Prefabricated Industrial Buildings

Modern Industrial Buildings / Steel Framed Industrial Buildings / Industrial Steel Buildings / Industrial Metal Buildings / Industrial Modular Buildings

What are the Prefabricated Industrial Buildings?

Prefabricated industrial buildings have revolutionized the construction industry, providing a streamlined and efficient method for building structures for a variety of industrial purposes. Often referred to as prefabricated buildings or precast structures, these buildings are manufactured in a controlled factory environment and then transported to the construction site for assembly. This method not only speeds up construction time, but also ensures consistency in quality and cost-effectiveness.

Prefabricated industrial buildings offer an attractive solution for businesses seeking efficient, economical, and high-quality construction. Their versatility, rapid construction, and durability make them suitable for a wide range of industrial applications.

WHY CHOOSE KHOME AS YOUR SUPPLIER?

K-HOME is one of the trusted industrial steel crane building suppliers in China. From structural design to installation, our team can handle various complex projects. You will receive a prefabricated structure solution that best suits your needs.

You can send me a WhatsApp message (+86-18338952063), or send an email to leave your contact information. We will contact you as soon as possible.

Advantages of Prefabricated Industrial Buildings

Fast Construction: One of the most notable advantages of prefabricated industrial buildings is their fast construction process. While traditional construction methods can take months or even years, prefabricated buildings can be built in a fraction of the time. This speed is critical for businesses that need to quickly establish operations or operate within a tight timeframe.

Quality Control: Manufacturing prefabricated components in a controlled factory environment ensures consistent quality. Each component is produced to precise specifications, reducing the risk of errors or defects that may occur during on-site construction. Steel components can be precisely cut and assembled in a controlled factory environment, ensuring tight tolerances and minimal on-site adjustments. This not only speeds up the construction process, but also improves safety by reducing the need for extensive on-site welding or cutting.

Cost-Effectiveness: Prefabricated industrial buildings are cost-effective due to their efficient manufacturing process and reduced on-site labor requirements. Factory production allows for precise use of materials, minimizing waste and reducing material costs. In addition, a shorter construction period means lower overhead costs.

Versatility and Customization: Prefabricated industrial buildings are versatile and can be customized to specific requirements. From size and layout to finishing materials and aesthetic features, these buildings can be tailored to a wide range of industrial applications, such as high ceilings for equipment installation and large windows for natural lighting.

Durability and longevity: Prefabricated industrial buildings are designed to withstand harsh weather conditions and heavy industrial use. Steel industrial buildings are an example of using prefabrication techniques to create strong and durable structures. As a material, steel has excellent strength, durability, and ability to withstand harsh weather conditions, making it an ideal choice for industrial applications.

Prefabricated Industrial Building Solutions

Prefabricated industrial buildings have applications in various fields due to their versatility and adaptability. Here are some common use cases:

Manufacturing facilities: Prefabricated steel industrial buildings are ideal for manufacturing plants, providing ample space for production lines, warehouses, and offices.

Warehouses and distribution centers: The need for efficient storage and distribution has led to the widespread use of prefabricated steel buildings in this industry. Their scalability and rapid construction make them suitable for rapidly expanding businesses.

Agricultural buildings: Prefabricated steel structures are used in barns, storage facilities, and equipment sheds in agriculture. Their durability and cost-effectiveness make them a popular choice.

Industrial Building With Crane

Prefabricated industrial building with crane is an efficient, flexible, and powerful form of industrial building. It combines the advantages of prefabricated steel structure with the function of a crane, providing strong support for industrial production. This form of building not only meets the requirements of industrial production for carrying capacity and flexibility. K-HOME prefabricated industrial steel structure will configure the corresponding specifications and quantity of cranes according to your needs. These cranes are usually installed in the middle or at both ends of the span of the plant so as to cover the entire working area and meet the handling needs of heavy equipment and materials.

Maximum load:

The maximum weight that the crane needs to lift will determine how the building structure is designed to accommodate these loads. We need to take into account not only the load of each crane in the calculation of the industrial steel crane buildings but also its deadweight to ensure the stability of the entire building.

Lifting height:

The lifting height is very easy to confuse with the hook lifting height. K-HOME only needs you to provide the lifting height of the goods for relevant calculations, which has lower requirements for you. You do not need to consider the height of the hook itself. The lifting height determines the height of the runway beam from the ground and the required clear height inside the building, making the design of the steel crane buildings more accurate.

Crane span:

The crane span is different from the span of the steel structure building. This requires the crane supplier and the steel structure building supplier to communicate and calculate the most suitable span. At K-HOME, your work will become very simple. We will directly calculate the relevant data when designing the steel crane buildings to ensure that your crane can operate perfectly.

Crane control system:

Radio-controlled cranes are becoming more and more common, and K-HOME provides you with both wired and wireless control methods for your choice. In addition, the cab-controlled crane system may be applicable in some industrial steel crane buildings, which have higher standards and need to be considered in the building design.

Crane maintenance platform:

A fixed permanent maintenance platform on the bridge will greatly increase the weight of the crane bridge and increase the wheel load. This is also a problem that needs to be considered when designing steel crane buildings. K-HOME provides you with the latest cranes, which, unlike traditional cranes, can greatly reduce your maintenance costs and complete the maintenance of the crane without complicated inspections and crane maintenance platforms.

Types of bridge cranes:

You can provide the maximum size and weight of the materials that will be lifted and moved within the workshop. K-HOME will recommend the most appropriate crane system based on the information you provide. There are several types of bridge cranes commonly used in steel structure workshops, including: 1. Single-beam bridge crane: This type of crane has a single beam or crossbeam that spans across the workshop and is suitable for light to medium lifting industrial steel structure applications. 2. Double-beam bridge crane: This crane has two beams or crossbeams that span across the workshop and can handle heavier loads and longer spans than a single-beam crane.

Prefabricated Industrial Building Design

Prefabricated industrial buildings can be highly customized to meet specific project requirements. Modular design principles allow for easy adjustments and expansions, ensuring that the building meets its functional purpose while also reflecting the unique needs and brand image of the company. Prefabricated industrial steel structure design is a complex and critical process that is directly related to the safety, economy, practicality and aesthetics of the structure.

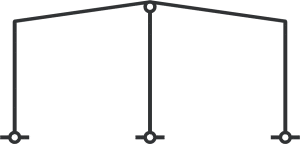

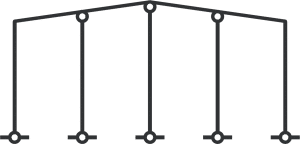

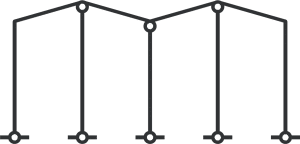

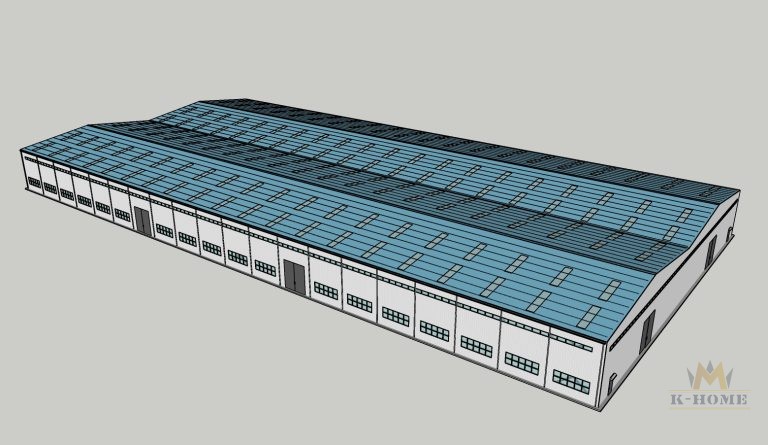

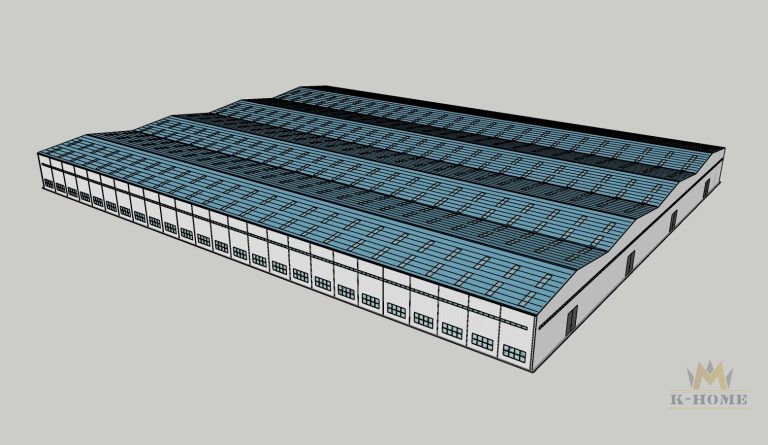

Single-span Double-sloped Roofs Double-span Double-sloped Roofs Multi-span Double-sloped Roofs Multi-span Multi Double-sloped Roofs

Safety is the primary principle of prefabricated industrial building design. Before designing a steel structure, it is first necessary to clarify the main functions and usage requirements of the industrial steel structure building, such as production, storage, office, etc., to ensure that the design can meet the actual use requirements. K-HOME prefabricated industrial building will consider the strength, stability and durability of various load combinations (such as gravity loads, wind loads, seismic loads, etc.) to ensure that the structure can work safely and reliably in different environments and conditions. Load calculation is an important part of steel structure design. According to the use nature and requirements of the building, load calculations are carried out in accordance with relevant specifications and standards, including permanent loads (such as structural deadweight), live loads (such as personnel and equipment weight), wind loads, seismic loads, etc. The accuracy of load calculations directly affects the safety and stability of steel structures.

The principle of practicality requires that the design of prefabricated industrial steel structures can meet the use functions of the building. K-HOME will communicate with you in depth to understand your specific needs and expectations, including space layout, equipment configuration, process flow, etc., to ensure that the design can meet actual needs. Pay attention to the comfort and convenience of users, such as reasonably setting the position of doors and windows, optimizing lighting and ventilation conditions, etc., to create a good working environment for staff.

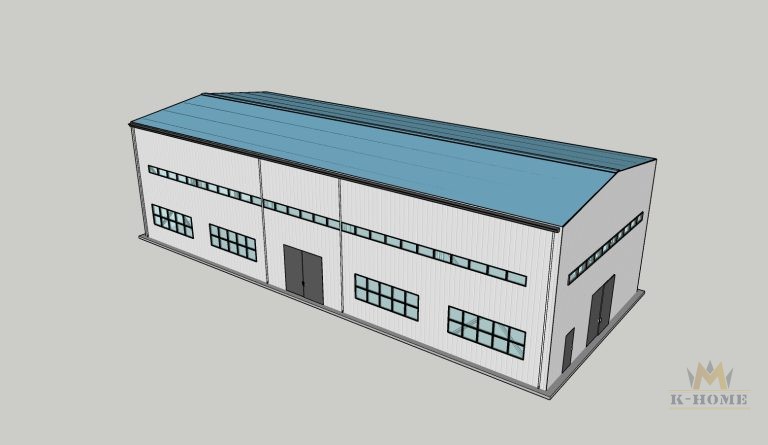

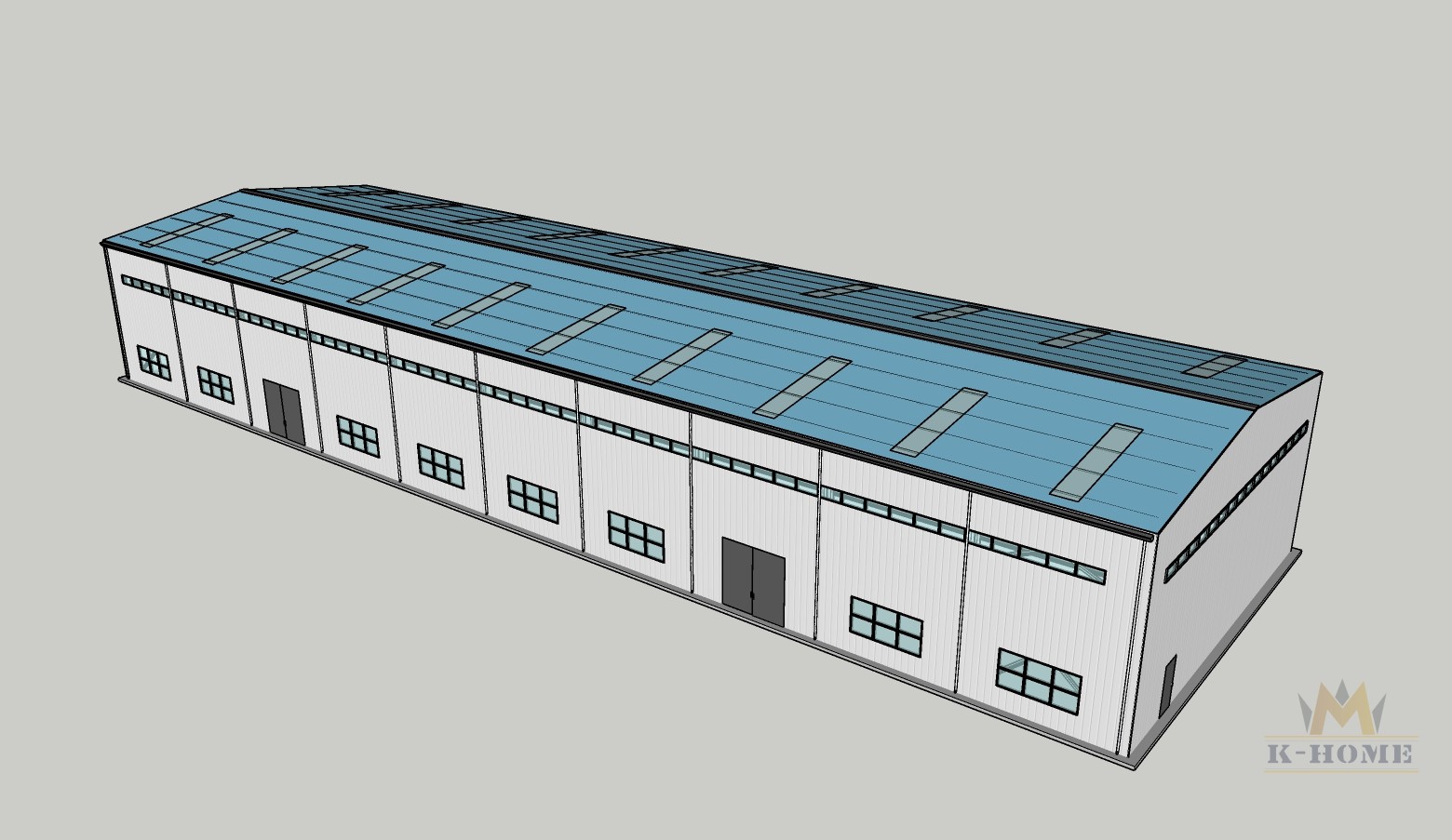

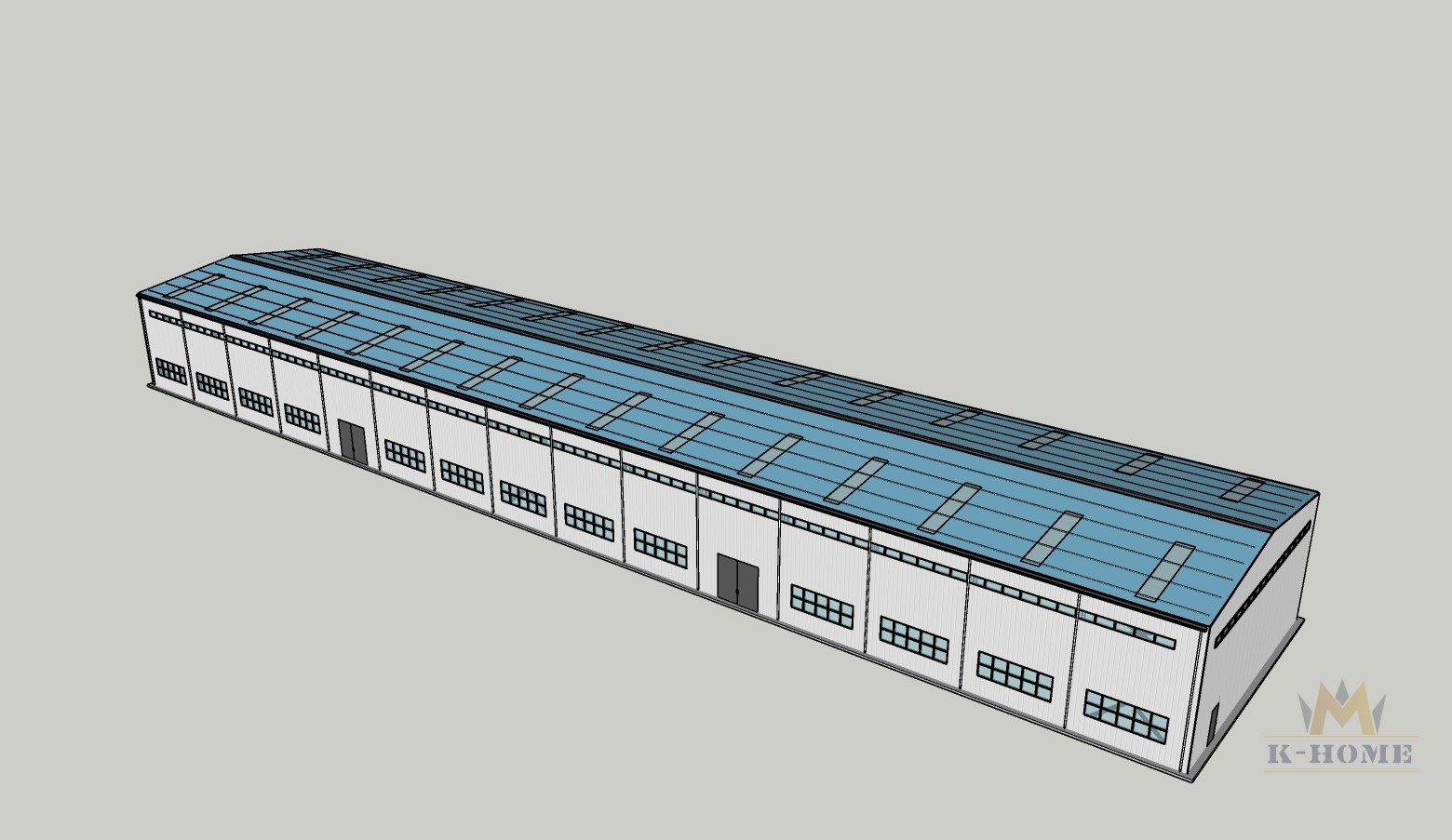

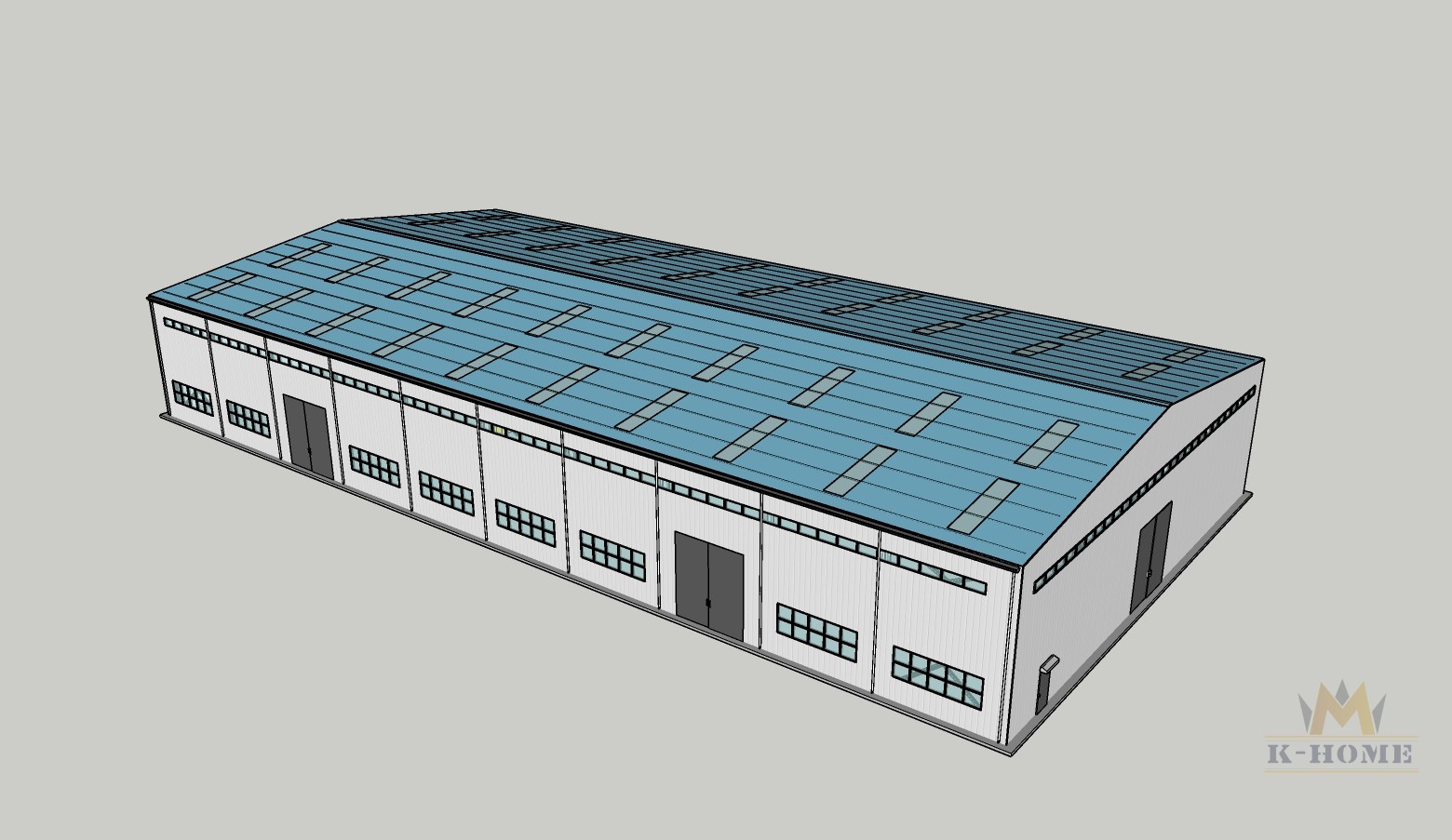

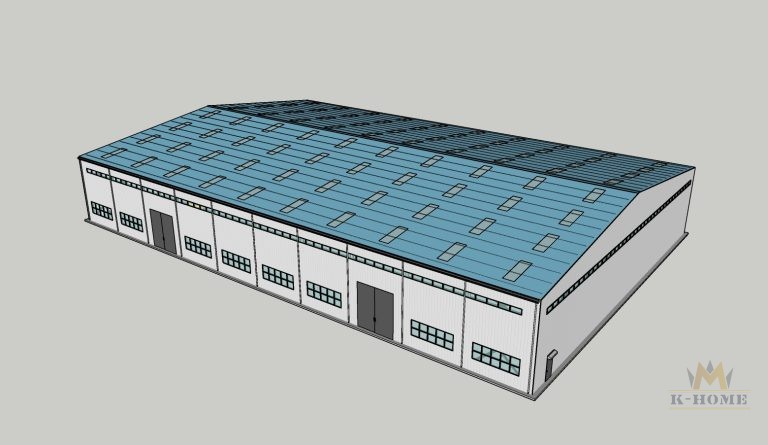

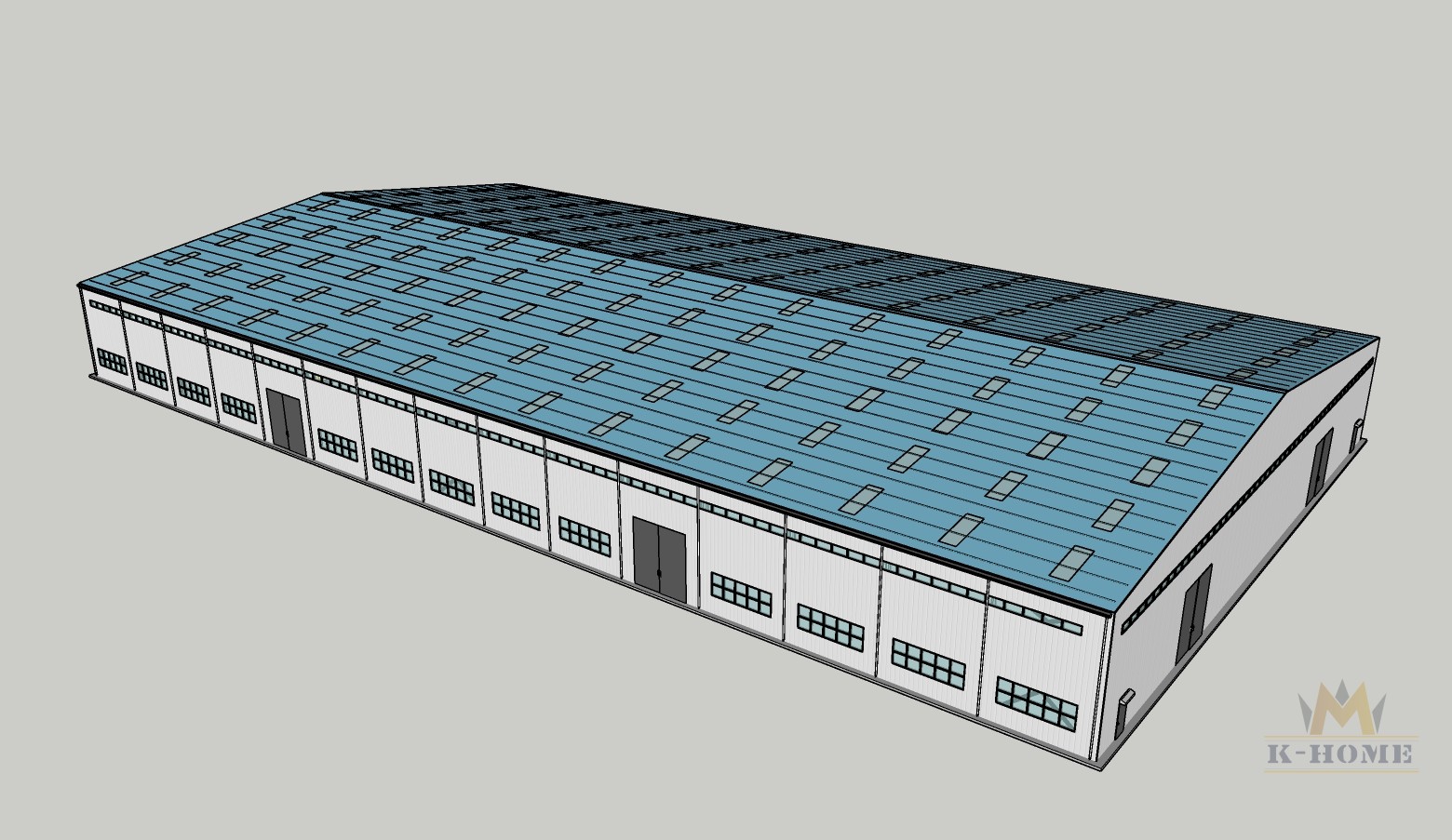

120×150 Steel Building (18000m²)

Economy is one of the important principles of prefabricated industrial building design. The design should reduce costs as much as possible while meeting safety and practicality. K-HOME reasonably designs the cross-sectional shape, size and layout of the structure according to the purpose, working conditions and load characteristics of the structure, reduces unnecessary waste, and tries to simplify the construction and construction process of the structure, reduce construction difficulty and cost, so as to improve the economic benefits of prefabricated industrial steel structures. After verification and optimization design, enter the detailed design stage. Detailed design includes: according to the optimized design results, draw detailed construction drawings, including structural plan, elevation, section, etc. Design the connection method of bolt connection between components to ensure the firmness and reliability of the connection. For components that need to be welded, design reasonable welding process and weld size. K-HOME will conduct economic analysis during the design process, compare the cost-effectiveness of different design schemes, and select the best solution for you.

With the improvement of people’s requirements for architectural aesthetics, aesthetics has become one of the important principles of prefabricated industrial steel structure design. Designers need to meet the premise of structural safety and economy: through reasonable design of the shape, size, appearance details, and color matching of the steel structure to make it coordinated with the surrounding environment, improve the overall aesthetics of the building, and achieve beautiful and practical effects.

Industrial Building Construction Company

K-HOME is a pioneering manufacturer of prefabricated industrial steel structures and a trusted provider of integrated building solutions. At K-HOME, we offer comprehensive prefabricated industrial building solutions to meet the diverse needs of our international clients. Our solutions cover every stage of the construction process, from initial design consultation to final installation and after-sales support.

K-HOME offers prefabricated industrial steel buildings for various applications. We provide design flexibility and customization.

At the core of our solutions is our commitment to design excellence. Our experienced team of architects and engineers works closely with clients to understand their unique needs and formulate custom designs that balance functionality, aesthetics, and sustainability. We employ modular design principles, allowing us to create flexible spaces that easily adapt to changing business needs.

-HOME recognizes that time is money. Our comprehensive prefabricated industrial building solutions streamline the construction process from design to installation, ensuring fast project completion without compromising quality. By leveraging advanced manufacturing techniques and modular construction principles, we deliver structures that are not only strong but also environmentally responsible.

K-HOME stands ready to provide world-class prefabricated industrial building solutions to clients around the world. Our in-house design team works closely with clients to understand their unique needs, providing exclusive prefabricated industrial steel structure solutions tailored to each client’s needs. We provide comprehensive support from initial consultation to final handover, ensuring that every project runs smoothly and meets the highest quality and safety standards. We believe that every industrial building should reflect its purpose, optimizing space utilization, energy efficiency and overall user experience. Our modular design approach further simplifies the construction process, reduces waste and increases flexibility. Our transparent pricing model ensures that customers have a clear understanding of project costs from the outset, allowing for better budget management. In addition, the long-term benefits of prefabricated buildings, such as lower maintenance costs and higher energy efficiency, contribute to significant cost savings over the life of the building.

Prefabricated Industrial Building Costs

The cost of prefabricated industrial steel structures is a complex and variable issue, which is affected by many factors, including project scale, design standards, material selection, construction conditions, regional differences, market labor costs, and project complexity.

- Material costs: As the main material for prefabricated industrial steel structures, the price of steel fluctuates greatly, affected by many factors such as international market raw material prices and domestic supply and demand. The specific cost needs to be calculated based on the steel usage and market price of the project. Auxiliary material costs include the cost of auxiliary materials such as enclosures, doors, windows, connectors, coatings, etc. These costs also need to be evaluated based on the specific needs of the project and market prices.

- Processing and production costs: Prefabricated industrial steel structures need to be processed and produced in factories, including cutting, welding, correction, and other processes. This part of the cost will be affected by factors such as process requirements, equipment investment, and production difficulty. Generally speaking, the processing and production costs account for a certain proportion of the total project cost, and the specific proportion needs to be determined based on the actual situation of the project.

- Transportation costs: Prefabricated components need to be transported from the processing plant to the construction site. The transportation costs will be affected by the transportation distance, transportation method, and component size and weight. The transportation costs may be relatively high for large or long-distance transportation projects.

- Installation costs: Installation costs include on-site hoisting, assembly, and other expenses. This part of the cost depends on factors such as the size of the installation team, the technical level, and the difficulty of the project. Complex installation environments and strict construction period requirements usually increase installation costs.

Since the cost of prefabricated industrial steel structures is affected by many factors, it is difficult to give a specific number. However, based on industry experience and market conditions, we can evaluate your project according to the specific circumstances. When estimating the cost, we fully consider the influence of various factors to ensure the accuracy and rationality of the estimated results.

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.