comprehensive advantages of a lightweight, easy installation, short construction period, good seismic performance, fast investment recovery, and less environmental pollution. Compared with the traditional reinforced concrete industrial workshop, the steel structure workshop is more in line with the development trend of the current era. It is more in line with the needs of sustainable development of the world economy. In the construction market, the long-standing dominance of concrete and masonry structures has been broken by steel structures buildings. The value of steel structure workshops has been recognized by people all over the world, and the steel structure buildings have been rapidly used in recent decades. In particular, the buildings required for industrial production are being replaced by steel structure workshops.

82×190 Steel Workshop Design

Description of 82×190 Steel Workshop

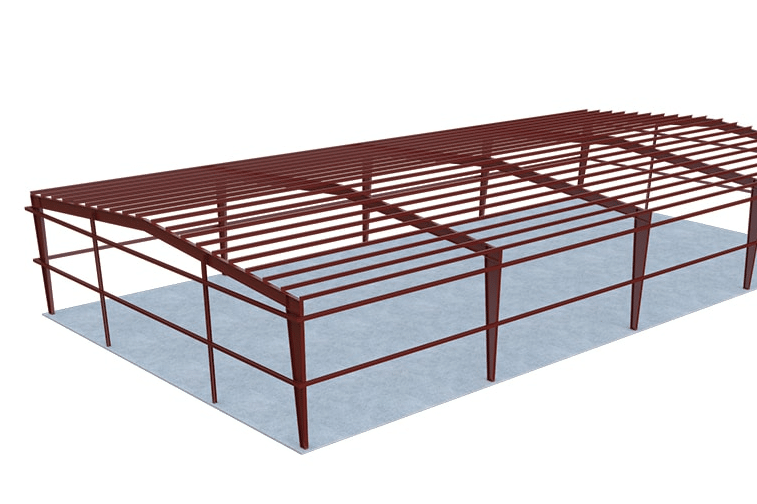

The main material of the steel workshop is H beams or square tubes, which are composed of single-span or multi-span steel structure materials. The maximum span can reach 40 meters, and a crane can be installed. The steel beams consist of hot-pressed or electric-welded H-beams, with pre-embedded bolts connecting the beams to the structure. The connection between beam and purlin, beam and beam is completed by high-strength bolts. The surrounding parts are composed of C-shaped steel, and the material of the wall panel and the top panel is color steel veneer or composite panels, which are connected together by self-tapping bolts. The insulation layer can be made of EPS, PU, rock wool, and so on. Doors and Windows: Doors and windows can be designed according to customers’ requirements. Doors are generally divided into conventional sliding doors and rolling shutter doors, and windows are generally sliding windows. The materials of doors and windows are divided into color steel, PVC, and aluminum alloy.

Components of 82×190 Steel Workshop

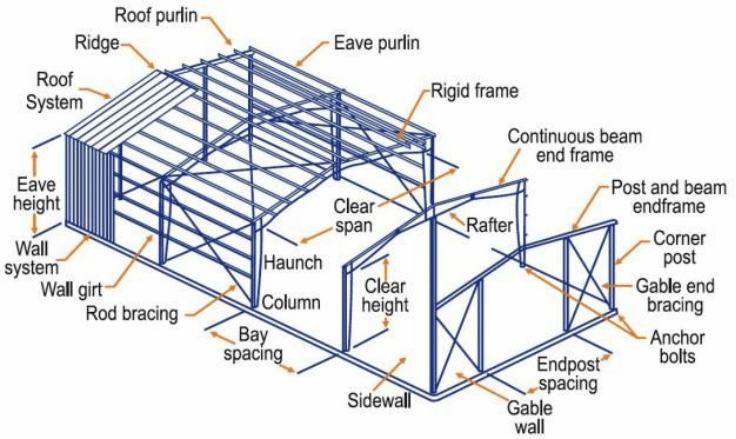

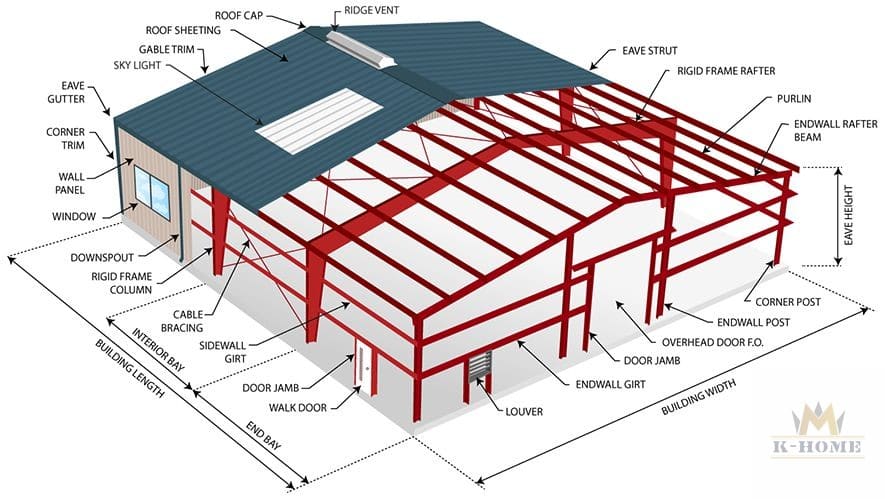

Steel structure workshop mainly refers to the main load-bearing components are composed of steel. It includes steel columns, steel beams, steel structure foundations, steel roof trusses, and steel roofs, note that the walls of steel structure buildings can also be maintained with brick walls. Specifically, it can be divided into light or heavy steel structure workshops.

- Steel Column

The steel structure steel column is generally H-beam steel, or C-shaped steel (usually two C-shaped steels are connected by angle steel) - Steel Beam

It is welded or riveted from steel plate or section steel. Because riveting costs labor and materials, welding is often the main method. Commonly used welded composite beams are I-beam and box-shaped sections composed of upper and lower flange plates and webs. It’s suitable for situations with high lateral load and torsional resistance requirements or limited beam height. - Crane Beam

The beam specially used to load the crane inside the workshop is called the crane beam; this is generally installed in the upper part of the steel structure workshop. The crane beam is the roadbed that supports the operation of the truss truck, and is mostly used in the workshop. There is a crane track on the crane beam, and the trolley travels back and forth on the crane beam through the track. The crane beam is similar to the steel beam, the difference is that there are dense stiffening plates welded on the web of the crane beam to provide support for the lifting of heavy objects by the truss truck. - Wind Column

The wind-resistant column is a structural component at the gable wall of a single-storey industrial workshop. The function of the wind-resistant column is to transmit the wind load of the gable wall, which is transmitted to the roof system through the connection of the hinge node and the steel beam to the entire bent-frame load-bearing structure. The down is passed to the base through a connection to the base.

Advantages of Steel Workshop

- Shock Resistance

Steel workshop are light in weight, high in strength and large in span. After the structural board and gypsum board are sealed, the light steel member forms a very strong “board rib structure system”, which has a stronger ability to resist earthquakes and horizontal loads, and is suitable for seismic intensity above 8 degrees area. - Wind Resistance

The steel workshop is light in weight, high in strength, good in overall rigidity and strong in deformation ability. The weight of the building is only one-fifth of that of the brick-concrete structure, and it can resist a hurricane of 70 meters per second, so that life and property can be effectively protected. - Durability

The steel workshop has high fire resistance and strong corrosion resistance. The steel structure workshop structure is all composed of cold-formed thin-walled steel component system, and the steel frame is made of super anti-corrosion high-strength cold-rolled galvanized sheet, which can effectively avoid the corrosion of the steel plate during construction and use. Influence, increase the service life of light steel components. The structural life can be up to 100 years. - Health

Dry construction is used to reduce environmental pollution caused by waste. 100% of the steel structure materials of the house can be recycled, and most of the other supporting materials can also be recycled, which is in line with the current environmental awareness; . - Comfort

The light steel wall adopts a high-efficiency energy-saving system, which has a breathing function and can adjust the dry humidity of the indoor air; the roof has a ventilation function, which can form a flowing air space above the house to ensure the ventilation and heat dissipation needs of the roof. - Quick installation

The construction period of the steel structure building is short, and the investment cost is correspondingly reduced. All the construction is dry, and it is not affected by the environmental season. For a building of about 300 square meters, only 5 workers and 20 working days can complete the whole process from foundation to decoration. - Environmental Protection

The steel structure building is easy to move, and the recycling is pollution-free. Materials can be 100% recyclable, truly green and pollution-free. - Energy saving

Our Services

- Advanced manufacturing capabilities

Humanized production site management; high-efficiency production equipment; advanced production technology; high-quality production team; IS09001 quality certification system; professional on-site processing services - Years of experience, factory direct sales

Manufacturers directly connect with customers, no middlemen, transparent prices, and discounts for large quantities. - Efficient customer service capabilities

Convenient integrated service model; fast delivery time; safe cargo transportation guarantee; high-quality product packaging services.

Other Steel Building Kits Design

Articles Selected for You

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.