What is a PEMB(Pre-Engineered Metal Building) Building?

PEMB Building (Pre-Engineered Metal Building) is a prefabricated steel structure building system designed for rapid construction of high-strength, long-span spaces. Unlike traditional on-site construction methods, all core components of PEMB buildings are pre-manufactured in a controlled factory environment and then transported to the project site for efficient assembly. This innovative approach allows it to flexibly adapt to a variety of scenarios, including industrial warehouses, manufacturing workshops, retail spaces, and even customized residences.

Choosing a PEMB solution for steel structure construction can significantly improve project efficiency and economy. Its modular characteristics greatly shorten the construction period, lean production reduces material waste and achieves cost savings, and the standardized design framework supports highly customized layouts (such as column-free long-span spaces), meeting diverse needs from basic warehousing to complex functions.

5 key Components of PEMB building construction

foundation plans for steel building

The foundation is an important part that supports the entire steel manufacturing building. Its bearing capacity is directly related to the stability and safety of the factory. Steel structure buildings generally have the characteristics of lightweight and large span, and the requirements for the foundation are relatively high. The methods of foundation treatment are different for different geological conditions and bearing requirements.

The following are several commonly used foundation treatment methods:

- Compacting method: compact the foundation mechanically or manually to improve the density and bearing capacity of the soil. This method is suitable for loose soil layers and can effectively reduce settlement.

- Pile driving method: pile driving method can be used in the case of insufficient bearing capacity or uneven soil layers. By driving the pile foundation into a deeper hard soil layer, the overall bearing capacity is enhanced.

- Foundation reinforcement: For some special geological conditions, chemical grouting, cement slurry injection and other methods can be used for foundation reinforcement. This method can effectively improve the bearing capacity and stability of the foundation.

- Replacement method: Replacement treatment can be carried out in the case of insufficient foundation bearing capacity. The original soil layer is excavated and filled with materials with higher bearing capacity to ensure the stability of the foundation.

Main frames

As the core load-bearing system of prefabricated metal buildings, the main frame is made of high-strength structural steel (usually Q355B grade steel) through high-frequency welding technology to form an H-shaped steel column and beam system. It bears all the static loads (such as roof weight) and dynamic loads (such as wind pressure and earthquake force) of the building. Its precise design and manufacturing directly determine the structural safety, durability and span customization capabilities of the project.

Secondary Framing

The secondary frame forms a secondary support network for prefabricated buildings. It includes components such as purlins, ties, braces, corner braces, supports, etc.

The secondary frame structure plays a vital role in strengthening the structural integrity and stability of the building. These components are usually made of durable steel materials and have multiple functions that contribute to the overall strength and function of the structure. For example, purlins are horizontal beams that are parallel to the main roof frame members and provide support for the roof deck. By evenly distributing the weight of the roof on the building’s frame, purlins help prevent sagging and ensure structural integrity, especially in larger spans or areas with heavy snow loads. Secondary frame systems often use Q235B steel, which is galvanized or painted to prevent rust.

Enclosure system

The enclosure structure consists of two modules: roof panels and wall panels, which provide physical closure and wind and rain protection.

The enclosure structure usually uses color steel tiles or composite sandwich panels. Color steel tiles are light and durable, suitable for factories and warehouses with high space requirements; composite sandwich panels are filled with materials such as rock wool, which have both thermal insulation and fire resistance.

These panels have various finishes to meet aesthetic and functional requirements. Customers can choose according to the purpose of the project and the use environment.

Functional accessories

Functional accessories are an indispensable part of PEMB buildings. They help improve the overall functionality, comfort and energy efficiency of the building.

Among these accessories, the door and window system meets the basic needs of lighting and ventilation, and the reasonable configuration of the roof air tower can enhance indoor air circulation and improve indoor air quality. The gutter system ensures that the roof drainage is unobstructed during the rainy season.

PEMB building frame types

As a professional PEMB manufacturer, K-HOME provides two mainstream PEMB building frame systems: portal steel frame and frame steel frame to meet the structural requirements of different application scenarios.

portal steel frame

The portal steel frame adopts a large-span rigid frame design, consisting of variable-section H-shaped steel columns and inclined beams to form an open space without intermediate support. It is particularly suitable for industrial plants, storage centers and logistics warehouses that require a wide internal layout. Its structural advantages are fast construction, cost-effectiveness, and flexibility to adapt to different span and height requirements.

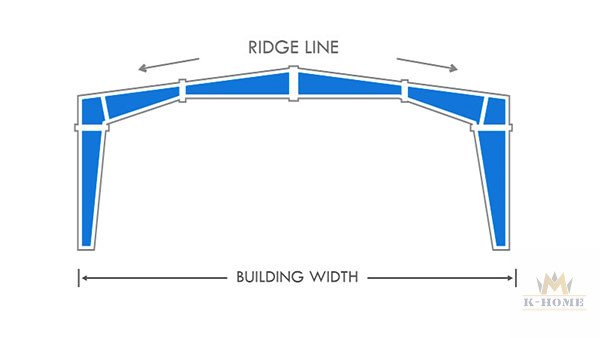

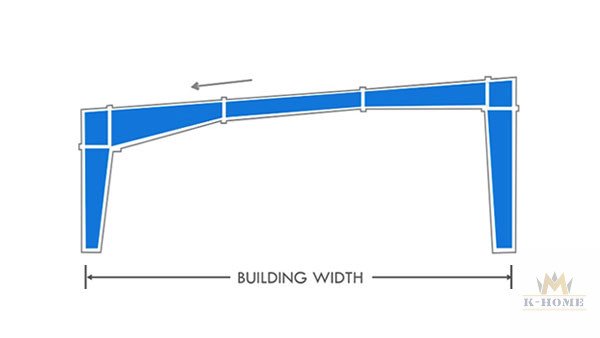

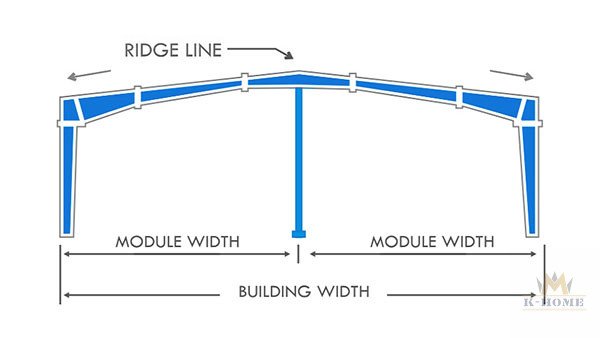

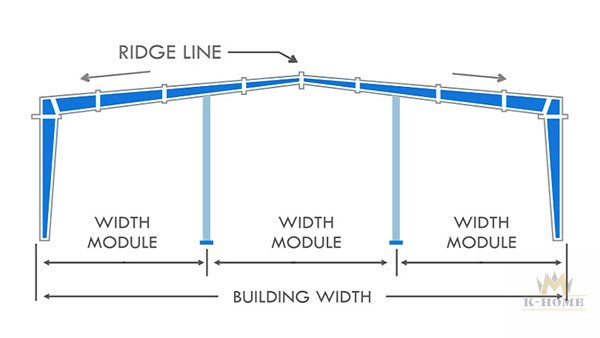

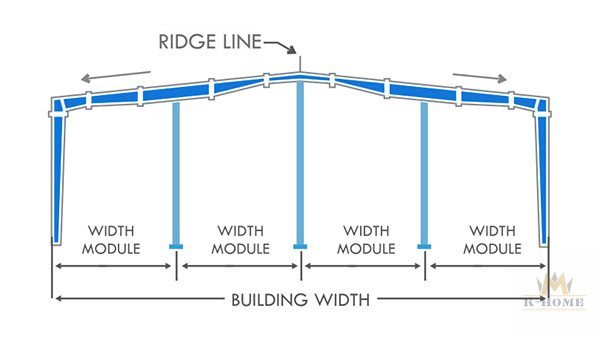

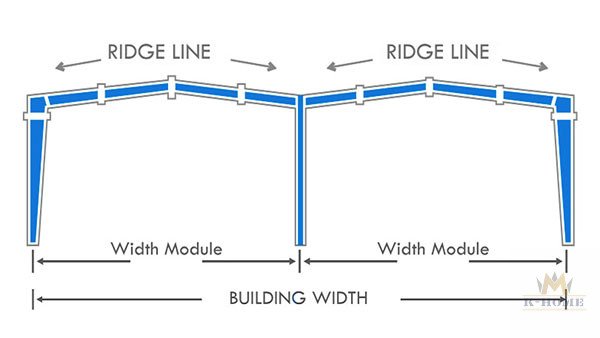

Types of portal steel frames

single-span double-sloped single-span single-sloped double-span double-sloped multi-span double-sloped multi-span double-sloped multi-span multi-sloped

frame steel frame

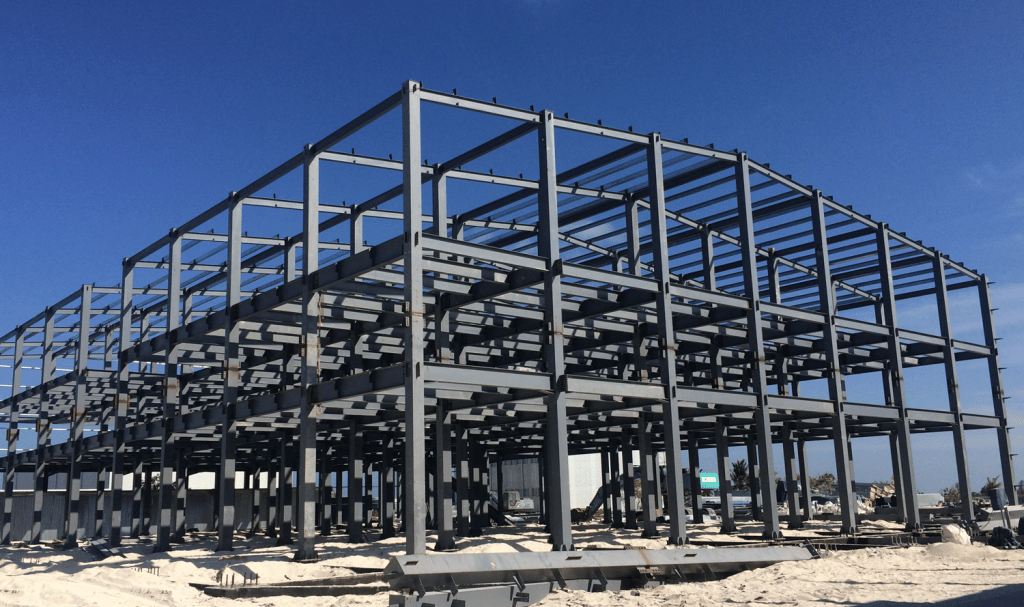

The frame steel frame constructs multi-story or high-rise steel structures through standardized beam-column nodes, with stronger load-bearing capacity and seismic resistance. It is suitable for projects such as commercial buildings, office buildings and multi-story workshops that require higher structural stability.

Both systems are made of Q355B high-strength steel, which are accurately calculated and prefabricated in the factory to ensure the safety, durability and rapid construction advantages of the building.

K-HOME can provide the most optimized steel structure solutions according to your project needs, from single-story large-span factories to multi-story industrial facilities, to achieve efficient and economical construction goals.

Key advantages of PEMB building structures

1. Construction speed

One of the most significant advantages of PEMB building is its fast construction time. Since the building components are prefabricated and manufactured off-site, the flow of tasks on the construction site will not be disturbed. Despite the adverse external weather conditions, the fabrication of PEMB materials continued. These steel structure kits can be quickly assembled after being delivered to the site, which can reduce the construction time by up to 50% compared to traditional methods. It is particularly suitable for industrial and commercial projects that need to be put into production quickly.

2. Cost-effectiveness

Pre-engineered metal building construction is generally more cost-effective than traditional building methods because it can effectively use materials, reduce labor requirements and shorten construction time.

3. Customized flexibility

PEMB building design is flexible and can meet user-specific needs and preferences. As a professional manufacturer, K-HOME is able to provide precise customization services on key parameters such as building span, height, and load-bearing capacity according to the specific usage needs of customers. We provide integrated solutions from design to installation to ensure the smooth implementation of the project.

4. Durability and Strength

The inherent advantages of steel structures enable prefabricated metal buildings to easily cope with harsh environmental challenges such as extreme climates and seismic activity. This feature ensures that steel-structured buildings can maintain excellent structural integrity and safety performance throughout their life cycle.

5. Sustainability

Pre-engineered building structures are constructed using steel. Steel is a highly recyclable material that can reduce waste and minimize the environmental impact of construction projects.

Application of Pre-Engineered Metal Building

PEMB buildings have become the preferred solution for many fields due to their durability, fast construction and long-term benefits. From large industrial facilities to commercial spaces, PEMB systems can flexibly adapt to the unique needs of different industries, providing economical, efficient and durable building options for various projects.

Industrial workshops and warehouses

PEMB buildings are particularly prominent in the construction of industrial plants and cargo warehouses. They can build large-span column-free designs, provide spacious interior spaces, and can adapt to different production layouts and the installation of heavy equipment.

Commercial pre-engineered buildings

Many shopping malls and supermarkets are also increasingly built with steel structures. The flexibility of steel structures can be built into fully enclosed or semi-enclosed structures to meet different business needs.

Public and community facilities

More and more indoor basketball courts, gyms, and libraries choose PEMB structures. Its fast construction characteristics can minimize the impact on the surrounding environment, while the seismic performance of steel provides additional protection for public safety.

Factors affecting PEMB building cost and effective methods to reduce costs

PEMB building cost is not a one-size-fits-all price. Its cost is affected by a variety of factors. Each factor plays a vital role in determining the overall budget of a building project. Understanding these factors can help you make informed decisions and ensure that your building project is cost-effective and successful.

● Size and complexity: The size of a steel building affects the steel consumption. The larger the size, the more material is required, which naturally increases the total cost. Secondly, the complexity of the building design also affects the cost, especially if special features are required. Custom designs and unique building elements increase the total cost. You can consult with us to get the most economical design.

● Materials and cladding: The type and quality of materials used in the building’s interior and exterior can significantly affect the cost. High-end finishes and specialized materials can increase the budget, while standard options can help reduce costs.

● Location and transportation: The cost of transporting steel structure kits to the construction site can vary depending on the location and distance. Remote or hard-to-reach locations may incur higher transportation costs, so it is crucial to consider this in your budget.

To minimize costs and ensure that PEMBs are cost-effective, consider the following tips:

● Partner with an experienced PEMB manufacturer or contractor: Partnering with a professional who has experience designing PEMB buildings can help optimize the design and materials, ensuring a cost-effective solution.

● Use standard components and features: Choosing standard components and features can reduce customization costs and streamline the construction process.

● Plan carefully to minimize transportation and labor costs: Efficient planning and logistics can help reduce transportation and labor costs, ensuring a more cost-effective project.

By understanding the factors that affect PEMB costs and taking proactive steps to manage these costs, you can achieve a successful and affordable construction project.

Pre Engineered Metal Building Manufacturers China

As a professional PEMB manufacturer, K-HOME is committed to providing you with high-quality, economical prefabricated steel structure buildings. We know that every project is unique, so we provide tailor-made steel structure solutions to accurately meet your diverse construction needs. All K-HOME steel structure buildings come from our strictly controlled source factories and are carefully built with the highest quality materials to ensure excellent high-standard steel building quality and durability. By shipping directly from the factory to your area, we effectively save the cost of the intermediate links and ensure that you can get prefabricated steel buildings at the best price.

Choosing K-HOME means that you are not only investing in a cost-effective steel structure solution, but also gaining our firm commitment to high standards of delivery and customer satisfaction.

Custom size

We offer customized prefabricated steel structures in any size, perfectly matching your multiple requirements.

free design

We provide free professional CAD design. You don’t need to worry about unprofessional design affecting building safety.

Manufacturing

We select high-quality steel materials and use advanced processing techniques to ensure the creation of durable and robust steel structure buildings.

installation

our engineers will customize a 3D installation guide for you. You don’t need to worry about installation problems.

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.

About Author: K-HOME

K-home Steel Structure Co., Ltd covers an area of 120,000 square meters. We are engaged in the design, project budget, fabrication, and installation of PEB steel structures and sandwich panels with second-grade general contracting qualifications. Our products cover light steel structures, PEB buildings, low-cost prefab houses, container houses, C/Z steel, various models of color steel plate, PU sandwich panels, eps sandwich panels, rock wool sandwich panels, cold room panels, purification plates, and other construction materials.