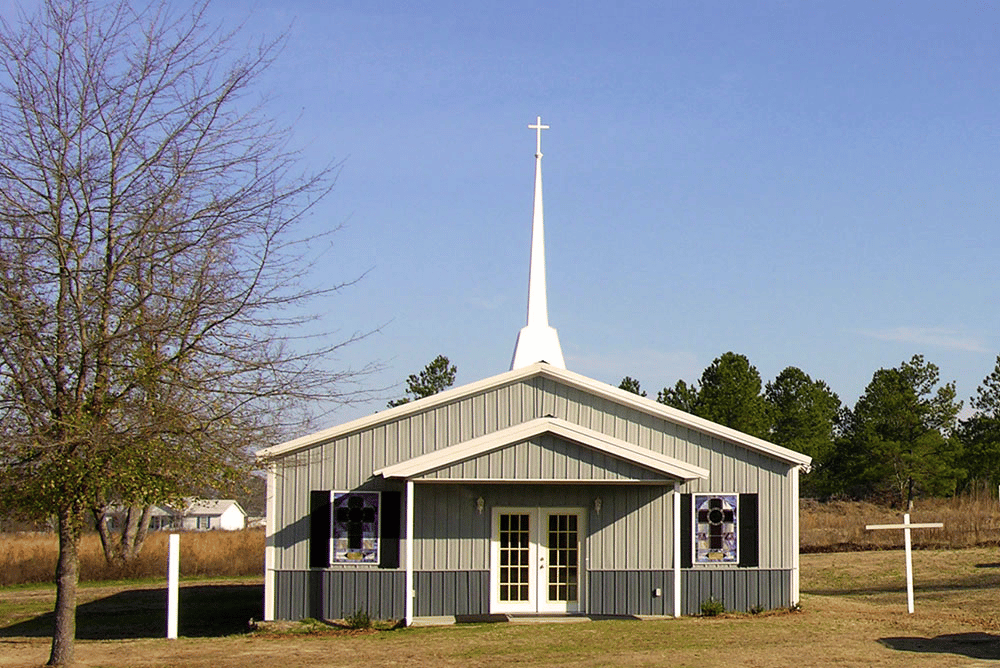

Prefab Steel Church Building

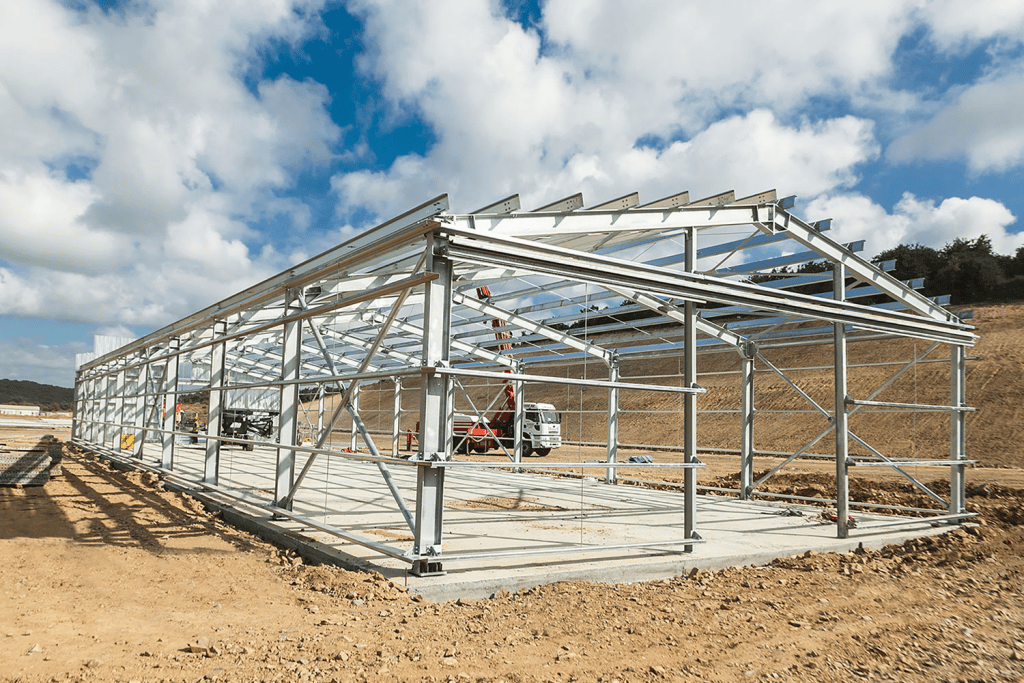

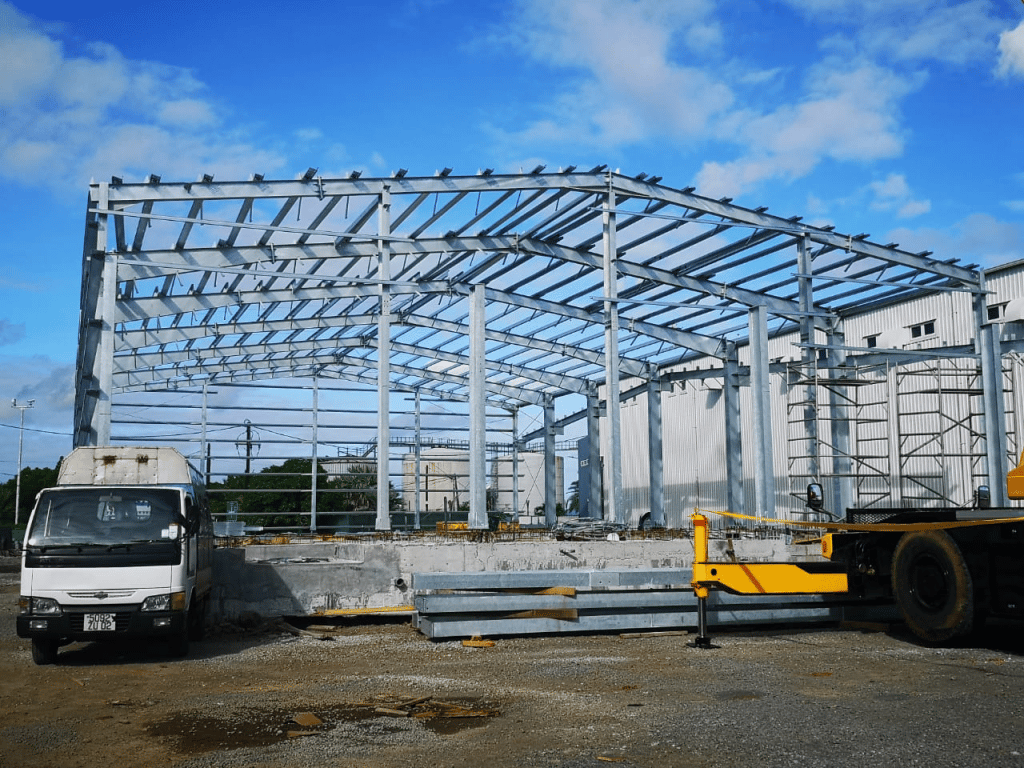

The prefab steel church building has lightweight, low foundation cost, convenient for construction, and installation shortens the construction period, can achieve on-site dry operations, reduce environmental pollution, and the materials can be recycled, which is in line with the environmental protection policies advocated by the world.

More importantly, the seismic performance and safety index of steel churches are better than those of concrete churches.

The steel structure building system is the best concatenation of the real estate industry, construction industry, and metallurgy industry into a new industrial chain. The steel structure building system is a building system that can be assembled naturally, and its construction is less affected by the season.

Compared with concrete structures, because the components are produced in the factory, the construction period of steel structure buildings is shorter. So it is loved by the majority of customers.

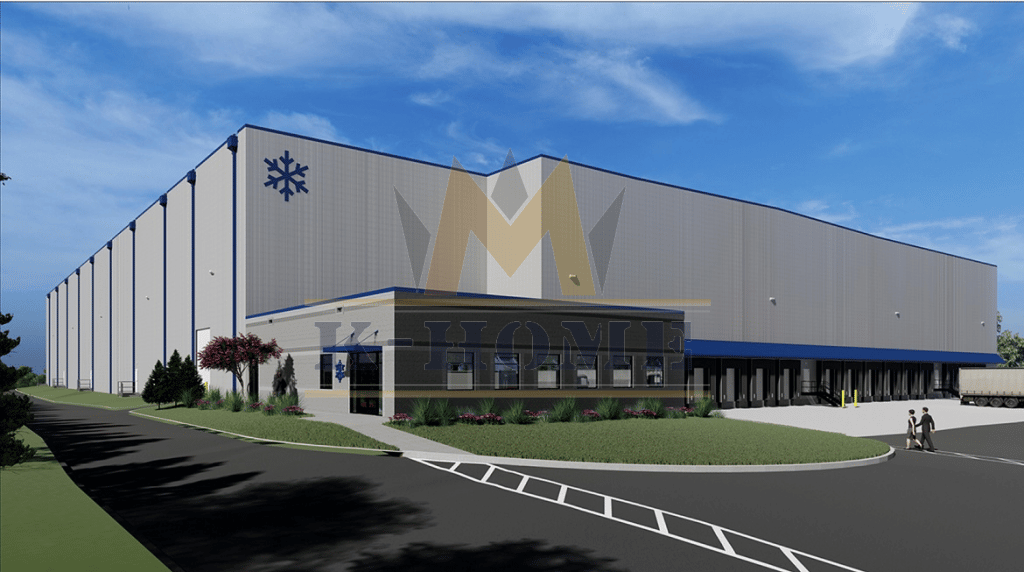

Steel structure building has a wide range of uses, mainly used in large-span venues, churches, warehouses, workshops, office buildings, bridges, and other super high-rise areas.

WHY CHOOSE KHOME AS YOUR SUPPLIER?

K-HOME is one of the trusted factory manufacturers in China. From structural design to installation, our team can handle various complex projects. You will receive a prefabricated structure solution that best suits your needs.

You can send me a WhatsApp message (+86-18338952063), or send an email to leave your contact information. We will contact you as soon as possible.

Our Prefab Metal Church Buildings Advantages

Prefab Metal Church Buildings are characterized by lightweight, good seismic performance, short construction period, and green and pollution-free advantages, which make them widely used. There are many advantages of steel structure building, such as:

1. The characteristics of the steel structure basically adopt a triangular roof truss system made of cold-formed steel components. After the structural plates and gypsum boards are sealed, the light steel components form a very strong board. Ribbed structure system, this kind of structure system has stronger seismic resistance and resistance to horizontal load and is suitable for areas with a seismic intensity of 8 degrees or more.

Wind resistance

The profiled steel structure has lightweight, high strength, good overall rigidity, and strong deformability. The weight of the building is only one-fifth of the brick-concrete structure, and it can withstand a hurricane of 70 meters per second so that life and property can be effectively protected.

Durability

The steel frame is made of super anti-corrosion high-strength cold-rolled galvanized sheet, which effectively avoids the influence of steel plate corrosion during construction and use. The service life and the structure life can reach 100 years.

Heat preservation

The heat preservation and heat insulation materials used are mainly glass fiber cotton, which has good heat preservation and heat insulation effect. The use of thermal insulation boards for external walls can effectively avoid the phenomenon of cold bridges on the wall and achieve a better thermal insulation effect. The insulation wool with a thickness of about 100mm can be equivalent to that of a brick wall with a thickness of 1m.

Environmental protection

The material can be 100% recycled, which is truly green and pollution-free. The steel structure of the house can be 100% recycled, and most of the other supporting materials can also be recycled, which is in line with current environmental protection awareness; all materials are green building materials and meet the requirements of the ecological environment. good for health.

Sound Insulation

The sound insulation effect is an important indicator to evaluate the residence. The windows installed in the light steel system are all made of hollow glass, which has a good sound insulation effect, and the sound insulation can reach more than 40 decibels.

Comfort

The light steel wall adopts a high-efficiency and energy-saving system, with a breathing function, the roof has a ventilation function, which can form a flowing air space above the house to ensure the ventilation and heat dissipation requirements inside the roof.

Fast Installation

All dry work construction, not affected by environmental seasons. For a building of about 300 square meters, only 5 workers and 30 working days can complete the whole process from foundation to decoration.

Energy-saving

All use high-efficiency energy-saving walls, with good heat preservation, heat insulation, and sound insulation effects, and can reach the energy-saving standard of 50%.

2. The architectural advantages of the steel structure system are highly engineered, the construction cost is reduced, and the construction period is shortened.

The harmonized and unified standards for steel structure buildings have realized the industrialized mass production of buildings, improved the engineering of construction, and made building components of different materials, different shapes, and different manufacturing methods have a certain degree of versatility and interchangeability.

At the same time, the pre-engineering of steel structure buildings integrates material processing and installation, which greatly reduces construction costs; and accelerates the construction speed, so that the construction period can be shortened by more than 40%, thereby speeding up the capital turnover of real estate developers and enabling construction Put into use earlier.

FAQs About Prefab Steel Church Building

More Metal Building Kits

Related Commercial Steel Buildings

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.