steel strucure factory

steel factory / factory steel structure / steel structure factory building / steel factory building

Are you planning to expand your production space but concerned about long construction times and high costs? Steel structure factory are the ideal solution for you. With their advantages of high strength, flexible design, and rapid installation, steel structures have become one of the most reliable building systems for constructing factories, workshops, and warehousing facilities. They not only significantly accelerate project completion but also provide high adaptability for future expansion.

K-HOME specializes in designing and manufacturing customized steel structure factory buildings that meet international standards, committed to meeting the diverse needs of clients in manufacturing, food processing, logistics, and heavy industry. With years of experience in international projects, K-HOME has become a trusted partner for global clients seeking efficient and reliable steel structure solutions.

What Is a Factory Steel Structure Building?

A factory steel structure is a type of modular building built mainly with steel columns and beams, usually enclosed with insulated wall panels or corrugated steel sheets. These buildings are widely adopted in industrial sectors because of their structural stability, ease of customization, and reduced construction time.

The steel used is typically high-quality galvanized Q235B, known for its corrosion resistance and long service life exceeding 50 years. Since components are pre-manufactured and assembled on-site, the overall construction timeline is shortened significantly compared to traditional methods. Additionally, the flexibility in layout and space planning allows businesses to design their workspaces more efficiently.

Key Components & Technical Specifications of steel structure factory

Most prefabricated steel structure factory buildings share similar structural elements. Understanding them helps clients know exactly what they are getting and helps K-HOME communicate more professionally during early discussions.

A factory steel structure is made of several key components that ensure strength, flexibility, and safety.

- Primary Frame: The backbone of a steel structure factory is the primary frame, composed of Q235/Q355 steel columns and beams. Clear spans range from 12–30 meters, and eave heights vary from 6–12 meters, accommodating machinery, production lines, and cranes.

- Secondary Frame: Includes C/Z-shaped purlins, bracing, and tie rods to support roof and walls, stabilize the structure, and allow easy installation of doors, windows, and skylights.

- Roof & Wall System: Made of color-steel sheets or insulated sandwich panels (EPS/PU/Rockwool), 50–100mm thick, providing thermal insulation, soundproofing, and energy efficiency.

- Foundation & Anchor Bolts: Concrete foundation with pre-embedded bolts connects columns securely, ensuring stability under heavy loads and machinery.

- Load Design: Designed to meet local wind, snow, seismic codes, and optional overhead crane loads. Safe for both live and dead loads, ensuring long-term durability. These specifications are what clients most often ask about and help K-HOME provide accurate quotes and reliable solutions.

material of steel structure factory building

| Component Structure | Material | Technical Parameters |

|---|---|---|

| Main Steel Structure | GJ / Q355B Steel | H-beam, Customized height according to building requirements |

| Secondary Steel Structure | Q235B; Paint or Hot Dip Gavalnized | H-beam, Spans range from 10 to 50 meters, depending on design |

| Roof System | Color Steel Type Roof Sheet / Sandwich Panel | Sandwich panel thickness: 50-150mm Customized size according to design |

| Wall System | Color Steel Type Roof Sheet / Sandwich Panel | Sandwich panel thickness: 50-150mm Customized size according to wall area |

| Window & Door | Color steel sliding door / electric rolling door Sliding Window | Door and window sizes are customized according to design |

| Fireproof Layer | Fire retardant coatings | Coating thickness (1-3mm) depends on the fire rating requirements |

| Drainage System | Color Steel &PVC | Downspout: Φ110 PVC Pipe Water Gutter: Color Steel 250x160x0.6mm |

| Installation Bolt | Q235B Anchor Bolt | M30x1200 / M24x900 |

| Installation Bolt | High-Strength Bolt | 10.9M20*75 |

| Installation Bolt | Common Bolt | 4.8M20x55 / 4.8M12x35 |

customized steel structure factory buildings according to your application

K-HOME’s prefabricated steel structure buildings have been successfully implemented in numerous countries and regions worldwide, including African markets such as Mozambique, Guyana, Tanzania, Kenya, and Ghana; the Americas such as the Bahamas and Mexico; and Asian countries such as the Philippines and Malaysia. We are familiar with diverse climate conditions and approval systems, enabling us to provide you with steel structure solutions that combine safety, durability, and economy.

Contact our customer service team today, and we will dedicate ourselves to creating a customized steel structure building perfectly suited to your needs.

If you provide the following information, we will provide you with a more accurate product quote.

Design Considerations for Factory Steel Structures

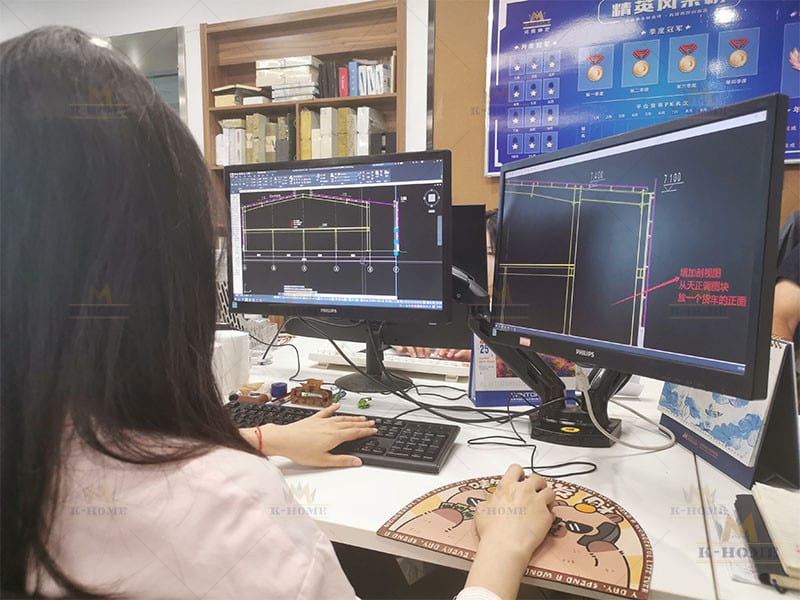

Good design is crucial for controlling costs, improving performance, and extending the lifespan of a factory steel structure. At K-HOME, we design every building based on the client’s project needs and local conditions.

Layout & Functional Planning

A well-planned layout considers production workflow, machinery height and load, forklift lanes, storage zones, and material flow for loading and unloading areas. These considerations ensure that the space is fully optimized for daily operations.

Span & Eave Height

Large spans and sufficient eave height create open, column-free spaces, which are ideal for assembly lines, vehicle or machine repair zones, and high-bay racking systems. This flexibility allows clients to adapt the building to their operational needs.

Crane Integration

For workshops requiring overhead cranes, the design incorporates crane runway beams, reinforced columns, and deflection control. These features ensure safety, structural stability, and smooth operation of crane systems.

Energy Efficiency

K-HOME integrates insulated wall and roof panels, natural ventilation, skylights, and environmental coatings. These energy-efficient solutions help reduce operating costs over the building’s lifecycle while maintaining a comfortable and safe working environment.

Future Expansion

The modular nature of a factory steel structure allows for fast extension, flexible space growth, and reconfiguration without damaging the existing structure. This adaptability is a major advantage for growing companies that may need to scale up operations in the future.

Price of Steel Structure Factory Buildings

Many clients ask about the cost of a factory steel structure building at the very beginning of a project. While the final price depends on specific design, size, and project requirements, the following ranges provide a general reference.

Price Reference (FOB China):

- Standard steel workshop: US$50–80 per m²

- With insulation panels or overhead cranes: US$70–120 per m²

- Heavy-duty or fully customised applications: US$120–200+ per m²

Factors Affecting the Cost:

Several key factors determine the final price of a factory steel structure:

- Steel price and weight: The type and amount of steel used is the biggest cost driver. High-grade steel or larger structures naturally increase cost.

- Span and eave height: Wider spans and taller eaves require stronger beams and columns, which add to material and fabrication costs.

- Wall and roof insulation: Insulated sandwich panels for cold storage or food-processing facilities cost more than standard color-steel sheets.

- Crane requirements: Overhead cranes need reinforced columns, crane rails, and specialized engineering, which increase costs.

- Foundation design: Soil conditions, seismic zones, and heavy-load requirements affect concrete foundation complexity and cost.

- Location and environmental loads: Wind, snow, or other climate factors may require additional structural reinforcement.

- Additional features: Number of doors, windows, mezzanine floors, and internal partitions all impact total cost.

Applications of Factory Steel Structure Buildings

Because of their flexibility, durability, and cost-effectiveness, factory steel structure buildings are widely used across various industries. Their modular design and large clear spans make them suitable for both heavy industrial use and precise operational requirements.

Manufacturing Plants

Factory steel structure buildings are ideal for manufacturing facilities due to their column-free space and adaptability. They are widely used for: Automotive parts production, Machinery assembly, Electronics manufacturing

The large clear spans allow easy installation of heavy machinery, assembly lines, and conveyors, enabling efficient workflow and operational flexibility.

Warehouses & Logistics Centers

Steel structure buildings are perfect for modern warehousing and logistics needs. Common applications include: Distribution hubs, High-bay storage facilities, Cold chain storage warehouses.

Insulated panels help maintain temperature control for cold storage, while the open floor plans allow flexible storage layouts and easy forklift operations.

Food Processing Industry

The hygienic and easily maintained interior of a factory steel structure makes it suitable for food-grade facilities, such as: Flour mills, Grain processing workshops, Beverage or dairy plants. The design allows for integration of ventilation, drainage, and clean zones, meeting strict food safety standards.

With such versatility, factory steel structure buildings have become the backbone of modern industrial development. Their ability to combine strength, speed, flexibility, and cost-efficiency makes them an essential solution for growing businesses across multiple sectors.

Why Choose K-HOME as Your Steel Structure Manufacturer?

As a professional steel factory manufacturer, K-HOME is committed to providing you with high-quality, economical prefabricated steel structure buildings.

Committed to Creative Problem Solving

We tailor each building to your needs with the most professional, efficient and economical design.

Buy direct from the manufacturer

Steel structure buildings come from the source factory, carefully selected high-quality materials to ensure quality and durability. Factory direct delivery allows you to get prefabricated steel structure buildings at the best price.

Customer-centric service concept

We always work with customers with a people-oriented concept to understand not only what they want to build, but also what they want to achieve.

1000+

Delivered structure

60+

countries

15+

Experiences

Frequently Asked Questions

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.