Prefabricated Cold Storage Construction

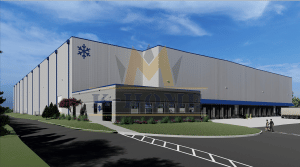

Cold Storage Building

In recent years, with the continuous progress of science and technology and the rapid development of the refrigeration industry, Cold Storage Construction has played an important role in the production, processing, and storage of various industries such as pharmaceuticals, Dairy, meat, aquatic products, vegetables, agricultural products, and flowers.

It replaces the original cold storage construction mode and operation mode with a new architectural concept. Nowadays, the use of cold storage buildings is getting wider and wider, and the building scale is getting bigger and bigger. It has great development prospects.

This type of cold storage building is mainly composed of an envelope structure, thermal insulation sandwich panels, etc. Both sides of the sandwich panels are composed of colored steel plates, aluminum plates, stainless steel plates, etc. The intermediate thermal insulation material is usually PU or PIR, etc. Its weight It is about 10% lighter than conventional building materials.

The cold storage building is a place for storing fresh agricultural products. Its function is to maintain the stability of the low-temperature environment, and the thermal insulation performance is usually referred to as thermal insulation. The good thermal insulation structure of the cold storage room can keep the cold energy produced by the cold storage unit to the greatest extent and less leak out in the cold storage. On the other hand, it is to minimize the leakage of heat from the outside of the cold storage to the inside of the cold storage, which is also the main difference between the cold storage and general house.

Related Commercial Steel Buildings

The PEB Steel Building

The Other Additional Attachments

WHY CHOOSE KHOME AS YOUR SUPPLIER?

K-HOME is one of the trusted factory manufacturers in China. From structural design to installation, our team can handle various complex projects. You will receive a prefabricated structure solution that best suits your needs.

You can send me a WhatsApp message (+86-18338952063), or send an email to leave your contact information. We will contact you as soon as possible.

Types of cold storage Construction building:

According to the scale of cold storage building capacity

At present, the division of cold storage construction capacity is not unified, and it is generally divided into large, medium, and small. The refrigeration capacity of large-scale cold storage buildings is above 10000t; the refrigeration capacity of medium-sized cold storage buildings is 1000~10000t; the refrigeration capacity of small cold storage buildings is below 1000t.

According to refrigeration design temperature

The cold storage building is a part of the cold chain system after the initial product temperature drops sharply, and it is also the base where the low-temperature products stay the longest in the cold chain system. Therefore, the requirements for product quality play an important role in the management of low-temperature logistics. The cold storage building is roughly divided into two categories: refrigeration and freezing: the cold storage warehouse is mainly used to store vegetables and fruits, fresh fish, fish eggs, eggs, fresh milk, juice, etc., and the frozen warehouse is mainly used to store meat, ice cream, etc.

According to the scale of cold storage building capacity, it can be divided into four categories: high temperature, medium temperature, low temperature, and ultra-low temperature.

- In the cold storage building, any storage temperature that is maintained above the product freezing temperature belongs to the refrigerated storage warehouse. Generally, the freezing point of fresh food is mostly above 12 °C. Due to the different properties of various products, the storage temperature is also different. The temperature is below 8°C. Generally, the design temperature of high-temperature cold storage buildings is -2°C to +8°C;

- The design temperature of medium temperature cold storage buildings is -10°C~-23°C;

- Low temperature, the temperature is generally -23°C to 30°C; Those below the temperature are all frozen warehouses, such as long-term frozen storage of frozen fish or meat, frozen food, etc., the storage temperature is about 123 ℃ or less.

- The temperature of the ultra-low temperature refrigerator is generally -30C to -80C.

Classification by main structure of cold storage building

Civil cold storage building

Civil cold storage means the main body of the building uses a reinforced concrete frame structure or a brick-concrete structure for cryogenic storage of frozen products. It is also a kind of cold storage with a relatively high utilization rate at present, which can be single-layer or multi-layer.

Assembled cold storage building

This is a new type of cold storage building. Except for the ground, all steel structure components are prefabricated in professional factories according to unified standards, and the cold storage building for cryogenic storage and frozen products is assembled on site. The prefabricated cold storage wall is a steel frame lightweight prefabricated heat insulation sandwich panel assembly structure, and the load-bearing components are mostly made of thin-walled steel.

The inner and outer panels of the warehouse board are made of color steel plate (the base material is galvanized steel plate), and the core material of the warehouse sandwich panel is a PU sandwich panel or PIR sandwich panel.

Advantages of assembled cold storage building

Since the assembled cold storage building components and heat insulation panels can be prefabricated in the factory in advance, the construction progress is fast and the construction period is short. And configure the corresponding refrigeration system. Compared with civil cold storage, it is beneficial to shorten the construction period.

The metal surface layer of the thermal insulation panel itself is a kind of airtight material. If the joints of the storage sandwich panels are properly handled during installation, the overall sealing and vapor barrier performance of the assembled cold storage building will be better.

Because the wall panel is not affected by the freeze-thaw cycle, the cooling and heating rate of the assembled cold storage is not limited like that of the civil cold storage, and the assembled cold storage can be activated or stopped at will. If the thermal insulation conditions and refrigeration equipment allow, the temperature of the warehouse can also be arbitrarily set, which is difficult for civil cold storage. If it is used as the envelope structure of the freezing room, it has more unique advantages.

Using the PU sandwich panels for the wall systems, the external blind rivets are used to fix the metal surface of the heat insulation board, and various sealants are used to prevent steam. It is much more convenient.

Compared with the civil cold storage, the assembled cold storage with the same peripheral building area has a relatively larger net area in the assembled cold storage, and its storage capacity is relatively increased.

Why choose steel structure cold storage building:

The insulation material of the assembled cold storage wall panel is generally made of polyurethane double-sided plastic-coated color steel plate, which has the advantages of lightweight, good heat insulation performance, safety and environmental protection, strong hardness, corrosion resistance, etc.

The advantages are as followings:

- The turnover rate is high, saving time and resources.

- Compared with civil cold storage, the cost of assembled cold storage building is lower than that of civil cold storage of the same capacity.

- The use of space is large. There is no limit to the height of the single-layer steel structure cold storage, and it can reach 20 or 30 meters. The shelf automation is adopted in the warehouse, and the utilization rate is much higher than that of the civil cold storage.

- The construction period is short

More Metal Building Kits

Articles Selected for You

Building FAQs

- How to Design Steel Building Components & Parts

- How Much Does a Steel Building Cost

- Pre-Construction Services

- What is a Steel Portal Framed Construction

- How to Read Structural Steel Drawings

Blogs Selected for You

- The Main Factors Affecting The Cost of Steel Structure Warehouse

- How Steel Buildings Help Reduce Environmental Impact

- How to Read Structural Steel Drawings

- Are Metal Buildings Cheaper Than Wood Buildings?

- Benefits of Metal Buildings For Agricultural Use

- Choosing the Right Location For Your Metal Building

- Making a Prefab Steel Church

- Passive Housing & Metal –Made for Each Other

- Uses for Metal Structures You May Not Have Known

- Why Do You Need a Prefabricated Home

- What Do You Need To Know Before Designing a Steel Structure Workshop?

- Why Should You Choose a Steel Frame Home Over a Wooden Frame Home

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.