Prefab Warehouse Buildings: Unlock Their Key Advantages for You

Explore prefab warehouse buildings: cost-effective, durable storage. Learn benefits & how to choose the right one for your business.

Why Prefab Warehouse Buildings Prefer Steel Structures as Their Primary Material?

In the past, traditional prefab warehouse buildings relied heavily on concrete for construction.

However, this approach suffers from two critical drawbacks: lengthy construction cycles (slow progress that fails to meet modern project timelines) and limited span capabilities—issues that restrict factories’ needs for large, flexible spaces.

It is precisely under such market demands that prefab warehouse buildings with steel structures—leveraging their unique advantages—have gradually become the preferred choice for modern warehouse construction. They address the shortcomings of traditional concrete buildings while delivering outstanding performance across multiple metrics.

First of all, in terms of strength and stability, steel itself boasts excellent compressive, tensile, and shear properties. Whether bearing excessive loads or withstanding long-term wear and tear, it maintains a stable, solid state—far superior to concrete in high-load scenarios.

Additionally, the flexible design of steel structures enables customized adjustments to meet specific factory production needs. Even for facilities requiring special functions (e.g., large-span production workshops or multi-story warehouse spaces), targeted design solutions ensure practical applicability.

Second, the construction efficiency of prefab steel structure factory buildings is a key advantage attracting developers and contractors. Thanks to the high prefabrication level of steel components, most processing is done off-site, with only on-site assembly required. This industrialized model simplifies construction procedures and drastically improves project efficiency—directly resolving the concrete building pain point of “on-site pouring and lengthy timelines.” Additionally, no complex support structures are needed during construction, effectively shortening the timeline. This saves project time and reduces costs from extended delays.

Additionally, environmental performance is a standout advantage of prefabricated steel structures. Steel is recyclable: when buildings are demolished or renovated, most steel components can be recycled and reprocessed, reducing construction waste. In contrast, most debris from demolished concrete buildings is non-recyclable. Steel construction also generates minimal dust pollution, aligning with modern green building requirements.

Although steel raw material procurement costs may be slightly higher, the combination of short construction timelines, low long-term maintenance, and material recyclability has driven widespread adoption of steel structures in prefabricated factories. From a long-term development and overall performance perspective, steel is more cost-effective. As steel processing and manufacturing technology advances, costs continue to decline—making prefabricated steel structures an increasingly preferred choice for factory construction.

Why K-HOME Is Your Trusted High-Quality Prefab Warehouse Buildings Supplier?

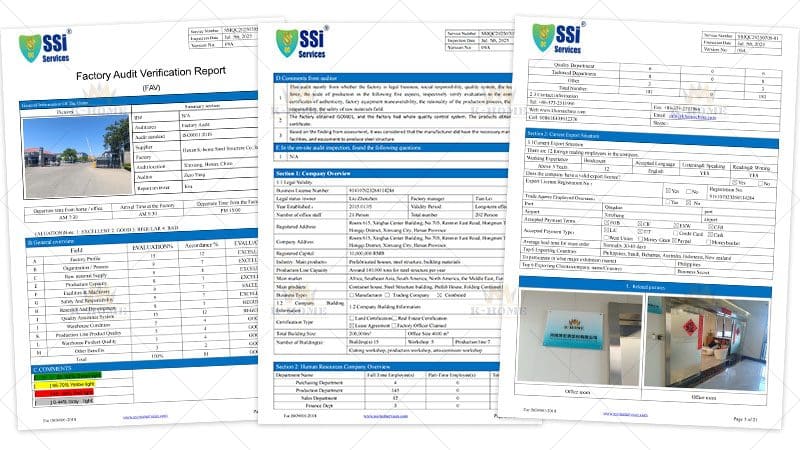

K-HOME (Henan Kunhong Steel Structure Co., Ltd.) is a professional high-tech enterprise with over 20 years of expertise in the steel structure industry. Specializing in the R&D, design, and production of prefab warehouse buildings, we serve high-demand markets across North America, Europe, and Asia—earning international recognition for our technical strength and reliability.

Our commitment to quality starts with strict adherence to international standards. K-HOME holds ISO 9001 (Quality Management), ISO 14001 (Environmental Management), and EU CE (EN 1090-1/2) certifications—ensuring every prefab warehouse building project meets global benchmarks. From raw material sourcing to final manufacturing, we follow rigorous international protocols.

Our core product line includes prefab warehouse buildings (container houses, light steel structures, and industrial workshops). Every component is designed and tested to GB 50017-2017 standards, with detailed structural calculation reports (covering load-bearing capacity, seismic resistance, and wind performance) provided for transparency. Our engineering team further uses professional finite element analysis software to simulate stress at each connection node—guaranteeing long-term structural safety.

Prefab Warehouse Buildings Layer Guide: Single-story or Multi-story?

When planning and constructing modern prefab warehouse buildings, choosing between single-story and multi-story designs requires more than a simple cost-benefit analysis. Clients must first understand site land use, then evaluate structural requirements and operational workflows for the entire warehouse or workshop.

▪ Single-Story Prefab Warehouse Buildings: Simplicity & Functionality

One of the greatest advantages of single-story prefab warehouse buildings is their fast construction speed. Since the single-story design eliminates the need for complex vertical components—such as multi-story stairs, elevators, or tall load-bearing columns—engineers do not need to calculate intricate vertical load distribution during the design phase. This simplifies both the design process and on-site construction. When it comes to on-site construction, workers simply need to assemble prefabricated steel structural components, such as steel beams and wall panels. This simplification not only shortens the overall project cycle but also allows the warehouse to be put into use more quickly.

From a practical application perspective, single-story prefab warehouse buildings are more suitable for storing various types of heavy goods and bulky goods. They are ideal for industries involving large-scale projects, fast cargo transfer, and frequent cargo inbound and outbound. This is because single-story prefab warehouse buildings mainly rely on ground space for storage; they can utilize automated equipment to improve warehouse utilization, achieve relatively faster cargo handling speeds, and have high ground load-bearing capacity—all of which facilitate easy loading and unloading of goods for large-scale projects.

As a result, single-story prefabricated warehouse buildings are usually the preferred choice for industries like heavy manufacturing and large-scale logistics, where there are higher demands for flexible space utilization.

▪ Multi-Story Prefab Warehouse Buildings: Maximizing Vertical Space

In urban or densely packed industrial parks, larger ground space often translates to higher construction and operational costs. Additionally, many cities restrict the development of large single-story factory warehouses.

Multi-story prefab warehouse buildings solve this by stacking two or more floors—boosting storage capacity without expanding ground footprint. Visually similar to traditional multi-story buildings, they organize goods by floor and feature heavy-duty freight elevators for efficient cargo transport.

Such warehouses are more suitable for industries with small-volume inventory, such as pharmaceutical companies storing medicines, electronic manufacturers storing electronic components, or retailers storing consumer goods.

Nevertheless, it is worth noting that one point that requires attention is that while managing goods stored across multiple floors, it is also necessary to ensure the normal operation of equipment like freight elevators. Therefore, customers who opt for multi-story steel structure warehouses need to invest more effort in inventory management and also attach importance to the regular maintenance of transportation equipment.

- Construction of Prefabricated Multi-Story Warehouse Buildings

- Construction of Prefabricated Multi-Story Warehouse Buildings

- Construction of Prefabricated Multi-Story Warehouse Buildings

Both types of prefabricated warehouse buildings have their own unique advantages. With the development of industry, various sectors have begun to pay more attention to efficiency and adaptability. For enterprises considering long-term development, prefab steel warehouse structures have become a popular choice for construction. This prefabricated construction method not only makes construction more convenient but also better meets the evolving needs of modern enterprises.

Key Construction Secrets for Durable Prefabricated Warehouse Buildings

In the field of industrial construction, steel structure prefab warehouse buildings—an important type of prefabricated warehouse buildings—are widely used for industrial storage facilities and production workshops, thanks to their high construction efficiency, sturdy durability, and flexible spatial layouts.

Most installation work of these prefab warehouse buildings’ steel structures is done at height, especially for bulk components. Ensuring stable support frames is critical for construction safety and stability. These frames are usually made of steel pipes (which resist deformation, ensuring overall frame stability) and must pass strict inspections to meet standard requirements for settlement and deflection. The frame’s settlement is affected by factors like rod elastic compression, pipe joint gap compression, and foundation settlement—so foundation tests, pressure tests, and timely adjustments are necessary to support subsequent steel structure installation.

Welding quality for steel structure prefab warehouse buildings depends heavily on welders—their technical skill and sense of responsibility. Skilled, responsible welders produce high-quality welds, making it critical to enhance their skills and quality awareness. This ensures every weld meets standards, preserving structural integrity.

To ensure installation quality, identify key control points pre-construction. The team must map the steel structure’s positioning axes, support axes, and embedded bolt locations, verifying alignment between design drawings and on-site measurements. For large steel frame dismantling of tall frames, work in height batches to mitigate risks.

During installation preparation, secure joint plates and high-strength bolt tool bags to both ends of steel beams. Install beams in the preset floor sequence, starting with 2-3 reference beams. Main beams are installed from lower to upper levels, followed by middle layers, with immediate high-strength bolt reinforcement. Use three theodolites to monitor steel column verticality and inclination, adjusting promptly to prevent middle column deviation.

The entire construction process of prefabricated steel structure warehouse must be based on the team’s full understanding of design drawings, clear component processing requirements, and an orderly installation plan. Every detail matters, as each step impacts the final safety and durability of the prefab warehouse building.

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.