Whether for industrial, agricultural, or commercial steel structures, once the installation and construction of these structures are completed, it isn’t very easy to modify their height. Therefore, this means you must undergo careful consideration and analysis to make the right decision when selecting the height of a steel warehouse.

Steel Warehouse Height: Scientific Methods for Selection

Determining the Minimum Height Standard for Steel Warehouses

When selecting the steel warehouse height, you need to start with core needs and focus on two key aspects: stored goods and operating equipment. These two factors directly determine the minimum value of the warehouse height.

Restrictions on Steel Warehouse Height from Various Building Regulations

Defining the maximum height boundary of a steel warehouse is not an arbitrarily set upper limit, but a reasonable range jointly defined by multiple objective constraints. Local building height restrictions, the load-bearing capacity of the site’s foundation, and the load impacts from regional meteorological factors (such as strong winds and snow accumulation) all restrict the steel warehouse height from different dimensions.

How to Calculate the Exact Height of a Steel Warehouse?

The formula for the internal clear height of a steel warehouse (a key factor in steel warehouse height design) is:

Internal Clear Height = Shelf Height (or maximum stacked height of goods if no shelves are used) + Height of a Single Goods Unit + Reserved Space at the Top + Floor Leveling Error

Calculation Logic for the Total Height of a Steel Warehouse

Total Steel Warehouse Height = Internal Clear Height + Roof Structure Height

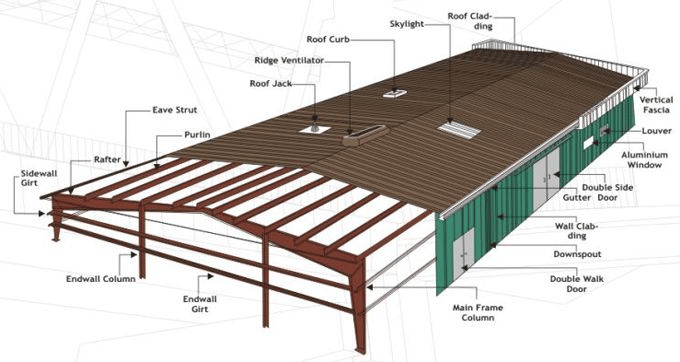

The roof structure height depends on the roof type. Common steel structure roofs include purlins, roof panels, and supporting components.

Adjustments can be made based on the actual roof design. When calculating, note that the roof structure height must cover all upper components to avoid insufficient total height due to missing calculations—this ensures accuracy in steel warehouse height determination.

Avoiding Blind Selection Mistakes in Steel Warehouse Height

Many clients tend to blindly reserve space when selecting the height for their steel warehouses, leading to cost waste and idle areas. Some hold the idea that “reserving more height will be useful eventually,” but this kind of height reservation—without tying it to actual storage or operational needs—only pushes up the overall steel structure construction cost.

For prefabricated steel warehouse projects, every extra meter in height requires corresponding thickening of steel columns and beams to maintain load-bearing capacity. This increases steel material usage by 5% to 8%, and also adds more high-altitude work during installation—naturally driving up both material and labor costs.

On the other hand, if the operating range of current equipment (like forklifts) is limited and can’t match the reserved height for the steel warehouse, the top-floor space will remain unused long-term. This not only wastes valuable storage area but also leads to higher energy consumption for lighting and ventilation compared to standard warehouses, all due to the excessively tall structure. Over time, this also raises routine maintenance costs, undermining the warehouse’s long-term cost-effectiveness.

Maximize Cost Efficiency with Scientific Selection of Steel Warehouse Height Solutions

- First, it is recommended that when collaborating with steel structure manufacturers or suppliers, you develop 2-3 alternative solutions with different heights for a steel warehouse. This allows you to screen options that better align with your needs based on core factors like storage suitability and construction costs, laying a solid foundation for scientific steel warehouse height selection.

- Second, you need to align with long-term development plans and clarify whether there will be storage expansion needs for the steel warehouse in the next 3-5 years, such as an increase in cargo types or order volume. If expansion is planned, you can reserve a moderate amount of additional height to avoid the renovation costs of heightening the warehouse later. If there is no clear expansion plan, excessive height reservation is unnecessary, as this prevents wasted upfront costs and idle space. This approach ensures the steel warehouse height not only meets current usage needs but also aligns with long-term cost-effectiveness considerations, supporting optimal steel warehouse height determination.

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.

About Author: K-HOME

K-home Steel Structure Co., Ltd covers an area of 120,000 square meters. We are engaged in the design, project budget, fabrication, and installation of PEB steel structures and sandwich panels with second-grade general contracting qualifications. Our products cover light steel structures, PEB buildings, low-cost prefab houses, container houses, C/Z steel, various models of color steel plate, PU sandwich panels, eps sandwich panels, rock wool sandwich panels, cold room panels, purification plates, and other construction materials.