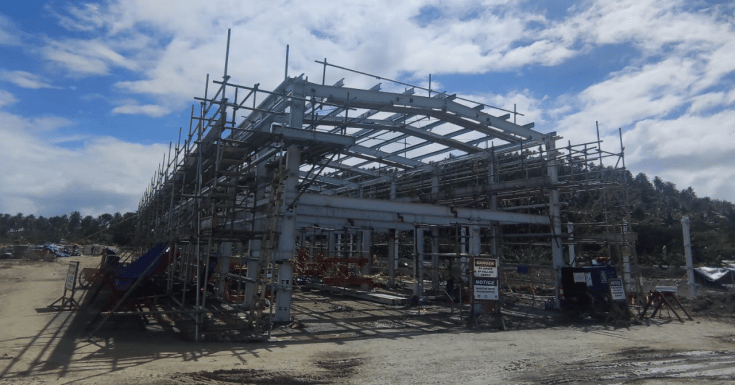

According to the development in recent years, steel structure buildings have gradually replaced traditional reinforced concrete structures, and steel structures have many advantages in the actual application process that traditional buildings cannot be more beautiful, such as fast construction time, low cost, and easy installation. , the pollution is small, and the cost can be controlled. Therefore, we rarely see unfinished projects in steel structures.

The matters that we need to consider when designing the steel structure building:

Load-bearing of steel structure building

Steel-structured workshops have to withstand external influences and pressures, such as strong winds, rainstorm seasons, blizzards, house maintenance and other factors.

Therefore, the size of the steel frame needs to be reasonably designed to withstand these external pressures. The bearing capacity of the steel column depends on the structural form of the column, the size of the section, the thickness and material of the steel plate composing the steel column, etc.

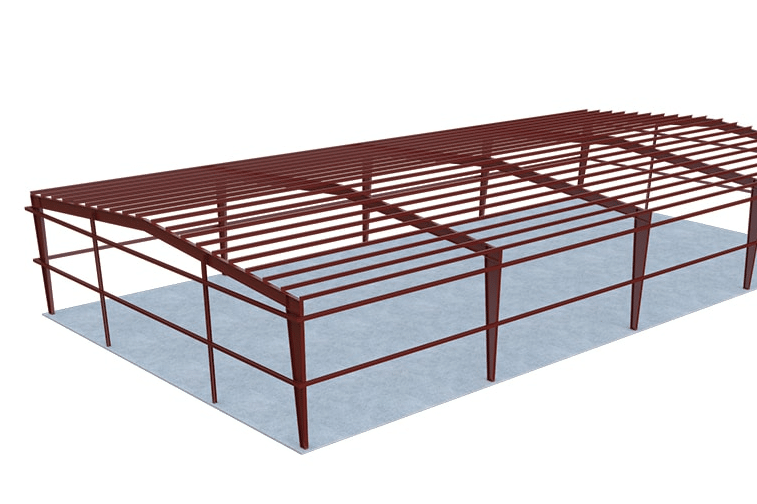

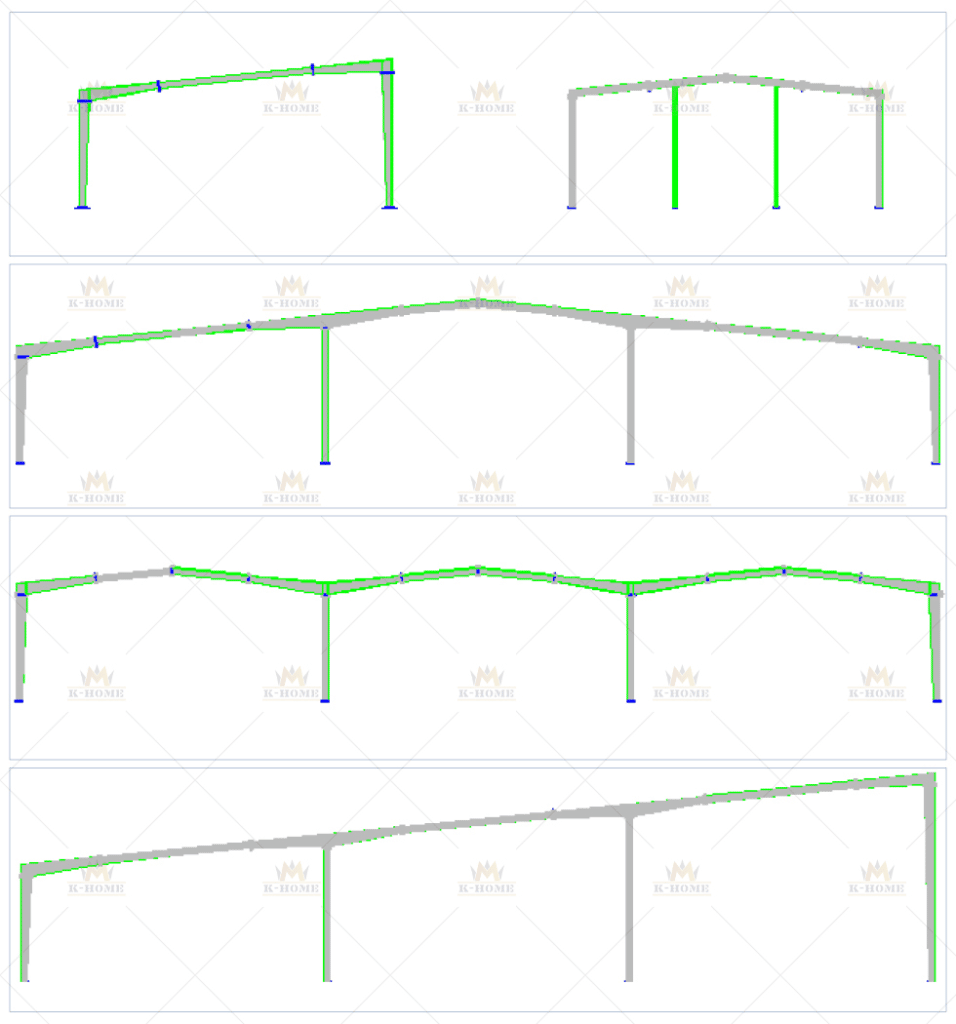

The structural form of the steel structure building

- Gate type steel structure;

- Frame steel structure – pure frame, central support frame, eccentric support frame, frame tube;

- Grid structure – grid, grid shell;

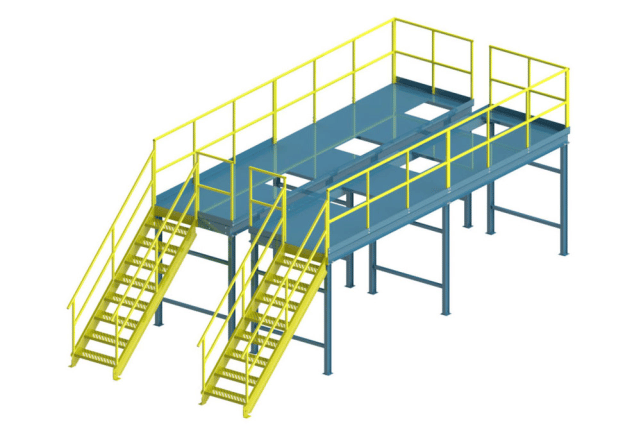

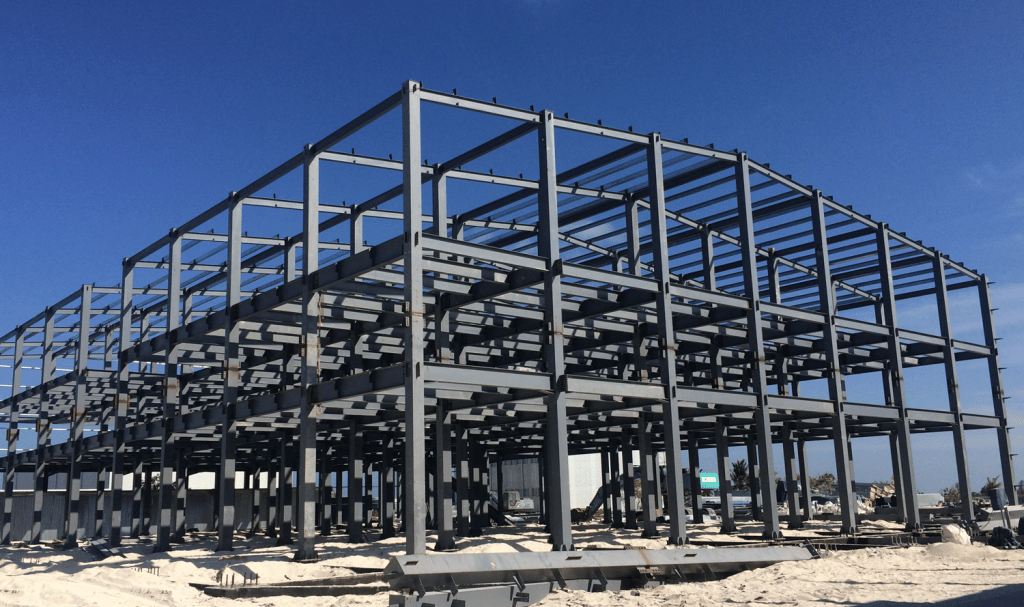

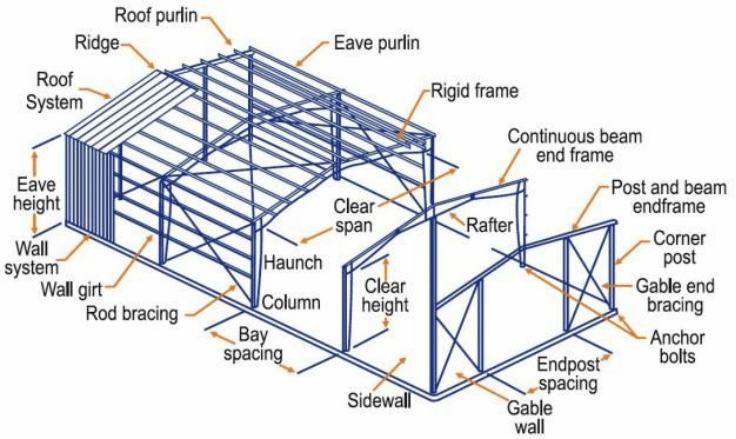

Our K-Home main business is gate-type steel structure, Gate type steel structure is a flat type structure made of steel. It is composed of columns with variable cross-sections and inclined beams with variable cross-sections. It has three hinges (one beam middle hinge, two-column foot hinges) statically indeterminate structures, or two hinges (Column foot) statically indeterminate structure, and its derivative type. Its columns and beams can be solid web or lattice. The solid-web type is to weld steel plates into an “I”-shaped heightened section; the lattice type is a (virtual) heightened section composed of small-section steel.

Gate type steel structure is one of the main building structure types. The structure is mainly composed of steel beams, steel columns, steel trusses and other components made of profiled steel and steel plates, and the components or parts are usually connected by welding seams, bolts or rivets. Because of its lightweight and simple construction, it is widely used in large workshops, venues, super high-rises and other fields.

Lighting Design Treatment of Steel Structure Buildings

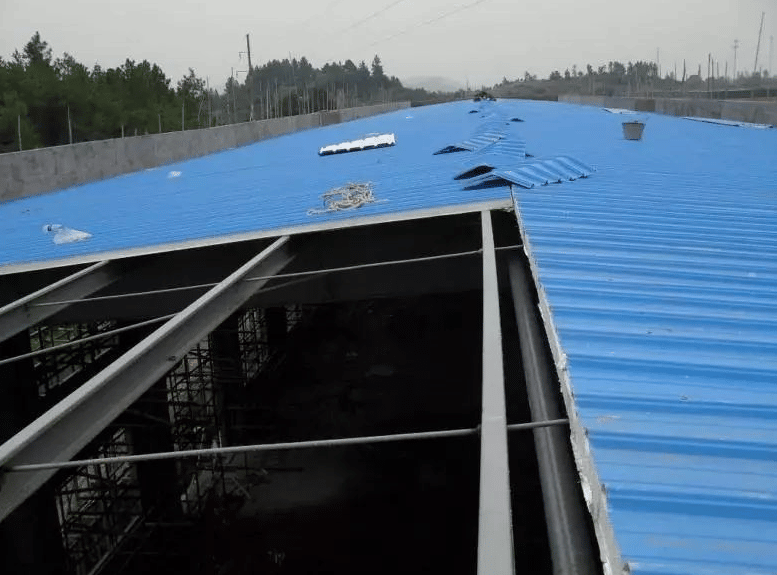

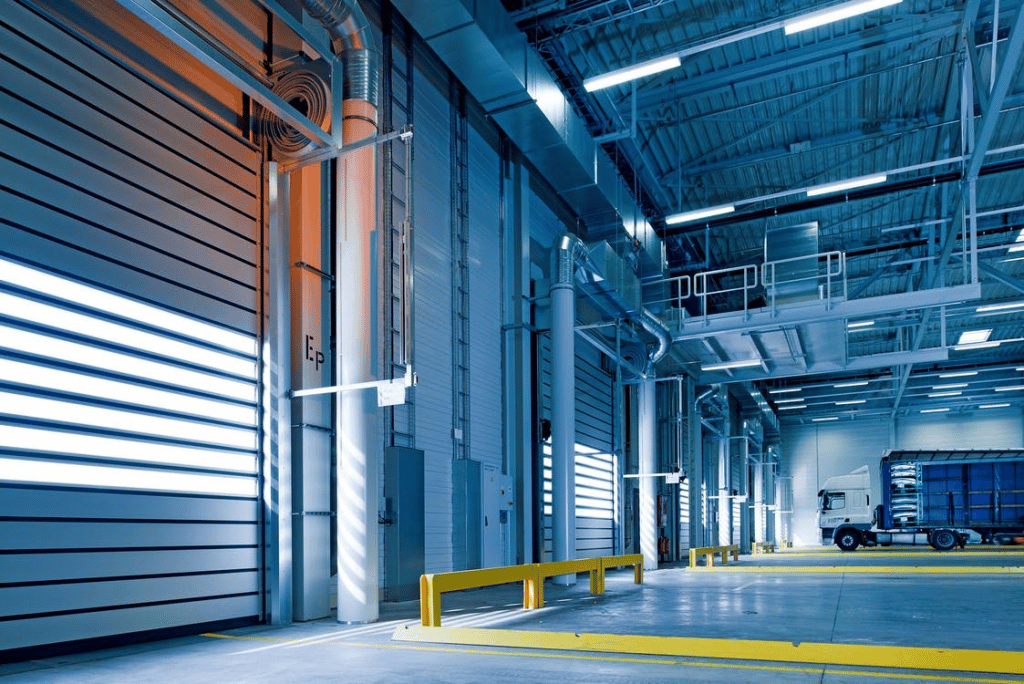

The construction area of steel structure workshops is generally large, and lighting is also a big problem, especially in some industrial workshops, lighting is a very important facility. Improve indoor lighting through skylights during the day, saving energy. When arranging lighting panels or lighting glass at specific positions on the metal roof, the service life of the skylight should be considered in coordination with the metal roof panel, and waterproofing should be done at the connection between the skylight and the metal roof panel.

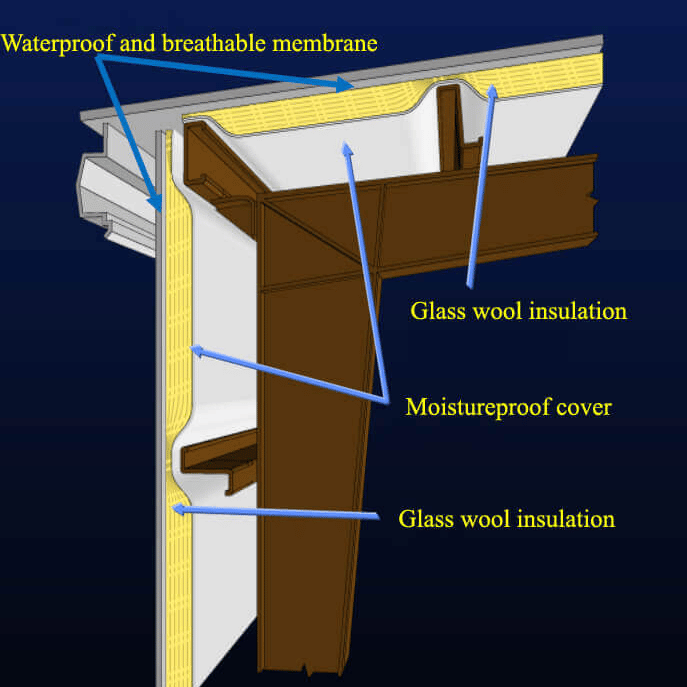

Moisture-proof treatment

Prevent the condensation of water vapor in the metal roof bottom layer and the metal roof layer, and drain the water vapor in the metal roof layer. The solution is to fill the metal roof layer with thermal insulation cotton, lay a waterproof membrane on the metal roof bottom plate, and have ventilation nodes on the metal roof plate.

Fireproof Treatment

The design of the steel structure workshop needs to consider the design of fire prevention. During the use of the steel structure workshop, there is a big hidden danger in fire. Although the steel structure does not burn, it is easy to conduct heat and is afraid of fire. Therefore, when the components of the workshop are over 600 degrees, the components The strength and yield point will decrease, which is easy to cause collapse accidents. Therefore, the steel structure workshop needs to be sprayed with a certain fireproof material to reach a certain thickness to resist the fire resistance of the building when it encounters a fire.

Sound proof and Thermal Insulation Treatment

Block the transmission of sound from outside to inside or from inside to outside. Fill the metal roof layer with sound insulation material (usually used as insulation cotton), and the sound insulation effect is expressed by the sound intensity difference between the two sides of the metal roof layer. The sound insulation effect is related to the density and thickness of the sound insulation material. It should be noted that sound insulation materials have different blocking effects on different frequencies of sound.

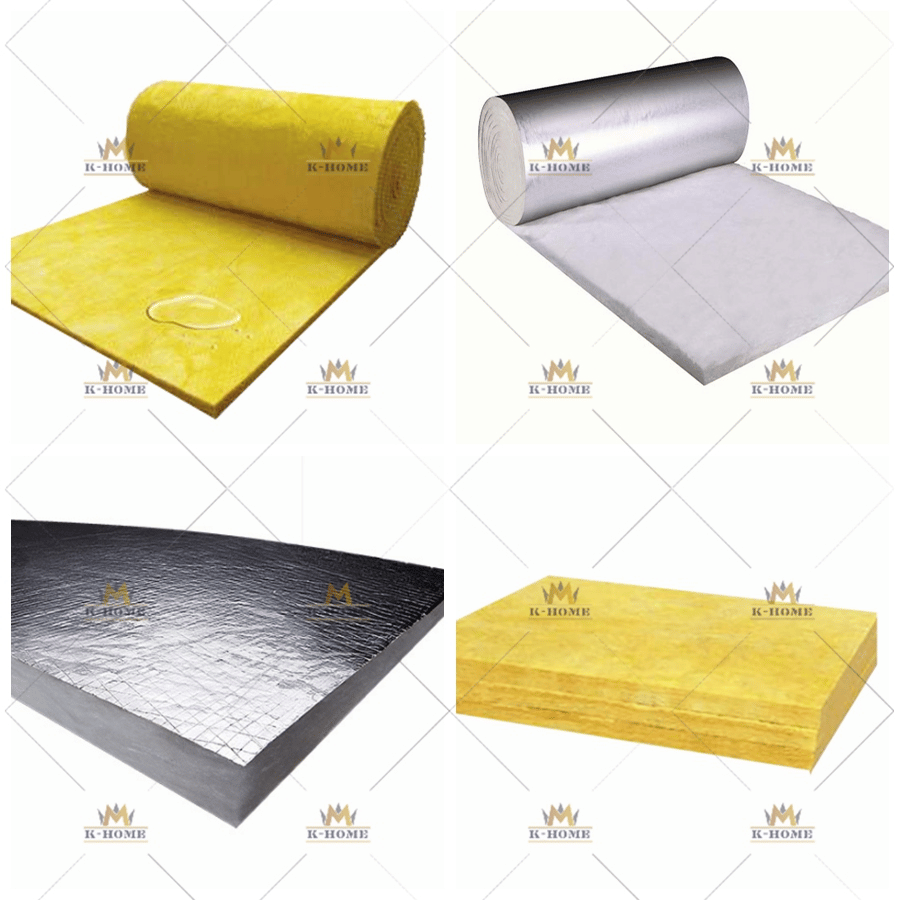

Glass wool is generally used for thermal insulation, moisture-proof and sound insulation of steel structures

Centrifugal glass wool for steel structure is a kind of material with convenient transportation, quick installation and high cost performance for building thermal insulation, sound absorption and noise reduction. However, only the combination of glass wool and veneer can achieve the best effect. The fire performance of the centrifugal glass wool with veneer can reach the A1 level, and it is extremely moisture-proof and mildew-proof!

Recommended Reading

Contact Us >>

Have questions or need help? Before we start, you should know that almost all prefab steel buildings are customized.

Our engineering team will design it according to local wind speed, rain load, length*width*height, and other additional options. Or, we could follow your drawings. Please tell me your requirement, and we will do the rest!

Use the form to reach out and we will be in touch with you as quickly as possible.

About Author: K-HOME

K-home Steel Structure Co., Ltd covers an area of 120,000 square meters. We are engaged in the design, project budget, fabrication, and installation of PEB steel structures and sandwich panels with second-grade general contracting qualifications. Our products cover light steel structures, PEB buildings, low-cost prefab houses, container houses, C/Z steel, various models of color steel plate, PU sandwich panels, eps sandwich panels, rock wool sandwich panels, cold room panels, purification plates, and other construction materials.