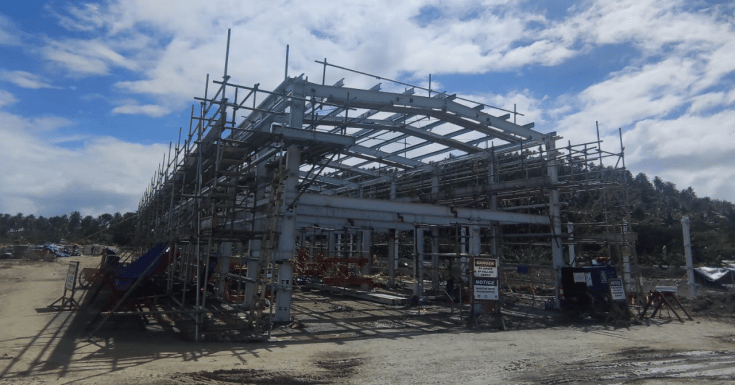

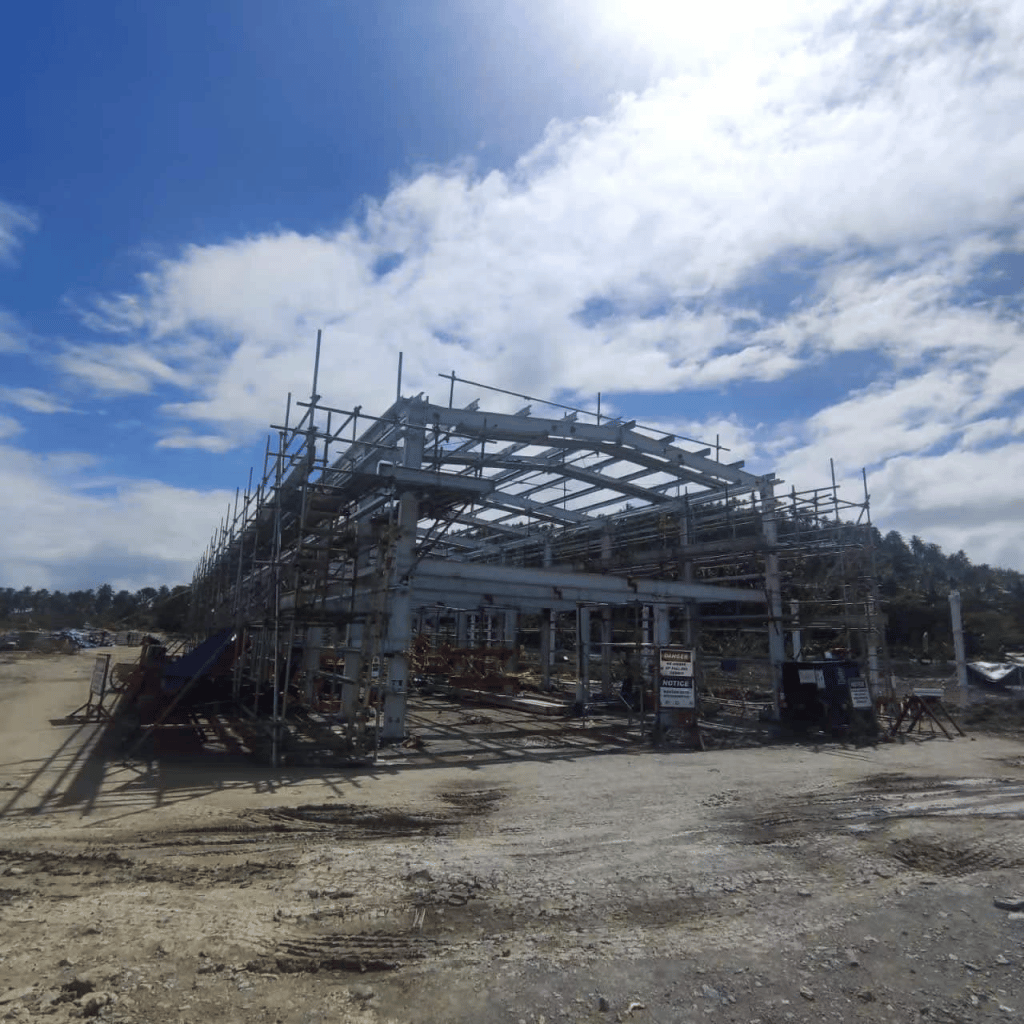

Steel Structure Buildings

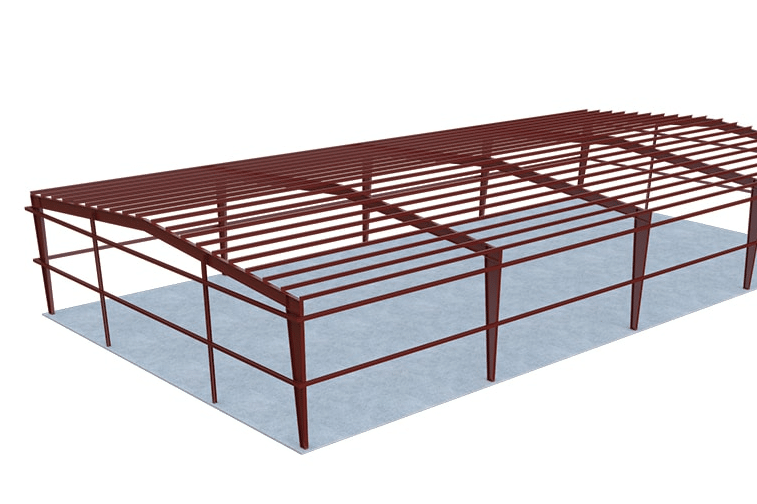

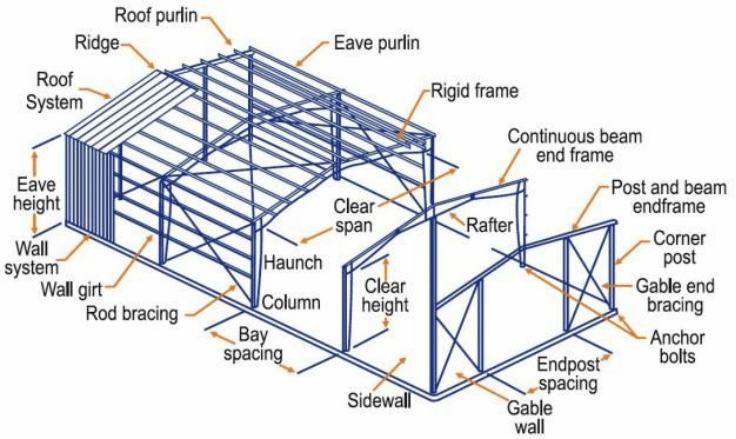

The Steel structure buildings is a building in which building steel constitutes a load-bearing structure. The load-bearing structure is usually composed of beams, columns, trusses, and other components made of section steel and steel plates. It forms an integral building together with the envelope structure such as roof, floor, and wall.

Construction steel usually refers to hot-rolled angle steel, channel steel, I-beam, H-beam, and steel pipe. A building whose components constitute a load-bearing structure is called a steel structure building. In addition, thin-walled sections such as L-shaped, U-shaped, Z-shaped, and tube-shaped, which are cold-rolled and formed from thin steel sheets, rolled or unrolled, as well as the load-bearing components formed by them, and small steel materials such as angle steel and steel bar, etc. Structural building, generally called light steel structure building. There are also suspension structure buildings using steel cables, which are also steel structure buildings.

The strength and elastic modulus of steel is high, the material is uniform, and the steel structure building has good plasticity and toughness, high precision, convenient installation, high degree of industrialization, and fast construction, but it has poor corrosion resistance and fire resistance and requires frequent maintenance.

Types of Steel Structure Buildings

The steel structure building is a structure mainly made of steel. It is mainly composed of steel beams, steel columns, steel trusses, and other components made of section steel and steel plates. The components or parts are usually connected by welds, bolts, or rivets. The steel structure building is one of the main types of building structures. Because of its lightweight and simple construction, it is widely used in large workshops, venues, super high-rises, and other fields.

The steel structure building types are divided according to the structural form, and can be divided into seven common steel structure types, such as layered steel structure, tower steel structure, and staircase steel structure:

WHY CHOOSE KHOME AS YOUR SUPPLIER?

K-HOME is one of the trusted factory manufacturers in China. From structural design to installation, our team can handle various complex projects. You will receive a prefabricated structure solution that best suits your needs.

You can send me a WhatsApp message (+86-18338952063), or send an email to leave your contact information. We will contact you as soon as possible.

Steel Structure Buildings Advantages and Disadvantages

As steel structures are used more and more widely in the market, people are paying more and more attention to steel structure factory buildings, and steel structure factory buildings have many advantages, such as:

Steel Structure Building Design

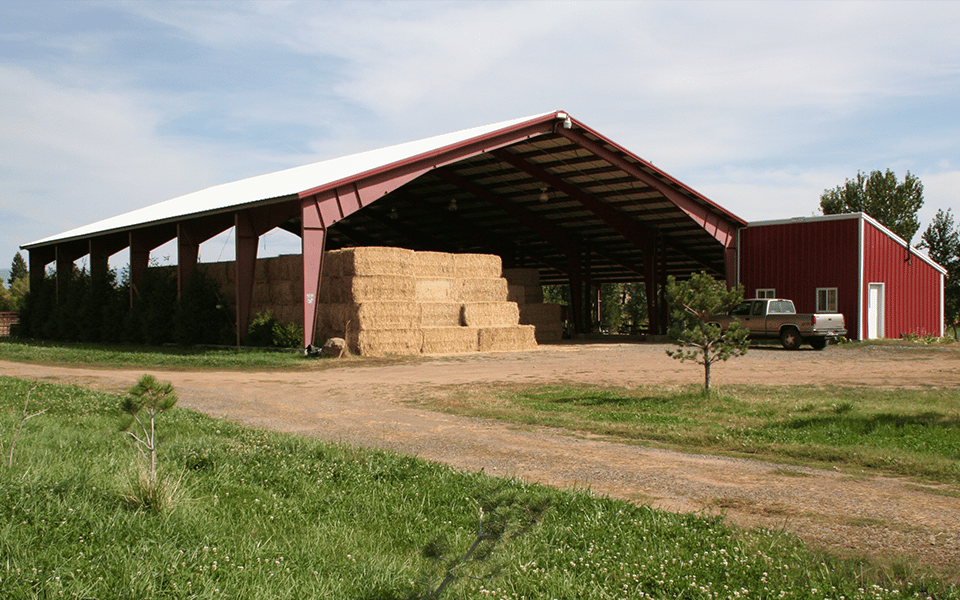

Single-span double-slope portal steel frame

Variable section columns and roof beams, are the most economical design. The roof slope is small, which saves the heating and insulation cost of non-use space. The common span is 15-36 meters, which is suitable for the needs of various types of buildings.

Double-span double-slope steel frame

The interior columns are designed to allow the structure to achieve larger roof spans, usually 36-72 meters which are more economical.

Multi-span double-slope steel frame

The design of the inner column makes the section of the component more economical, and at the same time meets the requirements of large depth. It is an economical structural form for shopping malls and commercial office buildings.

Multi-span multi-slope steel frame

The multi-span and multi-slope design is suitable for the needs of various types of buildings and makes more full use of the floor space.

High and low span steel frame

The interior columns are designed to allow the structure to achieve larger roof spans, usually 36-72 meters which are more economical.

Single-span double-slope steel frame

Equal cross-section column, joint design with fixed bottom end, can bear larger bearing bending moment, suitable for buildings with crane load

Single-span single-slope steel frame

Small roof beam slope and single-sided roof drainage area are suitable for the needs of various types of buildings such as shopping centers, convenience stores, and fire stations.

Composite steel frame

The design of the steel structure mezzanine is suitable for the needs of various types of buildings, and it is easy to separate the space inside the building.

Multi-layer frame

The steel structure frame system has a smaller weight than the reinforced concrete system and is suitable for multi-story building structures such as workshops, warehouses, and shopping malls.

Related Buildings

Articles Selected for You

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.